Types of Pop Rivets - Their Applications in the Automotive and Aerospace Industries

Pop rivet is a type of rivet used for single riveting, but special tools must be used for riveting. When riveting, the riveting core is pulled by the special riveting gun, so that the riveting body expands and plays the role of riveting. This kind of rivets is especially suitable for riveting occasions that are inconvenient to use ordinary rivets, so it is widely used in construction, automobiles, ships, aircraft, machinery, electrical appliances, furniture and other products.

Table of Contents

What is pop rivets?

A popular rivet is a fastener usually used to join two or more materials. It consists of a cylindrical rivet and a pull ring pre-mounted on the rivet. When the rivet is inserted into the material and the pull ring is pulled tight, the tail of the rivet expands and forms a permanent connection.

How do pop rivets work?

The working principle of pop rivets is very simple.

First, Drill a hole in the two plate materials, then Place the rivet into the drilled hole and Use a special riveting tool to pull the pull ring so that the end of the rivet expands and In this way, the two materials can be firmly joined together. Such connections have high strength and corrosion resistance, and are easy to install.

Different types of pop rivets

Rivet pulling can be divided into many types, each type has its own unique characteristics and application scenarios. The most common types include pop rivets, open pop rivets and sealed pop rivets. Pop rivets are suitable for most application scenarios, while open pop rivets and sealed pop rivets are suitable for occasions where tightness and water resistance are required.

Table of Types of pop rivets

Open Type Blind Rivets/Standard Blind Rivets

When you need to tighten between metals, you usually use open/standard blind rivets.It is mainly composed of a rivet body and a round head. When the mandrel pulls over the rivet body, the rivet body will expand to connect the metal material stably.

The application scenarios of open core rivets are very many. The main scenes are automobiles, metal, construction, containers, furniture, electrical appliances and so on.

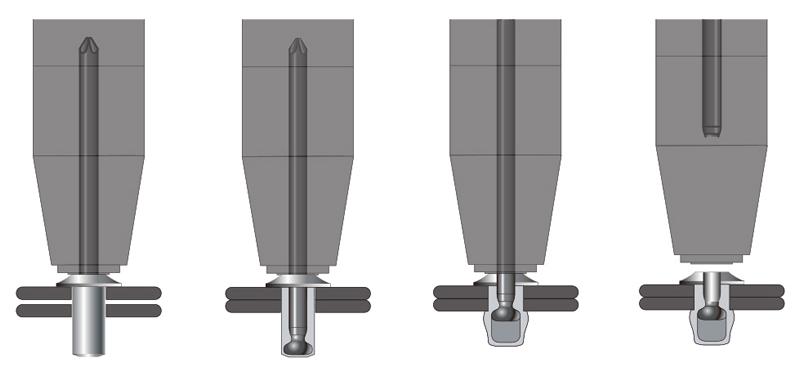

Peel Type Blind Rivets

Peel blind rivet has a larger support surface. When the mandrel is pulled out, the rivet body becomes larger, leaving a flower-like head. It is suitable for connecting metal and softer materials.

This kind of rivet is used very much in the construction industry. It is often used in the connection of drywall, paint and insulation materials. and can be used in scenes such as trailers, plastic parts, appliances and upholstery

Sealed Type Blind Rivets

Sealed rivet is more special, its mandrel head is closed in the rivet body, will not protrude from the end. Sealed rivet waterproof effect is good, mainly used in the connection between metals.

The main application scenarios for sealing rivets include metal, construction, and automotive industries. Due to its excellent waterproof effect, it is also possible to exist in products such as containers, furniture, air conditioning and heating systems

Uni-Grip/Multi-Grip Blind Rivets

Uni-Grip/Multi-Grip rivets have dents on the rivet body, and during the riveting process. the dents will be expanded, which can provide multiple grip forces to make the connection closer. It is often used for the connection between plastic and plastic, metal and metal.

This type of rivets is often used in the automotive, construction and metal industries. Furniture, electrical appliances, air conditioning production, will also use this rivets

Trifirm Rivets

When the lantern rivets are riveted, the tail is shaped like a triangular banana. Providing a larger contact area and good waterproof performance.

Application scenarios: automotive plastic components, plastic parts, containers, fragile or soft materials, thermal insulation board, gypsum board, structural workshop, refrigerated car box, etc

Now-Lock/Mono-Lock Blind Rivets

Now-Lock/Mono-Lock blind rivet can provide a large bearing surface behind the riveted plate. And has a good effect on the uneven drilling connection. Its core retention force is high, and its vibration resistance is good.

Main application scenarios: automotive industry, cabinets and chassis, heating and ventilation systems, mechanical manufacturing, refrigeration equipment, electronic communication equipment, etc

Hem-Firm Blind Rivets

Hem-Firm Rivets are structural rivets using interference lock technology, which can be used in the connection of metal and metal, metal and plastic, sheet and thick metal.

If you want to purchase rivets for automotive, rail, electric cabinet and other industries. you can consider this model

Lockbolt System Blind Rivets

Lockbolt Blind Rivets can be very effective in place of stud nuts. Clamping force is very high, can provide strong shock resistance.

Application scenarios: automobile, construction, bridge construction, mining, railway, refrigerated car box

Boom-Lock Blind Rivets

Boom-Lock Rivets have a very high strength-to-diameter ratio and can replace ordinary bolts or welding. It is very difficult to disassemble, with a one-time installation, never loose reputation.

Automotive, high-speed rail, medium and high voltage piezoelectric gas cabinet, home appliances, industrial and other industries will use this kind of rivets

Rivlok & Rivbulb Double-locking System Blind Rivets

Double-locking Rivet is a kind of high tensile and shear connection structure rivet. By pulling the core rod or the head of the nail rod. the nail body is expanded and deformed at the blind end to form a seismic and anti-loose connection.

In the automobile, high-speed rail, electric cabinet, home appliances, industrial and other industries. This type of rivets are widely used

Grooved Type Blind Rivets

If you want to rivet softer materials such as plastic and wood. This type of rivet is perfect. Metal connected to wood, metal connected to count you, bricks, etc., are more suitable.

In the construction, metal industry, furniture production, electrical equipment and injection parts and other fields. Grooved rivets are very many applications.

The commonly used material for pop rivets

In the choice of popular rivets, its material is very important, in general, we need to choose different materials according to the application scenario and requirements. Commonly used rivets are generally made of aluminum, stainless steel, carbon steel and copper. Customers most often choose aluminum when choosing materials. it is relatively light, and easy to process, corrosion resistance is very good.

Application scenario of pop rivets

Pop rivets have high strength, strong corrosion resistance and relatively light quality. so in the automotive and aerospace industries, popular rivets are widely used. In the automotive industry, the connections of components such as body frames, doors, hoods and luggage racks are all connected with pop rivets. In the aviation industry, the connection of the wings, fuselage and other parts of the aircraft is basically a pop rivets.

Answers to common questions about pop rivets

When we use popular rivets, we often encounter some problems. such as how to choose the right rivets for our projects, how to install rivets quickly and so on. In fact, solving these problems is very simple. Choosing the right materials, using the right tools can easily solve these problems.

The Times are constantly developing, technology is constantly improving, and there are many rivets to meet different scenarios. When we choose to pull rivets, we must choose according to our actual application scenario, if you feel the trouble of consulting various information, you can ask our riveting experts, we will tailor the rivets you need for you.