How to Choose Rivet Fasteners for Solar Cover?

Table of Contents

This blog will focus on solar cover material matching, corrosion resistance, structural stress adaptability, installation process and avoidance of common misconceptions. Systematically analyze how to choose the ideal rivet solution for your Solar Cover.

Why Choosing the Right Rivet is Crucial for Solar Cover?

In solar energy system, Solar Cover refers to the metal or composite protective shell installed at key locations such as modules, electrical boxes, rail brackets, tracker systems, etc. Its main function is to protect electrical components from dust and moisture intrusion, enhance structural stability, and improve the overall safety and durability of the system. Its main purpose is to shield electrical components, prevent dust and moisture intrusion, enhance structural stability, and improve overall system safety and durability. These Covers may be made of aluminum, stainless steel, plastic, or fiberglass panels with thin thicknesses and high structural dependence on connectors.

In solar covers, rivets serve three key roles as a permanent fastening solution:

- Sealing: Closed rivets prevent rainwater and salt spray from penetrating the interior of electrical compartments or control boxes;

- Protection: structural rivets provide tensile and shear strength to cover panels, preventing them from coming loose during wind loads or vibration;

- Assembly efficiency: single-sided mounting facilitates quick on-site construction and reduces the need for thread maintenance.

Therefore, choosing the right rivets (structural form, material, corrosion protection grade) is crucial to the stability of the Solar Cover’s performance, system life and post maintenance.

What are the common types of rivet fasteners used in solar cover?

- Features: Tail end closure, mandrel locking without falling off, effectively preventing water vapor from entering or debris from falling.

- Applicable scenes: inverter shell, electrical box cover, tracker control compartment and other parts that need to be sealed and protected.

- Advantages: structural sealing, anti-arbor falling off, better anti-corrosion performance.

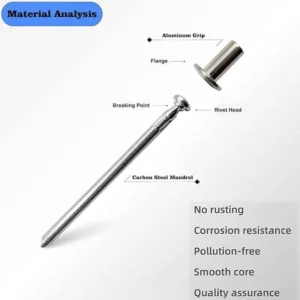

- Material: Aluminum + Stainless Steel Core / Galvanized Steel Body

- Characteristics: Rivet body tail part of the three-flap unfolding, forming a large area “anchor claw” locking force, suitable for connecting thin plates or brittle materials.

- Applicable scenarios: aluminum cover, composite panels or glass-based cover panels, especially suitable for BIPV systems.

- Advantages: low point pressure, stress distribution, protection of surfaces against tearing.

- Material recommendation: aluminum body + stainless steel core

- Characteristics: Adaptable to a wide range of board thicknesses, with a strong and soft backside expansion area like a light bulb.

- Applicable scenarios: rapid assembly of different thickness covers, such as metal roof covers, cable bridge attachments, etc.

- Advantages: Adaptable assembly tolerances, reduced number of SKUs in stock, stable mounting.

- Material recommendation: aluminum / galvanized steel / stainless steel

- Characteristics: High shear and tensile strength, often used as an alternative to bolted connections, not removable after installation.

- Applicable scenarios: shield structures with high loads, in vibration or high wind areas (e.g. Tracker’s housing).

- Advantages: Anti-loosening, anti-theft, anti-disassembly, high stability.

- Material recommendation: galvanized steel / stainless steel (with special tools)

| Rivet Type | Waterproof | Strength Level | Material Compatibility | Typical Applications |

|---|---|---|---|---|

| Open-End Blind Rivet | ✘ | Medium | Metal / Plastic Mixed | Cable covers, non-structural panels |

| Closed-End Blind Rivet | ✔ | Medium | Aluminum, Stainless Steel | Electrical enclosures, control boxes |

| Tri-Fold Blind Rivet | Moderate | Medium | Thin aluminum, composites | Glass-based or lightweight cover panels |

| Bulb-Tite / Multi-Grip Rivet | Moderate | Medium-High | Versatile for all materials | Variable-thickness cover fastening |

| Structural Rivet / Lockbolt | ✔ | High | Steel structures | Tracker covers, high-wind load sections |

5 Core factors to consider when choosing rivet fasteners for solar cover

When selecting the right rivet fastener for Solar Cover, it is important to consider key factors such as material construction, environment and installation process. The following are the five core selection considerations that directly affect the reliability, protection and service life of the riveted joint.

Factor I. Solar Cover Material Type

Why does the type of material of the solar cover matter? Different solar cover materials (e.g., aluminum, stainless steel, plastic, or composite) are sensitive to rivet expansion forces, clamping forces, and stress distribution.

- Aluminum or thin metal panels: Low expansion force, distributed stress type rivets such as Tri-Fold or Bulb-Tite are recommended to prevent cracking of the panel.

- Plastic or fiberglass panels: Light tensile force, closed cell type rivets should be used to prevent the mandrel from penetrating or falling inside the equipment.

- Composite or honeycomb panel construction: large spread rivets are required to reduce unit pressure and ensure that the structure does not peel.

Factor II. Working environment (corrosion and weathering resistance)

Why is solar cover so important to be put in the second point to explain? Solar Cover is mostly exposed to the outdoors, facing multiple corrosive environments such as sun and rain, salt spray, sand, acid rain, etc. Therefore, if you choose the wrong material, it is very easy to rust and corrosion failure.

- High humidity or coastal areas: must use stainless steel or Dacromet-treated rivets, through ≥ 240 hours of salt spray test.

