Table of Contents

Do you know what is the materials used to manufacture rivets? Do you know how different rivets made from different materials they will behave differently? By reading this guide, you will learn all about that. You can even know the price difference between rivets made of different materials. Let’s explore this together.

Table of Contents

What is the Materials Used to Manufacture Rivets?

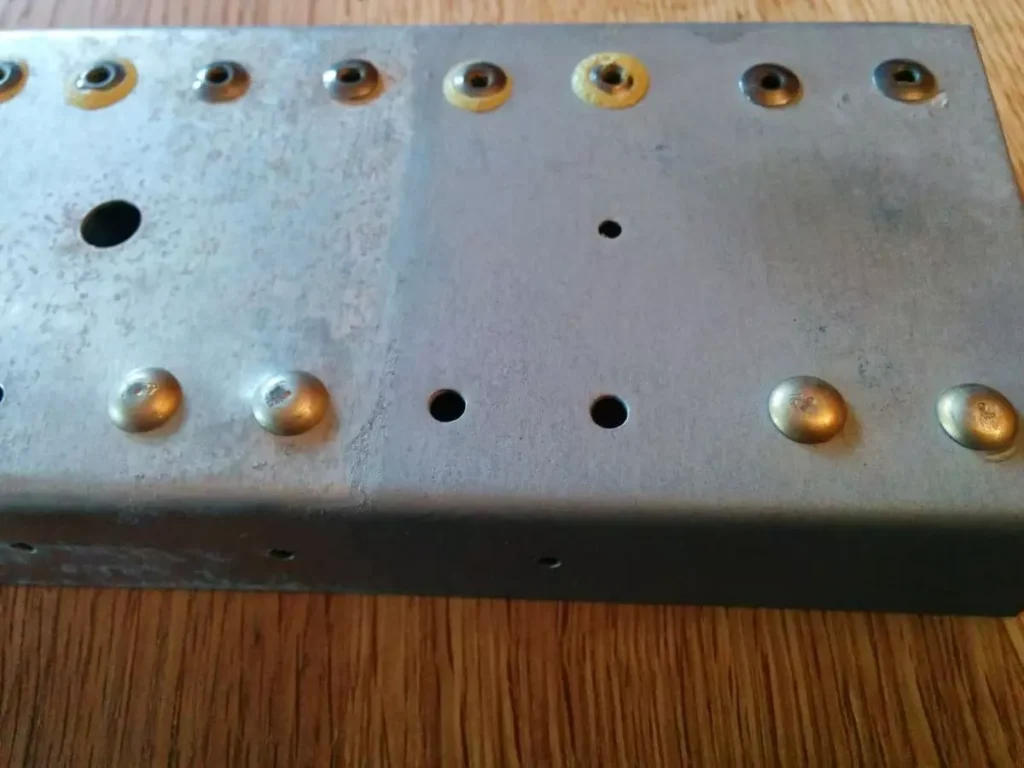

Rivets are usually made of metal materials. In order to meet the different needs for strength in different applications, there are a number of metal materials that can be used to manufacture rivets, all of which have different properties from each other. The common metal materials used to manufacture rivets are listed below:

- Aluminum

- Steel

- Stainless Steel

- Copper

- Brass

- Monel

- Titanium

- Nickel Alloy

Below is a comparison of the performance of rivets made from different materials.

| Rivet Material | Strength | Corrosion Resistance | Weight | Cost | Suitable Applications |

| Aluminum Alloy | Low | High | Light | Low | Aerospace, Automotive |

| Carbon Steel | High | Low (requires anti-corrosion treatment) | Heavy | Low | Machinery, Construction |

| Stainless Steel | Medium-High | High | Heavy | Medium-High | Shipbuilding, Food Industry |

| Copper | Low | High | Heavy | Medium | Electrical, Decorative Applications |

| Brass | Medium | High | Heavy | Medium | Instruments, Furniture |

| Titanium Alloy | High | Very High | Light | High | Aerospace, Medical Equipment |

| Nickel-Based Alloy | Very High | Very High | Heavy | Very High | Chemical, Marine Environments |

Influence of Material on Rivet Performance

The material determines the strength and durability of the rivet.

Influence of material on rivet strength

Rivets made with high-strength materials (e.g. carbon steel, stainless steel, titanium alloys) are stronger. Suitable for high load applications such as bridges, mechanical equipment, aerospace structures.

