Table of Contents

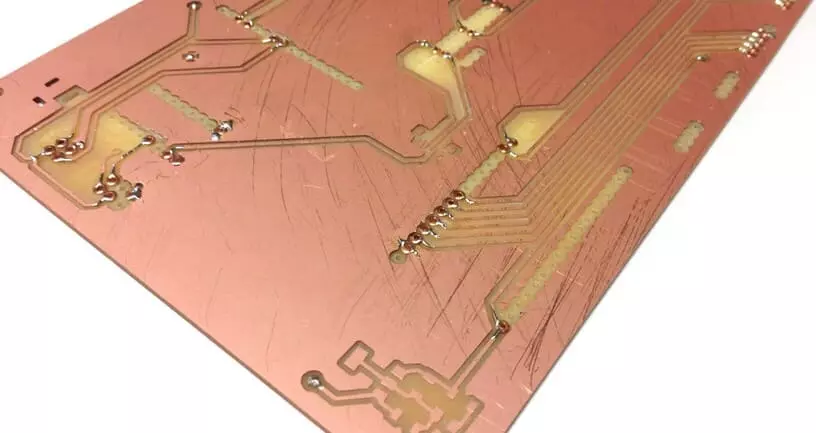

PCB is an important part of carrying electronic components and occupies an important position in various electronic devices. And PCB Rivet can provide more possibilities for pcb.

This blog introduces you to pcb rivet applications, advantages and how to choose the right pcb rivet. let’s learn more about it!

Table of Contents

What are PCBs?

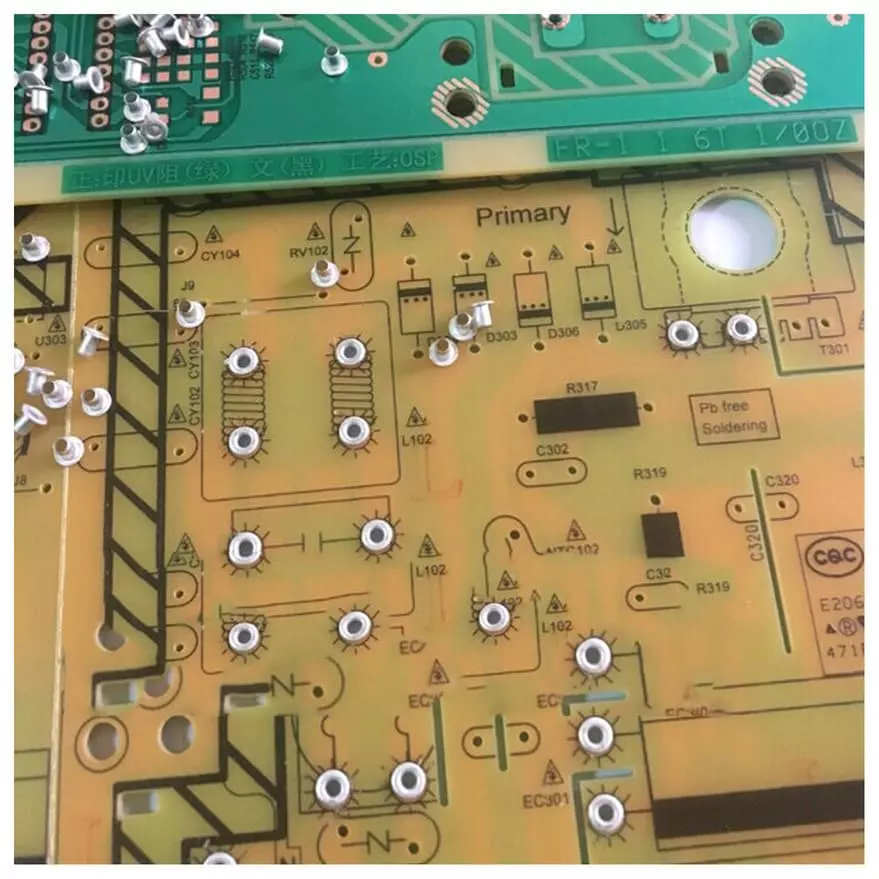

PCB’s full name is Printed Circuit Board. it is a kind of electronic components to provide mechanical support and realize the electrical connection of the basic components, is one of the core components of modern electronic equipment. what is the working principle of PCB? It can be laid on an insulated substrate by laying a conductive path (usually copper foil) to realize the transmission of electrical signals between electronic components. Because of its stable structure, low manufacturing cost and easy mass production, PCB is widely used in consumer electronics, industrial equipment, communication equipment, medical equipment, aerospace and other fields.

