Table of Contents

Blind rivet shear strength is something you need to know before ordering a blind rivet. So why is shear strength so important for blind rivets? This blog will tell you the answer!

Table of Contents

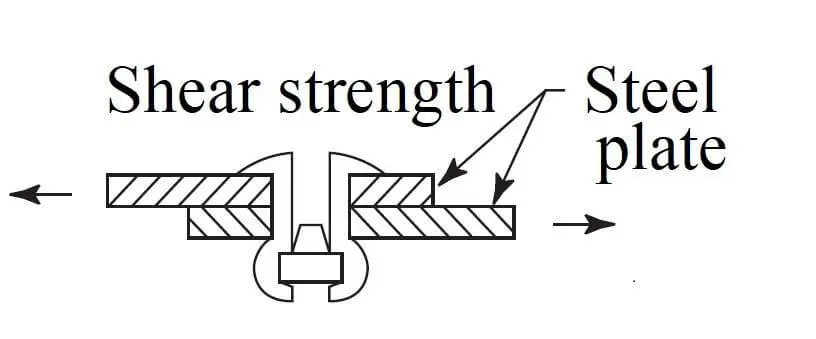

What is the Shear Strength?

Shear Strength is the ability of a material to resist damage by shear forces (forces parallel to the cross-section of the material). In other words, shear strength is the maximum stress at which a material will resist sliding or breaking when a force is applied parallel to the direction of its cross-section. Shear strength is usually expressed in terms of stress per unit area, and the units commonly used are megapascals (MPa) or pounds per square inch (psi).

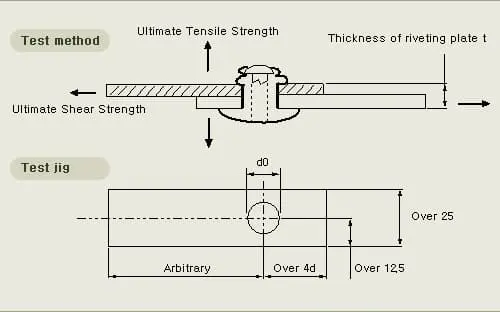

Determination of Shear Strength

Shear strength is usually determined experimentally. In a typical shear test, a sample material is held in a specific testing machine and a gradually increasing shear force is applied until the material breaks. The value of the stress at this point is the shear strength of the material.

The shear strength (τ) is usually calculated by the following equation:

τ=F/A

- F is the applied shear force.

- A is the area of the shear surface.

What is Blind Rivet Shear Strength?

The shear strength of a blind rivet is an important indicator in assessing the ability of a blind rivet to maintain the integrity of the connection in a given application. Shear strength is something you need to be concerned with if you have a project where the blind rivet will be used in applications that are subjected to high forces or loads that need to be sustained over a long period of time.

Common Range of Shear Strength for Blind Rivets

- Aluminium Blind Rivets: shear strength typically between 200 and 300 MPa, suitable for light duty applications.

- Steel Blind Rivets: shear strengths typically between 300 and 400 MPa, suitable for medium duty applications.

- Stainless Steel Blind Rivets: Higher shear strengths, typically over 400 MPa, for high loads and harsh environments.

Importance of Shear Strength for Blind Rivets

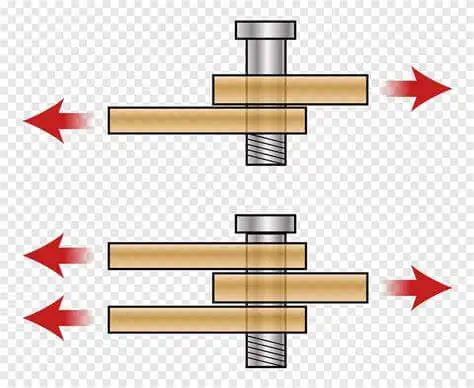

Shear Strength is extremely critical to Blind Rivets. Blind rivets are subjected to shear forces in many applications. Therefore, shear strength has a direct impact on the safety, durability and overall performance of the blind rivet connection. Here’s how important shear strength is to blind rivets:

1. Ensure Connection Strength and Security

The shear strength of a blind rivet determines the maximum shear force it can withstand. If the shear strength is insufficient, the rivet may break or fail during application, causing the connection to loosen or separate.

In high stress applications such as automotive or aerospace, blind rivets need to withstand the large shear forces generated during vehicle travel or flight. High shear strength rivets ensure the reliability of the connection and prevent accidents or failures.

