Table of Contents

Do you know types of Rivets and their Application.There are Many Different Types of Rivets in Order to be Suitable for Different Applications.Let’s take a look at it in detail

Table of Contents

History of Rivets

Rivet is a mechanical fastener used to join two or more pieces of material. It has a very long history that runs through the development or human civilization.

As early as around 2000 BC, rivets have been used to join metal and wood. During the Middle Ages, rivets were widely used in the manufacture of armor and weapons for knights. In addition to this, rivets were also used to join wooden bridges and buildings to enhance structural stability.

After the Industrial Revolution, rivets began to be used in a wide range of industrial applications. Including steam engines, boilers, railroad track connections and the construction of steel ship hulls. The famous Eiffel Tower and Golden Gate Bridge were built using rivets.

Blind rivet was invented in the mid-20th century. Its appearance greatly simplified the riveting process, replacing the traditional rivet, especially in single-sided operation applications.

With the development of automation technology, the role of blind rivets in industry has become increasingly critical. Its emergence has made industrial mass production possible.

4 Types of Rivets

The history of rivets is a long one. During this long history of development, many types of rivets have emerged. These include hollow rivets, solid rivets, blind rivets and high strength structural rivets.

I.Hollow Rivets

Hollow rivet has a hollow structure. It is often found in applications where weight reduction, lower material usage and efficient installation are required.

The design of the Hollow rivet makes it extremely lightweight, helping to reduce the overall weight of the structure. The design also reduces the amount of material used, which can effectively reduce production costs.

How do Hollow Rivets Work?

First, you need to select the appropriate hollow rivets. select the appropriate length and diameter of the hollow rivet based on the actual material thickness and application requirements of your project. then drill the holes in the material to be riveted. It is important to note that the hole diameter should match the diameter of the rivet.

In the next stage, the hollow rivet is inserted into the drilled hole, making sure that the head of the rivet is pressed against the surface of the material.

Finally, using a manual or pneumatic riveting tool, pull or tap the tail of the rivet to deform and fasten it to the back of the material. Check the rivet connection to make sure the rivet is fully deformed.

Hollow rivet is lightweight, saves material and is easy to install. These features make it an ideal mechanical fastener for a variety of applications. However, hollow rivet is not suitable for connecting heavy equipment because it is not very strong.

Applications of Hollow Rivets

Hollow rivet reduces the overall weight of the structure and is therefore particularly suitable for use in areas where lightweighting is required.

In aerospace, hollow rivet reduces structural loads on aircraft, improving fuel efficiency and performance. In automotive manufacturing, hollow rivet can be used to connect vehicle interiors, ensuring a strong connection while reducing body weight.

II.Solid Rivets

Solid rivets are the most traditional and basic type of rivets. Due to their very high strength, they are widely used in a variety of applications where high strength and durability are required for connections.

Solid rivets have a solid rivet body and are made of a metal material that provides high strength and durability.

How do Solid Rivets Work?

The installation of solid rivets is complex and slow. You need to prepare a special solid rivet installation tool in advance (the cost of this tool is very high). Then choose the right size of solid rivets according to the actual situation of your project. Drill holes in the material to be riveted.

Insert the solid rivet into the drilled hole. Apply pressure with the installation tool to deform the end of the rivet to form the “head”.

Applications of Solid Rivets

Solid rivets are used in application scenarios where there is a high demand for strength at the connection point. For example, the connection of key parts of aircraft structure; the connection of key parts of automobile chassis; the steel structure connection of buildings and bridges and the assembly of heavy equipment.

III.Blind Rivets

Blind rivets are a new type of rivet that was only invented in the early 20th century. Blind rivets can effectively solve the problem of narrow spaces where installation cannot be accomplished.The most important feature of Blind rivets is that they can be installed from one side.

Blind rivets can be installed very quickly, and there are many types of blind rivets to suit different application scenarios. For example, open end blind rivets are suitable for general mechanical connections, closed end blind rivets provide good waterproofing, and Peel type blind rivets reduce pressure concentrations and are suitable for connecting soft materials.

