Types of Lockbolts - How to Choose Lockbolts for Your Project?

Table of Contents

In industrial fastening applications, Lockbolts are widely adopted for their high strength, excellent vibration resistance, and consistent installation performance. However, during the actual selection process, many engineers and procurement personnel encounter a core question: What are the Types of Lockbolts? What are the differences between them, and how should one choose the appropriate solution?

To accommodate varying load conditions, installation methods, and application scenarios, the market has developed multiple Lockbolt types. This article will briefly outline the primary classification logic and typical applications of Types of Lockbolts, helping you quickly determine which category best suits your project requirements.

What Is a Lockbolt and How Does It Work?

When selecting structural fasteners, you often turn to lockbolts because standard bolts carry a risk of loosening, while welding may be constrained by efficiency, consistency, or site conditions. In this context, lockbolts become the preferred choice for many engineering projects.

What Is a Lockbolt?

A lockbolt is a high-strength, permanent mechanical fastener typically composed of two parts:

- Pin

- Collar

Unlike the hex bolts you’re familiar with, Lockbolt does not rely on thread preload to maintain the connection. Instead, it permanently locks the collar onto the pin body through mechanical forming, creating a stable, irreversible structural bond. For you, this means more controllable connection strength that doesn’t depend on manual tightening experience. Under long-term vibration or dynamic loads, the connection performance remains more stable.

How Does a Lockbolt Work?

The Lockbolt’s operating principle can be summarized as “Tension + Cold Forming + Mechanical Locking”, with the entire process highly standardized.

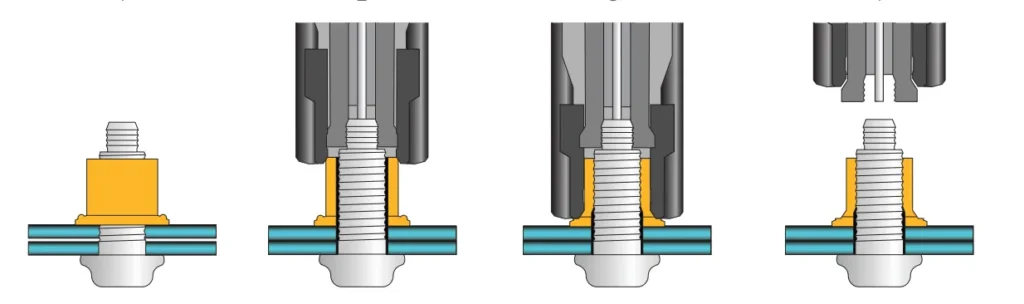

Key Steps in the Installation Process

Step 1: Insert the Pin Body

Insert the Lockbolt’s pin into the aligned connection hole.

Step 2: Collar Positioning

Place the collar over the rear end of the pin.

Step 3: Tool-Assisted Core Rod Pulling

Apply axial tension to the pin using the installation tool while radially compressing the collar.

Step 4: Collar Cold-Formed Locking

The collar is pressed into the pin’s groove (or tightly wrapped around the bare shaft), forming a permanent mechanical lock.

Step 5: Core Rod Fracture

Upon reaching the preset tension value, the core rod automatically fractures, completing the installation.

The direct benefit of this process for you is that every Lockbolt installation delivers highly consistent results, virtually independent of operator skill.

Key Characteristics of Lockbolts

Lockbolts are widely adopted in demanding structural connections for good reason. These three core properties are paramount for your engineering selection:

a. High Strength

- Lockbolts achieve tensile and shear strengths approaching or matching high-strength structural bolts

- Primarily used for load-bearing structures, not merely positioning connections

- Demonstrate stable performance in steel structures, bridges, and heavy equipment

b. Excellent Vibration Resistance

- Threadless design → Eliminates vibration-induced backlash or loosening

- Sleeve and stud form an integral mechanical lock

- Ideal for dynamic loads and prolonged vibration environments

Typical applications include: PV tracking systems; rail and transit infrastructure; truck chassis and construction machinery

c. Installation Consistency

- Installation process controlled by tool-applied tension and forming results

- Independent of manual torque judgment

- Simplified quality inspection (verifies breakage and proper forming)

Main Types of Lockbolts

Lockbolts fastener has many types, but there are two main types: 1.Lockbolt with Separating Pintails 2.Lockbolt without Separating Pintails.Next let’s take a look at these two types of lockbolts in detail.