PCB is a type of electronic component. It can well support miniaturized and high-density electronic products.As an indispensable core component of modern electronic devices, the quality of PCB is very important for users.

If you want to buy stable quality PCB, you can contact Top Quality Electronic Components Distributor – SZComponents.

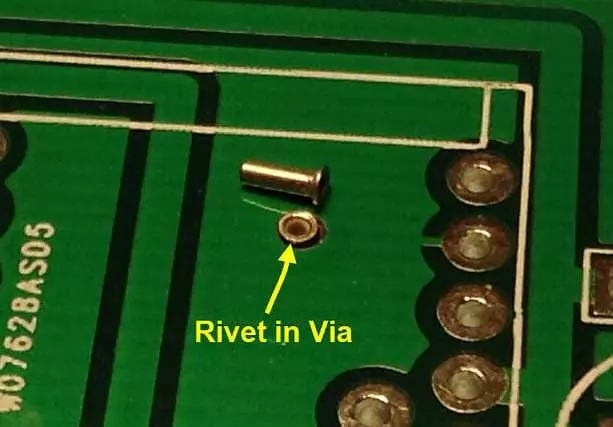

What are PCB Rivets?

PCB Rivets are types of rivets that are specifically designed to secure and support PCBs (Printed Circuit Boards). pcb rivets are usually made of lightweight materials such as plastic, aluminum or copper. pcb rivets are primarily used to provide mechanical support, electrical connections or space spacing for pcb boards without compromising the integrity of the pcb board.

PCB rivets are used a lot in the manufacturing of electronic devices. Examples include securing PCBs to enclosures, supporting multilayer circuit boards, connecting heat sinks or providing electrical shielding.

Why Use Rivets on Pcb?

In mechanical equipment, PCBs fulfill the needs of electrical connections, structural fabrication and heat dissipation. And pcb rivets provide a stable, reliable and efficient solution for this purpose.

1. Mechanical Fixing

Blind Rivets secure PCB boards to housings, frames, brackets or other components to ensure overall structural stability.

The advantages of using Blind Rivets to secure PCBs are listed below:

- Permanent connection: The connection provided by a blind rivet is a permanent one. There is no way to dismantle it without destroying it. Therefore, blind rivets will not loosen due to vibration or shock.

- Single Side Installation: Blind Rivets are very simple to install, requiring only one side of the sheet to be manipulated. This is particularly suitable for connections between PCB boards and chassis.

- Lightweight: Plastic or aluminum rivets are lightweight and suitable for electronic devices that require light weight.

2. Electrical Connections

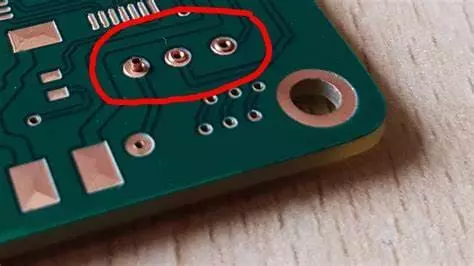

Copper rivets create reliable electrical connections inside the PCB or between the PCB and the outside.

- Low impedance conductive path: Rivets act as conductors to realize low impedance electrical connections between conductive layers of the PCB.

- Anti-interference performance: When the shield is installed, rivets can connect the shield with the grounding layer, providing good electromagnetic shielding effect and reducing electromagnetic interference (EMI).

- Durability: Rivets can withstand the effects of long-term vibration and thermal cycling better than welding, avoiding joint failure.

3. Vibration and Shock Resistant

Blind Rivets provide a stable connection for PCBs that are subjected to high vibration or shock environments for extended periods of time.

