Table of Contents

In general, alloy 2117 rivets do not require heat treatment. So why are we discussing this topic? Because in order to speed up the delivery, some customers will require heat treatment. Next, let’s explore the reasons of alloy 2117 rivets are heat treated.

Table of Contents

Alloy 2117 Rivets - Brief Introduction

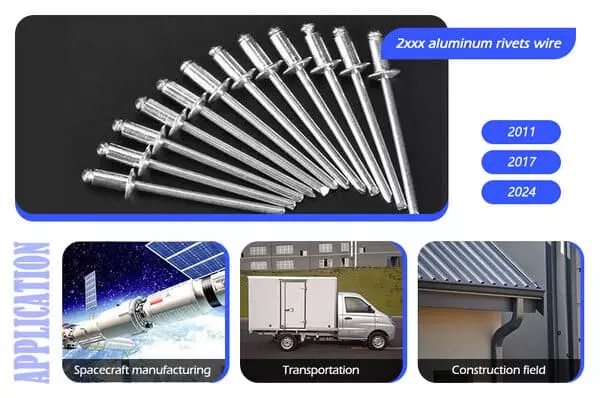

Alloy 2117 rivets use aluminum alloy 2117 as the raw material. Rivets made from this raw material have excellent strength, corrosion resistance, and machinability.Alloy 2117 is made from aluminum, copper, iron, manganese, and other elements, and is one of the more commonly used 2000 series aluminum alloys. Alloy 2117 rivets are used in a wide range of applications in aerospace, automotive, and other industries where high strength and durability are required.

Alloy 2117 is an age-hardening aluminum alloy that generally requires no heat treatment for use. It is stronger and more corrosion resistant than pure aluminum rivets, but slightly less so than some high-strength aluminum alloys that require heat treatment (such as 2024 alloy ). These rivets are self age-hardening at room temperature.

What is Heat Treatment?

Heat treatment is a process of changing the physical and mechanical properties of a metallic material by heating, holding and cooling it. Heat treatment processes are frequently used in the metal fabrication and processing industries. This type of treatment optimizes the properties of metallic materials such as hardness, strength, toughness and wear resistance. Heat treatment can be used for a wide range of metals and alloys, including steel, aluminum, copper and other metals.

The Main Purpose of Heat Treatment:

- Increase hardness and strength: through heat treatment, the internal structure of a material is changed, making it harder and more resistant to stretching.

- Increase toughness: Heat treatment increases the toughness of a material so that it is less likely to break under high stress.

- Improve machinability: Certain heat treatment processes can make a material softer or easier to machine.

- Remove internal stresses: During the manufacturing process, metal materials may accumulate internal stresses, and heat treatment can help release these stresses to minimize deformation and cracking of the material in subsequent use.

Common Heat Treatment Processes

There are four common steps in the process of heat treating metal rivets. They are annealing, quenching, tempering, normalizing.

The process of annealing involves heating the metal to a certain temperature and then cooling it slowly. The purpose of this step is to soften the metal material and make it easier to work with. And it reduces the hardness and internal stresses of the metal. This is one of the common steps used in the process of manufacturing and machining metals.

There are four general types of annealing:

- Complete annealing

- Stress relief annealing

- Spheroidizing annealing

- Recrystallization annealing

Quenching, a heat treatment process, is needed when you want to add hardness and strength to your metal products. The process of quenching involves heating the metal to a high temperature and then cooling it quickly to the point of hardening. Quenching usually requires the help of water, oil, air or other mediums to quickly lower the temperature of the metal.

The role of quenching:

- Increase the hardness and strength of the metal

- Increase wear resistance

- Less plasticity and ductility

Tempering is a step after hardening. When a metal material is quenched, the hardness of the metal increases but it becomes very brittle. This causes the metal to fracture on impact, so the purpose of tempering is to regulate the balance between hardness and toughness.

Temperature classification of tempering:

- Low temperature tempering (150°C-250°C):

- Uses: For workpieces requiring high hardness and wear resistance, such as cutting tools and molds.

- Characteristics: Hardness is slightly reduced, brittleness is reduced, but toughness is not significantly increased.

- Medium Temperature Tempering (250°C-500°C):

- Uses: Used for parts requiring higher strength and toughness, such as springs and automobile parts.

- Characteristics: A good balance of hardness and toughness is achieved.

- High temperature tempering (500°C-650°C):

- Uses: Used in the manufacture of structural parts requiring high toughness and good plasticity, such as shafts and connecting rods.

- Characteristics: lower hardness, but the toughness and ductility significantly improved.

4. Normalizing

Normalizing is the cooling of a metallic material in air after it has been heated above the austenitizing temperature and held there for a period of time. The purpose of normalizing is to refine the grain structure and equalize the hardness, strength and toughness of the material, as well as to eliminate internal stresses during processing.

Normalizing involves heating the metal to a very high temperature, usually between 850°C and 950°C.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Why Alloy 2117 Rivets Are Heat Treated?

In practice, Alloy 2117 rivets generallydo not require additional heat treatment; Alloy 2117 rivets are solution-treated and naturally aged during the manufacturing process, and are referred to as “self-curing” rivets. However, in practice, some customers have specific requirements for heat treatment prior to use or during assembly to improve mechanical properties or to suit specific applications.

Reasons of Alloy 2117 Rivets are Heat Treated

- Improved performance: In some applications, the strength of rivets is required. It is often necessary for rivets to achieve higher strength immediately after installation rather than waiting for the natural aging process. This requires heat treatment of alloy 2117 rivets.

- Reduced assembly time: If a customer needs to speed up the production process, heat treating rivets to achieve the desired strength in a shorter period of time can reduce the time spent waiting for natural aging.

- Application specificity: Certain aerospace, military or heavy industrial applications require higher levels of strength and toughness, and pre-treatment ensures that rivets will perform consistently in these environments.

There are a number of heat treatment steps, but artificial aging is the type of heat treatment most likely to be applied to alloy 2117 rivets.

In this process, the rivets need to be heated to an appropriate temperature (e.g. 150°C-200°C) and held for a period of time as a way to accelerate the hardening process of the material. This will increase the strength and hardness of the rivet in a shorter period of time and does not need to be accomplished by natural aging at room temperature.

It is important to note that temperature and time control are critical in the process of heat treating alloy 2117 rivets. Excessive aging may result in rivets that are very brittle and easily broken. Of course, when heat treating, you need to make sure that all rivets are heat treated consistently to ensure that the performance of the entire rivet batch is consistent.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Conclusion

After reading this blog, we know that alloy 2117 rivets usually do not require additional heat treatment. This is because a material like alloy 2117 is solution treated and artificially aged (T4 or T6 condition) before shipping. These measures have already provided alloy 2117 rivets with sufficient strength and hardness. However, in order to shorten the time it takes for customers to receive their rivet shipments, they may require additional heat treatment of the alloy 2117 rivets to speed up production.

Wholesale High Quality Alloy 2117 Rivets from Rivmate

In order to get high quality alloy 2117 rivets, you need to find a reliable rivets manufacturer.Rivmate is one of the top 3 rivets manufacturers and suppliers in China, which can provide you with professional rivets solutions.

You can get rivet samples for testing before formal order. Contact us now!