① Lockbolt with Separating Pintails

Lockbolt with Separating Pintails also comes in two types. As we know, there is a difference in the products strength is also different. It is worth noting that the strength of C6L lockbolt is a bit lower than that of C50L lockbolt.

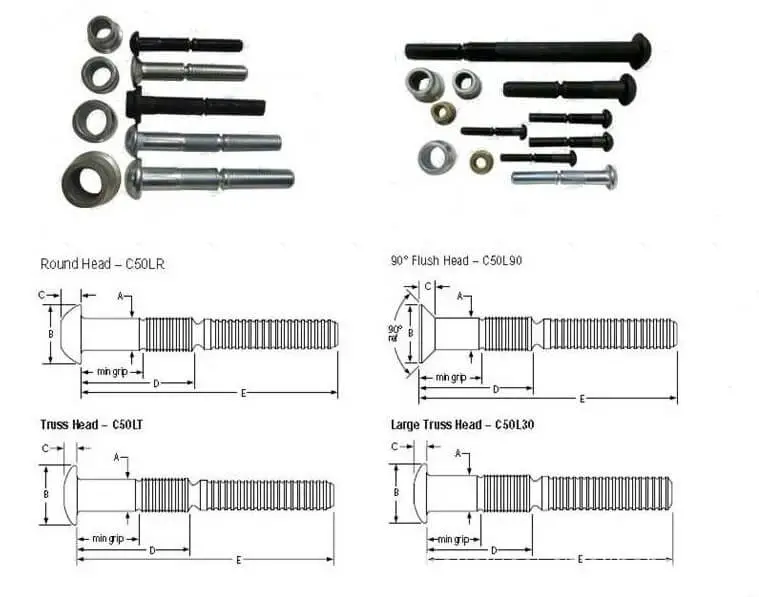

C50L Lockbolt

The C50L lockbolt is specifically designed for heavy-duty applications requiring ultra-high strength. It is the best solution for heavy duty industrial connections.Rivmate’s C50L lockbolt ranges in diameter from 12.7mm (1/2 inch) – 28.6mm (1-1/8 inch).

In real-world applications, the torque and shear strength of the C50L lockbolt exceeds that of conventional bolts. So lockbolt can replace traditional bolts in all applications.C50L lockbolt has many types to choose from, including dome head, carbon steel, and stainless steel.

C6L Lockbolt

The C6L lockbolt has been around for over sixty years. This lockbolt provides high shear strength and long lasting performance. It reduces rework and warranty costs and requires little or no training to complete the installation process quickly.The C6L lockbolt is available in aluminum, steel and stainless steel in diameters from 12.7mm (1/2 inch) – 28.6mm (1-1/8 inch).

② Lockbolt without Separating Pintails

The main feature of Lockbolt without Separating Pintails is the ability to connect multiple grip ranges. This reduces the pressure on inventory. This type of lockbolt has a precisely controlled grip range and clamping force, making it ideal for metal-to-metal fastening.

It has a variable length of broken tail after riveting. This will vary depending on the actual thickness of the riveted material. This unique property allows it to easily accommodate changes in material thickness.

Differences Between Different Types of Lockbolts

| Feature | C50L Lockbolt | C6L Lockbolt | Magna-Grip Lockbolt |

| Material | High-strength steel, stainless steel | Alloy steel, aluminum alloy | High-strength steel, aluminum alloy |

| Application Strength | Suitable for heavy load and high-stress applications | Suitable for medium to high-stress applications | Suitable for high-load applications |

| Mechanical Locking | Yes, mechanical locking with specialized tools | Yes, mechanical locking with specialized tools | Yes, mechanical locking with specialized tools |

| Vibration and Impact Resistance | Yes, designed for severe vibration and impact conditions | Yes, designed for severe vibration and impact conditions | Yes, designed for severe vibration and impact conditions |

| Corrosion Resistance | Yes, typically treated for corrosion resistance (e.g., galvanized, nickel-plated) | Yes, typically treated for corrosion resistance (e.g., galvanized) | Yes, typically treated for corrosion resistance (e.g., galvanized, nickel-plated) |

| Ease of Installation | Quick installation, suitable for mass production | Quick installation, suitable for mass production | Quick installation, suitable for mass production |

How to Choose Lockbolts for Your Project?