- Carbon steel rivets (especially medium and high carbon steel) have high tensile strength and are suitable for structures subjected to high stress.

- Titanium alloy rivets are lighter in weight while maintaining high strength, making them suitable for lightweight design needs (e.g., aircraft manufacturing).

Rivets made with medium strength materials (e.g. brass, nickel-based alloys) are of average strength. Suitable for scenarios with medium strength and corrosion resistance requirements, such as chemical equipment and shipbuilding.

Rivets made with low strength materials (e.g. aluminum alloys, copper) have very low strength. They are primarily used in lightweight structures such as aerospace skins and electronic equipment housings. But despite their low strength, aluminum rivets are widely used in the automotive and aerospace industries because of their light weight and corrosion resistance.

Influence of material on rivet durability

The durability of rivets is mainly affected by corrosion resistance, fatigue life, heat resistance and other factors.

corrosion resistance

The durability of rivets of different materials in wet, high salt, acid and alkali environments varies significantly. Stainless steel rivets (such as 304, 316 stainless steel) have good corrosion resistance. Aluminum alloy rivets have good oxidation resistance. Carbon steel rivets are easy to rust, usually need galvanized, nickel-plated and other surface treatment to improve corrosion resistance. Nickel-based alloy rivets (such as monel alloy) in strong acid, alkali, high temperature environment with excellent performance, commonly used in chemical and marine industries.

fatigue life

The durability of rivets under long-term vibration and alternating loads depends on the fatigue properties of the material:

- Titanium alloy rivets: high fatigue strength, suitable for aircraft, high-performance automobiles.

- Stainless steel rivets: better fatigue resistance, suitable for mechanical equipment and construction industry.

- Aluminum rivets: shorter fatigue life, prolonged vibration may lead to cracking, but suitable for light load scenarios.

heat resistance

The stability of rivets in high temperature environments depends on the heat resistance of the material.

- Carbon steel rivets: strength decreases above 400°C.

- Stainless steel rivets (e.g. 316 stainless steel): can withstand temperatures up to 600°C.

- Titanium alloy rivets: retain high strength at 800°C.

- Nickel-based alloy rivets (e.g. Inconel 718): retain strength above 1000°C.

Do You Have Any Questions?

Let Us Solve Your Problem

Differences in the Cost of Rivets Made of Different Metal Materials

The cost of rivets manufactured from different metal materials is mainly influenced by factors such as raw material prices, processing difficulty, durability and market availability. Below is the cost analysis and comparison of various rivet materials.

Key factors affecting the cost of rivets

- Raw material prices: the main cost of rivets from the metal raw materials, different metal prices fluctuate greatly. Such as titanium alloy and nickel-based alloys are far more expensive than aluminum and carbon steel.

- Processing difficulty: some materials (such as stainless steel, titanium alloy) high hardness, processing costs are higher, requiring special tools and technology.

- Durability and service life: high corrosion resistance and high strength rivets have a longer service life, reducing maintenance and replacement costs.

- Market supply: commonly used materials (e.g., carbon steel, aluminum) are in sufficient supply and at lower prices. While the supply of high-end alloy materials is limited and prices are higher.

Comparison of Material Costs for Various Types of Rivets

| Rivet Material | Raw Material Cost | Processing Difficulty | Durability | Overall Cost |

| Aluminum | Low | Low (Easy to process) | Medium (Corrosion-resistant) | Low |

| Carbon Steel | Lowest | Low (Easy to process) | Low (Requires anti-corrosion treatment) | Lowest |

| Stainless Steel | Medium | Medium (High hardness, higher processing cost) | High (Corrosion-resistant) | Medium-High |

| Copper | Medium-High | Low (Easy to process) | High (Corrosion-resistant, Good conductivity) | Medium-High |

| Titanium Alloy | High | High (Difficult to process, requires specialized equipment) | Very High (Lightweight, High Strength, Corrosion-resistant) | High |

| Monel | Highest | Very High (Difficult to process, High-Temperature Resistance) | Very High (Acid & Alkali Resistant, High-Temperature Resistant) | Highest |

Do You Have Any Questions?

Let Us Solve Your Problem

Wholesale Rivets from Rivet Factory

If you are looking for reliable rivet manufacturers, please contact us.Rivmate is a top China rivet factory, which can provide you with rivets made of different materials. Besides that, we can also provide customized riveting solutions for your projects.

Before placing a formal order, please obtain a sample of rivets for testing.