Table of Contents

“Multi grip blind rivets vs rivets” is something that confuses a lot of people when it comes to choosing the right rivets. This guide gives you a detailed overview of the definition and pros and cons of multi grip blind rivets and open rivets, as well as the differences between them. Let’s have a detailed look at the differences between multi grip blind rivets vs rivets!

Table of Contents

Multi Grip Blind Rivets vs Rivets

Multi grip blind rivets and open type blind rivets are the most commonly used types of blind rivets. It is believed that many business owners consider whether to use multi grip blind rivets or open type blind rivets when choosing the right blind rivets for their projects.

So when should you choose multi grip blind rivets over open type blind rivets? The main differences between them are adaptability and range of applications. multi grip blind rivets have a wide riveting range and can be used with a wide range of material thicknesses. This feature allows business owners to reduce the stress and cost of managing rivet inventory. In addition to this, multi grip blind rivets can rivet many different material combinations, providing consistent clamping force.

In contrast, open type blind rivets have a fixed riveting range. It is better suited to less demanding, simple and uniform static joining environments.

Of course some of the main features of rivets these two rivets have. Some of the main advantages of rivets include:

- Blind side mounting

- Quick and easy installation process

- Permanent connection

What are Multi Grip Blind Rivets?

Multi grip blind rivets can replace a wide range of other general purpose rivets. As we know from its name, multi grip blind rivets are flexible enough to rivet different material thicknesses. This feature makes it very popular in practical use.

From a practical standpoint, multi grip blind rivets reduce the need for large inventories of rivets and the hassle of changing rivet sizes. In other words, your project can be just one type of rivet with multi grip blind rivets.

The Main Advantages of Multi Grip Blind Rivets

Multi grip blind rivets have many other advantages, including:

- Better Hole Filling: Even irregular, oversized and misaligned holes fill well.

- Increased Weather Resistance: Due to good hole fill, moisture is less likely to penetrate the environment.

- Better inventory management: multi grip blind rivets with one rivet range can replace multiple rivets with different rivet ranges.

- Excellent vibration resistance

1. Better Inventory Management

One size of multi grip blind rivets can be riveted to multiple material thicknesses (e.g. 3-6mm or 6-9mm). This simplifies inventory and reduces management and purchasing complexity.

2. Excellent Hole Filling Properties

Multi grip blind rivets work on the principle of radial expansion of the rivet tail. It provides good fill even when holes are irregular, oversized and misaligned. But operators can’t let this reduce the accuracy required for the hole.

3. Reduced Installation Errors

It is well known that multi grip blind rivets can rivet many different thicknesses of material in one size. Therefore, there is no need to change rivet sizes frequently during use. This, to some extent, reduces the possibility of selection errors, improves construction efficiency and reduces rework costs.

4. Weather and Vibration Resistance

Due to the high hole filling capacity of multi grip blind rivets, it is very difficult for moisture and dust to penetrate the environment. They are also resistant to vibration compared to open end rivets.

What are Rivets?

The most common type of rivet used is the open end rivet. Open end rivets are the first type of rivet that most people will think of. Open end rivets are ideal for any thin, lightweight application that requires riveting. Its biggest advantage is that it is cheaper than multi grip blind rivets.

However, any application that exceeds the riveting range will cause the riveted joint to fail. Open end rivets must be selected accurately to provide excellent riveting results.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Pros and Cons of Rivets

Pros

- Open end rivets, as the most commonly used blind rivets, have many advantages that other fasteners do not.

- Low cost: The cost of open end rivets is the lowest. Because of its simple structure, it is suitable for high-volume use.

- Moderate strength: the deformation of the end of the open end rivet will provide a moderate clamping force, which can meet the regular strength requirements.

- Complete specifications: as the most commonly used rivets, it is the most complete specifications, can be adapted to different thicknesses and hole diameters.

Cons

Of course, the fact that there are MULTI GRIP BLIND RIVETS out there means that there are drawbacks to open end rivets. Here are the common disadvantages:

- Fixed grip range: only for materials of a specific thickness.

- High requirements for hole accuracy: hole diameter and rivet OD must match.

- Limited dynamic load capacity: limited clamping force, vibration resistance and resistance to dynamic loads.