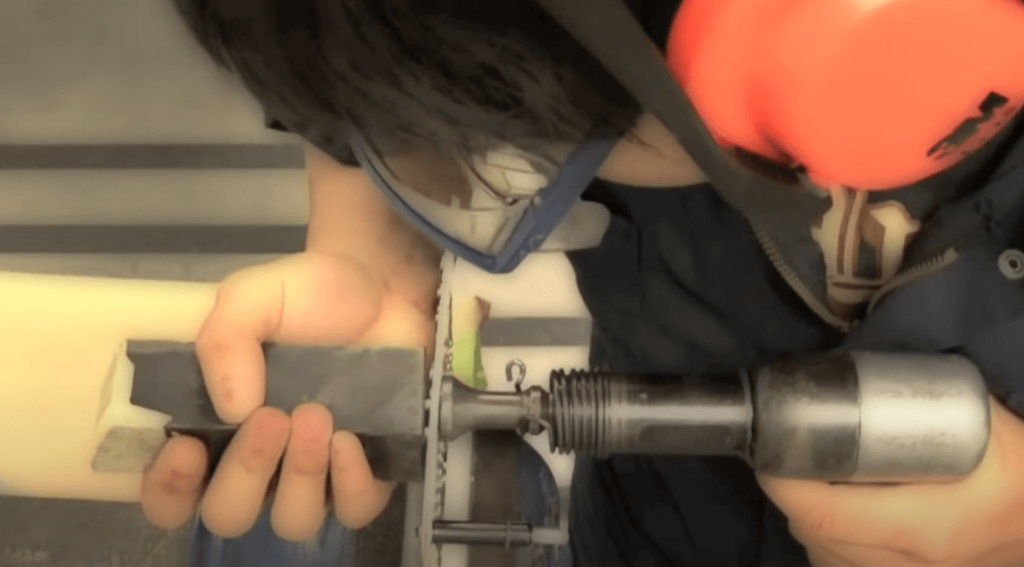

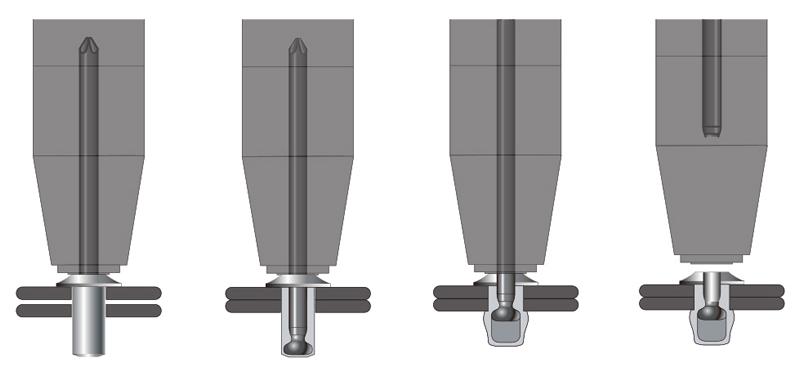

How do Blind Rivets Work?

Blind rivets are the easiest and quickest of the rivet types to install. This is why Blind rivets are available in large scale production.

Blind rivets are formed by the deformation of the rivet body to form an extruded, stabilized joint.

Examples

Common examples of blind rivets include:

- Open Type Blind Rivets

- Sealed Type Blind Rivets

- Peel Type Blind Rivets

Applications of Blind Rivets

Blind rivets are the most widely used of all rivet types. Blind rivets are used in both light equipment and heavy industry, such as automotive manufacturing, aerospace manufacturing, construction and infrastructure connections. Blind rivets are used in electronics and furniture manufacturing.

It can be said that in modern industrial production, blind rivets are everywhere.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

IV.Structural Rivets

Structural rivets are also known as high strength rivets. It is a type of rivet specifically designed to withstand high loads and provide high strength connections. They are widely used in structural connections that require high strength and durability, such as in construction, bridges, heavy equipment, aerospace and automotive manufacturing.

How do Structural Rivets Work?

The joining principle of structural rivets is similar to that of other rivets. But structural rivets have one great feature. The locking mechanism of structural rivets is specially designed. In order to enhance the strength of the connection, to ensure that the rivets are firmly locked after installation, to prevent loosening, the locking device of the structural rivets are specially designed.

Examples

Common examples of blind rivets include:

- Monobolt Rivets

- Lockbolt Rivets

- Bom Rivets

- Hemlok Rivets

- Hucklok Rivets

- Multi Grip Blind Rivets

- Bulb Tite Blind Rivets

Applications of Structural Rivets

- Structural Steel Connections for Buildings and Bridges: Connections in critical areas provide high strength and durability to ensure structural stability and safety.

