How to Choose Rivet Fasteners for Solar Panels?

Table of Contents

How to Choose Rivet Fasteners for Solar Panels?

Rivets are an integral part of applications in the solar industry. So do you know what types of rivets are used in solar panels?

By reading this blog, you will come to know about the various knowledge of rivet fasteners for solar panels. This includes the role, impact, selection and common mistakes.

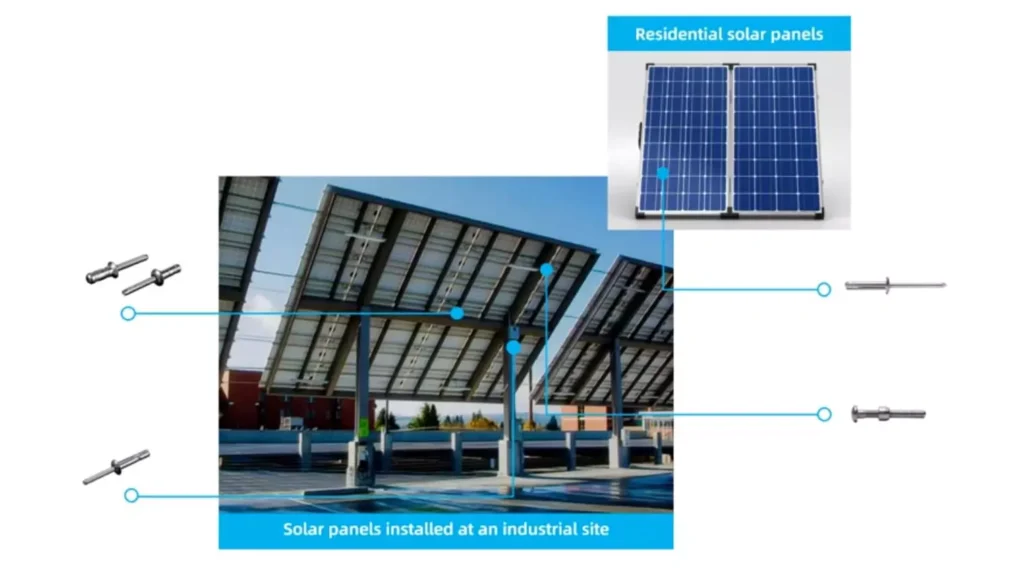

Rivet connections in solar panel (module + holder) systems

Rivets assume a key structural connection role in solar panel systems. These fasteners are mainly used for fixing and reinforcing between the module frame, junction box, bracket structure and auxiliary accessories of solar panel.

Compared with bolts or welding, rivets have the advantages of single-sided installation, lightweight, anti-loosening, and adaptability to thin-walled structures. Therefore, rivets are particularly suitable for riveting aluminum alloys and composite materials widely used in photovoltaic systems.

In the module section, rivets are often used to fix the aluminum frame, support piece and junction box bracket of the solar panel. The characteristics of rivets ensure the structural integrity of the module and resistance to wind loads. In the bracket system, rivets connect rails, columns, diagonal braces and other parts. Structural rivets provide high strength, long-term stability, and are an important connection solution to support the safe operation of the entire PV system.

Impact of rivet selection on solar panels

Rivet selection in the solar panel (Solar Panel) system is not just a matter of fastener specifications, the results of its selection directly affect the service life of the entire photovoltaic system, corrosion resistance, structural stability, as well as construction and installation efficiency.

I. Impact on solar panel system lifetime

Solar panel projects are typically designed for a life of 20-30 years. And solar panel fasteners, as the most basic mechanical components of the solar panel system, any early failure may lead to component loosening, structural damage or even system shutdown.

If the selection of improper (such as insufficient strength, grip force mismatch), solar panel rivets may be in the wind load, thermal expansion and contraction, long-term fatigue under the action of falling off or fracture, thus shortening the actual operating life of the system.

For example, if low-strength open end rivets are used in the splicing part of the main bracket, micro-displacement and stress concentration may occur under continuous wind load, leading to fatigue failure of the connection.

II. Impact on corrosion protection performance

Most photovoltaic systems are exposed to outdoor environments, facing rain, moisture, salt spray, ultraviolet rays and other erosion. If the rivet material and structural materials there are galvanic corrosion differences (such as carbon steel rivets with aluminum profiles), will accelerate the corrosion reaction, resulting in connection failure and corrosion diffusion.

Quality rivet selection should give priority to stainless steel, aluminum or Dacromet treatment, avoid the use of bare carbon steel or low quality plated products. This will ensure that the rivet body is electrochemically compatible with the material being joined.

For example, there have been previous cases where aluminum bezel + carbon steel rivets developed red rust within months in a humid environment, with corrosion extending to the junction box or frame structure.

III. Impact on structural stability

There are many types of blind rivets, and different rivet structure types have different grip, shear strength and fitment range. The use of open end rivets can lead to loose connections in high stress structures, while structural rivets (e.g. Monobolt, Lockbolt) provide high strength locking force and vibration resistance, and are suitable for critical connections such as brackets and ground piles.

