What is the Process of Self-Piercing Rivets?

Table of Contents

Traditional welding and conventional riveting have gradually shown limitations in the combination of aluminum, composite materials, and mixed materials such as aluminum and steel. At this point, more and more engineers have begun to pay attention to the process of self-piercing rivets. This technique can achieve efficient and reliable mechanical connections without the need for pre-drilling.

Self-Piercing Riveting (SPR) is an advanced connection technology. It uses specially designed rivets and high-pressure equipment to achieve rapid assembly without compromising the material’s properties. This article will provide a detailed analysis of the process flow, technical principle, and application value of SPR from a professional perspective, covering its use in industries such as automobiles, aviation, and construction.

Self-Piercing Rivets (SPR for short) is an advanced mechanical fastening method. It uses high pressure to directly press the rivet into the material. The tip of the rivet pierces through the upper layer of material and expands and locks in the lower layer of material, thus forming a strong mechanical connection.

The structure of self-piercing rivets mainly consists of three parts:

- Head: Fixed on the surface of the material, providing clamping force.

- Shank: Penetrates the material and transmits pressure.

- Hollow Tail: Expands in the lower layer of the material to achieve a locking effect.

Compared with traditional riveting or welding processes, SPR has significant features:

- Single-sided operation → Installation can be completed without touching the backside.

- No pre-drilling required → Save processes and improve production efficiency.

- No heat-affected zone (HAZ) → Avoid common metal property degradation or deformation in welding.

According to industry research, the application ratio of SPR in automotive lightweight manufacturing has exceeded 60%, especially in the dissimilar joining of aluminum alloys and steel. Its popularity stems from the demand for high strength, environmental friendliness, and high-efficiency assembly.

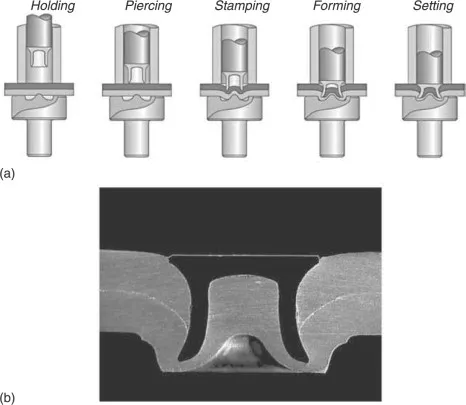

The Step-by-Step Process of SPR

Self-piercing riveting (SPR) is an efficient and reliable mechanical joining method. The entire process is divided into four key steps, each of which directly determines the quality and strength of the joint.

1) Preparation

- Correctly overlap and place the layers of the materials to be joined.

- Insert the SPR rivet into the press head of the riveting equipment.

- Ensure that the anvil is tightly in contact with the material to provide support for the subsequent forming process.

2) Positioning and Piercing the Upper Layer

The rivet pierces the upper layer of material under high pressure. Important note: The rivet does not completely penetrate the lower layer of material but maintains a certain thickness to prevent damage to the material’s integrity.

3) Expansion & Mechanical Interlock

Under the constraint of the lower die, the tail of the rivet gradually expands outward.

After the tail expands, it “hooks” onto the lower layer of material, forming a stable mechanical interlock.

This process determines the shear strength and fatigue resistance of the joint.

4) Completion and Locking

The head of the rivet remains on the surface of the material, exerting a surface clamping force. The tail of the rivet is fully locked inside the material. Eventually, a permanent connection is formed without the need for additional fasteners or welding processes.

Key Process Parameters of the SPR Process

The success of self-piercing riveting (SPR) is not only dependent on the performance of the equipment, but also on multiple key process parameters. If not properly controlled, it can easily lead to joint failure or material damage. The following four aspects are the most important:

a. Setting Force (Pressing Force)

- Insufficient pressure applied → The rivet fails to fully expand, causing the joint to loosen.

- Excessive pressure applied → The material may be crushed, especially for aluminum alloys or thin plate structures.

