Table of Contents

Rivets are permanent connections. However, rivets can come loose if they are not used properly. What are the causes of loose rivets?

By reading this guide, you will understand the consequences of loose rivets and how to avoid them from happening.

Table of Contents

Consequences of loose rivets

Loose rivets may seem like a small problem, but they can lead to structural failure, safety hazards and high maintenance costs. The consequences of loose rivets are mainly in terms of structural stability, safety risks and maintenance costs.

- Stress concentration and fatigue injury.

- Risk of connection failure.

- Impaired pneumatic performance.

- Loose rivets may trigger a chain reaction and risk of sudden failure.

- Increased maintenance costs.

What Causes Loose Rivets?

I. Material and design factors

Rivet material or structural defects

- Nail core tension is insufficient or improper heat treatment, resulting in insufficient clamping force after riveting.

- Rivet body hardness is too high, the expansion is not sufficient to form an effective locking.

- The size or angle of the nail head is not reasonably designed, preventing the rivet tube from fully expanding.

Problems with connected materials

- Material surface is uneven, oil or rust, reducing friction.

- Rivet and material coefficient of thermal expansion difference, temperature changes lead to fluctuations in clamping force

II. Installation process issues

Improper riveting operation

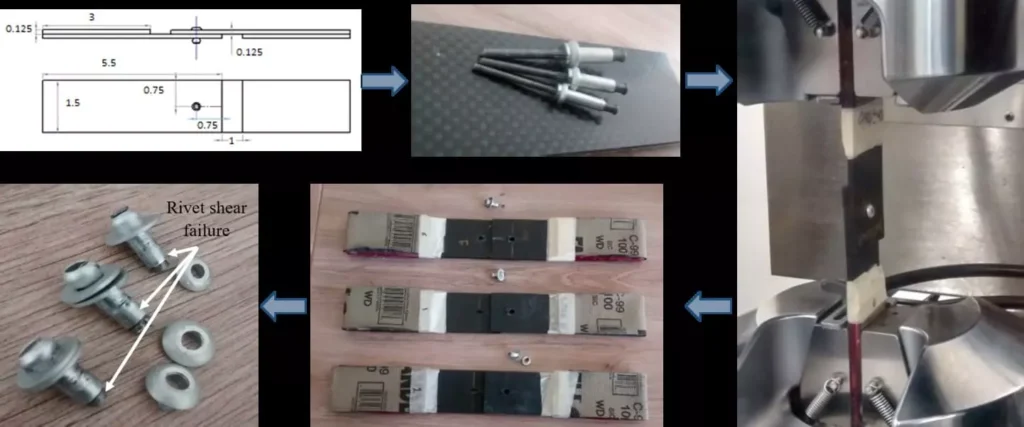

- Drill hole diameter is too large (beyond the rivet outer diameter of 0.1-0.2mm range), resulting in insufficient contact area.

- Insufficient or excessive riveting pressure: insufficient pressure so that the rivet is not fully deformed, excessive pressure may damage the material.

- Riveting angle deviation, resulting in lateral force generation.

Poor tool matching

- Rivet gun power is not enough or claw wear, need to pull the rivet many times, resulting in uneven nail core breakage.

- Not selected to match the rivet specifications of the gun head, such as external locking wire drawing rivets require special tools

III. External environmental factors

Vibration and Shock

- Continuous vibration (e.g. engine, transportation) causes small displacements, gradually weakening the clamping force.

- Sudden impacts (e.g. collisions) instantly exceeding the rivet’s tolerance limits.

temperature cycling

Frequent temperature changes cause material fatigue, which can lead to the risk of rivet failure. In outdoor metal structures, rivets may loosen due to temperature differences between day and night.

IV. Maintenance and quality control

Inadequate maintenance of tools

- Rivet gun claws, springs or seals are worn out and not replaced in time, affecting the stability of the nail grip.

- Compressed air contains moisture or impurities, resulting in unstable air pressure

Lack of quality testing

Failure to regularly test rivet pull-off force or torque to detect potential defects.

V. Other special scenario factors

- Corrosion or abrasion: long-term exposure to moisture or corrosive environments, the strength of the rivet is reduced.

- Overloading: exceeding the rivet’s designed load-bearing capacity, accelerating loosening or fracture.

Do You Have Any Questions?

Let Us Solve Your Problem

What Remedies can be Taken After Rivets has come Loose?

Direct replacement of loose rivets

If the rivets are loose, lose head, shear off or miss rivets, need to directly replace or replenish the rivets.

Care should be taken when replacing:

- Use gas cutting tool to cut off the old rivet head to avoid the vibration of wind shovel affecting the neighboring rivets.

- Clean the nail hole and check the inclination of the hole wall, if more than 5 ° or affect the bolt fit, need to ream or use wedge washers.

- After replacement, make sure that the new rivets have the same strength as the original structure, if necessary, expand the nail holes and use larger diameter rivets.

Replacement of high-strength bolts

In the repair of steel structure, rivets can be replaced by high-strength bolts, and the diameter of bolts can be converted according to equal strength. If there are no serious defects in the nail holes (such as wrong holes, elliptical holes), the bolts can be used directly; otherwise, they need to be reamed or add washers.

Glue or spacer reinforcement

- Glue reinforcement method: use high-temperature, high-viscosity glue coated around the rivets, clamped to dry (for non-stressed parts).

- Rubber pad reinforcement method: cut and rivet size matching rubber sheet, pad in the loose place to increase friction.

Regular inspection and maintenance

For structures subjected to power loads (such as plants and vehicles), periodically tap to check whether the rivets are skipping, if more than 10% need to be replaced. At the same time to avoid overloading or violent vibration, to reduce the rivets uneven force

Do You Have Any Questions?

Let Us Solve Your Problem

Custom Riveting Solutions for Your Project

Loose rivets not only threaten equipment safety, but also lead to high maintenance costs. Whether it is the high-frequency vibration scenario of aviation grade, the extreme temperature difference test of industrial equipment, or the micron-level error requirements of precision electronic components, we provide full-process customized riveting solutions:

- Scientific material selection: matching stainless steel, titanium alloy, Monel and other materials to ensure the compatibility of the coefficient of thermal expansion of the rivet and the connected parts;

- Technological innovation: combined with hydraulic riveting, frozen preload and other advanced technologies, precise control of clamping force and deformation, resistance to fatigue and impact;

- Anti-loosening guarantee: integrated locknut, self-lubricating coating and fiber-optic stress monitoring technology to provide aerospace-grade long-term stability;

- Full-cycle service: from failure analysis, tool matching to spectral inspection, we escort your project with NASM 1312 process standards.

Inquire today for exclusive solutions – extend the life of your structure by 30% and reduce O&M costs by 50% with artisan riveting technology! Contact us now!