Table of Contents

Rivets failure has a number of ways, the two main ones being shear failure of rivets and tensile failure of rivets.This blog will be centered around shear failure of rivets and will give you a detailed overview of its causes, consequences and how it can be avoided.

Let’s explore it together!

Table of Contents

What is the Shear Failure of Rivets?

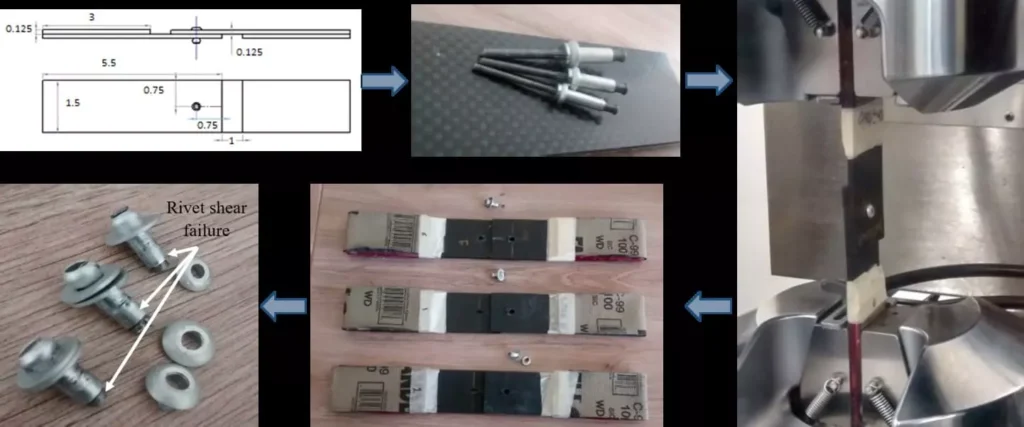

Shear failure of rivets refers to the fracture or deformation of rivets when subjected to transverse shear force (Shear Force) due to insufficient material strength or forces exceeding their design load carrying capacity. This type of failure usually occurs in the stem portion of the rivet, resulting in the inability of the rivet to continue to securely connect the component, and may even result in the failure of the entire structure.

Working Mechanism of Shear Failures

The role of shear forces

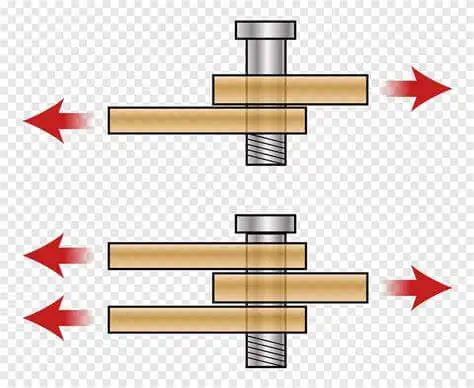

- Rivets are commonly used to join two or more overlapping materials. Shear is a transverse force acting on the rivet stem that attempts to separate the connected materials from each other in parallel directions.

- The shear force acts on the contact surface between the rivet and the material being joined, and the rivet stem needs to resist this force.

Specific manifestations of shear failure include:

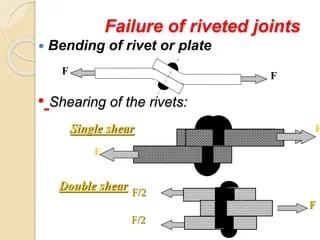

- Single Shear Failure: The rivet breaks on one shear surface, e.g. where a single layer is joined.

- Double Shear Failure: The rivet breaks on two shear surfaces, such as in the case of two layers of material being riveted together.

- Deformation of the rivet stem: plastic deformation of the rivet stem may occur prior to failure

Reasons for Rivet Shear Failure

There are many reasons for rivet shear failure. But basically it has to do with the rivet itself and the shear force applied. The following are the main causes of rivet shear failure:

1. Excessive Shear Force

There is an upper limit to the amount of shear any rivet can withstand. If a rivet is subjected to a shear force that exceeds its design strength, the rivet stem will not be able to withstand the stress. Therefore, this is the time when the rivet will fail in shear.

For example, when rivets are used on bridges, if a heavily loaded truck passes through and the rivet is subjected to excessive shear force, rivet fracture may occur.

