Wholesale Closed End Blind Pop Rivets

Your single source for wholesale closed end blind pop rivets, with factory-direct manufacturing and stable supply.

Closed End Blind Rivets – Sealed Blind Fastening Solutions

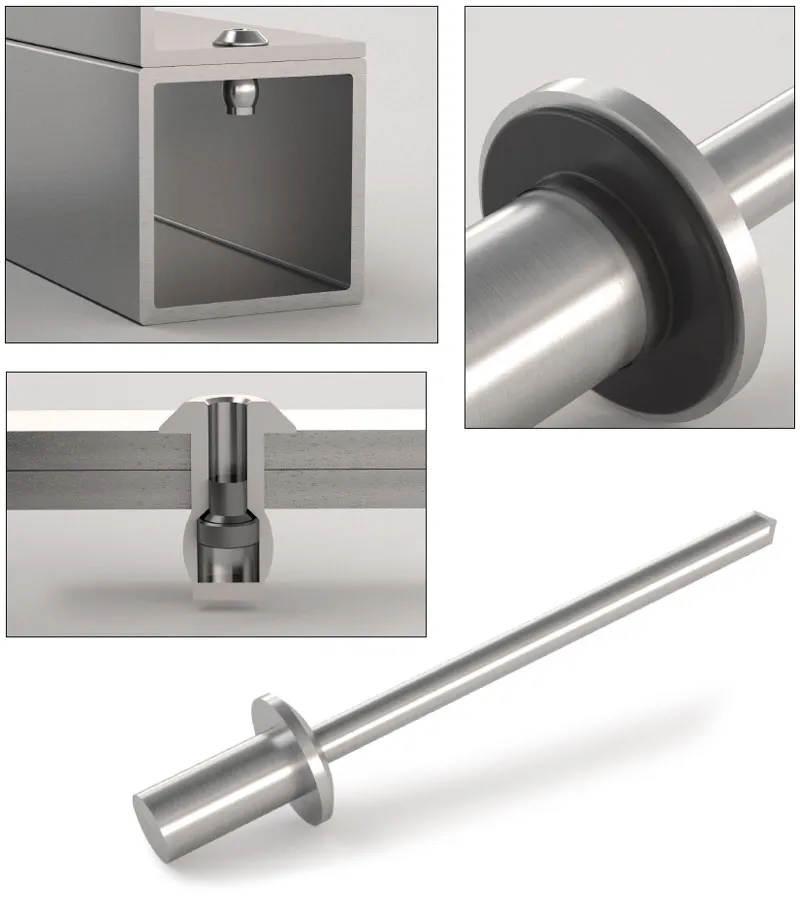

Closed End Blind Rivets are fasteners that support single-side installation (blind installation), featuring a closed-end structure at the tail. Upon riveting completion, the mandrel fractures at the predetermined breaking point and remains sealed within the rivet body. This design structurally reduces the risk of liquids, dust, and mandrel residue entering the joint area.