- Therefore, in production, it is necessary to conduct process tests to find the appropriate pressure range. Data shows that the appropriate pressing force can increase the joint strength by 15%-20%.

b. Anvil Design

The shape of the lower die directly determines the expansion method at the tail end.

Conical, slot-shaped or specially designed lower dies will affect the expansion angle of the rivet tail end and the joint’s bite quality.

A correct lower die design can enhance the shear strength of the joint and reduce stress concentration.

c. Material Compatibility

- SPR is particularly suitable for combinations of different materials, such as: aluminum + steel, galvanized steel + composite materials.

- Different material combinations require different design of rivets and setting of pressing force.

- In the automotive industry, the connection of aluminum + steel is a typical application of SPR, which can effectively reduce the weight of the entire vehicle while maintaining safety performance.

d. Rivet Design

The diameter, length and hollow depth of the nail body determine the expansion effect.

If the diameter is too small, the strength is insufficient; if the diameter is too large, the material is prone to damage.

Designing reasonable geometric parameters for the nail can ensure stable locking in multi-layer or high-strength materials.

| Feature | Self-Piercing Riveting (SPR) | Conventional Riveting | Welding |

|---|---|---|---|

| Pre-drilled Hole Required | No | Yes | No |

| Heat Source Required | No | No | Yes |

| Suitable for Dissimilar Materials | Yes | Limited | Poor |

| Installation Speed | Fast | Slow | Moderate |

| Surface Quality | Smooth | Average | Weld Spatter / Distortion |

| Automation Compatibility | High | Medium | High |

① Is pre-drilling required?

SPR does not require pre-drilling and eliminates the need for additional processes. Traditional riveting requires drilling holes, which makes the process quite complicated. Welding does not require drilling, but it may damage the surface coating.

② Is a heat source required?

SPR is a cold processing technique and does not require a heat source. Traditional riveting also does not require a heat source. Welding must rely on electricity or flames, which will create a heat affected zone (HAZ) and alter the properties of the metal.

③ The ability to be compatible with different materials

SPR is highly suitable for combinations such as aluminum + steel, galvanized steel + composite materials, etc.

Traditional riveting is limited in multi-material connections.

The welding performance on the connection with different materials is poor, and it is even impossible to achieve.

④ Installation Speed

SPR can complete locking in a single operation, and it is very fast.

Traditional riveting is slow because it requires drilling holes.

The welding speed is moderate, but it is highly dependent on the environment and the skills of the workers.

⑤ Appearance Quality

The SPR connection points are smooth and do not require additional grinding. Traditional riveting leaves behind the rivet heads and the appearance is usually unsightly. Welding is prone to slag and thermal deformation, and the post-processing procedures are complex.

⑥ Automation Compatibility

SPR is highly suitable for robots and automated production lines.

The traditional riveting process has a limited level of automation and relies heavily on manual operations.

Welding can be automated, but it has high energy consumption and poses significant safety risks.

Self-piercing riveting (SPR) as an advanced mechanical connection method has been widely adopted in industries such as automotive, aerospace, and construction. Its advantages are not only reflected in the simplification of the process, but also in multiple aspects such as strength, efficiency, and environmental protection.

1. No need for pre-drilling → Enhances production efficiency

- During installation, SPR does not require drilling, eliminating the need for additional processes.

- Compared with traditional riveting, the production cycle can be shortened by 20% to 30%.

- For large-scale assembly lines, this means higher production capacity and lower production costs.

2. High strength and durability → Excellent shear resistance and fatigue resistance properties

- The SPR forms a mechanical interlocking structure, capable of withstanding high shear loads.

- Under long-term vibration and impact conditions, the fatigue life of the joint is significantly better than that of spot welding.

- Industry research indicates that the fatigue life of the SPR joint is 15%-25% higher than that of traditional spot welding.

3. Suitable for different materials → Aluminum + Steel, Galvanized Steel + Composite Materials

- SPR can be easily connected with different material combinations.

