What is Self-Piercing Riveting?

Table of Contents

What is self-piercing riveting? As materials become increasingly diverse, traditional welding or bolt connections often fail to meet the demands for both lightweight and strength. Especially in applications involving aluminum alloys, high-strength steel, and multi-layer composite materials, issues such as heat affected zones, additional hole processing, and fatigue life have gradually exposed limitations. Companies began to seek more efficient and reliable alternative processes.

Self-Piercing Riveting (abbreviated as SPR) is precisely an innovative connection technology that conforms to this trend. It does not require pre-drilling or additional heating. Instead, it can complete the connection in a single pressurization process through specially designed rivets and molds. Nowadays, SPR has been widely applied in industries such as automobiles, aviation, and home appliances.

What is Self-Piercing Riveting?

Self-Piercing Riveting (abbreviated as SPR) is an advanced mechanical connection technique. Its most significant feature is that it does not require pre-drilling. The self piercing rivets are pressed directly into the material under high pressure, penetrating the upper layer of the material and expanding and deforming in the lower layer, thereby achieving reliable mechanical locking. The entire process does not rely on heat energy and does not cause the common heat-affected zone problems seen in welding, making it particularly suitable for the connection of aluminum alloys, high-strength steels, and multi-layer composite materials.

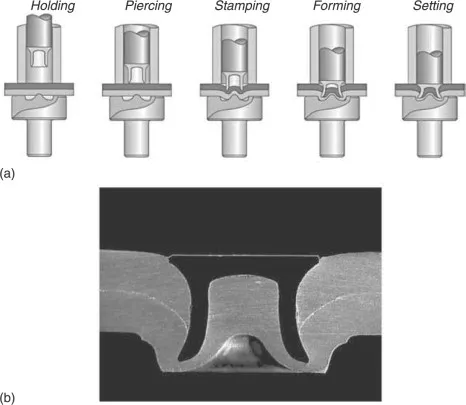

The principle of its process can be simplified into the following four steps:

- The rivets are pressed into the surface of the material under high pressure;

- They penetrate the upper layer of the material but do not penetrate the lower layer;

- They expand in the lower layer of the material, forming an anchoring deformation;

- A permanent connection is achieved, with excellent tensile and shear strength.

The following is the schematic diagram of the SPR process (example):

The key advantage of this process lies in its high efficiency and consistency. The installation cycle of a rivet is usually less than 1 second, making it suitable for automated production lines. According to automotive industry research data, the use of SPR can reduce the weight of the vehicle body by 5% – 10%, while maintaining or even enhancing the structural strength.

Advantages of SPR

Self-Piercing Riveting (SPR) has rapidly gained popularity in the automotive, aerospace and home appliance manufacturing industries, and is gradually replacing some traditional welding and bolt connection methods. Its advantages are not only reflected in efficiency and cost, but also in the significant improvement of material compatibility and product performance. Here are the six core advantages:

1. No Pre-Drilling Required

The traditional bolt or riveting process requires pre-drilling, which increases the number of steps and time. SPR, however, does not require pre-drilling. The rivets are directly pressed into the material under high pressure and the locking is completed.

- Fast production cycle: Installing a single SPR rivet typically takes less than one second;

- Reduction of equipment wear: Avoiding the wear of cutting tools caused by drilling;

- Less material waste: No scrapping due to errors in hole positions.

2. Material Flexibility

Welding usually requires that the materials have similar compositions and thicknesses; otherwise, cracks or joint failures are likely to occur. SPR has an advantage in this regard:

- Different Material Connection: Can easily connect combinations with high welding difficulty such as aluminum + steel, aluminum + magnesium, and aluminum + composite materials;

- Multi-layer Structure: Can achieve a firm connection of up to 3-4 layers of stacked materials;

- Support for Lightweighting Trend: The proportion of aluminum body panels is expected to exceed 30% by 2025 (source: IHS Markit), and SPR precisely meets this demand.