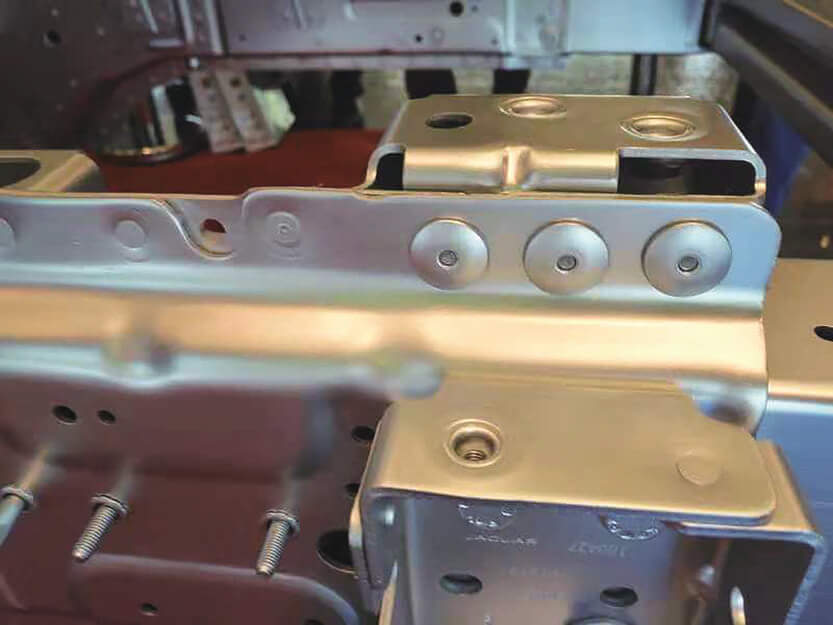

Compared to open end blind rivets, the closed-end design is better suited for applications demanding protection and reliability. It enhances connection security without requiring additional seals and is commonly used in electrical equipment, outdoor structures, and industrial assemblies with low failure tolerance.

Material Options for Closed End Blind Rivets

- Humid / Outdoor Environments → Prioritize Stainless Steel

- Strength Priority, Controlled Environments → Carbon Steel (with Surface Treatment, e.g., Galvanized)

- Lightweight, Indoor Applications → Aluminum

Aluminum:Aluminum closed end blind rivets offer lightweight properties and resistance to general corrosion, making them suitable for indoor equipment, electronic enclosures, and weight-sensitive structural components.

Steel:Carbon steel provides higher mechanical strength, ideal for industrial assemblies prioritizing structural integrity.

Stainless Steel:Stainless steel closed-end blind rivets offer superior corrosion resistance, making them suitable for outdoor equipment, humid environments, and electrical/medical applications.

