Table of Contents

Many types of blind rivets have emerged to suit the requirements of different projects. So do you know the types of structural pop rivets? Do you know their characteristics and application scenarios? This blog will give you the answer.

Table of Contents

What Are Structural Pop Rivets?

Structural pop rivets are specialised blind rivets designed to withstand high loads and severe conditions. In contrast to conventional blind rivets, structural pop rivets typically have a portion of the mandrel locked into the body of the rivet after riveting is complete, creating a monolithic structure. This design enhances the strength and durability of pop rivets, allowing them to withstand greater shear and pull-out forces.

If you are looking for an ultra-high vibration resistant solution, structural pop rivets would be ideal for you. They are widely used in heavy duty applications such as trucks, tractors, trains, trailers, steel structures and many other applications.

Types of Structural Pop Rivets

There are many different types of structural pop rivets to suit different intensities and conditions. Here are some common types of structural pop rivets.

1.Interlock Rivets (Now-Lock Blind Rivets)

Interlock Rivets are installed in such a way that the end of the mandrel combines with the locking mechanism inside the rivet body to form a solid locking structure. The mandrel of this type of rivet will not fall off or loosen, and can effectively increase the shear and pull-out strength of the blind rivet.

2.Monobolt Rivets (Mono-Lock Blind Rivets)

This structural rivet is designed to be an all-metal construction where the mandrel will be completely locked into the rivet body. It has very high tensile and shear resistance and usually has excellent watertight sealing properties. If your project is for shipbuilding, heavy equipment and structural steel construction etc., then monobolt rivets are the best choice for you!

3.Bulb Tite Rivets (Bulbtight Trifirm Rivet)

Bulb tite rivets. also known as tri bulb rivets, are a specially designed type of blind rivet. This type of blind rivet expands into a bulb shaped head at the end of the rivet after installation.Bulb tite rivets in combination with a washer provide excellent waterproofing properties. Ideal for auto body construction, solar panel attachment and refrigerated truck installation.

4.Hemlok Rivets (Hem-Firm Blind Rivets)

Hemlok rivets, like other standard structural rivets, have a mandrel that is securely locked into the rivet body during the riveting process and will not loosen or fall out.

Hemlok rivets have extremely high overall strength and stability and can withstand high shear and pull-out forces. The joint remains secure under dynamic loads or vibration.

5.Lockbolt Rivets

Lockbolt rivet is an ultra-high strength mechanical fastener typically used in applications requiring extremely high shear and pullout strength. It consists of two main parts: a bolt and a locking ring (or collar).Lockbolt is often used as an alternative to traditional bolt and nut combinations, and excels especially in vibrating environments.

6.Hucklok Rivets (Rivlok & Rivbulb Double-locking System)

HuckLok Rivet is a riveted fastener designed to provide a reliable mechanical connection under extreme conditions.The HuckLok Rivet is installed with its mandrel securely locked into the rivet body to form a monolithic structure. This rivet is particularly suited for applications that require strong resistance to shear and pullout forces, such as aerospace, automotive manufacturing and heavy equipment.

7.Bom Rivets (Boom-Lock Blind Rivets)

BOM Rivet, is a fastener designed to repair and reinforce joints where standard rivets cannot be used due to wear or oversized holes.Known for their strong mechanical properties and ease of installation, BOM rivets are used in heavy equipment, railroads, construction, and other industrial applications where reliable connections are required.

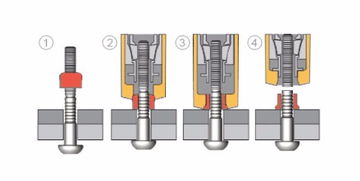

How Do Structural Rivets Work?

Structural rivets are the high-strength type of blind rivets. So they work roughly the same way. In addition to mechanical expansion. Structural rivets have a locking mandrel as an internal mechanism that ensures that the rivet forms a strong link in the hole. These two key mechanisms give structural rivets extremely high shear and pull-out strength.

The working principle of structural rivets is basically similar to that of blind rivets. The difference is that the structural rivets in the riveting process. In addition to the tail of the rivet body expansion and deformation, its mandrel will be locked or broken in the rivet body to form a whole structure.

This special locking process increases the overall strength of the rivet. and it ensures that the mandrel will not loosen or fall off.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Prons of High Strength Structural Pop Rivets

1. Extremely High Strength

Designed to withstand high loads, High Strength Structural Rivets provide extremely high shear and pull-out forces. They are designed to ensure joint reliability under high loads and dynamic conditions in aerospace, automotive manufacturing, bridge construction and other areas where high strength connections are required.

2. Locking Arbor

Structural pop rivets have the mandrel securely locked into the rivet body after installation, which can effectively prevent the mandrel from loosening or falling out. This unique locking mechanism enhances the overall strength and vibration resistance of the rivet and ensures that the connection remains stable over the long term.

3. Vibration Resistance and Durability

High-strength structural rivets excel in vibration and dynamic loading environments due to the locking design of the mandrel, reducing the risk of connection failure due to loosening. This feature makes them ideal for use in heavy machinery, railroads, aerospace and other applications that are subjected to high levels of vibration, extending the life of the structure.

4. Consistency and Precision

High-strength structural rivets provide consistent tightening force and locking depth during installation, ensuring uniform strength and performance at each connection point. This consistency makes them suitable for high-precision and demanding industrial applications, such as high-pressure pipeline connections, aerospace component assembly, etc., ensuring the security of each connection point.

