Table of Contents

Get an in-depth look at what to look for when riveting stainless steel materials and explore the techniques, benefits and tips for quality connections.

Table of Contents

Riveting technology utilizes the deformation of the rivet and the unique internal locking involved to achieve a stable connection, revolutionizing the traditional method of joining stainless steel components.

Because rivets are quick to install, they provide a stable connection without damaging the surface structure of the material, ensuring that the stainless steel material is firmly bonded. Take an in-depth look at this effective method and explore its endless possibilities for joining stainless steel materials.

The Knowledge Behind Riveting Stainless Steel

Riveting is an efficient and accurate method for joining components made of stainless steel together. By using rivet tools, this riveting process offers many advantages over traditional sheet joining methods. You can see the difference between riveting and other joining methods such as welding in our blog. Let’s delve into the knowledge contained behind riveting stainless steel.

Ⅰ.Material Compatibility

One of the key factors affecting the effectiveness of riveted joints is the combination between different materials. The contact of different materials with each other may or may not lead to many different results. Examples include galvanic corrosion, differences in thermal expansion, electromagnetic interference, wear or mechanical friction, mismatch of mechanical properties, insulation failure and electrochemical reactions.

Unlike traditional methods such as welding, riveting requires a clear consideration of compatibility between materials due to the need to use metal rivets to join materials.

Ⅱ.Minimising Rivet Failure through Correct Riveting

The use of rivets as riveting fasteners in the riveting of stainless steel materials offers significant advantages. This minimises engineers’ working time due to the rivets’ advantage of quick installation.

However, the rivets need to be correctly aligned and positioned. Ensure that the rivet and the material to be joined are accurately aligned to prevent deflection during the riveting process. This minimises the possibility of rivet failure and therefore improves the quality of the joint.

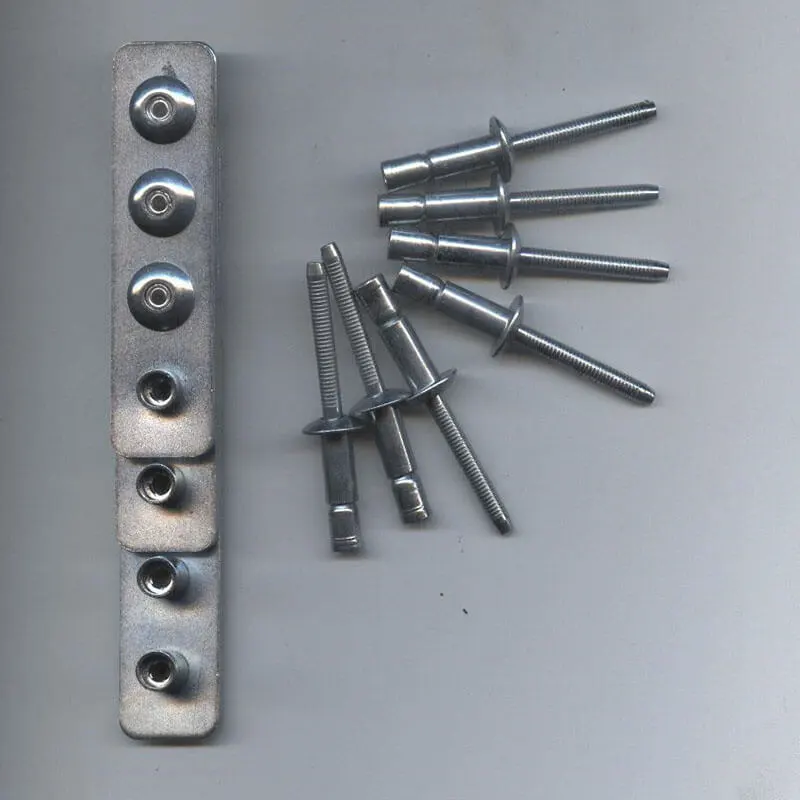

Ⅲ.Optimising Rivet Quality Through Correct Selection of Rivet Size

Understanding the rivet specification aspects associated with riveting is critical to optimising the quality and performance of the riveted joint. The proper rivet diameter and length may have a direct impact on the final outcome of the riveted joint.

For example, when riveting stainless steel, the rivet diameter needs to be selected to match the hole diameter, and the length should be sufficient to create a solid lock after riveting. This will ensure the best riveting results.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Advantages of Riveting Stainless Steel

Riveted stainless steel offers several significant advantages. For example, high strength connections, ease of installation and efficiency make it the preferred choice for a variety of applications. Let’s explore these advantages in more detail below.