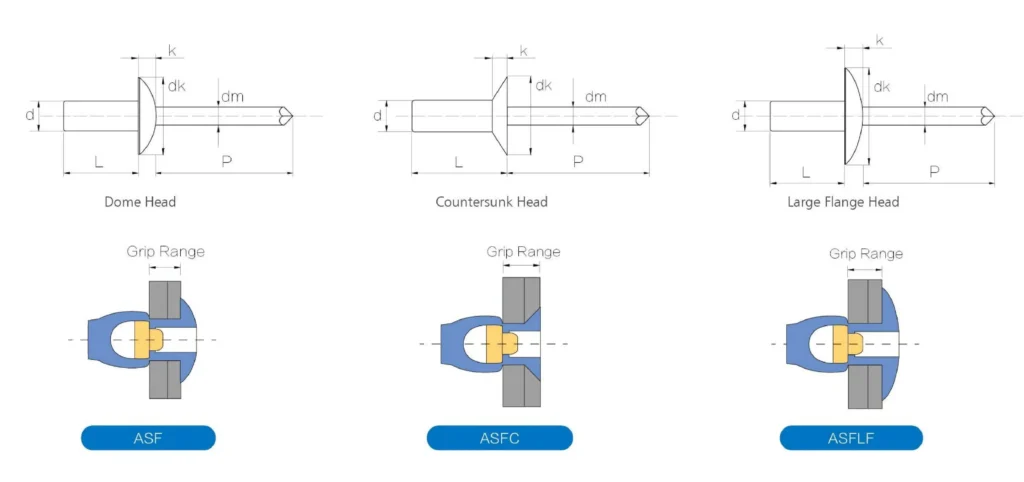

Product Range of Closed End Blind Rivets

Aluminum&Steel Sealed Type Dome Head

Body:Aluminum; Mandrel:Steel

Aluminum&Steel Sealed Type CSK Head

Body:Aluminum; Mandrel:Steel

Aluminum&Steel Sealed Type Large Flange

Body:Aluminum; Mandrel:Steel

Aluminum&Stainless Steel Sealed Type Blind Rivet

Body:Aluminum; Mandrel:Stainless Steel

Full Stainless Steel Sealed Type Blind Rivet

Body:Stainless Steel; Mandrel:Stainless Steel

Customize Closed End Blind Rivets

Customize Closed End Blind Rivets according to your requirements; MOQ: 10,000

The Technical Parameters of Sealed Type Blind Rivet

| Diameter[d] | Size | Body Length[L] | Grip Range | Drill | Tensile | Shear |

| 3.2(1/8") | 3.2×6.5 | 6.3-7.3 | 0.5-2.0 | 3.3-3.4 | 1350N | 1100N |

| 3.2×8.0 | 7.8-8.8 | 2.0-3.5 | ||||

| 3.2×9.5 | 9.3-10.3 | 3.5-5.0 | ||||

| 3.2×11.0 | 10.8-11.8 | 5.0-6.5 | ||||

| 3.2×12.5 | 12.3-13.3 | 6.5-8.0 | ||||

| 4.0(5/32") | 4.0×8.0 | 7.8-8.8 | 1.5-3.5 | 4.1-4.2 | 2200N | 1600N |

| 4.0×9.5 | 9.3-10.3 | 3.5-5.0 | ||||

| 4.0×11.0 | 10.8-11.8 | 5.0-6.5 | ||||

| 4.0×12.5 | 12.3-13.3 | 6.5-8.0 | ||||

| 4.0×15.0 | 14.8-15.8 | 8.0-10.5 | ||||

| 4.8(3/16") | 4.8×8.0 | 7.8-8.8 | 2.0-3.5 | 4.9-5.0 | 3100N | 2200N |

| 4.8×9.5 | 9.3-10.3 | 3.5-5.0 | ||||

| 4.8×11.0 | 10.8-11.8 | 5.0-6.5 | ||||

| 4.8×13.0 | 12.8-13.8 | 6.5-8.0 | ||||

| 4.8×14.5 | 14.3-15.3 | 8.0-9.5 | ||||

| 4.8×16.0 | 15.8-16.8 | 9.5-11.0 | ||||

| 4.8×18.0 | 17.8-18.8 | 11.0-13.0 | ||||

| 4.8×21.0 | 20.8-21.8 | 12.0-16.0 | ||||

| 4.8×25.0 | 24.8-25.8 | 14.0-19.0 | ||||

| 6.4(1/4") | 6.4×12.5 | 12.3-13.3 | 1.5-6.5 | 6.5-6.6 | 4900N | 3600N |

| 6.4×14.0 | 13.8-14.8 | 3.0-8.0 | ||||

| 6.4×16.0 | 15.8-16.8 | 5.0-10.0 | ||||

| 6.4×19.5 | 19.3-20.3 | 8.5-13.5 | ||||

| 6.4×24.0 | 23.8-24.8 | 13.0-17.5 |

DIFFERENCE

Closed End vs Open End Blind Rivets-Sealing, Risk, and Application Boundaries

Fundamental Differences in Sealing Capabilities

Closed-end blind rivets utilize a sealed tail structure to prevent liquids, dust, and mandrel residue from entering the joint area at the riveting point, making them suitable for applications requiring protection. Open-end blind rivets feature an open tail structure and lack waterproof or dustproof capabilities, being applicable only in non-sealed scenarios.

Differing Risk Levels and Failure Consequences

In electronic devices, outdoor structures, or control enclosures, water ingress or foreign object entry through open-end rivets often triggers system-level failures. The closed-end design specifically aims to mitigate such unacceptable failure risks, not merely enhance joint strength.

Application Boundaries and Selection Principles

Open-end blind rivets are unsuitable for environments involving moisture, dust, outdoor exposure, or where rivet shank residue must not enter internal spaces. Closed-end structures should be prioritized in such cases. For indoor, non-sealed assemblies where cost sensitivity is paramount, open-end rivets remain the more cost-effective choice.

Sealing Explanation

How Closed End Blind Rivets Achieve Sealing Performance

Why Closed End Provides Superior Protection

The key to closed end blind rivets lies in their closed-end structure. After riveting, the mandrel breaks at its predetermined fracture point and remains fully enclosed within the rivet body. This structurally blocks any path for liquids, dust, or foreign objects to enter the joint area through the rivet tail.

The protective efficacy of closed-end rivets does not rely on adhesives or additional seals, but stems from the integrally sealed state of the rivet tail after forming. Provided hole diameter matching and grip range selection are correct, the tail will not develop cracks, ensuring consistent protective performance during mass assembly.