2. Insufficient Strength of Rivet Materials

There are many types of metal materials that can make rivets. If your project uses rivets made of low-strength materials (such as aluminum or plain steel) to join high-strength materials or highly loaded structures, then rivet shear failure may occur. This is because the material of the rivet itself is not strong enough to withstand such high shear pressure.

In addition to this, if the rivet itself is defective, such as internal porosity or cracks, it may also lead to rivet failure.

3. Improper Rivet Size

Problems are also likely to occur when using rivets that are too small in diameter or not long enough. For example, if the rivet diameter is too small, there is no way it can provide enough shear bearing area. If the rivet is not long enough, there is no way to effectively secure multiple layers of material.

4. Poor Rivet Installation

Rivets may not hold material tightly if the operator fails to expand the rivet properly when installing the rivet.

In high vibration environments, under-expanded rivets loosen and eventually shear failure occurs.

5. Environmental Factors

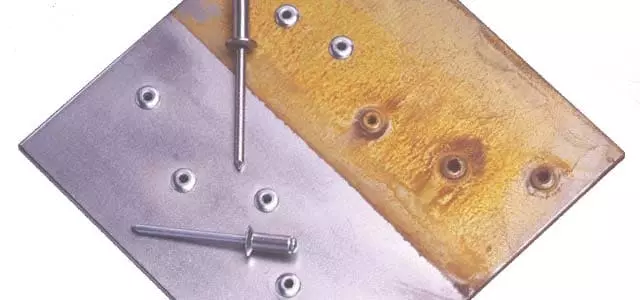

If your project is in a high or low temperature environment, the mechanical properties of the rivet material may be reduced. In addition to this, if the rivets are exposed to corrosive environments for a long period of time (e.g., oceans, high humidity areas), then the material of the rivets will be corroded, which will reduce the shear strength.

6. Insufficient Number of Rivets

In the actual application of industrial equipment, if the number of rivets in the critical parts of the use of insufficient, is very easy to lead to the rivet shear failure of the situation.

For example, if the number of rivets is not enough design, then it will lead to individual rivets to withstand excessive shear force. This leads to rivet fracture. Or uneven distribution of rivets, some of the rivets are subjected to excessive shear load, will also lead to the occurrence of rivet shear failure.

Conclusion: Shear Failure of Rivets

| Cause Category | Specific Manifestation |

| Excessive Shear Force | The rivet is subjected to a force exceeding its design capacity, causing the shank to break. |

| Improper Material and Size Selection | The rivet material lacks sufficient strength, or the diameter is too small to withstand the stress. |

| Mismatch in Hole Size | Gaps between the rivet and the hole are too large or too small, leading to stress concentration or rivet damage. |

| Poor Installation | Rivet is not properly expanded or is damaged, resulting in a loose connection. |

| Stress Concentration | Stress concentrates around the shank or hole edges, causing fractures. |

| Environmental Factors | Corrosion, high temperature, or low temperature reduces the rivet’s strength. |

| Dynamic Load or Fatigue | Continuous vibration or cyclic stress causes the rivet to fatigue and eventually fail. |

Do You Have Any Questions?

Let Us Solve Your Problem

Effects of Rivet Shear Failure

An intact rivet is the only one that can perform at its best. Shear failure of rivets may have a range of negative effects on the stability, safety and performance of a structure. The following are the main effects of rivet shear failure:

- Reduced Structural Strength: Shear failure can weaken the bond between the connectors, resulting in a reduction in the overall strength of the structure.

- Overall Structural Failure: If the failed rivet is located in a load-bearing component or a critical connection location, it can trigger a chain reaction that can lead to the collapse or separation of the overall structure.

- Exacerbated vibration: Rivet shear failure can result in insufficient retention of connecting components, leading to loosening or gaps.

- Failure to function: Failure to function of the connection may result in the equipment not functioning properly.

What are the Typical Manifestations of Shear Failure of Rivets?

