Do Rivets Rust? Why Blind Rivets Rust and How to Prevent It?

Table of Contents

In the field of metal assembly, many users ask: Do rivets rust? Why do some rivets show signs of rust after a few years of use, while others remain stable for a long time? In fact, whether rivets rust depends on the material, structural form, and usage environment. This is also the issue that enterprises most often overlook when choosing fasteners. Especially in blind rivets, the residual mandrel in the structure can lead to “blind rivet corrosion”, causing potential problems such as water seepage and structural loosening. Therefore, understanding “why rivets rust” is the first step in choosing the right rivets and ensuring structural reliability.

Do Rivets Rust?

Whether rivets will rust or not depends entirely on the material and structural form. If you are concerned about rusting, you should give priority to choosing aluminum rivets, stainless steel rivets or steel rivets that have undergone anti-corrosion treatment, and avoid incorrect metal combinations.

- Steel rivets will rust.

If it is ordinary carbon steel without galvanizing, nickel plating or protective coating, it will corrode rapidly in a humid or outdoor environment. - Stainless steel rivets hardly ever rust.

The 304/316 material is self-protected by a chromium oxide film, which can resist corrosion for a long time and is suitable for coastal, high-humidity and industrial environments. - Aluminum rivets do not rust, but they will form an oxide layer.

Alumina is a stable protective film that does not spread or flake off like rust and is harmless to the structure. - Copper rivets do not rust, but their surface will change color.

It will develop a patina, which is a natural passivation process and does not affect its functionality. - Mixed metal rivets may cause electrochemical corrosion.

For example: Aluminum plate + steel core rivets → In a humid environment, the steel core is more prone to rust. If blind rivets are used and the mandrel remains, it will further accelerate corrosion.

Why Blind Rivets Rust?

Why do blind rivets rust? This is not caused by a single factor, but is the result of the combined influence of environment + material + structural design.

①. Environmental Factors

The working environment of blind rivets is often not ideal. Metals are most prone to oxidation in the following environments: high humidity (such as HVAC, kitchen equipment, condensation systems); salt spray environments (coastal areas, road de-icing salt, shipping containers); frequent rain exposure or outdoor exposure. Under these conditions, the exposed parts of carbon steel blind rivets will rust rapidly, which is why stainless steel or aluminum materials are often chosen for outdoor engineering.

②. The material itself is not corrosion-resistant.

Ordinary blind rivets made of low-carbon steel and with thin coatings or no anti-corrosion treatment are very prone to rust. In contrast:

Aluminum rivets → will not rust (form a protective oxide layer)

Stainless steel rivets → High corrosion resistance

Therefore, material is the first factor determining lifespan.

③. Galvanic Corrosion

This is the most easily overlooked problem with blind rivets. When the material of the rivet is different from that of the base material, a potential difference is formed. In a humid or salt-containing environment, electrochemical corrosion will occur.

- Aluminum plate + steel core rivets → The steel core rusts faster.

- Stainless steel rivets + galvanized steel plate → The galvanized coating wears out faster.

- Copper rivets + aluminum plate → The aluminum plate corrodes severely.

Rivmate Engineering Recommendation: Ensure that the rivets and the base material are at the same corrosion potential level, or use isolation washers / coatings.

④. Insufficient or Damaged Surface Coating

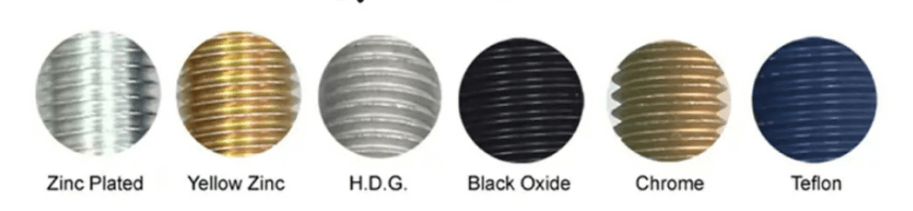

If the surface coating of blind rivets is uneven, too thin or scratched during transportation and installation, it can also lead to local rusting. Common coatings:

- Galvanized (most commonly used, 60–120 g/m²)

- Nickel-plated

- Anodized (for aluminum materials)

- Spray-coated finish

The damaged coating area = the first place to rust.

⑤. Open-end rivets have poor water resistance and are prone to moisture infiltration.