Limitations of Sealing Performance

Closed-end blind rivets are not an “absolutely waterproof solution.” When the hole diameter is significantly oversized, the riveting angle is incorrect, or the rivet is used near the grip range limit, micro-cracks may appear in the tail, thereby reducing the protective effect. In scenarios involving long-term water pressure immersion or high protection level requirements (such as IP67 and above), evaluation must still be conducted in conjunction with an overall structural sealing solution.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

HOW TO CHOOSE

Select the Right Closed End Blind Rivet for Sealed Applications

I. Grip Range Selection is Fundamental to Sealing Reliability

Grip range is not merely about “anything that clamps will do.” For closed-end blind rivets, the total thickness of the materials being joined should fall within the middle range of the grip range, not at the upper or lower limits.

For example, with a total plate thickness of 3.8 mm, selecting a rivet with a grip range of 3.0–5.0 mm facilitates better tail formation compared to 3.5–4.0 mm, reducing the impact of tail micro-cracks on sealing performance.

II. Hole Diameter Matching Directly Determines Protection Effectiveness

An oversized hole weakens the sealing effect of closed-end rivets, creating potential leakage paths; an undersized hole may damage the rivet body or compromise installation consistency.

For a Ø4.8 mm rivet, the commonly recommended hole diameter is 4.9–5.0 mm. This ensures smooth insertion while facilitating stable, sealed tail formation after riveting.

III. Material Selection Must Balance Environmental Conditions and Risk Factors

Closed-end applications often involve specific environmental requirements. Material choices should not be driven solely by strength or cost considerations:

- Aluminum body + stainless steel core: Suitable for light-duty structures and humid environments

- All-stainless steel: Ideal for outdoor equipment, electronics, or medical applications

- Carbon steel (requires surface treatment): Strength-focused, but long-term corrosion risk must be evaluated

Unsuitable material combinations may cause galvanic corrosion or abnormal breakage, indirectly compromising seal reliability.

APPLICATIONS

Industries Requiring Sealed Blind Fastening Solutions

Electrical Enclosures

Used for structural connections in electrical cabinets and control panels, reducing the risk of moisture or dust ingress through riveted joints.

Outdoor Equipment

Suitable for assembling outdoor equipment and components, providing more reliable connection protection in exposed environments.

Industrial Assemblies

Used for industrial equipment housings and auxiliary structural components, meeting requirements for connection stability and failure risk control.

Electronic Devices Housing

Suitable for electronic device housing assembly, preventing potential impacts on internal components from mandrel residue or infiltration.

Medical Equipment Components

Applied to structural connections in medical devices demanding high cleanliness and reliability.

Control Cabinets and Panels

Commonly used in industrial control cabinet and panel assemblies, enhancing overall protection without requiring additional seals.

FAQs

Q1: Are closed end blind rivets fully waterproof?

A: Closed end blind rivets significantly reduce the risk of water and dust ingress at the riveted joint, but they are not an absolute waterproof solution. Their protective effectiveness depends on hole diameter matching, grip range selection, and installation quality. For high protection ratings or prolonged exposure to water pressure, they must be used in conjunction with an overall sealing design.

Q2: When should closed end blind rivets be used instead of open end rivets?

A: Closed end blind rivets should be prioritized for applications involving moisture, dust, outdoor exposure, or situations where mandrel residue must not enter equipment interiors. Open end rivets are typically sufficient for indoor, non-sealed, and cost-sensitive scenarios.

Q3: Does installation affect the sealing performance of closed end blind rivets?

A: Yes. Oversized holes, non-vertical riveting, or mismatched pulling force can cause incomplete tail formation or micro-cracks, compromising the seal. Consistent installation conditions are critical for maintaining sealing integrity.

Q4: What material should be selected for outdoor or humid environments?

A: For outdoor or humid environments, closed end blind rivets with stainless steel bodies and stainless steel mandrels are generally recommended to reduce corrosion risks and ensure long-term reliability.

Q5: Do you support bulk supply and OEM customization for closed end blind rivets?

A: We support bulk supply and OEM customization, including specifications, material combinations, and packaging solutions, suitable for long-term project procurement and industrial-grade stable supply needs.