The scenarios in which different lockbolt is used are also different. So how should you choose the best lockbolt rivets for your project? You need to decide based on factors such as specific application requirements, material thickness, load requirements and environmental conditions. Below is a detailed guide to help you choose between these lockbolts:

a. Application Strength and Load Requirements

The C50L Lockbolt is suitable for applications requiring extreme strength and heavy loads. For example, heavy machinery, railroad vehicles, bridge design, etc. C50L Lockbolt provides extremely high tensile and shear strengths to withstand heavy loads and high stresses.

C6L Lockbolt provides excellent tensile and shear strength for medium to high strength applications. For example, in the automotive industry, construction, and general industrial manufacturing.

Magna Grip Lockbolt can accommodate a wide range of material thicknesses in addition to providing high strength connections. You can choose this type of lockbolt if you want to reduce the variety of stock.

b. Material Thickness and Adaptability

Both the C50L Lockbolt and the C6L Lockbolt are suitable for joining high-strength applications in a fixed thickness range. Unlike the Magna grip lockbolt, which has a large clamping range that allows joining materials of different thicknesses.

So if you want to reduce your inventory, then go for the Magna grip lockbolt, but it is more expensive.

c. Vibration and Shock Resistance

Both the C50L Lockbolt and the C6L Lockbolt will hold strong under vibration and shock conditions and will not easily loosen or fall off.

The Magna grip lockbolt also has the characteristics of other types of lockbolt and is more versatile.

d. Environmental Conditions and Corrosion Resistance

Lockbolt, regardless of type, is usually treated to prevent corrosion. For example, galvanized or nickel plated, as the practical environment for lockbolt rivet is generally harsh.

Choose The Right Lockbolts for Your Project

Choose C50L Lockbolt if your application requires extremely high strength and heavy-duty capabilities, such as heavy machinery, railroad vehicles and bridge construction.

Choose C6L Lockbolt if your application requires medium to high strength connections, such as in the automotive industry, building construction and general industrial manufacturing.

Choose Magna-Grip Lockbolt if your application needs to accommodate materials of varying thicknesses while requiring high load capacity, such as the automotive industry, aerospace, construction and heavy equipment, and railroad transportation.The Magna-Grip Lockbolt’s large clamping range gives it an advantage in inventory management and material adaptability.

The existence of different Types of Lockbolts is not intended to increase complexity, but rather to address fundamental differences across industries in load patterns, vibration levels, construction conditions, and safety requirements.

Steel Structures

Steel beams, support members, and node connections often endure both tensile and shear forces simultaneously. Connection failure in these areas directly compromises overall structural safety. In such scenarios, lockbolts are widely adopted primarily because they achieve stable connections through mechanical locking, independent of manual torque for preload assurance. In practical engineering, steel structures typically prioritize collar-type and grooved structural lockbolts for enhanced vibration resistance and long-term reliability.

Bridges

Bridge connections endure long-term alternating stresses from vehicular loads while exposed to outdoor environments, where vibration, temperature fluctuations, and corrosion simultaneously occur. Under these conditions, traditional threaded connections often become weak points, whereas Lockbolts’ threadless mechanical locking structure significantly reduces loosening risks.

Therefore, high-strength, grooved Lockbolts are commonly used in bridge engineering. During on-site construction, the pintail design is incorporated, where breaking the tail confirms each connection point meets design requirements.

Solar Mounting Systems

Photovoltaic systems endure prolonged outdoor exposure, continuously subjected to wind loads, temperature fluctuations, and periodic vibrations. Connection loosening often triggers widespread structural risks rather than isolated failures. Additionally, PV projects typically involve large scales and numerous installation points, demanding high construction efficiency and consistency. Against this backdrop, pintail lockbolts paired with grooved structures emerge as a common solution.

Railways

Rail transit systems impose extremely stringent safety requirements on fasteners. You must contend with high-frequency vibration, impact loads, and explicit industry regulatory constraints. Consequently, the application of Lockbolts in rail transit represents a manifestation of “safety design logic.” Engineers typically select structural or grooved Lockbolts specifically engineered for vibration resistance and fatigue endurance to ensure stable connections under prolonged high-frequency operational conditions.

Heavy Equipment

In heavy machinery and construction equipment, components endure continuous vibration and impact loads during operation. Frequent inspection or retightening of connections significantly increases maintenance costs and downtime risks. For this reason, Lockbolts are frequently employed in critical load-bearing and high-vibration areas.

In practical applications, grooved Lockbolts are commonly used in high-vibration zones, while pintail designs are better suited for field installation or maintenance scenarios.