3. High Strength and Durability

The SPR connector has been precisely designed and possesses excellent mechanical properties:

- Shear resistance and peel resistance are higher than those of spot welding;

- Longer fatigue life: Under repeated loading conditions, the joint’s lifespan can be increased by 20% – 30%;

- Stronger corrosion resistance: Due to the absence of welding heat affected zone, the material coating remains intact.

4. Eco-Friendly Process

Compared with welding, SPR has more advantages in terms of energy consumption and environmental impact:

- No need for arcs or sparks, enhancing workshop safety;

- Energy saving: Energy consumption is approximately 30% lower than that of resistance spot welding;

- Reduced emissions: No welding smoke or ozone is produced, improving the working environment;

- Compliance with environmental protection: Compliant with EU RoHS and automotive industry sustainable development requirements.

5. Automation Ready

SPR is highly suitable for automated production lines:

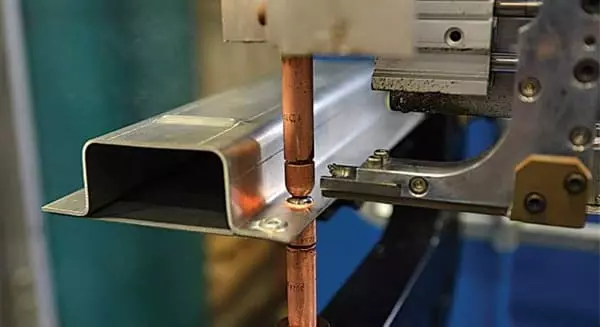

- Easy integration of robots: The riveting equipment can be installed on a six-axis robot to enable multi-angle operations;

- High consistency: The installation depth and expansion angle of each rivet are all controlled;

- High efficiency: In the body shop, one production line can install tens of thousands of SPR rivets, with efficiency not inferior to spot welding.

6. Aesthetic & Consistent Finish

The joint surface formed by SPR is smooth and free of heat marks, and has excellent appearance consistency:

- No need for secondary polishing: Eliminates the post-processing of solder joints;

- Surface coating remains intact, facilitating subsequent spraying or electrophoretic processes;

- Stable quality: Reduces appearance defects caused by variations in operators.

Limitations of SPR

Although self-piercing riveting (SPR) has advantages such as high efficiency, environmental friendliness, and compatibility with multiple materials, there are still certain limitations in practical applications, which require enterprises to make trade-offs when selecting types and planning processes.

High investment cost of the equipment

SPR requires specialized riveting equipment and dies. Compared with spot welding, the initial investment is higher, especially in vehicle assembly lines or large-scale production lines, where the equipment cost may amount to several million dollars. Although the operating cost is lower in the long run, the financial threshold is relatively high for small and medium-sized manufacturing enterprises.

Not suitable for super thick or high-hardness materials

SPR is more suitable for thin plates and medium-thickness materials (typically 0.5 – 4 mm). When the material is too thick or has a high hardness, the rivets may not fully expand, resulting in a decrease in connection strength. This limits its application in heavy machinery and thick plate structures.

Permanent connection, not easy to disassemble

Once an SPR joint is formed, it is a permanent mechanical lock. Compared with bolt connections, it cannot be easily disassembled or reassembled. If the product requires regular maintenance or replacement of parts, SPR is not the best choice. This is also an important factor that some manufacturers need to consider in the assessment of maintenance accessibility and life cycle cost.

Comparison with Other Joining Methods

In modern manufacturing, common joining methods include welding, traditional riveting and bolted connections. Self-piercing riveting (SPR), with its high efficiency, lightweight and environmental-friendly features, has demonstrated obvious advantages in certain applications. However, different processes have their own applicable scopes, and a comprehensive selection should be made based on material, structure and maintenance requirements.

Compared with Welding

- SPR does not require a heat source and does not produce a heat-affected zone (HAZ), thus maintaining better mechanical properties of the material.

- It can connect materials that are difficult to weld, such as aluminum alloys and high-strength steels.

- It is more suitable for parts with coatings or surface treatments as it does not damage the coating.

