Table of Contents

What is a Speed Rivet? Do you want to know about speed rivets in detail before you buy it?This blog will provide you with the most comprehensive explanation. Let’s read it together.

Table of Contents

What is A Speed Rivet?

Speed rivets break the concept that blind rivets can only be riveted individually. Engineers installing speed rivets with specialized tooling can perform continuous, rapid riveting. This type of riveting is ideal for automated assembly work in bulk.

So why do speed rivets work continuously?

Because speed rivets are not like traditional blind rivets, which need to be installed one by one. When you install speed rivets, you can install dozens of rivets at once. Each time you complete the riveting process, the next rivet in the tool is automatically in place, ready for the next operation.

Types of Speed Rivets

Speed rivets come in several different types, depending on the actual requirements of your project. The following are common types of speed rivets:

BRV Speed Rivets

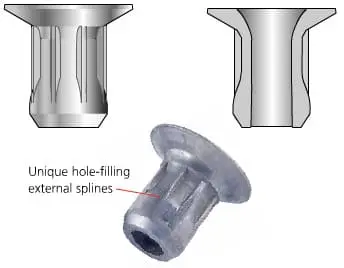

BRV Speed rivets have a unique bulbous rear end. The shortening of the ball end during installation ensures the strength of the connection. And its large head-shaped tail provides a large carrying area for soft materials.

BRV Speed rivets are also characterized by their ability to fill irregular holes. Most importantly, of course, speed rivets cost less than welding or other rivets when working in the field!

CBT Speed Rivets

CBT Speed rivets date back to the 1930s. It is available in a variety of finishes including galvanized, brass and other options.

CBT Speed rivets have a consistent clamping force that reduces damage to soft or brittle materials. For this reason, it is often used in household appliances and lightweight manufacturing.

NeoSpeed Speed Rivets

Neospeed speed rivets are the strongest and most versatile fastening system on the market, according to data presented by Avdel Neospeed.Neospeed speed rivets provide enough strength and installation speed that it can be installed up to four times faster than traditional threads or rivets!

Neospeed speed rivets have a unique rivet design. This design allows for increased clamping force and a wide riveting range. It provides multi-grip capability and can accommodate materials of varying thicknesses.

This type of speed rivets is half the weight of traditional rivets, effectively reducing the overall weight of the equipment. Reduces energy consumption during operation.

Advantages of Speed Rivets?

Why was the speed rivet invented? Because it has many advantages that other riveted fasteners do not have. Let’s read on.

No Need to Reload Rivets

When engineers install speed rivets, they preload the speed rivet gun with a large number of speed rivets, thus eliminating the need to repeatedly load rivets when installing industrial equipment. Using speed rivets for the same project can save a great deal of time, especially if the manufacturer is doing mass production.

Very Fast Installation

The best thing about Speed rivets is that it installs very quickly. And it’s perfect for high volume installations.

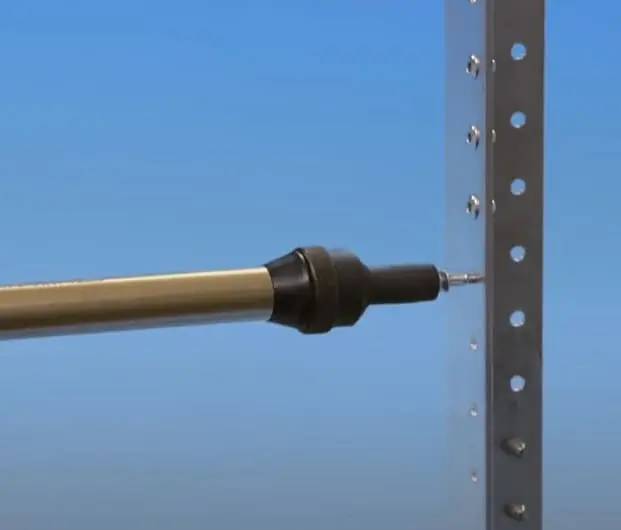

Speed rivets can be installed on factory automated assembly lines using automatic riveting machines. Trust me, you can save up to two-thirds of the time!

