Table of Contents

What is a tri fold rivet?This is a question that every program owner who applies tri fold rivet needs to know. This guide will explain to you in detail “what is a tri fold rivet”. Let’s explore it together!

Table of Contents

What is a Tri Fold Rivet?

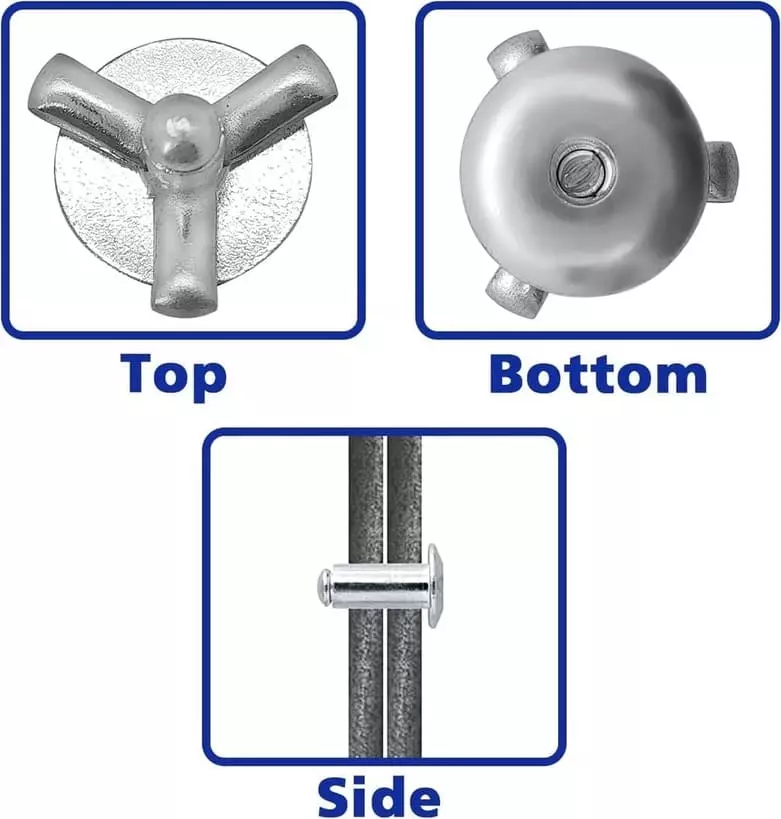

Tri fold rivets are a type of blind rivet. It is a specialized type of blind rivets produced and processed with multi-station cold heading equipment. After riveting, its rivet body splits into three folds to provide a larger riveting area.

Tri fold blind rivets are generally made entirely of aluminum, making them ideal for lightweight applications.Tri fold rivets can be riveted to materials that other fasteners can’t, such as plastic, wood, glass, rubber, automotive dashboards, automotive exhaust systems, lightboxes, and other fragile, flexible materials.Tri fold rivets Tri fold rivets provide a stable connection to these materials without damaging the surface.

Pros and Cons of Tri Fold Blind Rivets

Tri Fold Blind Rivets form three evenly spaced folds at their end during installation. This deformation feature increases the contact area between the rivet and the base material, thus increasing the clamping force and reducing the localized pressure on the material. The following is a detailed analysis of its advantages and disadvantages.

Pros of Tri Fold Rivets

1. Increased Contact Area

Tri fold rivets have a special structural design. When installed, it forms three folds at the end, which are evenly distributed on the backside of the base material.

Because of this special design, tri fold rivets perform well on brittle and soft materials. It reduces localized stresses and protects soft or brittle materials (e.g. plastics, composites, thin metal sheets). Avoids pulling through or deformation of the base material.

2. High Clamping Force

Tri fold blind rivets not only rivets brittle materials well, it also has a tail fold that grips the material firmly and provides a stable clamping force.

Because of this advantage, tri fold blind rivets are often used in high vibration environments and can be effective in improving joint reliability. It is especially good for thin-walled or lightweight materials.

3. Adaptation to a Wider Range of Materials

Compared to other types of blind rivets, tri fold rivets can join a wider range of materials. It can not only connect metal materials, but also soft and brittle materials.

