What Is Riveting in Metal Work?

Table of Contents

What makes riveting in metal work so compelling? Riveting, as a traditional and still widely used technique, has been employed in aviation, construction, automobiles, and manufacturing for over a century. In metal processing, the significance of riveting cannot be overlooked. Unlike the detachable nature of bolt connections or the need for high temperatures and complex processes in welding, riveting achieves a balance of strength, durability, and vibration resistance through the mechanical deformation of the rivets, which securely bond multiple pieces of metal together.

What is riveting? Why choose riveting instead of welding or bolts? Which type of rivets should be used in different scenarios? This article will gradually answer these questions. We will start with the definition and process principle of riveting, and deeply analyze different types of rivets and tools. We will compare the differences between riveting and other connection methods, and provide professional cases based on actual application scenarios. As a fastening component expert, Rivmate will offer you reliable material selection and tool recommendations.

What Is Riveting in Metal Work?

a. Definition

“Riveting in metal work” refers to the process of permanently joining two or more pieces of metal together using rivets. This is a classic mechanical fastening method that does not rely on threads or welding. It can provide a long-lasting and stable connection while maintaining the properties of the metal.

Riveting is achieved by the deformation of the rivets during the installation process to lock in place:

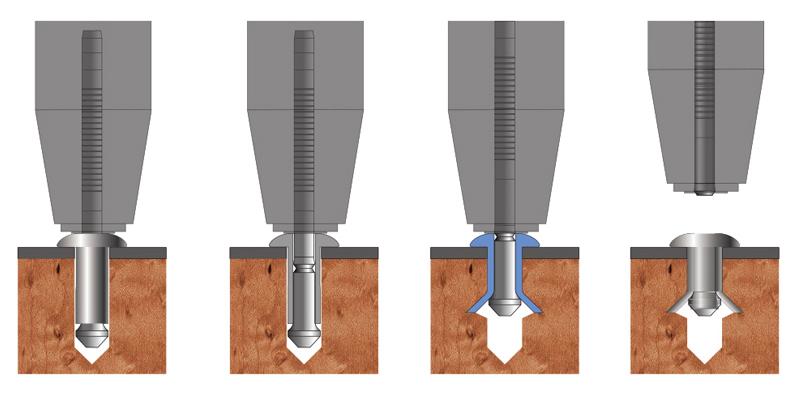

- Solid Rivets: By hammering or applying hydraulic pressure, the tail end of the rivet undergoes plastic deformation, thereby pressing the workpiece together.

- Blind Rivets: Using a mandrel to break, it forces the tail end of the rivet to expand and fix the workpiece. This method requires only a single operation and is highly suitable for enclosed or narrow spaces.

c. Characteristics

- Riveting is a type of permanent connection, which cannot be disassembled after installation.

- It does not require threads and is particularly suitable for thin plates or different types of metals.

- There is no heat-affected zone, and it does not alter the mechanical properties of the metal.

- It has good resistance to vibration and impact and is suitable for long-term load-bearing structures.

d. Standards and Specifications

In engineering applications, the riveting process must comply with international standards:

- ISO 15973: General requirements for blind rivets.

- ASTM F468/F468M: Specifies the material and performance requirements for metal rivets.

These standards ensure that the rivets meet the industry standards in terms of strength, durability and safety.

Riveting Process Explained

Riveting is a systematic process. Only by following the correct procedures can the strength and long-term reliability of the connection be ensured. The standard procedure is as follows:

Step 1: Measurement and Marking of Hole Positions

Precisely measure and mark the hole positions on the workpiece. It is recommended to use a scriber or a punch for positioning to prevent the drill bit from slipping. Accurate hole positions are the first step to ensure the quality of riveting.

Step 2: Drilling and Deburring

Drill holes according to the diameter of the rivets. The hole diameter should be larger by 0.1–0.2 mm than the diameter of the rivet body. After drilling, the burrs must be removed. If the hole opening is not smooth, the rivet cap will not fit tightly, ultimately leading to loosening.

Step 3: Inserting Rivets

Insert the rivet vertically into the hole. Ensure that the cap is flush against the surface of the workpiece. If there is any gap, you need to recheck the hole diameter or adjust the position of the workpiece.

Step 4: Use tools for shaping

- Blind rivets: Pull the core shaft with a riveting gun until it breaks, causing the tail to expand and lock the workpiece.