1.High Strength and Durability of Riveting

One of the main advantages of riveting is its ability to provide excellent strength and durability. It maximises the life of the structure. This is mainly due to the fact that the rivets’ reliable mechanical connection can withstand high stresses and loads.

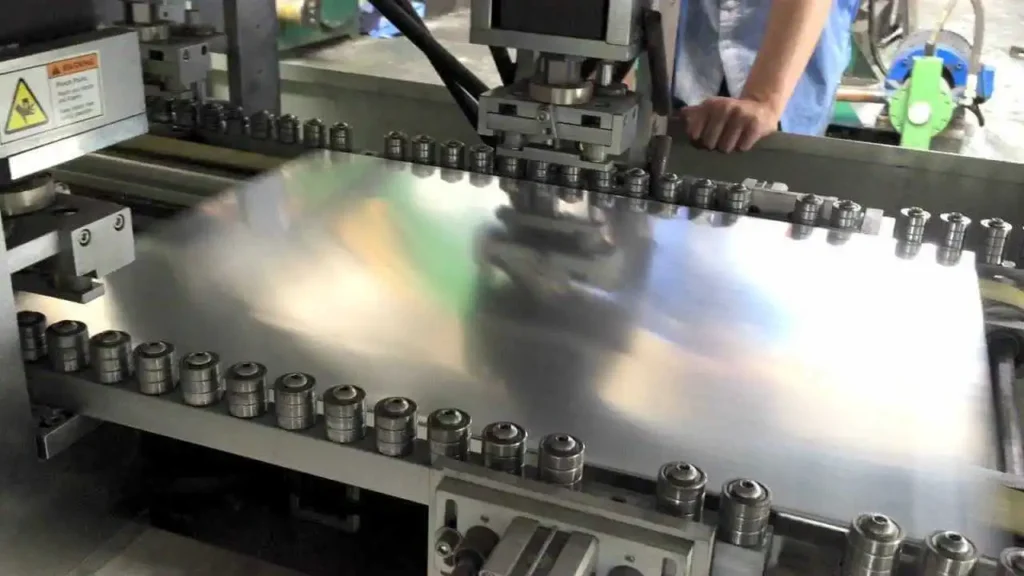

2.High Productivity and Fast Installation

Compared to welding or bolting, riveting can increase the speed of installation and therefore productivity. Prior to assembly line installation, all that is required is to punch fixed holes in the material to be joined and the process can be completed quickly with the use of blind rivets. Increased speed means reduced production time and increased efficiency.

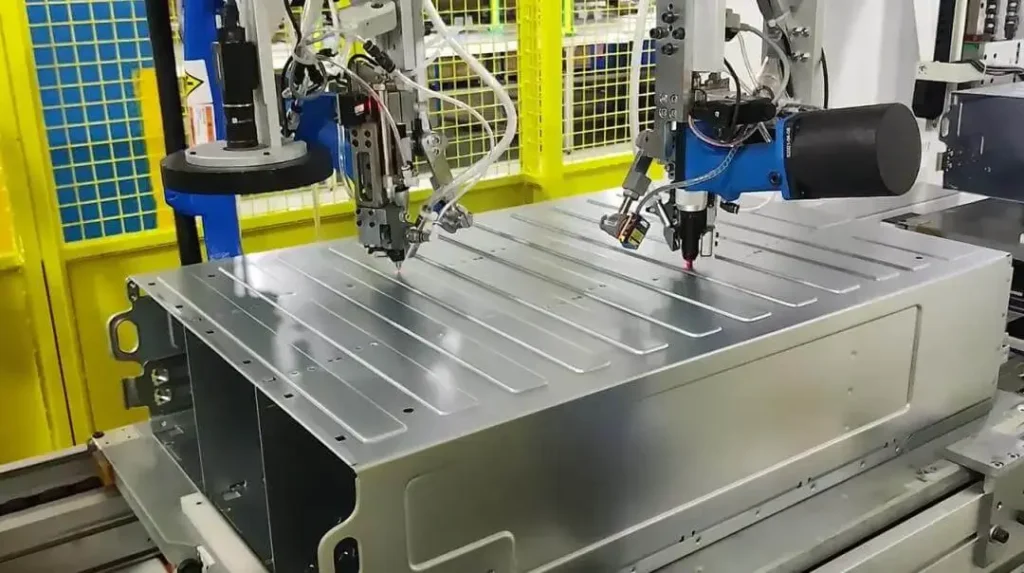

In contrast to other thin sheet joining methods, riveting allows for unilateral installation. It is particularly suitable for applications where access from both sides is difficult and simplifies the assembly process. And the use of pneumatic riveting tools can complete the riveting process faster, can significantly improve production efficiency, very suitable for mass production of new.