Let’s enjoy a quick install of the speed rivet! Let’s appreciate how time-saving the following speed rivet installations are.

Cost-effective

In actual production, speed rivets cost less than welded or blind rivets. Both the cost of time and the economic cost of the rivets themselves. This can be a huge saving to your budget!

Smooth Exterior

Speed rivets have a very flat surface with no bumps after the installation is complete. This provides a very aesthetic appearance. Especially suitable for applications where a smooth surface is required!

For example, speed rivet is used extensively in the plastic housings and heat sinks of electronic devices and in the metal housings and internal frames of household appliances.

Why Use Speed Rivet Technology?

Speed rivets provide stable clamping force while increasing the efficiency of production setups. The more you read, the more I’m sure you realize that the best part about speed rivets is that they don’t need to be reassembled after a single rivet is installed. speed rivets can be installed dozens of times at a time. This is very important in industrial automated assembly lines, and means that engineers’ installation efficiency is greatly improved.

What is the Difference Between Speed Rivets and Traditional Blind Rivets?

| Comparison Item | Speed Rivets | Blind Rivets |

| Installation Speed | Very fast, suitable for high-efficiency, large-scale production, especially for automated assembly lines | Fast, but typically slower than speed rivets |

| Operation Method | Single-sided operation, ideal for applications with limited space | Single-sided operation, suitable for applications with limited space |

| Installation Tools | Suitable for automation, requires specialized speed riveting equipment, can also use manual tools | Uses standard riveting tools, suitable for various settings |

| Connection Strength | High-strength connection, excellent resistance to vibration and impact | Provides strong connections, suitable for medium-strength applications |

| Applicable Materials | Suitable for a variety of materials, including metals, plastics, and composites | Suitable for a variety of materials, including metals, plastics, and composites |

| Residual Mandrel | No residual mandrel, smooth surface after installation | Mandrel remains inside the rivet body after installation, slightly protruding |

| Cost Efficiency | Low cost for mass production, higher initial equipment cost but lower on-site installation cost | Lower initial cost, but slightly less efficient for mass production |

| Customization | Customizable design, tailored to meet specific assembly requirements | Highly standardized, broad adaptability |

| Water and Dust Resistance | Some types (e.g., closed-end) provide water and dust resistance | Closed-end rivets provide water and dust resistance, but standard types have weaker water resistance |

| Typical Applications | High-efficiency assembly lines, such as in automotive, electronics, home appliances, and furniture manufacturing | Automotive, construction, electronics, home appliances, furniture manufacturing, repairs, and on-site assembly |

Application of Speed Rivets

Speed Rivets are used in a variety of industrial environments due to their unique benefits. A look at some of the applications for speed rivets:

1.Speed Rivets for Domestic Electric Appliance

The use of household appliances is very high. It is believed that there are a lot of appliances in everyone’s home, so keeping each appliance fully assembled requires a lasting solution.Speed rivets are widely used in household appliances to connect a variety of different housings for assembly. Although traditional blind rives can also complete the process, speed rivets are faster.

In addition, speed rivets weigh half or less than blind rivets. This reduces the overall weight of the appliance. It helps the customer to make different visits to the appliance and enhances the happiness of the customer.

2.Speed Rivets for Lightweight Construction

In the industrial sector, in addition to heavy equipment, there are also lightweight structures. Lightweight construction needs to ensure that the overall weight of the equipment does not feel heavy.

Speed rivets manufacturers can provide lightweight designs. Maintaining reliable strength while still making your equipment lighter. This technology improves structural integrity by not damaging materials.

3.Speed Rivets for Electronic Equipment

Electronic devices often have high weight requirements. So it is not possible to use fasteners that are inherently heavy, and Speed rivet brings the solution.

Speed rivets reduce the cost of electronic equipment while reducing its weight. This is very helpful in selling electronic equipment.

Increase Production Efficiency with Rivmate Speed Rivets

Want to improve the efficiency of production? Rivmate Speed Rivets is one of the best speed rivets solution providers. Purchase speed rivets and apply them to your project for the fastest productivity.

Contact us today for high quality speed rivets solutions for your assembly needs. Our engineers will provide the best solution for your project.