In addition, the special structure (such as Tri-Fold, Bulb-Tite) can effectively disperse the stress, to avoid the glass or sheet caused by the concentration of pressure injury, to enhance the overall system stability.

Case in point: the use of structural rivets to connect main beams and cross braces can reduce micro-motion wear and enhance wind load resistance and fatigue resistance.

IV. Impact on installation efficiency

In the solar module factory packaging line, the use of large flange blind rivets with automatic rivet guns can be realized within 2 seconds per point of installation, significantly increasing production capacity.

The structural form, installation method and grip range of rivets directly affect the construction efficiency and consistency. In large-scale solar module packaging or bracket assembly, the choice of a wide grip range, reliable core breakage, support for automated riveting rivet type (such as Multi-Grip, Tri-Fold) can significantly improve the assembly efficiency.

The single-sided mounting feature also makes them ideal for structures with inaccessible backs, reducing labor requirements and construction difficulties, while avoiding rework later in the process.

How to Choose Rivet Fasteners for Solar Panels?

✅ Component Aluminum Bezel Connection

Aluminum bezels for solar panel’s components are characterized by thin-walled aluminum profiles that require light weight, corrosion resistance, and thermal expansion compatibility. Therefore rivets are required

Rivet type is recommended:

Recommended Materials: Aluminum Body + Aluminum Core or Stainless Steel Core

Recommended Head Type: Round head, small flange

These two types of blind rivets have a lower expansion force, which can effectively prevent the riveting from cracking the solar panel frame. Moreover, the main raw material of bulb tite blind rivets and tri fold blind rivets is aluminum, which can well match the thermal expansion coefficient of aluminum.

✅ Mounting Structure Joints (Main Connections)

Solar panel supports are always in an outdoor environment. Therefore, they need to carry wind load, snow load, and need to have long-term vibration resistance and high structural reliability requirements.

Recommended Rivet Type:

- Monobolt Rivets

- Lockbolt Systems

- Hemlok Rivets (High Tensile Mechanical Locking Rivets)

Recommended Materials: Galvanized Steel / Stainless Steel

Recommended Head Type: Round or countersunk head, high grip construction type

These rivets are structural blind rivets. They have high shear and tensile resistance, and they are loosen-proof and can be used as an alternative to bolted joints.

✅ Cable Management & Fixtures

Application Features: Thin sheet construction, fast installation, avoid scratching the surface

Recommended Rivet Type:

- Bulb-Tite Blind Rivets

- Multi-Grip Rivets

Recommended Materials: Stainless Steel / Aluminum

Recommended Head Type: Large Flange Head

Rationale: Uniform expansion, stress distribution, anti-slip, suitable for quick assembly.

✅ Junction box holder or plastic fixing

The junction box or plastic parts of the solar panel usually need to be mounted on the back side and riveted to a plastic shell material with very limited riveting space.

Recommended Rivet Type:

- Closed-End Blind Rivets

- Small Flange / Sealing Rivets

Recommended Material: Aluminum / Stainless Steel Core

Closed or structural rivets in blind rivets are waterproof and dustproof. The mandrel will not come off after installation is completed, thus providing high strength.

✅ Glass backsheets or composite connections (BIPV / thin film modules)

The glass backsheets or composite materials of solar panels are fragile, sensitive to stress and require cushioning for expansion. Application Characteristics: Fragile materials, sensitive to stress, need to cushion expansion

Recommended Rivet Type:

- Tri-Fold Rivets

- Soft-Grip Rivets (cushion construction type)

Recommended Material: Aluminum body + Stainless steel core

This type of rivet after riveting the tail of the three-flap unfolding, dispersing the stress. It can avoid point pressure cracks and is suitable for joining dissimilar materials.

| Application Area | Recommended Rivet Type | Suggested Material | Key Features |

|---|---|---|---|

| Aluminum frame joints | Open-End / Tri-Fold | Aluminum / SS stem | Lightweight, corrosion-resistant, thermal expansion compatible |

| Mounting structure joints | Monobolt / Lockbolt / Hemlok | Zinc-plated Steel / SS | High strength, fatigue-resistant, anti-vibration |

| Cable trays & accessories | Bulb-Tite / Multi-Grip | Aluminum / Stainless | Fast installation, distributes load, avoids panel damage |

| Junction box brackets | Closed-End / Small Flange | Aluminum / SS stem | Sealed design, rust-resistant, low-profile for backside use |

| Glass backsheet / composites | Tri-Fold / Soft-Grip | Aluminum / SS stem | Stress dispersion, safe for brittle materials |

Common mistakes and ways to avoid them when using rivets on solar panels

By strictly controlling the rivet selection and installation details, the overall reliability, safety and corrosion resistance of the solar system can be effectively enhanced.

❌ Mistake 1: Carbon steel rivets were chosen to connect the aluminum frame, leading to galvanic coupling corrosion

If you are using carbon steel rivets to rivet an aluminum bezel, there is a good chance that you will have problems. There is a large potential difference between the aluminum and carbon steel, which can form a microcell in environments with moisture or salt spray, accelerating corrosion of the aluminum bezel.