The tail of an open-end blind rivet is an open structure, which allows water vapor to enter the rivet through the core shaft breakage hole. Once the inner wall becomes damp, it is more prone to corrosion. If the core shaft remains, it will also accelerate oxidation. Therefore, open-end rivets are generally not recommended for use in damp environments such as exterior walls, roofs, and coastal areas.

⑥. Internal Corrosion Caused by Residual Core Shaft

In most cases, the mandrel of a blind rivet remains inside the rivet body. If the material is not corrosion-resistant or the environment is humid:

- Rust inside the mandrel

- Rust causes volume expansion

- May lead to loose connection or rust stains on the surface

Blind Rivets, with their fully enclosed bottom structure, can avoid this problem and are the preferred choice for waterproofing projects.

What metal is completely rust proof?

The truth is that no metal is completely rust-proof. All metals have the potential to rust under the right conditions.

However, certain metals are highly resistant to rust because of their chemical properties and special surface treatments. Common metals are stainless steel, aluminium and copper. Their resistance to rust, in descending order, is stainless steel > aluminium > copper.

a. Open-End blind rivets are the most prone to rust.

When the core shaft of an open-type blind rivet breaks, the tail end of the rivet will form a completely exposed opening. This structure allows water, moisture and salt fog to more easily enter the interior of the rivet, causing the core shaft to be immersed in a humid environment for a long time. The remaining steel core shaft begins to corrode inside, and rust will gradually seep out along the surface of the rivet, forming red rust or black spots.

Therefore, the Open-End rivets have the weakest corrosion resistance among all blind riveting structures and are not suitable for use in roofs, exterior walls, coastal areas, or high-humidity environments. They are more suitable for dry indoor settings and scenarios with low corrosion risks.

b. The closed-end blind rivets have the best waterproof and anti-corrosion properties.

The tail of the closed-type rivet is completely sealed, and after riveting, the core shaft is locked in the metal sealing cavity. This structure can completely prevent rainwater, condensate water and water vapor in the air from entering the interior of the rivet, avoiding corrosion of the core shaft and also preventing the occurrence of electrochemical reactions inside.

The Closed-End rivets can achieve an almost 100% sealing effect. They are one of the most reliable blind riveting solutions for roofing systems, curtain wall structures, outdoor equipment, and marine environments. Their durability is significantly superior to that of ordinary open-type rivets.

c. Sealed Rivets with EPDM Washer offer stronger protection performance

Some blind rivets used in outdoor or roof systems are equipped with EPDM waterproof gaskets on the rivet heads. These gaskets can absorb the gaps in the uneven surfaces of the panels, forming a secondary sealing layer to prevent rainwater and wind pressure from entering the holes. When used in conjunction with the Closed-End structure, the overall waterproofing performance can approach the IP67 standard, significantly enhancing the corrosion resistance of outdoor systems.

This type of rivets is often used as an alternative to roof self-drilling screws, or for key structures such as metal facades and photovoltaic supports, and it maintains a stable performance over a long period of time.

Which type of blind rivets is the least prone to rust?

Arranged from weakest to strongest in terms of waterproof and anti-corrosion capabilities, it is as follows:

- Open-type blind rivets (most prone to rust)

- Common blind rivets (medium corrosion resistance)

- Closed-type blind rivets (excellent corrosion prevention capability)

- Closed-type + EPDM gasket (best, outdoor-grade waterproof)

How to Remove Rust From Rivets?

In daily engineering use, want to remove the rust on the blind rivets, the current method is divided into two main categories: physical removal and chemical removal. Next I will explain in detail the various methods of removing rust.

Mechanical Removal

If there are not many rusted rivets, you can use some items with high friction, such as wire brushes, sandpaper, grinding wheels and other tools to scrub or sand the surface of the rivets to remove the rust. This method is suitable for light rusting situations.

Chemical Removal

Rust can be effectively removed from rivets using chemical solutions or rust removers. Common rust removers include acid solutions, acid cleaners, and acid sprays. When using chemical rust removers, follow product instructions and use them safely.

Electrolytic Rust Removal

Electrolytic rust removal is a method of removing rust through an electrochemical reaction. The rivet is used as the cathode and is immersed in an electrolyte with an anode (such as an iron plate), which causes the rust to come off the surface of the rivet by the action of an electric current. This method is suitable for more serious rust cases.

Anti Rust Coatings

After the rust has been removed, an anti-rust coating such as anti-rust paint, coating or coating can be applied in order to prevent re-rusting. These coatings provide protection against re-rusting of rivets. The cost of maintenance is reduced.

How to Prevent Rivets from Rusting?