Compared with Conventional Riveting

- SPR does not require pre-drilling, offering a faster process and shorter production cycle.

- Locking can be achieved in a single stamping operation, reducing the number of procedures.

- It avoids the problem of material stress concentration caused by drilling.

Compared with Bolting

- SPR is lighter in weight, does not require nuts and washers, and is suitable for lightweight design.

- Installation is faster, eliminating the need for tightening and preload force detection steps.

- However, bolts are detachable, while SPR provides a permanent connection.

Comparison Table: Self-impacting Riveting vs. Welding vs. Bolt Connection vs. Traditional Rivets

| Characteristic / Process | Self-Piercing Riveting (SPR) | Welding | Bolted Joint | Conventional Riveting |

|---|---|---|---|---|

| Requires Pre-Drilled Hole | No | No | Yes | Yes |

| Requires Heat Source | No | Yes | No | No |

| Applicable Materials | Multiple (e.g., Aluminum + Steel, Composites) | Best with Similar Materials | Almost All Materials | Multiple Materials, but Drilling Required |

| Strength Performance | High Shear & Peel Strength | High, but May Decrease Due to HAZ | High (Depends on Bolt Grade) | Moderate |

| Serviceability | Permanent, Non-Removable | Permanent, Removal Requires Cutting | Removable, Reusable | Permanent |

| Weight Performance | Lightweight, No Nuts/Washers Needed | Relatively Light, Local Reinforcement at Weld | Heavier, Requires Additional Components | Heavier, Uses Solid Rivets |

| Production Efficiency | Very High, ~1 sec/point | High, but Process Dependent | Moderate, Torque Control Required | Moderate, Requires Drilling + Riveting |

| Environmental Performance | No Smoke/Sparks, Low Energy Consumption | High Energy Use, Smoke and Sparks Present | Neutral | Neutral |

Applications of SPR

Self-Piercing Riveting (SPR) has been widely adopted in various industries due to its efficiency, environmental friendliness and compatibility with multiple materials. Here are three typical application scenarios:

Automotive Industry

SPR plays a crucial role in the trend of automotive lightweighting. The combination of aluminum alloy and high-strength steel is the core for reducing the weight of the vehicle body, and SPR can achieve stable and reliable connections between different materials.

- Whole vehicle application: Brands such as Tesla, Jaguar Land Rover, and BMW have widely adopted SPR technology.

- Application areas: Lightweight components such as body frames, doors, engine covers, and luggage compartment covers.

- Industry data: According to the European Automobile Manufacturers Association (ACEA), using SPR technology can reduce the weight of the vehicle by 5% to 10%, while maintaining or improving crash safety.

Aerospace

In the aerospace field, the material combinations are more complex, often involving a multi-layer structure of composite materials + aluminum alloys + titanium alloys. SPR has provided a reliable solution for this.

- Advantage: Avoid thermal damage to the composite material caused by welding; maintain interlayer strength.

- Application scope: Lightweight structures such as fuselage skins, hatches, and wing panels.

- Industry trend: Manufacturers like Boeing and Airbus are gradually testing SPR to replace some traditional mechanical fasteners, reducing assembly time and maintenance costs.

Construction & Appliances

SPR is not only applicable to high-end manufacturing, but also has been adopted in the construction and home appliance industries.

- Construction Field: Used for rapid installation of steel plate roofs, curtain walls and metal frames. SPR can penetrate galvanized steel plates and coated plates while maintaining the anti-corrosion performance.

- Appliance Field: Widely applied in thin plate connections of products such as refrigerators, washing machines and air conditioners.

- Value Enhancement: Improves assembly efficiency, reduces coating damage caused by hot welding, and enhances appearance quality.

Self-tapping riveting is not only a key technology for automotive lightweighting, but is also expanding to various industries such as aerospace, construction, and home appliances. As the demand for different materials, high strength, and environmentally friendly processes continues to increase, the application scope of SPR will continue to expand.