Cons of High Strength Structural Pop Rivets

- Installation of high strength structural pop rivets requires specialized tools (e.g., rivet guns) and a high level of force to be applied during installation to ensure that the mandrel is locked.

- Not once installed, the High Strength Structural Pop Rivet connection is essentially permanent and difficult to remove or adjust.

- High-strength structural pop rivets are typically more expensive than standard rivets, especially in terms of materials, manufacturing processes and installation tools. While they offer extremely high performance, the overall cost of high-strength structural rivets is higher and may not be appropriate for projects with limited budgets.

Applications of Structural Rivets

Structural pop rivets are ideally suited for applications where strength is required. Its excellent strength and reliability make it ideal for use in a wide variety of industrial and structural applications where a strong, durable connection is required. Below are some typical specific application scenarios:

Aerospace

- Aircraft Structural Connections: In aerospace, structural blind rivets are used to connect aircraft shells, wings and internal structural components. These rivets are able to withstand high vibration and extreme temperature changes in flight, ensuring the long-term stability and safety of aircraft structures.

- Cabin Interior Installation: Structural rivets are used to fasten decorative panels, seat supports and other components in the cabin interior, providing a strong connection and withstanding various stresses in flight.

Automotive Industry

- Body Assembly: In automotive manufacturing, structural blind rivets are used for body and chassis connections such as doors, roofs, trunk lids and fenders. They provide reliable shear and pull-out strength to ensure the structural stability of the vehicle in operation.

- Chassis and Suspension: Structural rivets are also used to connect key components of the chassis and suspension system to withstand the significant loads and vibrations generated during vehicle operation.

Construction

- Structural Steel Connections: In the construction industry, structural blind rivets are used to connect support beams, steel columns and other critical components in steel structures to ensure the overall strength and durability of the building structure.

- Curtain Wall and Facade Installation: Structural rivets are commonly used to fasten curtain walls, metal panels and glazed facade systems in buildings, providing a high-strength fixing and ensuring security in all weather conditions.

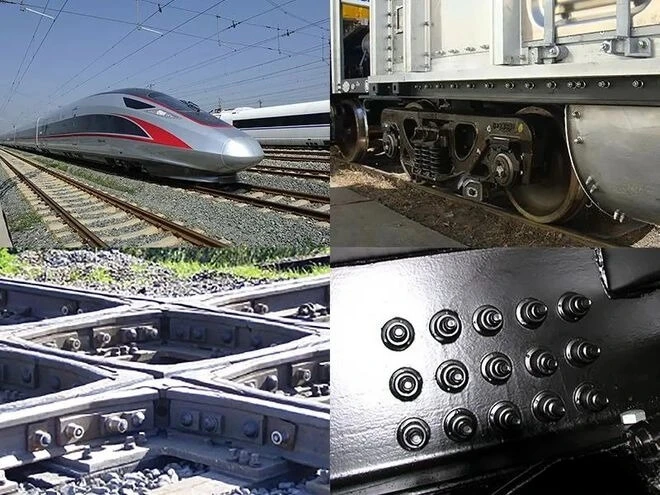

Railroad and Heavy Equipment

- Railroad Vehicles: Structural rivets are used in the manufacture and maintenance of railroad vehicles. It can connect components such as the body structure, chassis and axles. Their high vibration resistance ensures the stability and safety of trains in motion.

- Heavy Machinery and Equipment: In the assembly of heavy equipment such as excavators and cranes. Structural rivets are used to connect the main load-bearing structures and mechanical arms. Stuctural pop rivets provide the necessary strength and stability.

Wind Turbine and Energy Equipment

- Wind Turbines: Structural rivets are widely used in the manufacture of wind turbines. And it can connect turbine blades, towers and generator supports. Structural pop rivets can provide the necessary strength to resist wind and vibration during operation.

- Energy Equipment: In other energy equipment such as solar racks, oil rigs and power transmission towers. Structural rivets are used to connect critical components to ensure reliable operation under extreme conditions.

Tools for Installing Structural Pop Rivets

H6065 Lockbolt Tool :This pneumatic rivet gun is capable of riveting lockbolt rivets and hemlok rivets in all materials.The H6065 weighs only 2.9kg but has a working tension of up to 39,200 N. It can rivet 5.0mm (3/16) and 6.4mm (1/4).

P Series Blind Rivet Tool: There are three models of this rivet gun, P840,P848,P866.The working pull force of different models of rivet gun is different. And it can rivet 2.4mm(3/32″) to 6.4mm(1/4″) rivets.

C Series Blind Rivet Tool: This rivet gun is also available in three models, C848,C864,C866.It can riveting monobolt rivet, hemlock rivet and other types of pop rivet.Rivet size can be 2.4mm (3/32″) to 6.4mm (1/4″). ).

Conclusion

Structural pop rivets are an important type of blind rivets.Structural pop rivets can provide high shear strength and pullout strength. If you have projects that require strength. then structural pop rivets are the best choice for you.

However there are many types of structural pop rivets. You need to choose the right type of structural rivets according to the specific requirements of your project. Of course, you can demand the help of pop rivet manufacturer. Please contact our engineers.

Order High Quality Structural Rivets from Rivmate

Rivmate is the top pop rivet manufacturer and supplier in China.If you want to use high quality structural pop rivets to enhance the quality of your project or your customer’s satisfaction. Please contact us.

Whether it’s a bulb tite rivet with a waterproof effect. Or a high-strength lockbolt rivet, bom rivets, you can get it all from Rivmate.

If you want to buy high quality structural rivets, please contact us!