In order to avoid losses due to the rusting of rivets, in practice, engineers use a variety of methods to prevent the rusting of rivets. Next, I will list the common rust prevention measures.

Choose Materials that Resist Rust

You’ve got to have a business that requires high levels of rust resistance, so when choosing raw materials at the outset, choose materials with good corrosion resistance, such as stainless steel (especially 316 stainless steel), galvanised steel, and so on. Rust-resistant materials can isolate a lot of rusting situations, and even if rusting occurs because of harsh environments, the process will be prolonged for a long time. These materials provide better resistance to rust and reduce the risk of rivets rusting.

Surface Treatment

To achieve a good anti-rust effect, in addition to selecting rust-resistant performance strength raw materials. You can also carry out surface treatment of rivets, such as galvanising, electroplating, spraying anti-rust coatings, etc., to form a layer of protection, isolate the contact of oxygen and moisture, reduce the possibility of rust.

Protective Measures

If you have a project that requires a particularly high level of rust prevention, in addition to the above two measures, you can also take additional protective measures on rivets that are exposed to humid environments. For example, use waterproof tape, waterproof paint, protective sleeves, etc., so that you can effectively isolate the rivets from contact with moisture.

Regular Maintenance

In addition to preparing in advance to prevent rust, it is also important to check the condition of the rivets regularly while the project is already in operation. Any signs of rust can be detected and dealt with in a timely manner. Cleaning the surface of the rivets of dust and dirt and avoiding the accumulation of moisture will help to prevent rust and corrosion.

Use the Right Sealing Material

In applications where sealing is required, ensure that the selection of a suitable sealing material is effective in preventing moisture from penetrating the contact surface around the rivet. For example, use closed rivets to complete the joints on your project.

FAQ: Rivet Rust & Waterproofing

Q1: Do rivets rust?

They are prone to rusting, particularly carbon steel rivets which are most susceptible to corrosion in damp or salt spray environments.

Q2: Do aluminum rivets rust?

It does not rust, but forms a harmless oxide film that actually protects the material.

Q3: Do stainless steel rivets rust?

Generally not, but slight corrosion may still occur under conditions of high salt spray or galvanic corrosion.

Q4: Do pop rivets leak?

Open-ended rivets may leak, whereas closed-ended rivets or those fitted with EPDM gaskets provide complete waterproofing.

Rivmate Expert Recommendations: How to Choose Rivets That Won’t Rust

Outdoor / High Corrosion Environment: Select Stainless Steel Closed-End Rivets

The outdoor environment has high humidity and is constantly exposed to rain and oxygen. Carbon steel rivets will rust rapidly, while stainless steel materials offer excellent corrosion resistance. The closed structure can also prevent water vapor from entering the interior, making it suitable for HVAC, outdoor cabinets, and facility supports.

Metal Roofing: Aluminum Rivets with EPDM Washer

The roof is exposed to wind, rain and temperature changes for a long time, thus having a high risk of water leakage. Aluminum has good corrosion resistance, and the EPDM gasket can achieve reliable sealing to prevent water leakage from the roof. It is a standard configuration in the metal roof industry.

Coastal Equipment: Select All-Stainless Rivets

The salt spray concentration near the seaside is very high, which is extremely corrosive to metals. Only Full SS Rivets, whose cap body and core shaft are both made of stainless steel, can ensure long-term durability and prevent failure due to galvanic corrosion or internal water accumulation.

General Interior Assembly: Select Aluminum Blind Rivets

The indoor humidity is low and there is no salt fog corrosion. The aluminum rivets are lightweight, cost-effective, and easy to install. They are the best choice for home appliances, furniture, and sheet metal assembly, offering both cost-effectiveness and stable performance.

Get Your Corrosion-Resistant Rivet Solution Today

If your project involves outdoor conditions, high humidity, salt spray, long-term vibration or high-intensity working conditions, then choosing the right anti-corrosion rivets is of utmost importance. The Rivmate engineering team can provide you with fast, professional and practical fastening solution support, including:

- Free sample delivery (including various specifications such as stainless steel, aluminum, closed type, waterproof type, etc.)

- Free evaluation of anti-corrosion options: Provide material suggestions based on environmental grades (indoor / outdoor / seaside / chemical)

- Recommendations for board thickness / materials / clamping range matching to ensure reliable connection

- OEM brand packaging and long-term stable supply capability, supporting cross-regional delivery

If you are looking for a truly rust-proof solution for rivets, please feel free to contact Rivmate for professional technical support and quotations.

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met