- Solid rivets: Apply force using a hammer or hydraulic equipment to cause plastic deformation in the tail, thereby fixing the workpiece.

During operation, ensure that the tool is perpendicular to the workpiece to avoid uneven force application.

Step 5: Check the Quality of Connectors

After the riveting is completed, conduct an inspection:

- The head of the rivet should be firmly attached to the surface without any looseness.

- The rivet expansion should be uniform and full, without any skewing.

- The surface of the workpiece must not have any cracks or deformations. If necessary, a sampling tensile test can be conducted to verify the riveting strength.

Types of Rivets in Metal Work

In metal processing, different types of rivets are used in various scenarios. They have distinct characteristics in terms of structure, installation method, and application scope. Here are some of the most common types:

Feature: Made entirely from a single metal rod, it has extremely high strength.

Application: Widely used in aviation, bridges and heavy machinery, for structures that need to withstand high loads and vibrations.

Advantages: The highest strength and reliability, making it the standard choice in the industrial and engineering fields.

Limitations: Installation requires bilateral operability and must be carried out using hammering or hydraulic equipment.

② Blind Rivets

Features: Fixed by core shaft breakage, supports single-sided operation.

Application: Suitable for scenarios where the backside is not accessible, such as in automotive manufacturing, home appliance assembly, and metal enclosures.

Advantages: Installation is quick, the process is simple, and the operation can be completed in a narrow space.

Limitation: The strength is slightly lower than that of solid rivets, and it is not suitable for critical load-bearing structures.

③ Semi-tubular Rivets

Feature: The rivet end is hollow, and it requires less force during installation.

Application: Commonly used in light industrial products, electronic equipment, and decorative items.

Advantages: Easy to install, reduces tool wear, suitable for medium and low-intensity requirements.

Limitations: The tensile and shear strengths are limited, and they are not suitable for high-load conditions.

④ Special Rivets

Closed-end Rivets: The tail end is sealed to prevent the penetration of liquids or gases. They are commonly used in air conditioning systems, ships and electronic equipment.

Sealed Rivets: Incorporate sealing rings to enhance corrosion resistance, suitable for outdoor and humid environments.

Multi-grip Rivets: One rivet covers different thickness ranges, reducing the risk of incorrect selection and suitable for maintenance or assembly of complex parts.

Riveting Tools Used in Metal Work

In metal processing, choosing the appropriate riveting tools is just as important as the rivets themselves. The correct tools can enhance efficiency, reduce operational errors, and ensure the quality of the connection. The common types of riveting tools include the following:

Features: Simple structure, easy operation.

Applicable scenarios: Small-scale DIY projects, repair tasks, or applications with low strength requirements.

Advantages: Low price, easy to carry.

Limitations: Low efficiency, difficult to handle thick metals or batch riveting, and prolonged operation can cause fatigue.

Features: Driven by compressed air or hydraulic system, it can continuously provide stable pulling force.

Applicable scenarios: Industrial mass production, such as automobile manufacturing and steel structure assembly.

Advantages: High efficiency, suitable for high-intensity and large-diameter rivets.

Limitations: Requires an external air source or hydraulic system. The initial investment and maintenance costs are relatively high.

③ Cordless Electric Rivet Gun

Features: Powered by batteries, balancing flexibility and portability.

Applicable scenarios: On-site installation and maintenance tasks, or situations with limited space.

Advantages: Easy to operate, fast speed, does not rely on air source, suitable for medium-sized riveting.

Limitations: The battery capacity limits the operating time, and the cost is higher than that of manual tools.

Rivmate Recommendation Tools

As a professional fastener brand, Rivmate offers compact electric riveting guns and industrial-grade blind riveting guns, which perform exceptionally well in practical applications:

- Compact electric gun: Lightweight and flexible, suitable for narrow spaces and on-site operations.

- Industrial-grade blind riveting gun: Highly efficient and durable, meeting requirements for mass production and high-strength applications.