Rivmate Expertise & SPR Solutions

As a professional supplier specializing in mechanical fastening technology, Rivmate has accumulated rich experience in self-tapping riveting (SPR) field. The company not only offers various specifications of SPR rivets, but also can customize overall solutions for customers, helping enterprises enhance production efficiency and product performance.

a. Varied Selection of Rivets

Rivmate supplies SPR rivets in various materials such as aluminum, stainless steel and high-strength steel. Different materials can meet various requirements including lightweighting, corrosion resistance and high strength, ensuring suitable options for industries such as automotive, aviation and home appliances.

b. Process Optimization and Automation Support

Rivmate is not only a supplier of rivets, but also offers process optimization suggestions. The engineering team can recommend the best riveting solution based on the material characteristics and product structure of the customers. At the same time, Rivmate supports automation line integration, helping customers quickly transition from experimental verification to mass production.

c. Strict Standards and Quality Assurance

All Rivmate SPR fasteners strictly adhere to international standards such as ISO, DIN, and IFI. They have undergone rigorous testing in terms of dimensional tolerance, mechanical properties, and durability, ensuring that each joint is reliable and consistent.

d. Customized Engineering Services

Rivmate offers a complete process support ranging from engineering selection to customized solutions. Customers can enjoy services such as material testing, sample verification, and connection strength assessment, ensuring the optimal match between the rivets and the process. This “one-stop” service significantly shortens the development cycle and reduces potential production risks.

FAQs on Self-Piercing Riveting, SPR

Q1: What is the main difference between self-tapping riveting and traditional riveting?

Traditional riveting usually requires pre-drilling, followed by inserting and securing solid or hollow rivets. Self-tapping riveting (SPR) does not require pre-drilling. The rivets penetrate the upper layer material under high pressure and expand to form in the lower layer. This means that the SPR process is faster and more efficient, while also reducing the weakening of the material caused by drilling.

Q2: Is SPR suitable for the combination of aluminum and steel, or steel and steel?

Yes. SPR is highly suitable for cross-material bonding, especially for the combination of aluminum and high-strength steel, which is a typical requirement for lightweight automotive bodies. At the same time, SPR is also applicable to steel + steel and aluminum + aluminum connections. Industry data shows that in aluminum + steel joints, SPR can maintain excellent shear strength and fatigue resistance, and is more consistent than welding.

Q3: Is SPR stronger than welding?

It depends on the specific application. SPR joints typically outperform spot welding in terms of peel strength and fatigue life, but in some thick plate welding scenarios, welding may be more suitable. The advantage of SPR lies in the absence of a heat-affected zone (HAZ), and the material properties are not damaged by heat. Therefore, it often performs better in the fields of aluminum alloys and composite materials.

Q4: Can the SPR process completely replace welding?

At present, SPR cannot fully replace welding. The reasons are as follows:

- For extremely thick or highly hard materials, SPR is difficult to achieve effective connection;

- In some structural components, welding still has cost and strength advantages;

- SPR is more suitable for the connection of lightweight car bodies, thin plates, and multi-layer heterogeneous materials.

Therefore, in actual manufacturing, multiple processes are often combined. For instance, in the manufacturing of car bodies, SPR is frequently used in conjunction with spot welding and bonding to balance strength, efficiency and cost.

Unlock the Future of Lightweight Manufacturing with SPR

Self-tapping riveting (SPR) has become an important trend in modern manufacturing. It does not require pre-drilling and does not rely on heat sources, enabling efficient connection of dissimilar materials such as aluminum alloys and steel. In the automotive, aerospace, construction, and home appliance industries, SPR is gradually replacing traditional welding and bolted connections. Its advantages lie in lightweighting, high strength, environmental friendliness, and compatibility with automation, bringing higher production efficiency and product value to enterprises.

If your enterprise is in search of a more reliable and efficient connection process, Rivmate can provide you with comprehensive support. From nail selection, process optimization to integration of automated production lines, our engineering team can tailor solutions specifically for you.

👉 Contact Rivmate immediately to obtain the SPR selection guide, or communicate directly with the engineering team to explore the self-tapping riveting solution that is most suitable for your product.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met