- Excellent fatigue resistance: Rivet connections can effectively absorb vibration and shock energy, preventing the loosening of electronic components and PCB boards.

- High reliability: Compared to screws, rivets are less likely to loosen in long-term use, making them particularly suitable for automotive electronics and aerospace applications.

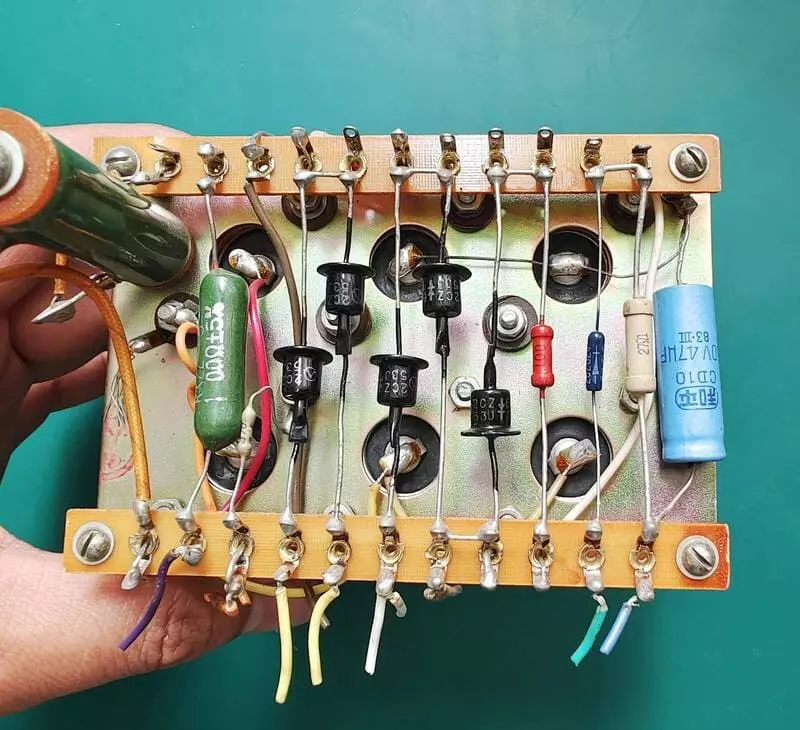

4. Alternative Welding Process

Many of the electronic components on a PCB are connected using soldering. But soldering may damage the materials and surfaces on the pcb. In some scenarios, rivets can replace the traditional soldering method and avoid the defects that soldering may bring.

- No heat damage: Soldering can cause warping of PCBs or material degradation due to high temperatures, whereas rivets do not require heat treatment.

- Efficient Installation: Rivets are easy and fast to install and are suitable for automated assembly, increasing productivity.

- Environmentally friendly requirements: Part of the design avoids the use of hazardous substances (such as lead) in the solder, rivets become an environmentally friendly fastening solution.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

What Type of Rivets Would be Used on Pcbs?

The main function of PCB rivets is to secure pcb boards or related components (such as heat sinks, brackets, shields, etc.). And pcb rivets provide mechanical support, structural stability and electrical connections for these components or products.

Compared with traditional screws and welding methods, pcb rivets have more obvious characteristics. The types of rivets used to connect pcb are as follows:

- Plastic rivets (nylon rivet, polycarbonate rivet)

- Metal rivets (aluminum rivet, stainless steel rivets, copper rivet)

Plastic rivets are very lightweight and have excellent insulating properties, making them ideal for low load applications or scenarios where electrical isolation is required.

Metal rivets are available in a variety of materials, but they have similar characteristics. For example, they provide high strength and reliable electrical conductivity, making them ideal for electrical grounding, high load or heat dissipation applications.

Applications of PCB Rivets

- Consumer Electronics: Fixed PCB boards and shields in smartphones, laptops, tablets.

- Industrial Controls: PLC controllers and multi-layer PCB supports.

- Automotive electronics: fixing and thermal management of on-board control modules.

- Communication equipment: High-density PCB fixing in base stations and routers.

- Medical devices: isolation and fixation in precision electronic devices.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How to Choose Rivets for PCB?