- Wind and Seismic Resistance: Structural rivets are capable of withstanding high wind and seismic stresses for high-rise buildings and critical infrastructure.

- Machinery and Equipment: Used in the connection of key components of heavy machinery and equipment, such as excavators, cranes and rollers, to ensure stability under high loads.

- Construction Vehicles: Used in chassis and body connections of construction vehicles to provide high strength and vibration resistance.

- Body and Chassis Connections: Used in the connection of body panels, chassis and suspension systems, providing high strength and durability to ensure the safety and stability of the vehicle during driving.

- Safety Components: Used in the manufacture of critical safety components such as seat belt buckles and brake systems to ensure high reliability.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Comparison of 4 Types of Rivets

| Feature | Solid Rivet | Hollow Rivet | Blind Rivet | Structural Rivet |

| Structure | Solid, robust | Hollow, lightweight | Hollow with a mandrel | Solid or special design, high strength with locking mechanism |

| Strength | Very high, suitable for high-load applications | Lower, suitable for light to medium-load applications | Medium, suitable for general load applications | Very high, suitable for high-load and critical structural applications |

| Weight | Heavy, adds weight to the structure | Light, suitable for weight reduction applications | Medium, depends on material | Medium to heavy, depending on design and material |

| Installation Difficulty | Requires access from both sides and specialized tools | Requires access from both sides, relatively easy to install | Single-sided operation, quick installation, ideal for situations where access from both sides is not possible | Requires specialized tools, more complex installation, provides high-strength connection |

| Application Areas | Aerospace, construction, bridges, heavy machinery | Electronics, light structures, furniture manufacturing | Automotive, construction, electronics, furniture manufacturing | Construction, bridges, heavy equipment, aerospace, automotive manufacturing |

| Vibration Resistance | High, suitable for high-vibration environments | Lower, not suitable for high-vibration environments | Medium, some types have anti-vibration designs | Very high, designed to prevent loosening in high-vibration environments |

| Durability | Very high, suitable for long-term use | High, but depends on material and environment | Medium, suitable for various environments | Very high, suitable for harsh environments and long-term use |

| Material Choices | Steel, aluminum, stainless steel, copper | Aluminum, steel, stainless steel, copper | Aluminum, steel, stainless steel, copper | High-strength alloy steel, stainless steel, aluminum alloy |

| Corrosion Resistance | High, especially with stainless steel and coated materials | Medium, depends on specific materials and environment | Medium to high, some models have corrosion-resistant designs | High, especially with stainless steel and coated materials |

| Common Types | Round head, flat head, countersunk | Round head, countersunk | Open-end, closed-end, peel type, large flange, multi-grip | BOM庐 Rivet, Monobolt庐 Rivet, HuckBolt庐 Rivet, Magnalok庐 Rivet |

Which Type of Rivet to Choose?

There are several factors to consider when choosing the right rivets for your project:

- Determine Application Requirements: Determine your project’s load requirements, such as high load, medium load, and low load applications. Different types of rivets (hollow rivets, solid rivets, blind rivets, structural rivets) are suitable for different application scenarios.

- Material Considerations: Ensure that the material of the rivet is compatible with the material being riveted, whether it be metal, plastic, wood or other substances. Electrochemical corrosion may occur between incompatible metal materials.

- Installation Environment: Determine one or two-sided operation, consider waterproofing and corrosion protection needs

- Budget and Cost: Balance cost and performance and select a cost-effective rivet.

By evaluating these factors, you can select the rivet that best meets your project needs and ensures optimal performance.

Conclusion

Now that you have read the detailed guide above, the history and many other things about riveting must now be clear. And you are now aware of the different types of rivets available and its various applications. As industrial technology evolves, rivets will gradually replace traditional welding and complex joining processes. We look forward to the arrival of rivets as the dominant joining method!

Rivmate Rivet: Combination of Affordability and High Quality

Are you ready to choose high quality and reliable rivets for your project or business? At Rivmate, you will get the most cost-effective rivets with affordable prices and quality that exceeds international standards. So, contact Rivmate Rivet today and realize a secure, stable and long lasting connection!