Lockbolts vs Bolts vs Structural Blind Rivets

Comparison Table

| Comparison Aspect | Lockbolts | High-Strength Bolts | Structural Blind Rivets |

|---|---|---|---|

| Connection Method | Mechanical locking (collar swaging) | Threaded preload | Mechanical locking (single-side installation) |

| Vibration Resistance | Very high | Moderate (depends on anti-loosening measures) | High |

| Installation Consistency | Very high (tool-controlled) | Highly dependent on installation torque | High |

| Single-Side Installation | No | No | Yes |

| Installation Efficiency | High | Low | Very high |

| Removable | No | Yes | No |

| Typical Applications | High-load, high-vibration structures | Serviceable structural connections | One-side access, high-efficiency installation |

When Lockbolts Are Essential

High Loads Combined with Severe Vibration

When your connection endures significant tensile/shear forces while subjected to prolonged vibration or alternating loads, threaded connections become potential failure points. Lockbolts eliminate loosening pathways through mechanical locking—not relying on thread preload—making them ideal for such conditions.

Demanding Installation Consistency

In bulk projects or critical structural components, you cannot tolerate quality fluctuations caused by manual torque variations. Lockbolt’s installation outcomes are determined by tools and the mechanism itself, making the performance of every connection point more predictable.

Long-Term Operation, Low Maintenance Requirements

For projects with extremely high post-commissioning maintenance costs (e.g., bridges, rail transit, large steel structures), Lockbolt’s permanent connection characteristics significantly reduce the risk of repeated inspections and rework.

When Structural Blind Rivets Are More Efficient

Not all high-demand projects require Lockbolt. In many practical scenarios, Structural Blind Rivets are actually the superior solution.

Single-Side Installation Only

If your connection point is inaccessible from the rear, traditional bolts and Lockbolt become structurally impractical. Structural Blind Rivets enable installation from a single side while delivering near-structural-grade strength performance.

Emphasizing Installation Efficiency and Construction Costs

In projects with high installation density and tight cycle time requirements, Structural Blind Rivets significantly reduce installation time and decrease reliance on operator experience. This advantage is particularly evident in photovoltaic mounting systems, thin-walled steel structures, and modular assembly.

Sufficient Strength, Not Extreme Strength

If your structure isn’t subjected to extreme load conditions, blindly using Lockbolts may result in unnecessary cost increases. While meeting safety factors, Structural Blind Rivets often achieve a better balance between strength, efficiency, and cost.

FAQs About Types of Lockbolts

1. How many types of lockbolts are there?

From an engineering selection perspective, there is no fixed number of lockbolt types. They are typically categorized based on structural design, locking mechanism, pin configuration (grooved or smooth shaft), and installation method. Understanding these classification principles is more valuable than memorizing specific models, enabling you to make informed choices quickly across different projects.

2. What are the main differences between collar-type and pintail lockbolts?

The core distinction lies in whether installation quality is verified by breaking the tail. Collar-type lockbolts achieve mechanical locking through cold-forming of the collar ring. Pintail lockbolts add a break-off core pin design, allowing you to visually confirm whether the designed locking force has been achieved by observing the broken tail. This makes them particularly suitable for field construction and large-scale installation projects.

3. Which type of lockbolt is best for high-vibration applications?

In conditions involving continuous vibration or alternating loads, grooved lockbolts are typically the superior choice. The grooved structure provides the collar with distinct mechanical engagement points, effectively suppressing micro-motion and fatigue loosening. They are commonly used in applications such as photovoltaic mounting systems, rail transit, and heavy equipment.

4. Can lockbolts replace high-strength bolts in structural applications?

In many structural applications, lockbolts can substitute high-strength bolts, particularly in projects demanding superior vibration resistance and installation consistency. However, replacement decisions require evaluation based on load conditions, disassembly requirements, and industry standards—not a simple one-to-one substitution.

5. When are structural blind rivets a better option than lockbolts?

Structural blind rivets often prove a more efficient choice when your project requires single-side access or prioritizes installation efficiency and construction costs, provided structural loads do not reach ultimate conditions. While meeting safety factors, they offer a better balance between strength, speed, and cost.

Get the Most Secure Connection with Rivmate Lockbolt Solutions

At Rivmate, we are committed to providing our customers with the best lockbolt rivets solutions and products. We offer quality lockbolt and customization services that exceed your expectations, such as header customization, material customization, and customization according to drawings. Contact us today for a consultation!

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met