Differences Between Multi Grip Blind Rivets and Rivets

| Feature | Multi-Grip Blind Rivets | Open Type Blind Rivets |

| Grip Range | Wide grip range, suitable for varying material thicknesses. | Fixed grip range, designed for specific thicknesses. |

| Versatility | Highly versatile; can adapt to multi-layer or mixed material combinations (e.g., metal + plastic). | Less versatile; primarily used for uniform materials and thickness. |

| Inventory Requirements | Reduces the need for multiple rivet sizes, simplifying inventory management. | Requires different sizes for different thicknesses, increasing inventory complexity. |

| Installation Flexibility | Accommodates material thickness variations, reducing installation errors. | Requires precise thickness matching to avoid improper installation. |

| Clamping Force | Consistent clamping force across variable thicknesses. | Provides reliable clamping only within the specified thickness range. |

| Material Protection | Distributes pressure evenly, reducing the risk of damage to soft or thin materials. | Can cause pull-through or deformation in soft or thin materials due to smaller contact area. |

| Cost | Higher unit cost due to advanced design and functionality. | Lower unit cost, suitable for budget-conscious applications. |

| Dynamic Load Resistance | Performs well under vibration and dynamic loads. | Limited resistance to dynamic loads; may loosen under vibration. |

Conclusion:

- Multi-Grip Blind Rivets excel in adaptability, reducing inventory, and accommodating material thickness variations, making them ideal for complex or high-performance applications.

- Open Type Blind Rivets are simpler and cost-effective, better suited for straightforward, static connections with consistent material thickness.

How Do You Tell Multi Grip Blind Rivets Apart?

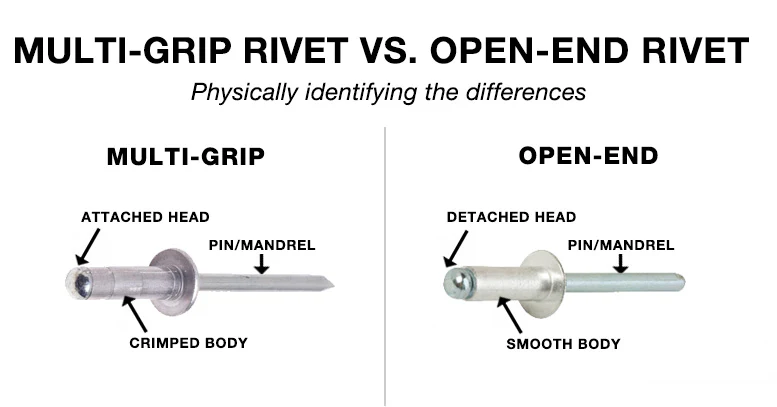

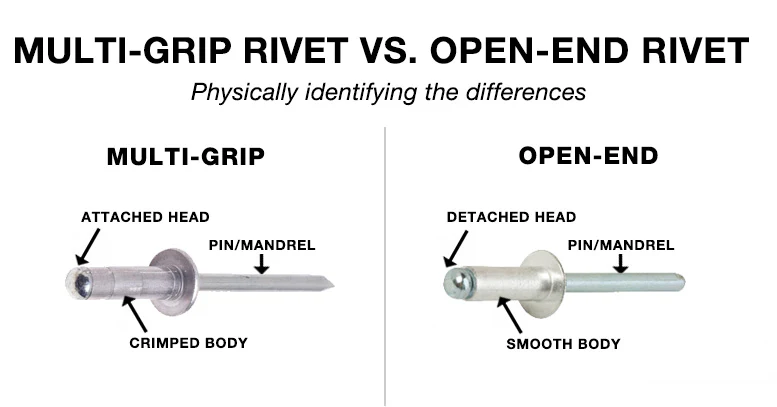

The most direct way to differentiate between multi grip blind rivets is by the appearance of the rivet body. multi grip blind rivets typically have three imprints on the end of the rivet. the riveting range of multi grip blind rivets is changed by adjusting the position of the imprints. Therefore, this is its unique appearance and the best and most direct way to identify multi grip blind rivets.

Wholesale High Quality Multi Grip Blind Rivets and Rivets

Multi grip blind rivets and open rivets are both common types of blind rivets. This guide shows you the details of “multi grip blind rivets vs rivets”. If you want to buy the right multi grip blind rivets or open type blind rivets for your project, please contact us!