What is a Threaded Rivet Insert? A Ultimate Guide

This article is the most detailed guide to Threaded rivet insert. It will help you understand how to use threaded rivet inserts and how to choose the most appropriate threaded rivet insert for your project.

Table of Contents

As an important type of connecting element in the field of fasteners, the Threaded Rivet Insert plays an important role in modern engineering and manufacturing.

In this article, we will take an in-depth look at the definition, types, working principles, installation and usage of Threaded Rivet Inserts, as well as evaluating the elements that go into selecting the best Threaded Rivet Insert. Providing you with a comprehensive guide to your knowledge of this specialized fastener.

What is a Threaded Rivet Insert?

Threaded rivet inserts are fasteners that are used to form reliable threaded connections in thin sheet materials. The market for thin sheet applications is very high, so the number of threaded rivet inserts used is also very high.There are various types of threaded rivet inserts, including hex rivet nut, countersunk rivet nut.

In order to achieve a stable connection, threaded rivet inserts are usually made of high-strength metals. For example, stainless steel, aluminum alloy, etc. Threaded rivet inserts usually have internal threads that can be used to install threaded bolts, screws, nuts or other threaded connections.

Types of Threaded Rivet Insert

Threaded Rivet Inserts need to be mounted to different sheet metal to provide a stable threaded connection. By itself, it already has the capability of connecting to a thin plate. However, when connecting to other components that are not sheet metal, a bolt is required.

There are various types of threaded rivet inserts and the most commonly used threaded rivet inserts have been listed below.

1.Flat Head Rivet Nut

Flat head rivet nut has a flat top and internal threaded structure. The flat top design saves space by allowing it to fit snugly into thin sheet material without protruding over the surface. This is beneficial for applications where space is limited or where a recessed design is required. It is also the most commonly used type of threaded rivet insert.

2.Countersunk Head Rivet Nut

Countersunk head rivet nut is a threaded rivet insert with an inserted head design. It has an embedded recess in the top that allows it to be embedded in thin sheet material, flush with the surface. This design keeps the top of the nut from protruding, thus not interfering with the flatness of the material surface and maintaining an aesthetic appearance.

3.Reduced Head Rivet Nut

Reduced head rivet nut is a threaded rivet insert with a reduced head design. Reduced head rivet nuts have a relatively small top surface that is thinner than traditional flat or inserted head rivet nuts. This design reduces the projection of the nut on the surface of the material after installation, resulting in a more compact connection, especially for applications where space is limited or where the surface of the material needs to be kept flat.

4.Closed End Rivet Nut

Closed end rivet nut is a threaded rivet insert with a closed end design. The bottom of the closed end rivet nut is closed with no openings. This design allows the nut to have a closed bottom after installation, preventing liquids, gases and other contaminants from entering the connection area. The closed end provides better sealing and protection, protecting the internal threaded connection from the outside environment.

5.Jack Nut

Jack Nut is a special type of nut, a fastener with an expansive design, also known as a prestressed nut. It consists of a housing and an internal thread. When the internal thread is subjected to the rotational force of a bolt or screw, the shell expands and clamps into the material in which it is installed.

How do Threaded Rivets Insert Work?

Rivet nut installation of standard parts consists of four main components: the rivet nut, the rivet nut tool, the attached sheet, the attachment assembly, and the bolt or screw. To properly install the rivet nut, a hole is drilled in the thin plate to match the size of the rivet nut.

The video above shows the actual installation process and results of the threaded rivet insert.

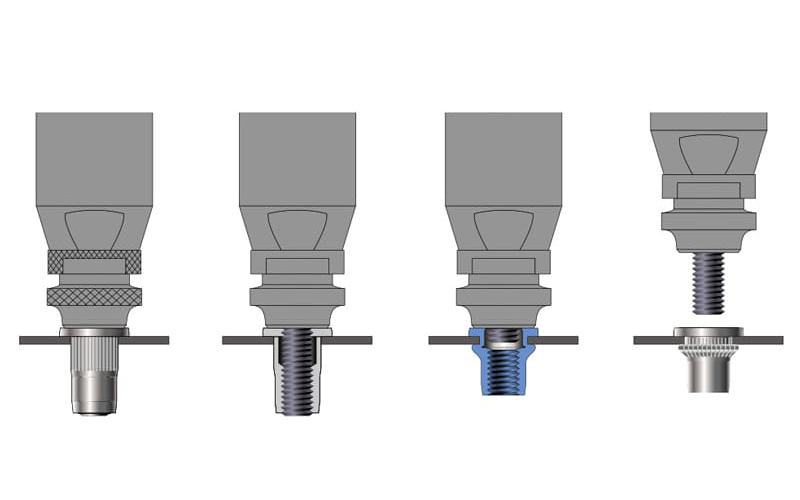

When you install a rivet nut using a rivet nut tool. The top of the rivet nut is pulled by pressure to deform for extrusion. This stabilizes the joining of many different sheet components together. The diagram below shows the complete installation of a rivet nut.