- Strong UV/high-temperature areas: avoid the use of lightweight materials that are prone to fatigue and aging, and pay attention to the thermal stability of the rivet mandrel.

- BIPV façade or building integrated systems: consider exterior color matching, waterproof rating and environmental certifications (e.g. RoHS/REACH).

Factor Ⅲ: Connection location and installation accessibility

In practice, Solar Covers are often enclosed or space-constrained structures. Therefore, when installing solar cover, part of the position can only work on one side, bolts or washers are not available.

- Blind hole structure (can not be operated from the back): Blind Rivets should be used (Blind Rivets) structure, such as closed type or three-flap type.

- Narrow space installation: It is recommended to use low head type, small flange, short core blind rivets to avoid interference with other parts.

- Do not allow loose maintenance: choose non-removable structure rivets to enhance structural safety and anti-theft and anti-loosening ability.

Factor IV. Load Strength and Vibration Durability

Solar Cover is used in outdoor environments, so it is inevitably subjected to wind pressure, transportation vibration, or equipment thermal expansion stress. If the rivet fasteners are not strong enough or locked securely, they are very prone to loosening or fatigue fracture.

- Structural connections (e.g. supports, cover main fixings): structural rivets such as Lockbolt or Hemlok with ≥5kN shear strength are required.

- General fixing points (e.g. cable covers): multi-grip blind rivets can be used to simplify stocking and ease of installation.

- Dynamic loads: It is recommended to choose rivets with anti-loosening design, mandrel locking, and verified seismic performance.

Factor V. Installation efficiency and tool compatibility

The last and most important thing is to pick the right rivet installation tool. Why is this important? Solar Cover is basically assembled on site, so the installation configuration is based on manual + pneumatic tool operation, and the efficiency directly affects the construction cycle and cost.

- Batch projects (e.g., power stations/distributed stations): recommend the use of products with clear broken cores and compatible with automatic rivet guns to improve consistency.

- Maintenance-friendly structure: Specialized low-tension rivets can be used to reduce the burden on installers.

- Tool adaptation issues: need to confirm in advance that the rivets are compatible with the construction unit’s commonly used rivet gun models (stroke, pull force, opening size).

In summary, the selection of Solar Cover rivets is not simply a matter of matching dimensions, but a systematic and integrated judgment of structural mechanics, material suitability, corrosion life and installation feasibility. Correct selection can significantly improve the overall performance and delivery quality of the product, and reduce the risk of maintenance and failure.

Recommended rivet types for solar cover applications

| Solar Cover Application Scenario | Recommended Rivet Type | Material Suggestion | Key Performance Benefits |

|---|---|---|---|

| Aluminum panel / frame protection | Tri-Fold Rivets / Closed-End Rivets | Aluminum / SS stem | Stress dispersion, anti-tear, corrosion-safe with aluminum |

| Inverter / control box enclosure | Sealed Blind Rivets / Bulb-Tite Rivets | Stainless / Zinc-coated | Waterproof, vibration-resistant, ideal for outdoor electronics |

| Cable covers / accessory brackets | Open-End Rivets / Multi-Grip Rivets | Aluminum / Stainless Steel | Fast installation, fits varying thicknesses, inventory-saving |

| Tracker enclosure / wind-load area | Structural Rivets / Lockbolts | Galvanized or Stainless | High shear & tensile strength, anti-loosening, long service life |

Behind every Solar Cover rivet application is a judgment based on the environment, structural stresses, material properties and mounting method, Rivmate offers standard to customized PV-specific rivet solutions, technical recommendations and sample services for all types of cover structures.

Get Rivet Fasteners for Solar Cover Solutions from Solar Rivet Supplier

In solar energy systems, Solar Cover is an important component for electrical control, module protection and system sealing. The way it is fastened not only determines its structural strength, but also has a direct bearing on the system’s long-term corrosion and vibration resistance and operational stability. Through the systematic explanation in this article, you have already understood the key dimensions involved in choosing the right rivets for Solar Cover – from material suitability, waterproof structure, mechanical properties to construction efficiency, reasonable selection not only enhances the reliability of the system, but also effectively reduces the risk of operation and maintenance and maintenance costs.

As a supplier specializing in PV fastening system solutions, Rivmate has a mature Solar Cover rivet product series, covering tri-fold type, waterproof closed type, multi-grip structure type and other types of products. All of them have passed ISO and RoHS certification, and we can provide one-to-one customized selection service according to module structure and usage scenarios. We not only provide samples, drawings and test reports, but also support riveting tools and installation technical guidance to help customers improve project quality control and delivery efficiency.

📢 Come and meet our engineering team at the Rivmate booth!

We will be showcasing a new generation of rivet solutions for photovoltaics at the upcoming Fastener Expo. This includes customized products for Tracker systems, BIPV projects and automated assembly lines. On-site you will receive:

- Exclusive rivet sample packs

- Free structural selection advice

- Project case studies and technical drawings

Please contact us for a booth number or to schedule a networking appointment to explore more efficient and safer riveting solutions for Solar Cover.

Share:

What is the Difference Between Countersunk Rivets and Regular Rivets? – Rivmate Expert Guide

What is the Difference Be

What are Countersunk Blind Rivets Used for?

What are Countersunk Blin

Problem with Rivet Mandrel Breaking

Problem with Rivet Mandre

Rivet Corrosion: Causes, Prevention, and Engineering Solutions

Rivet Corrosion: Causes,