4. Reduced Damage to Base Material

The deformation characteristics of Tri fold blind rivets reduce the risk of material damage. This provides better protection for soft materials (e.g. plastics, aluminum alloys).

Cons of Tri Fold Rivets

- Limited Strength: Tri-Fold Blind Rivets have relatively low tensile and shear strength despite the large contact area.

- Higher Cost: Complexity of design and manufacture results in a slightly higher price than a common blind rivet. May not be cost effective in low budget projects.

- Not Suitable for High Temperature Environments: Tri-Fold Blind Rivets may lose performance in high temperature environments.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Install Tri Fold Rivets?

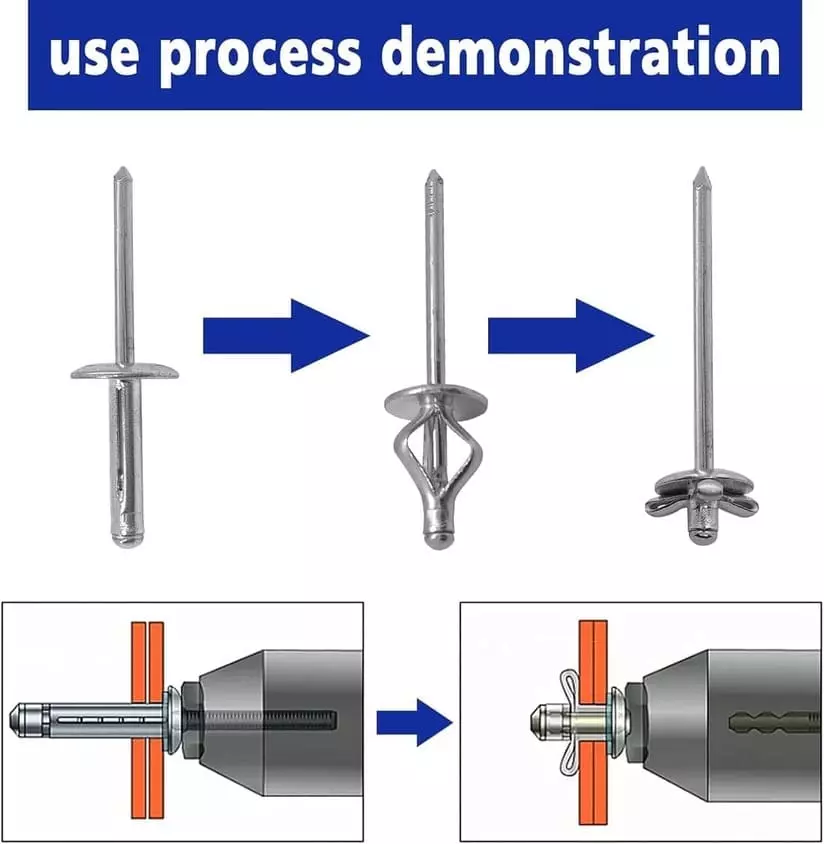

The installation process for Tri fold blind rivets is the same as installing regular blind rivets. It involves the following three steps:

- Insert the correct size rivet

- Installation using a pneumatic rivet gun

- Checking the installation

If you want to learn how a blind rivet is installed, please read the “how to install pop rivets“.

Tips of Installing Tri Fold Blind Rivets

- Check for even spreading of the tail section: mandrels that are not completely pulled off during installation or irregular holes may result in uneven spreading of the tail folding piece.

- The thickness of the base material should be within the rivet grip range: If the thickness of the base material is outside or below the designed grip range of the tri fold rivets, the tail fold may not unfold evenly.

What is a Tri Fold Rivet Used for?

Tri fold blind rivets are used in a wide range of scenarios where there is a need for stress dispersion, high clamping force and protection of soft or brittle materials because of their unique tail design. The following are the main applications for tri fold blind rivets.