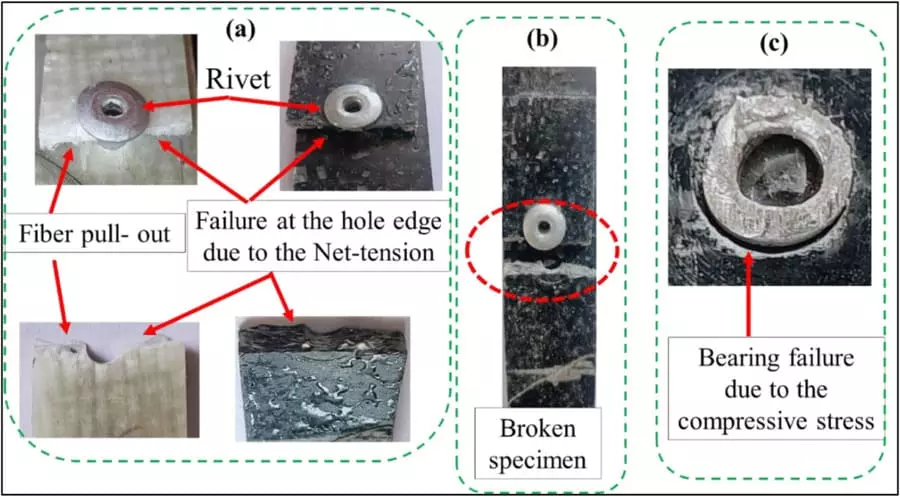

Shear failure of rivets usually manifests itself in the following ways:

- Fracture of the rivet stem in the area subjected to shear force

- Significant bending or tensile deformation of the rivet stem prior to failure.

- The head of the rivet is pulled apart by the shear force, or is completely detached from the stem

- The hole in which the rivet is located increases in diameter or cracks in the hole wall, resulting in a loose connection or even complete failure.

- The rivet does not break outright, but the edge of the hole in the material being joined is torn or deformed, resulting in a reduction in the strength of the connection.

- Visible cracks appear on the surface of the rivet

Do You Have Any Questions?

Let Us Solve Your Problem

How to Prevent Shear Failure of Rivets?

Preventing shear failure of rivets needs to start from a number of aspects, such as design, material selection, installation process, environmental adaptability and so on. But the core measures are mainly the following six:

Choosing the Right Rivet Material

In your practical use, if you want to from avoiding the occurrence of rivet shear failure, you can use high-strength materials. For example, according to the actual application needs of your project to choose enough strength rivet material. Common materials and their suitable application scenarios are listed below:

- Aluminum rivets: suitable for light load environment.

- Stainless steel rivets: suitable for high load and corrosive environment.

- Carbon steel rivets: suitable for heavy load environment, but need anti-corrosion treatment.

In addition to this, it should be noted that the rivet material should match the strength of the material being riveted. This can effectively avoid stress concentration or loose connection on too hard or too soft materials.

Optimized Size and Distribution

In addition to selecting high-strength materials, the occurrence of rivet shear failure can be reduced by optimizing the size and number of rivet distributions.

The larger the rivet diameter, the larger its shear cross-sectional area, thus increasing the rivet’s shear resistance. Increasing the number of rivets in the reconnection area and spreading the load can prevent individual rivets from being subjected to excessive shear forces.

Ensuring the Quality of the Installation

Depending on the type, size and material of the rivet, select the appropriate riveting tool. For the installation process, the force applied needs to be uniform and not over-tightened or loosened. It is recommended to use pneumatic rivet guns, which can maintain the consistency of the quality of the connection.

Adaptation to the Work Environment

- When using rivets in corrosive environments, corrosion-resistant materials should be selected or the rivets should be galvanized, plated and other anti-corrosion treatments.

- In high or low temperature environments, rivets should be made of materials that can withstand temperature fluctuations.

- In high vibration or shock environment, should choose the rivets of anti-loosening design, and reasonable distribution of rivet position and spread the load.

To further minimize rivet shear failure, the environment in which the rivets are used is a key consideration.

Regular Inspection and Maintenance

Although rivets are permanent connections, they need to be inspected and maintained on a regular basis if rivet shear failure is to be avoided as much as possible. Rivets can be visually inspected for looseness, cracks or deformation. Timely replacement of rivets that may be subject to shear failure will prevent a chain reaction.

Load to Design Matching

Shear strength needs to be calculated before rivets are officially used. Ensure that the rivet design meets the load renewal of the actual application and avoid overloading.

Custom Riveting Solutions for Your Project

It is impossible to completely avoid rivet shear failure. Therefore, all we can do is to minimize the possibility of this happening. If you still don’t know how to choose the right rivet, please contact us! We will provide you with professional riveting solutions.

Get rivet samples for testing now!