What is a Bom Rivet?

Table of Contents

What is a Bom Rivet? During industrial procurement and fastener selection, many engineers or procurement personnel may encounter the term “Bom Rivet” in BOMs (Bill of Materials), RFQs, or technical documents.

Is it a specific type of rivet, or a non-standard, misused term? Misunderstanding this term can easily introduce risks during quoting, selection, or ordering. This article systematically explains the true meaning of Bom Rivet based on real industrial procurement scenarios, and how to correctly understand and handle this term in fastener procurement.

What is a Bom Rivet?

BOM Rivet is specifically designed for connections in applications requiring extreme strength and durability. It can be used to repair damaged rivet holes or in situations where higher strength and greater clamping force is required. These are the hallmarks of the Bom rivet. To be clear, bom rivets are a type of high strength structural rivet.

BOM Rivet is a type of high strength structural rivet with a large clamping range and repair capabilities. Capable of providing reliable fixing under high load and vibration conditions. Its strength is far beyond that of traditional blind rivets and ordinary structural rivets.

Bom rivets are widely used in the automotive industry, aerospace, construction and heavy equipment, rail transportation and other fields.

Applications of Bom Rivets

Bom rivets have a lot of features that other blind rivets don’t have. These excellent characteristics make them popular in the heavy equipment or industrial industries.

With traditional rivet usage, rivet holes may wear out or enlarge due to repeated use or stress.Bom rivets can copper over fill damaged holes, extending the life of the component and reducing the cost of replacement or repair.

Automobile Industry

In the automotive industry, high-strength and durable connections are often required, especially in critical areas of the body and chassis.Bom rivet is particularly suitable for use in dynamically loaded areas of the vehicle due to its vibration and shock resistance.Bom rivet is often used for fixing automotive bodywork, chassis, suspension systems and other components.

Aerospace Industry

Like the automotive industry, aerospace has high vibration resistance requirements for fasteners.

Bom rivets maintain consistent and reliable performance in extreme environments. That’s why it’s widely used for connecting fuselages, wings and other critical structures of airplanes.

Heavy Machinery and Equipment

Excavators, cranes and other heavy machinery have key components that require reliable rivets to connect them. Heavy machinery and equipment are subjected to tremendous stress and vibration during operation, and the high strength and impact resistance of Bom rivets ensures the performance of such equipment.

How Does Bom Rivet Work?

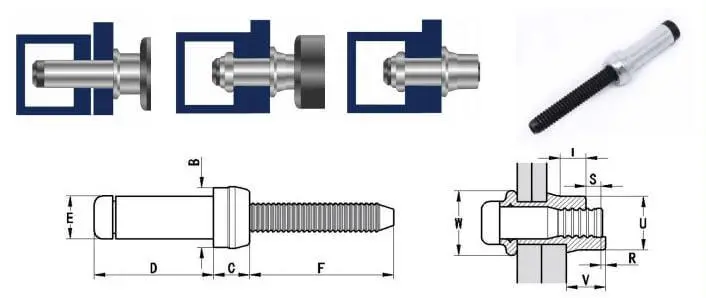

Although Bom rivets are one of the commonly used riveted fasteners in industry. But many engineers may be curious about how it forms a stable connection. Here is a brief description of how the bom rivet connection works. For ease of understanding, we have divided the installation process into three steps.

Insert Bom Rivet and Start the Tool

The BOM rivet is inserted into the pre-drilled hole so that the head of the rivet is pressed against the surface of the material. At this point, the rivet body penetrates the material being joined.

A specialized riveting tool is then used to apply a tensile force to pull on the mandrel inside the rivet. This tool is usually manual, pneumatic, or electric and can provide enough force to pull the mandrel.

Deformation Fixation

After starting the rivet pulling tool, the nozzle pulls on the mandrel so that the mandrel begins to move outward.

Immediately thereafter the end of the rivet body begins to deform on the backside of the material. This deformation usually extends outward, creating a mechanically locked structure.

The deformation of the tail allows the rivet to form a stable attachment surface on the backside of the material, thereby securely locking the material. This mechanically locked structure provides extremely high tensile and shear strength.

Mandrel Breaks and Completes Fixation

When the applied tension reaches a certain level, the mandrel breaks at a predetermined position. A portion of the mandrel remains within the rivet body, ensuring the integrity of the joint.

Ultimately, the head and deformed tail of the rivet securely clamp the material being joined, creating a strong, durable mechanical joint.

2 Common Types of Bom Rivets

There are many suppliers of Bom rivets, but overall there are just two types: 1. Avdel Avbolt 2. Huck Bom. Rivmate can provide you with all types of Bom rivets, solving all your purchasing needs at once.

① Avdel Avbolt

The Avdel Avbolt is designed for heavy duty fastening applications. Applications such as construction, train cars, containers, mining equipment and bridges can all be connected using Avdel Avbolt.

In addition to extremely high tensile and shear strengths, the Avbolt offers the benefits of blind fitting, including in restricted access areas. Like all blind bolts, Avbolt is easy to install and requires minimal operator training.