Selecting the right Blind Rivets for PCBs (Printed Circuit Boards) is critical to ensure fixing reliability, heat dissipation and overall stability. Selecting the right rivets requires comprehensive consideration of material, electrical properties, size, environment and other factors.

1. Determine the Use of Rivets

First of all you need to know clearly the main purpose of the Blind Rivet in PCB:

- Mechanical fixing: fixing PCB boards to housings, brackets or other structural components.

- Electrical Connections: Connecting multiple PCB conductive layers to provide electrical ground or low impedance pathways.

- Thermal Management: Transferring heat from the PCB board to a heat sink or enclosure.

- Electrical Isolation: Isolates the metal enclosure from the PCB via plastic rivets to prevent short circuits.

- Multi-Layer Support: Stacks multiple layers of PCB boards and provides precise spacing.

According to the specific application environment and functional requirements to choose the rivet material:

Plastic rivets:

- Features: lightweight, good insulation, anti-corrosion.

- Applicable scenes:

Occasions requiring electrical isolation between PCB and metal enclosure.

The application of tensile and shear strength requirements are not high.

Humid environment to avoid corrosion of metal rivets. - Commonly used materials: nylon, polycarbonate and so on.

Metal rivets:

- Features: high strength, good electrical conductivity, excellent heat dissipation performance.

- Applicable scenes:

Need electrical conduction or grounding occasions.

High load or high vibration occasions.

Equipment with high heat dissipation requirements. - Material Selection:

Aluminun: light weight and corrosion resistant, suitable for lightweight applications.

Stainless steel: corrosion resistance and high strength, suitable for wet or high-strength environments.

Copper: Excellent electrical and thermal conductivity, suitable for grounding and heat dissipation applications.

3. Select Rivet Size According to PCB Thickness

- Rivet Diameter: Choose a rivet that is slightly larger than the diameter of the PCB hole to ensure a tight fit. Common PCB hole diameters are 2.5mm, 3mm, corresponding rivet diameters are 2.8mm, 3.2mm.

- Rivet length: Ensure that the rivet length can cover the total thickness of the PCB and the structure to be connected, and at the same time have enough margin for riveting molding. Calculation formula: rivet length ≥ total material thickness + rivet margin (generally 1.5 times the rivet diameter).

4. Consider the Environment and Conditions of Use

Select the rivet type according to the environment in which the equipment will be used:

- High vibration environment: choose metal rivets with good fatigue resistance (e.g. stainless steel). Give preference to structural rivets that provide higher vibration resistance.

- Humid or corrosive environments: Use corrosion-resistant materials (e.g., stainless steel, aluminum alloy or galvanized rivets).

- High temperature environments: Use rivet materials with good thermal stability (e.g. stainless steel or aluminum alloys). Avoid deformation of plastic rivets due to high temperature.

- Electrical Shielding Requirements: Select rivets with good electrical conductivity (e.g. copper rivets) and ensure good grounding of the shield and PCB.

5. Consider Rivet Head Type

- Countersunk head blind rivets: the surface is flat after riveting, suitable for occasions where a smooth appearance is required. Suitable for electronic devices that need to save space or prevent surface bulging.

- Dome Head Blind Rivet : riveted to provide higher tensile and shear resistance. Suitable for structures requiring high strength fixing.

- Large flange head rivets: larger head area to disperse pressure, to avoid PCB boards due to local stress damage. Suitable for fixing thin boards or brittle materials (such as plastic shells).

Conclusion

PCB Rivets provide lightweight and efficient fixing and connection solutions for PCB projects and electronic component projects. They are indispensable fasteners in the manufacture of modern electronic equipment due to their simple installation, lightweight design and versatility.

Through this guide, I believe you have a clear idea about the introduction, advantages and application scenarios of pcb rivets. If your project requires the use of pcb rivets on pcb projects, please understand to contact our engineers.

Custom High Quality PCB Rivets for Electronic Components

Are you looking for a reliable riveting solution for your pcb project or electronic component detailing? Don’t worry, Rivmate can provide professional riveting solutions for you.

If you need samples of pcb rivets, please contact us now!