- It is particularly suitable for aluminum + high-strength steel in automotive manufacturing, or aluminum + composite materials in aerospace.

- This feature solves the problems of low efficiency and unstable quality in welding connections between different materials.

4. Environmental protection and safety → No sparks, no smoke, low energy consumption

- SPR is a cold processing technique.

- It does not require an electric arc or flame, does not produce welding fumes, and does not damage the anti-corrosion coating.

- It has lower energy consumption and higher safety, aligning with the green manufacturing trend.

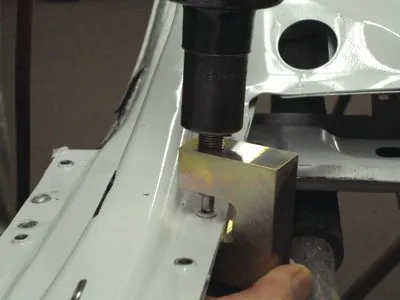

5. Automated production-friendly → Easy to integrate into robotic production lines

- SPR equipment can be seamlessly integrated with robots.

- In the manufacturing of car bodies, SPR has become the mainstream choice for robotized assembly.

- It has high consistency and can ensure the stability of mass production.

Limitations of the SPR Process

Although self-piercing riveting (SPR) performs exceptionally well in terms of lightweighting and connection between different materials, it is not a perfect process.

1. High initial equipment cost

- SPR requires a specialized press riveting machine (hydraulic or servo-driven).

- The equipment investment is much higher than that of traditional core pulling guns or welding equipment.

- For large-scale production enterprises, the investment can be offset by increased production capacity, but for small and medium-sized enterprises, the upfront cost pressure is relatively large.

2. Not suitable for extremely thick or highly hard materials

- SPR is suitable for sheet materials with a thickness ranging from 0.5mm to 3mm.

- If the material is too thick or too hard, the rivets may not be able to penetrate completely, resulting in poor connection.

- In such scenarios, traditional bolts or welding might be more appropriate.

3. Permanent connection (Not suitable for structures that need to be disassembled)

The joints formed by SPR are irreversible mechanical locking. Once installed, they cannot be easily disassembled or reused like bolts. If the product requires maintenance or frequent component replacement, SPR is not the best choice.

Applications of SPR in Industry

Self-piercing riveting (SPR) has been widely adopted in various industries due to its efficiency and material compatibility. Here are some typical cases:

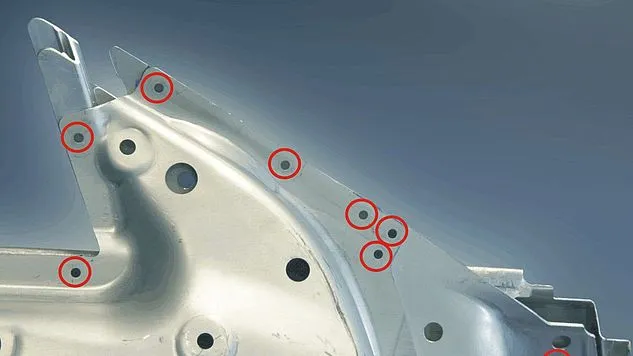

Automotive Industry

SPR is the most prominent application in automotive lightweighting. Car manufacturers such as Tesla, Jaguar Land Rover, and BMW extensively use SPR in aluminum body manufacturing. Research shows that over 70% of aluminum bodies in the European market are produced using the SPR process.

Advantages: Enhances vehicle rigidity, reduces weight, and complies with energy-saving and emission standards.