Avbolt is also available in a variety of sizes from 3/16 inch to 5/8 inch (4.8 mm to 16 mm). Rods are made of alloy steel and black oxide, while sleeves and collars are made of carbon steel, zinc plated and have a clear passivated coating. Flange rings are also available with three-piece bolts in 3/8-inch, 1/2-inch, and 5/8-inch diameters.

② Huck Bom

Huck BOM rivets are commonly used in military equipment, automotive suspensions, amusement park rides, and other applications where a strong, lasting connection is required. These blind rivets are ideal for high-strength applications and can be easily installed using any standard riveting tool.

BOM fasteners are available in sizes ranging from 3/16-inch to 3/4-inch and are constructed of mild steel sleeves, medium carbon steel pins, and a zinc-plated clear chromate coating.

Huck BOM fasteners also feature a mechanical lock that creates a vibration-resistant connection and eliminates rod loosening. When properly installed, the pin will separate flush from the sleeve, so no additional grinding is required.

The Main Advantages of Using Bom Rivets

Bom rivets are the premier choice for ultra-high strength blind hole fasteners. Below are the main advantages of bom rivets over traditional blind rivets.

High Strength Connections

BOM rivets are made from high-strength materials (such as high-strength steel or aluminum alloys) that provide excellent tensile and shear strength for high load and stress applications.

Conventional blind rivets, on the other hand, are typically suitable for medium strength applications, and while they can also provide a reliable connection, they may not be as good as BOM rivets under very high loads and stresses.

Repair Damaged Holes

BOM rivets are designed with a larger diameter to repair rivet holes that have become larger due to wear or damage, restoring structural strength and extending the life of the component.

Conventional blind rivets require replacement with larger rivets or other repair treatments when the hole diameter becomes too large.

Mechanical Lock

Compared to traditional blind rivets, BOM rivets provide extremely high tensile and shear strength through a mechanical locking structure where the rivet forms a solid lock on the backside of the material. Traditional blind rivets may not provide as much strength as BOM rivets.

Bom Rivet vs Blind Rivet

| Feature | BOM Rivet | Traditional Blind Rivet |

| High-Strength Connection | Provides exceptional tensile and shear strength, suitable for high-load and high-stress applications | Provides moderate strength connection, suitable for medium-strength applications |

| Repair Damaged Holes | Can repair worn or damaged rivet holes, restoring structural strength | Does not have repair capability, requires replacement or other repair methods |

| Vibration and Impact Resistance | Maintains stability and firmness under high vibration and impact conditions | Can withstand some vibration and impact, but less stable under high-strength conditions |

| Mechanical Locking | Provides high connection strength through mechanical locking | Relies mainly on rivet body deformation, less effective than mechanical locking |

| Corrosion Resistance | Treated for corrosion resistance, suitable for harsh environments | Can also be treated for corrosion resistance, but its importance might be lower |

| Wide Grip Range | Adapts to different material thicknesses, reducing inventory variety | Fixed grip range, requires selection based on material thickness |

FAQs - What is a Bom Rivet?

Q1. What is a BOM Rivet?

BOM Rivet (also commonly referred to as BOM-type structural rivet) is a high-strength structural rivet designed to withstand significant tensile and shear forces.

It is typically used in industrial applications demanding high joint strength, vibration resistance, and long-term reliability, such as steel structures, heavy equipment, and solar mounting systems.

Q2. How does a BOM Rivet work?

BOM Rivets create a reliable mechanical locking structure by breaking the mandrel.

During installation, the mandrel is pulled by the rivet gun, causing the rivet body to fully expand and lock on the backside. The mandrel ultimately breaks at a predetermined tensile force, forming a high-strength, irreversible connection.

Q3. What are the main advantages of BOM Rivets?

Core advantages of BOM Rivets include: high tensile strength, high shear resistance, excellent vibration resistance, and high installation efficiency.

Compared to standard blind rivets, they are better suited for load-bearing structural connections, maintaining stable performance under harsh environments or prolonged vibration conditions.

Q4. Where are BOM Rivets commonly used?

BOM Rivets are widely applied in photovoltaic mounting systems, steel structural frameworks, construction machinery, rail transit, and heavy equipment manufacturing.

They are particularly suited for single-side installation scenarios where access from the reverse side is impossible but bolt-level strength is required.

Q5. Can BOM Rivets replace bolts or welding?

In many applications, BOM Rivets can serve as alternatives to bolts or welding, though specific project conditions must be evaluated.

When projects prioritize faster installation efficiency, consistent connection quality, and avoidance of welding heat-affected zones, BOM Rivets often represent a more cost-effective solution.

Realize the Success of Your Business at Rivmate

Bom rivets have been the ideal solution for heavy equipment since they were invented. Currently bom rivets are gradually replacing traditional bolts. Our guide is a stepping stone before you buy bom rivets, outlining their definition and showing you the benefits and applications of bom rivets.

If you are looking for bom rivets that are trusted by customers across the globe, then you have come to the right place.Rivmate has been providing quality bom rivets to customers across the globe for a moderate number of years. Our state-of-the-art rivet manufacturing facility produces the world’s best bom rivets, blind rivet and rivet nut.

We customize bom rivets according to your project requirements and offer competitive after sales service. Still hesitate? Why not experience our free sample evaluation? Request a quote now!

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met