Table of Contents

What is Riveting? Do you know how riveting works? What is the difference between riveting and welding in practice? This article will explain what is riveting from the definition of riveting, application, purpose, operation method, and the comparison of welding to you in detail.

Table of Contents

What is Riveting?

Riveting is a commonly used metal joining process, and this thin sheet joining method is very efficient and reliable. Riveting is the permanent joining of two or more pieces of material together through the use of rivets. Its high strength, durability, and ease of operation make it widely used in construction, aerospace, automotive manufacturing, shipbuilding, and other areas where strong connections are required.

Welding and riveting are two commonly used metal joining processes. However, in contrast to welding, where two or more materials are fused together, riveting simply creates a hole in the joint.

What is the Riveting Process?

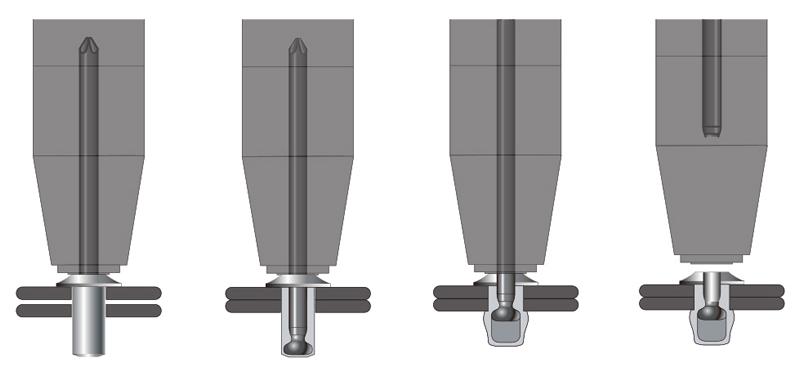

A riveted joint is formed by impacting or squeezing the end to create a deformation that expands the rivet body to form a stable connection. Below is the full process of riveting.

- Inspection Before Riveting: Prior to riveting, the joining section needs to be carefully designed and the surfaces of the parts must be clean to ensure a good connection. Then mark the locations to be riveted and make sure the parts are properly aligned.

- Drilling and Installing the Rivet: Drill holes in the marked locations. The diameter of the hole should be appropriate for the size of the rivet selected. Ensure that the location and depth of the holes are accurate. Insert the rivets into the pre-drilled holes to ensure they form a connection between the parts.

- Riveting Tivets with Tools: Use a rivet gun or other special tool to complete the rivet installation process. Place the nail part of the rivet onto the nozzle of the tool and start the riveting tool.

- Inspection and Testing: After the riveting is complete, inspections are made to ensure that the connection is secure. This includes checking the shape of the rivet head to make sure there is no misalignment or damage.

What is The Purpose of Riveting?

Engineers use riveting for three purposes really:

1. Cost-effective

2. Save installation time

3. Stability and vibration resistance

As we all know, the best feature of riveting is that it is very quick to install. This is especially important during mass production in factories, which can save a lot of labor costs. You will earn more!

Next to the automotive, rail and aerospace industries, where riveting is particularly used, Rivet provides excellent vibration resistance and stability to every part of the system.

In actual field use, rivetting is cheaper than other joining methods of the same quality!

The Examples of Riveting

There are many examples of riveting in actual production processes. Basically every industrial product has rivetting on it. This includes automobile manufacturing, aircraft manufacturing, joining of building structures, ship building, joining of components for electronic devices and household appliances.

- Aircraft fuselage and wing attachment

- Body panel connections

- Bridge construction steel connections

- Ship hull and deck connections

- Connection of components and housings inside electronic equipment

- Connections of panels and frames of household appliances such as washing machines, refrigerators and ovens

- Connections of train bodies and chassis for rail transportation

What are The Disadvantages of Riveting?

Although Riveting has significant advantages in many applications, it is not perfect and still has some drawbacks and limitations. Here are some of the major advantages of Riveting:

- Permanent connection, difficult to disassemble and unfavorable for maintenance.

- Material limitations, too thin or too thick may not be suitable for riveting.

- Deformed heads or tails may affect the flatness of the joined surfaces.