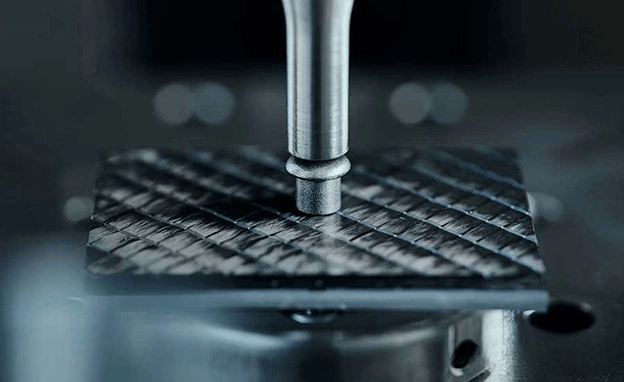

Aerospace Industry

In aircraft manufacturing, SPR is often used for the structural connection of aluminum alloys and composite materials. Compared to welding, SPR avoids the problem of heat affected zone and can maintain the original mechanical properties of the materials.

Advantages: Enhances structural reliability and extends service life.

Appliances & Construction

In the home appliance industry, SPR is used for assembling coated steel plates in refrigerators, washing machines, etc. In the construction industry, SPR is applied to curtain walls and lightweight frameworks.

Advantages: High connection strength, does not damage the anti-corrosion coating, enhances product durability.

Rivmate Expertise & Solutions

As a professional brand in the field of fasteners, Rivmate can provide customers with comprehensive self-piercing riveting (SPR) solutions. Our products and services cover the entire process from rivet selection to process validation, helping customers achieve efficient and reliable production.

Characteristics of Rivmate SPR Rivets

- Multiple material options available: Aluminum, stainless steel, carbon steel, suitable for various environments and strength requirements.

- Wide range of Grip Options: Compatible with thin plates, multi-layer plates and connections of different materials.

- Strictly compliant with standards: All products comply with the ISO 14589 and DIN 7337 international standards, ensuring consistency and reliability.

Support Provided by Rivmate

Process Evaluation and Testing: Based on the customer’s material combination and strength requirements, provide professional tests to ensure the best performance of the joints.

Automation Production Integration Support: Assist customers in seamlessly integrating SPR technology into robots or automated production lines.

Customized Solutions: Offer exclusive nail design and process optimization tailored for specific industries (such as automotive, aviation, construction).

FAQ

Q1: Is the self-piercing riveting process completely without any pre-treatment?

Answer: Basically, no pre-treatment is required. The SPR rivets can penetrate the upper layer material under high pressure. However, in some scenarios, it is still necessary to ensure that the material surface is clean and there is no excessive coating to guarantee the quality and long-term stability of the joint.

Q2: Can SPR replace welding?

Answer: In many scenarios involving lightweight and composite material connections, SPR has gradually replaced spot welding. For instance, in the combination of aluminum and steel, SPR performs better. However, in thick plates and heavy-load structures, welding still has its irreplaceable advantages. Therefore, whether it can be replaced needs to be determined based on specific applications.

Q3: Will the SPR process damage the galvanized coating?

Answer: SPR offers better protection for the galvanized layer compared to welding. Welding generates high temperatures, which can damage the anti-corrosion coating; while SPR is a cold processing method and does not cause a heat affected zone. However, at the punctured area of the rivet, the local coating may still suffer minor damage. Generally, this impact can be reduced by optimizing the design of the lower die or through subsequent protective treatments.

Q4: Does Rivmate offer a complete solution for SPR equipment?

Answer: Yes. Rivmate not only offers various specifications of SPR rivets, but also can recommend or assist in integrating compatible press riveting equipment according to customer requirements. We can also provide process debugging and training to ensure that customers can smoothly introduce the SPR process.

Self-piercing riveting (SPR) is an efficient, environmentally friendly, and suitable process for connecting different materials. Its core procedure is “penetration → expansion → locking”. With advantages such as no need for pre-drilling, high strength, suitability for different materials, and automation friendliness, SPR has become the mainstream choice in industries such as automotive, aviation, and construction.

Whether you are exploring lightweight solutions or looking for reliable methods for connecting different materials, Rivmate can provide you with complete SPR products and process support. We not only offer standardized rivets that comply with ISO 14589 / DIN 7337, but also provide process testing, equipment integration and customized solutions for your industry needs.

Contact Rivmate immediately to obtain the Self-Drilling Riveting Selection Guide, and choose the best solution for your project.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met