3.No Need for High Temperature Operation

The riveting process is a cold process and does not involve high temperature operations. It can effectively avoid the problem of heat-affected zone during welding, and will not deform or degrade the material due to thermal stress.

Can always maintain the original mechanical properties of stainless steel material good corrosion resistance. Especially in high-strength and high-precision applications, the use of riveting is far greater than welding.

4.Keep Nice and Tidy

Another advantage of riveting is that it keeps the surface of the stainless steel material flat and smooth. No secondary surface preparation is required.

Like the welding process deforms the surface of the material through thermal stress and loses its original colour. This problem needs to be solved by secondary surface treatment. The use of riveting to connect stainless steel materials is very good to avoid this problem. After riveting, the stainless steel surface is flat and smooth, with good aesthetic effect. Ideal for applications requiring high decorative and aesthetic qualities. And riveted stainless steel does not require additional coatings or plating, saving handling costs and time, while providing natural protection against corrosion.

Factors to Consider when Selecting Blind Rivets for Riveting Stainless Steel

There are several factors to consider when choosing a blind rivet. The right choice can significantly affect the quality of the riveted joint. Let’s explore some of the key factors that should be considered.

1. Material Compatibility

When selecting blind rivets for stainless steel materials, the first consideration is to ensure that the rivet material is electrochemically compatible with the stainless steel material. In order to avoid galvanic corrosion, stainless steel rivets are preferred, or highly corrosive materials such as nickel-based alloys and titanium.

In addition to electrochemistry, the coefficient of thermal expansion must also be considered. When riveting stainless steel materials, you should choose materials with a coefficient of thermal expansion similar to that of stainless steel. Prevent the occurrence of stress and deformation caused by temperature changes.

2. Matching of Apertures and Diameters

Matching rivet diameter to hole diameter is another important consideration when selecting a riveting system. Matching the hole diameter to the rivet diameter improves the quality of the riveted joint and the strength of the connection. It reduces the likelihood of rivet failure. Therefore, it is critical to select a rivet diameter that matches the hole diameter.

3. Cost Effectiveness

Of course, the last thing you should ignore when choosing the right blind rivets is the cost. As a qualified business owner, you need to choose the right metal rivets for the budget area of your project. Balancing cost and performance. While the best option for riveting stainless steel materials is to use stainless steel rivets, it can be more expensive. If you are not on a budget and the application scenario is not very demanding, you can also go for cheaper steel rivets.

Of course, consider the long-term benefits of riveting, including reduced maintenance, increased durability and longer service life. Still using stainless steel blind rivets will reduce the overall cost.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Frequently Asked Questions

1.Can I Use Any Type of Stainless Steel for Riveting?

There are many types of stainless steel and rivets basically work well to rivet them. Whether it is lower toughness of 430 stainless steel, or high strength requirements of 410, 420 stainless steel, there are corresponding rivets can be well connected to them.

2.How Does Riveting Compare to Welding?

Compared with traditional welding methods, riveting has the advantages of speed and accuracy of installation, no heat generation and accelerated production efficiency. If you’d like to learn more about riveting vs welding, keep reading.

3.What are the Common Disadvantages of Riveting Stainless Steel?

Common defects include excessive deformation, material cracking, residual stress and fatigue failure. These defects can be minimized by adjusting the riveting pressure and optimizing the riveting process. This includes factors such as reducing stress concentrations and reducing tool travel.

4.Can I Use Riveting to Join Dissimilar Metals?

Yes, rivets can be used to join dissimilar metals (including stainless steel) to other materials such as aluminum, copper or titanium alloys. However, when doing so, material compatibility must be considered.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Conclusion

In conclusion, riveted stainless steel has numerous advantages, but also has a number of shortcomings. By understanding the knowledge behind riveting stainless steel, you can improve your riveting stainless steel considerations and achieve satisfactory results in your projects.

Rivmate - Best Blind Rivet Manufacturer and Supplier

If you need to rivet a variety of metals, including stainless steel, Rivmate can provide you with matching high quality blind rivets. Our blind rivets provide better joint quality and stability for riveted joints. With Rivmate rivets, engineers can maintain consistent rivet quality.

We also offer tools such as high strength structural rivets and pneumatic rivet guns. We have experts in rivet customization, rivet manufacturing, rivet nut manufacturing and riveting tools. Now you can contact us for details and get the corresponding samples.