This incorrect connection can lead to oxidation, chalking and even structural failure of the bezel, which will not meet the 25-year durability requirement.

Methods of circumvention:

- Prefer aluminum or stainless steel rivets. If galvanized steel is used, ensure that it has a closed passivation treatment.

- For seaside or high salt areas, Dacromet treated or all stainless steel rivets are recommended.

- Ensure that dissimilar metals are separated by insulating coatings or shims.

❌ Mistake 2: Using rivets with excessive expansion forces to join glass or composites, leading to cracking

Brittle materials such as glass backsheets, foam sandwich panels, and thin composite panels on Solar panels cannot withstand concentrated expansion stresses.

If the incorrect type of rivet is used, it can cause cracking of the panel, peeling of the sandwich, and result in module seal failure or aesthetic defects.

Methods of circumvention:

- Use stress-dispersing rivets such as Tri-Fold or Bulb-Tite to avoid concentrated point loads.

- Control clamping thickness and hole diameter tolerances to avoid over-expansion of the rivet body due to over-gripping.

- When one of the material combinations is brittle, use soft expansion construction or rivets with rubber gaskets.

❌ Mistake 3: Using general-purpose blind rivets instead of structural rivets to connect the main bracket is not strong enough

Standard general-purpose blind rivets have low tension and shear force, which can’t bear the load of the bracket and wind load.

The use of non-high-strength rivets for connection will cause the connection points of the solar panel to loosen and rivet off, resulting in system structure safety risks.

Method of circumvention:

- Structural high strength rivets such as Monobolt, Lockbolt, Hemlok, etc. must be used for main support nodes.

- Require performance indexes of shear ≥5kN and tensile ≥4kN (can refer to specification or project requirements).

- Confirm the reliability by shear test or pull-out force test.

❌ Mistake 4: Neglecting to match rivets to installation tool, resulting in unlocked or retained mandrels

When you install solar panel outdoors, you need to use the right riveting tool. Mismatch of riveting force or jaw size is very easy to cause the mandrel not broken, not locked after pulling off.

If you use the wrong tool or wrong installation, the riveting force at the connection point will be insufficient, the mandrel will be loose, the riveting will be false tight and the risk of leakage will be high.

Method of circumvention:

- Use original or standardized rivet guns with regular checks of pulling force and core break accuracy.

- Prevent human error by using pneumatic or electric rivet guns that automatically recognize the completion of the pull-off.

- For structural rivets, prioritize the use of hydraulic tools to ensure installation consistency.

❌ Mistake 5: Improperly designed rivet position, too small a distance from the edge or large hole diameter error

When riveting thin plate materials, you need to consider how to set the rivets. Rivets that are too close to the edge of the plate or holes that are too large will not provide sufficient locking force when expanded.

Insufficient connection force can result in rivet slippage, sheet cracking, insufficient grip and short installation life.

Method of circumvention:

- Follow the design principle of minimum margin ≥2 x hole diameter to ensure stable riveting.

- Control the hole diameter and rivet matching within ±0.1mm tolerance.

- For thin plates/aluminum profiles, preference should be given to large flanges or deep expansion rivets to increase the force area.

FAQs about Solar Panel Rivet Fasteners

What is the life expectancy of rivets in a solar panel?

The service life of rivets in solar panel systems is typically more than 20 years. This assumes, of course, that the right materials (e.g., stainless steel, aluminum or Dacromet-treated steel) are used and that they have good corrosion resistance and structural stability.

In the design of PV projects, rivets should be used as permanent connectors in line with the life expectancy of the module body and the mounting system. Even in the outdoor high humidity, high salt spray and other environments, more should be selected with ISO certification and salt spray test verification of the PV special rivets. This ensures that they will not corrode, loosen or fail due to structural fatigue throughout the system life cycle.

What quality standards or certifications should PV-specific rivets meet? (e.g. ISO, RoHS)

As a key connecting element in solar energy systems, PV rivets should comply with the following quality standards and environmental certifications to guarantee stable performance, structural safety and compliance with global market requirements:

- ISO 9001

- ISO 9227

- ISO 14589 / DIN 7337

- RoHS

- REACH

Rivmate is proud to have all of the above quality certification standards. Rivmate can provide you with high quality solar panel rivets that far exceed international standards:

- Material Certificate

- QC Sheet

- COC

- Third party certificates (e.g. SGS, TÜV)

Custom Solar Panel Rivet Solutions for Your Solar Business

Rivmate specializes in high performance riveting solutions for the photovoltaic industry. These range from standard blind rivets and structural rivets to customized riveting products for BIPV systems. We understand that every PV project is different in terms of structural design, environmental conditions and installation methods. Therefore, through flexible customization services, we provide our customers with fastening solutions that are matched to the material, grip range, expansion structure and surface finish.

Whether you are a module manufacturer, a racking supplier or an EPC project implementer, Rivmate can provide you with solar-specific rivets that meet international standards (ISO, RoHS, REACH) and are salt spray tested and certified, as well as samples, drawings, assembly recommendations and volume delivery services. Contact us today to customize a riveting solution for your solar business.

Share:

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met