2. Accommodate Dynamic and Repetitive Loads

Blind rivets in many applications are subjected to repetitive or dynamic loads such as vibration, shock or mechanical stress. These loads generate repeated shear forces that can cause gradual fatigue or fracture of rivets with low shear strength.

In practical applications, such as in railway, construction and mechanical equipment. Blind rivets are often exposed to constant vibration or dynamic loads. High shear strength rivets maintain the integrity of the joint under these conditions, reducing the risk of fatigue fracture.

3. Extended Service Life

Blind rivets with high shear strength are less likely to deform or break during use. This feature extends the life of the joint and reduces the frequency of maintenance and replacement.

For example, in outdoor structures such as bridges, pylons or building facades, the durability of blind rivets is very important. High shear strength rivets ensure that these structures remain stable and safe even after prolonged exposure to environmental stresses.

4. Adaptation to the Connection of a Wide Range of Materials

Different materials require different shear strengths for the connection. The shear strength of a blind rivet must match the strength of the material being joined in order to form a solid connection.

For example, when joining metals to composites, the shear strength of the rivet needs to be high enough to prevent joint failure due to differences in material hardness. Selecting blind rivets with high shear strength can accommodate this type of dissimilar material joining requirement.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Factors Affecting the Blind Rivet Shear Strength

The shear strength of a qualified blind rivet provides the ability to resist fracture or deformation. Shear strength is a key indicator in assessing the suitability of a rivet for a particular application and is influenced by a number of factors. The following are the main factors that determine the shear strength of blind rivets:

1. Material of Blind Rivets

Blind rivets are usually made of aluminium, steel, stainless steel, copper and other materials. The strength of the material itself directly affects the blind rivet shear strength.

- Aluminium: lightweight but with relatively low shear strength, suitable for light duty applications.

- Steel: High shear strength for medium to heavy duty applications.

- Stainless steel: very high shear strength and corrosion resistance for high loads and harsh environments.

- Copper: good corrosion resistance but low shear strength for specialised environments.

- Material treatment: The treatment process of the material, such as heat treatment or surface hardening treatment, also affects the shear strength. Proper heat treatment can significantly improve the strength and durability of the material.

2. Rivet Diameter

The larger the diameter of the rivet, the larger the shear area and the higher the shear force it can withstand. Therefore, larger diameter rivets typically have higher shear strength.

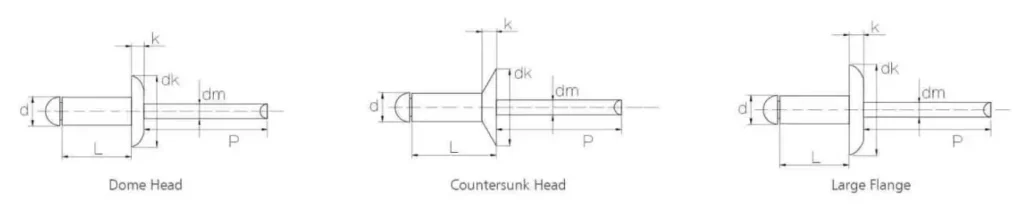

3. Rivet Shape and Construction

Different head types of blind rivets affect the shear strength. Blind Rivets are generally available in the following three head types:

- Dome Head

- Coutersunk Head

- Large Flange Head

A large flange head provides a larger bearing area, which distributes stresses and increases the stability of the connection. In addition the mandrel locking mechanism of structural blind rivets improves overall shear strength as the mandrel provides additional strength support within the rivet body.

4. Properties of the Connected Material

The strength and hardness of the material being joined has a direct effect on the shear strength of the rivet. If the joining material is soft or brittle, it may break before the rivet reaches its shear strength.

5. Installation Quality

Only correctly installed blind rivets can be maximised. If the rivet is not installed correctly, the desired shear strength may not be achieved.

6. Operating Environment

Extreme high or low temperatures may affect the mechanical properties of a material, thereby reducing its shear strength. For example, some materials may soften or lose strength at high temperatures.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Conclusion

Reading this far, I’m sure you’ve gained some insight into the shear strength of blind rivets. This includes the definition of shear strength, factors affecting the shear strength of blind rivets and importance.

If you are in the decision making stage before purchasing a Blind Rivet, please feel free to contact us. We will give you help!

Custom Blind Rivet Shear Strength for You

If your existing supplier of Blind Rivets is not able to meet your requirements. Or you are looking for pop rivet manufacturer who can supply high shear strength blind rivets.Rivmate can solve your sourcing problem.

Whether you need to buy high shear strength blind rivet or low shear strength blind rivet, you can find the solution from Rivmate.