- Inadequate sealing of rivets other than specially designed rivets may result in gas or liquid leakage.

Is Riveting as Strong as Welding?

Riveting and Welding are two different joining techniques, each with unique benefits and application scenarios.

Riveting is superior to welding in terms of strength to shear, dynamic loads and vibration. However, in terms of tensile strength, under extreme high load conditions, welding is stronger.

So in conditions where high vibration and dynamic load resistance is required, riveting may be more suitable, while in static load conditions where high tensile and shear strength is required, welding usually performs better.

| Comparison Item | Riveting | Welding |

| Connection Type | Mechanical connection using rivets | Fusion connection by heating and melting materials |

| Connection Strength | High strength, suitable for high tensile and shear strength applications | Very high strength, often matching or exceeding base material strength |

| Vibration and Impact Resistance | Excellent, especially suitable for high vibration and impact conditions | Good, but may develop fatigue cracks under long-term vibration |

| Removability | Removable, but requires destroying the rivet | Generally not removable unless cutting the welded part |

| Ease of Operation | Relatively simple, especially for single-sided operations | Requires high skill and precise control |

| Applicable Materials | Various materials including metals and non-metals | Mainly used for metal materials |

| Corrosion Resistance | Depends on rivet material and surface treatment | Can achieve excellent corrosion resistance with proper welding techniques and post-treatment |

| Suitable Environments | Suitable for various environments, including high vibration and impact | Suitable for structures needing high strength and continuity |

| Equipment and Tools | Manual, pneumatic, or electric riveting tools | Welding machines (including arc welding, gas welding, laser welding, etc.) |

| Installation Speed | Quick installation, ideal for mass production and assembly tasks | Relatively slow, especially for complex or large-scale welding |

| Connection Continuity | Gaps between rivets | Forms a continuous joint with good sealing properties |

| Application Areas | Aerospace, automotive, construction and bridges, shipbuilding, electronics, etc. | Aerospace, automotive, construction and bridges, pipelines and pressure vessels, shipbuilding, etc. |

| Cost Efficiency | Lower initial cost, but requires periodic inspection and maintenance | Higher initial cost, but may have lower maintenance costs in the long run |

| Durability | Long-term stability, especially in dynamic load and vibration conditions | Long-term durability, but requires special design and control in high vibration conditions |

Frequently Asked Questions About Riveting

To save you time, we’ve listed a few frequently asked questions about riveting.

Is Riveting Durable?

Durability is one of the characteristics of rivets. As mechanical connectors, rivets are widely used in various industrial and engineering applications due to their high strength and durability.

The materials used to make rivets are usually high-strength materials such as steel, aluminum and stainless steel. Rivets are also available in a variety of finishes such as galvanized, nickel plated and anodized.

In addition, rivets are mechanically locked to hold materials together. Its unique locking method provides a stable connection over time.

Is Riveting Permanent Or Semi Permanent?

Permanent connections generally have the following two characteristics:

- Firm fixing

- Not easy to dismantle

Obviously, Riveting is normally regarded as a permanent connection.Rivets provide high strength and durability, ensuring the long-term stability of the connection. However, riveted connections can also be removed under special circumstances. However, this can damage the rivet fixing structure, making it impossible to continue using it.

Conclusion

Regardless of the connection method, the choice is based on the actual application.Riveting can be used for the vast majority of connection applications. Riveting can be used for a wide range of applications, from non-strength connections such as furniture to strength-demanding connections such as automotive bridges.

Of course, this may reduce your business costs, or it may increase your business costs. The difference in price between different types of rivets is significant. If you want to know whether riveting is suitable for your project, you can contact our engineers. Rivmate not only provide rivets, but also rivets.

Custom Riveting Solution. Rivmate can Help You!

Rivmate is one of the top rivet manufacturers and suppliers in China, and has provided rivets and rivet solutions to more than three hundred companies around the world. We have a professional team of engineers and rich types of rivets. You can solve all riveting problems at once.

Whether your project is a regular project or a demanding project such as automobile, we can meet your needs. Contact us for professional riveting solutions today!