How to Install Threaded Rivets Insert?

The process of installing threaded rivet insert is very simple and quick. All you need to have is a matching tool and you will be well on your way to enjoying this installation process.

There are two commonly used tools on the market as follows:

- Air Rivet Nut Gun

- Hand Rivet Nut Tool

Rivet Tool and Rivets to Install Threaded Inserts

1.Air Rivet Nut Gun

Pneumatic rivet nut guns are one of the easiest installation methods to use. A rivet nut gun can install all sizes of rivet nuts and they have different sizes of heads to change.

Pneumatic rivet nut guns are often used in mass use scenarios. For example, in industry, construction, manufacturing, and automotive. A qualified pneumatic rivet nut gun can save a lot of labor costs.

2.Hand Rivet Nut Tool

Manual rivet nut tool is suitable for home use. It is very inexpensive but requires the use of a lot of force to complete this installation process. So when your project doesn’t require a lot of rivet nuts to be installed, you can opt for this type of installation. Though it is cumbersome, it saves you a lot of financial cost.

How to Use a Threaded Rivet Insert Tool?

I found a tutorial on Youtube for installing the tool using a manual rivet nut tool. Many thanks to the youtube author for the great work. If you have questions about installing rivet nuts, check out this video tutorial. I believe this can be a good help for you.

How to Use Threaded Rivets Insert?

这是测试文本,单击 “编辑” 按钮更改此文本。

Pros and Cons of Threaded Rivet Inserts

Threaded rivet insert is a widely used fastener. It is used to join thin sheet materials and provide threaded attachment points. Understanding these pros and cons is critical in making informed fastener decisions for your business and projects.

1.Strength and Reliability

Threaded rivet inserts provide good tensile strength and reliability by forming a threaded connection in the material. They are able to withstand high tensile forces and ensure a solid connection.

2.Suitable for a Wide Range of Materials

Threaded rivet inserts are suitable for use with a wide range of sheet materials, including metals, plastics and composites. They are used in a wide range of applications in automotive manufacturing, aerospace, electronic equipment, machine building and furniture.

3.Easy Installation

Installation of the Threaded rivet insert is very simple. All you need to do is to purchase a special rivet nut tool and you can complete the installation process very quickly. This installation process is usually faster and easier than traditional welding or thread cutting.

4.Specialized Tools Required

The installation process of Threaded rivet insert is very simple. However, it often requires the use of specialized tools. Tools often add a certain amount of economic cost and complexity. But the savings in labor costs are also very high. For mass production scenarios, the economic benefits of specialized riveting tools are high.

5.Restricted to Thin Sheet Materials

Threaded rivet inserts are still very limited in their use. It is usually suitable for thin sheet materials and may not be suitable for thicker materials. So you need to understand the usage scenario of your project in detail before choosing a fastener for your project.

6.Limited by Material Strength

The tensile strength and reliability of a threaded rivet insert is limited by the strength of the material itself. If the material is not strong enough, the threaded connection may not be strong enough.

Which Threaded Rivet Inserts Is Best for Your Business

Which type of threaded rivet insert to use depends on the requirements of your project. The application requirements for most projects can be categorized into the following categories based on material and application.

- Hex Head Rivet Nut

- Reduced Head Rivet Nut

- Countersunk Head Rivet Nut

- Jack Nut

If your application scenario requires a high level of mounting force and torque transfer. Then the hex rivet nut is an excellent choice.

If your project is interested in the surface flatness of the product, you need to keep the appearance aesthetically pleasing. Then countersunk rivet nut is a very suitable choice. It flattens the surface of the connectors and provides a more aesthetically pleasing appearance.

When you need to install components from limited space or narrow holes. then go for the reduced rivet nut. it has a smaller head size to fit in areas with restricted space.

Conclusion

Threaded rivet inserts are a very simple way to make connections. A reliable and consistent connection can be achieved by extruding a deformation, and the Threaded rivet insert provides a reliable connection point for different threaded fasteners.

This technology may seem overly complex and intimidating at first, but once you understand the basics, it can be your most economical and reliable option.

Get Best In Class Threaded Rivet Inserts from Rivmate

Rivmate is a China Threaded rivet insert and rivet nut supplier. Known for its superior quality fastener products and excellent customer service. We provide threaded rivet insert and rivet nut solutions to customers from different companies around the world.

Our threaded rivet insert and rivet nut are ISO and IATF certified and meet international product safety guidelines. Please take advantage of our large inventory and fast delivery time and professional OEM solutions. We are an excellent OME Rivet Nut manufacturer in China.

A successful business can’t exist without reliable fastener products from a trustworthy factory. We understand the market demand in Asia, Europe and America and have been producing high quality and sustainable rivet nut products for more than a decade. The perfect fastener product to make your business a success. Contact us today!