- Doors: interior trim panels, speaker brackets, door lock mounts

- Dashboard: bracket attachment, trim panel fixing

- Roof liner: roof liner made of structure

- Fenders and sound panels: wheel liners, connection of sound panels to chassis frame

- Curtain wall system: connection of aluminum or plastic panels to supporting structure

- Door and window frames: aluminum frames connected to walls

- Decorative panels: interior partitions, ceiling decoration

3. Industrial Equipment

- Lightweight frame: equipment housing and support frame

- Pipe supports: fixing flexible pipes with metal supports

- Shields: Plastic or metal protective covers for equipment installation

4. Electronic Equipment

- Equipment casing: metal or plastic casing with frame connection

- Display bracket: fixed aluminum or plastic panel

- Thermal components: heat sinks and support frames

Do You Have Any Questions?

Let Us Solve Your Problem

Tri Fold Rivets vs Pop Rivets

| Comparison Aspect | Tri-Fold Blind Rivets | Open Type Blind Rivets |

| Design Features | Forms three evenly distributed folds at the tail, providing a large contact area and reducing stress on the base material. | Simple circular deformation at the tail, suitable for general purposes with a simpler structure. |

| Tail Shape After Installation | Symmetrical three-fold tail with a large contact area, minimizing localized stress. | Single expanded shape with a smaller contact area, leading to localized stress concentration. |

| Applicable Materials | Soft, brittle, or thin materials such as plastics, composites, and aluminum sheets. | Suitable for metals and hard materials; less protective for soft and brittle materials. |

| Tensile Strength | Relatively low, suitable for medium to low load applications. | Higher, suitable for medium to high load scenarios. |

| Shear Strength | Moderate, suitable for lightweight and non-critical structural connections. | Higher, suitable for applications with high shear loads. |

| Clamping Force | High clamping force, especially suitable for dynamic loads and vibration environments. | Moderate clamping force, suitable for static and non-vibration environments. |

| Protection for Base Material | Excellent protection for soft or brittle materials, minimizing damage risks (e.g., cracking or pull-through). | Moderate protection; may damage soft or thin materials due to stress concentration. |

| Corrosion Resistance | Material-dependent (e.g., aluminum, stainless steel); suitable for humid or outdoor environments. | Wider material options (e.g., coated steel, stainless steel); corrosion resistance is adjustable as needed. |

| Cost | Higher due to the complexity of design and manufacturing. | Lower, with simpler manufacturing and higher cost-effectiveness. |

| Typical Applications | Ideal for protecting base materials like soft, brittle, or thin materials; dynamic loads and vibration-prone environments (e.g., home appliance housings, plastic panels, car interior trims). | Suitable for high-strength connections in hard materials, or for applications where base material protection is less critical (e.g., metal frames, equipment assembly). |

There are many similarities and differences between Tri fold blind rivets and open type blind rivets. Business owners need to choose the most suitable blind rivets according to the actual requirements of the project.

Advantage Comparison

Tri-Fold Blind Rivets Advantage:

- Ideal for joining soft, brittle or thin-walled materials such as plastics, composites or aluminum alloys.

- Large contact area reduces the risk of damage to the base material, especially in dynamic loading or vibration scenarios.

- Provides higher clamping forces on thin-walled materials, reducing the risk of pull-through.

Open Type Blind Rivets Advantage:

- Simple to manufacture and low cost for high volume applications.

- Higher tensile and shear strength for higher load scenarios.

- Simple installation requirements and adaptability to bore tolerances for a wide range of metal materials

Limitations Comparison

Tri-Fold Blind Rivets Limitations:

- Lower tensile and shear strength, not suitable for high load or critical load bearing structures.

- Requires higher accuracy of holes and improper installation may result in uneven tail folds.

- Higher cost, not cost-effective in low-budget projects.

Open Type Blind Rivets Limitations:

- Weak protection against soft or brittle materials, may cause damage to parent material.

- Small tail contact area does not provide the large support area of tri-fold rivets

Wholesale High Quality Tri Fold Rivets from Rivmate

By reading this guide, I am sure you have a deep understanding of “what is a tri fold rivet”. This is also something you must know before buying a lot of tri fold rivets for your project.

Are you looking for a reliable tri fold rivet manufacturer?Don’t worry, Rivmate can provide you with high quality and affordable tri fold blind rivets for your project.If you want to buy, please contact us!

Get rivet samples for testing now!