Comparison Table: Why Riveting Instead of Welding or Bolting?

| Method | Advantages | Disadvantages | Typical Use Cases |

|---|---|---|---|

| Riveting | – Single-sided installation possible – No heat-affected zone – Reliable under vibration | – Permanent, not easily removed – Requires pre-drilled holes | Aircraft structures, automotive, bridges |

| Welding | – Very high strength – Seamless connection – No need for additional fasteners | – Requires skilled labor – Heat can alter metal properties – Not suitable for dissimilar metals | Heavy structures, pipelines, pressure vessels |

| Bolting | – Easy to install and remove – Adjustable and reusable – Wide availability | – Loosens under vibration – Requires access to both sides – Adds weight in large assemblies | Machinery, construction, temporary joints |

If the goal is to achieve a permanent, reliable and vibration-resistant metal connection, riveting is often the better choice. Welding is suitable for high-strength and thick plate structures, while bolts are more suitable for situations requiring disassembly.

Rivet connections are widely used in metal processing. Due to their high strength, strong reliability, and excellent vibration resistance, they remain a core connection method in multiple industries. Here are some typical applications:

Aeronautics and Astronautics

Riveting is a fundamental process in aircraft manufacturing. It is used for airframe skins, wings, and cabin structures. Aluminum rivets are widely used due to their lightweight and corrosion resistance. According to data from Boeing, a large passenger aircraft may require over 2 million rivets.

Automotive Industry

Riveting is commonly used in body structure, chassis and exhaust system. In lightweight vehicle design, aluminum rivets and high-strength blind rivets are widely employed. Their advantage is that they can maintain the connection even under vibration conditions, unlike bolts which are prone to loosening.

Architecture and Bridges

Used for assembly of steel structures and connection of load-bearing components. In large bridges, riveting can withstand high shear forces and long-term loads. Although modern buildings increasingly use high-strength bolts, riveting remains indispensable in the maintenance of some historical buildings.

Household Appliances and Electronics

It is applied to the assembly of metal casings, chassis, and brackets. Blind rivets are the preferred choice as they can be operated on one side and are suitable for enclosed shells. At the same time, they avoid the heat damage to electronic components that may be caused by welding.

DIY and Furniture

It is commonly used in metal frames, leather products and handicrafts. Manual riveting guns and small-sized rivets can meet the requirements. It is suitable for individual enthusiasts and small workshops, and is simple and easy to use.

FAQ

Q1: What is riveting in metal work and why is it used?

Riveting connection is a process that permanently fixes two or more pieces of metal together using bolts. Its advantages lie in reliable structure, resistance to vibration, and no need for heat treatment, and it does not alter the properties of the metal like welding does. Therefore, it is widely used in the fields of aviation, automobiles, and construction.

Q2: What are the main types of rivets in metal work?

Common types of rivets include:

- Solid Rivets: High in strength, suitable for load-bearing structures.

- Blind Rivets: Operated from one side, suitable for enclosed spaces.

- Semi-tubular Rivets: Require less installation force, suitable for light industry and decoration.

- Special Rivets: Such as closed-type, waterproof-type, and multi-clamping-range rivets, meeting specific requirements.

Not entirely. Welding generally offers higher strength, especially for thick metal structures. However, welding requires skilled techniques and may alter the metal properties. Riveting is more stable in vibrating environments, less likely to loosen, and is suitable for thin plates and different metals. Both should be chosen based on the actual application.

Q4: Can you remove and replace rivets in metal structures?

Yes, but it requires destructive removal. Usually, the head of the rivet is drilled off with a drill bit, and then the rivet body is pushed out. When replacing, a new rivet needs to be reinstalled. Therefore, riveting is regarded as a permanent connection method, unlike bolts which are easier to disassemble.

Find the Right Riveting Solution with Rivmate

Riveting in metal work is a reliable, permanent fastening method using different types of rivets and tools. Whether in aviation, construction, or automotive and household appliance manufacturing, riveting is widely used due to its reliability and vibration resistance properties.

Do you need to select the appropriate rivets and tools for your project?

Rivmate, as a professional fastener brand, offers a complete range of rivets and riveting tools, covering stainless steel, aluminum, steel, and various special materials. Our products have undergone rigorous testing and meet international standards, capable of meeting different requirements ranging from DIY to industrial production.

Please visit the Rivmate Technical Resource Center to obtain more application guidelines and technical materials. You can also directly Contact the Rivmate Expert Team to receive targeted selection advice and support.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met

How to Pop Rivet in Tight Spaces

How to Pop Rivet in Tight