Table of Contents

Self piercing rivets are by far the best solution for lightweighting industrial sheet products. This blog will introduce you to the advantages and disadvantages of self piercing rivets.

Through this article you will learn the definition of self piercing rivets, how it works and why you should buy sprits from the manufacturer.

Table of Contents

What is Self Piercing Rivets?

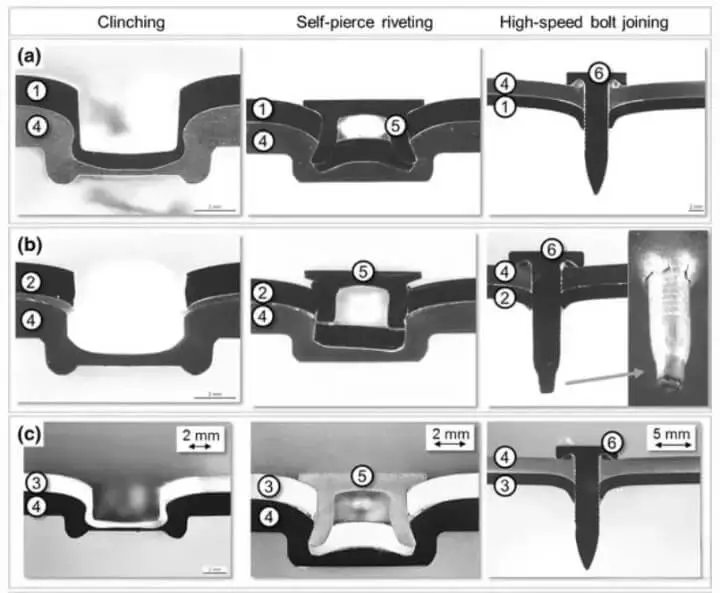

Self-Piercing Riveting (SPR) is a cold joining technology that does not require pre-opening holes. In recent years it has gradually become one of the core processes to replace traditional welding. Its core principle is to drive special rivets to penetrate the upper layer of material through pressure and form a mechanical interlocking structure in the lower layer of substrate, ultimately forming a high-strength, low deformation rigid joint.

How do Self Piercing Rivets Work?

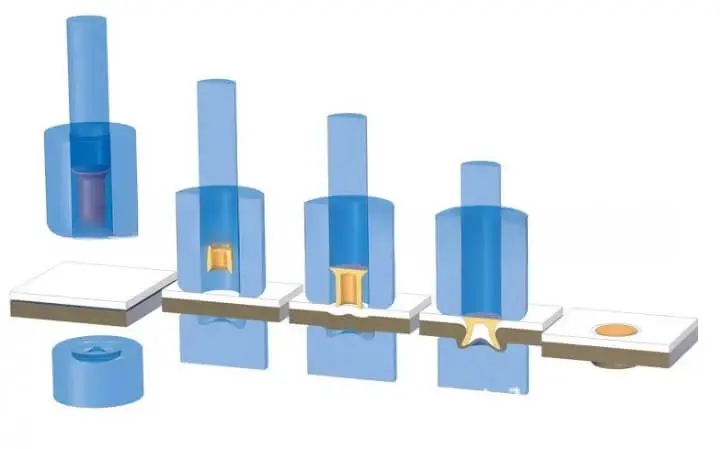

Mechanism of formation of mechanical interlocks

The geometry of a self-pierce rivet is precision designed (usually semi-hollow or solid axisymmetric). Under the synergistic action of the punch and the die, the tail of the spr rivet pierces the upper sheet (e.g., aluminum alloy) while the lower material (e.g., steel plate) flows plastically under the constraints of the die’s grooves, wrapping around the rivet to form a button-like latch (see Figure). The key to this cold deformation process lies in the precise control of the relationship between the geometric parameters of the mold, the hardness of the rivet, and the stamping force. For example, in the case of a hybrid aluminum-steel joint, the rivet hardness needs to be set lower than that of the steel plate but higher than that of the aluminum plate to avoid delamination or rupture of the plate.

Thermodynamic advantages of cold forming

In contrast to conventional welding (e.g. spot welding), SPR is performed at room temperature, with no heat input resulting in phase change of the metal or heat affected zone (HAZ). For example, in the manufacture of aluminum alloy bodies, spot welding can cause the material to melt partially, destroying the anodic oxide layer, whereas SPR preserves the surface coating of the material (e.g., corrosion-resistant plating on the body) intact. The installation of self piercing rivets avoids welding fumes and spatters and complies with the European Union’s ELV regulations on lead, cadmium and other hazardous substances.

Do You Have Any Questions?

Let Us Solve Your Problem

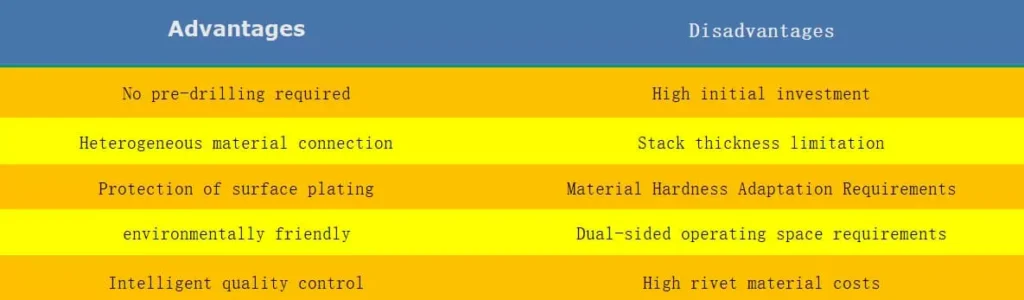

Advantages of Self Piercing Rivets

In automotive manufacturing, spr technology has replaced most welding. This is because spr has many advantages that welding does not have.

1. Efficient process without pre-holing

The SPR is joined by customized rivets (semi-hollow or solid) that penetrate directly into the upper sheet, in parallel with the cold forming process.

Compared to conventional spot welding, self piercing rivets reduce the process flow (pre-treatment + welding + post-treatment) by 30%. Tesla’s Shanghai factory uses Böllhoff SPR equipment (model Rivtec), which allows for single-point joining times of 0.75 seconds (production line data source: Tesla 2023 Sustainability Report).

Case: In BYD Seal model, SPR replaces 60% of welded joints, and the efficiency of the body production line is increased by 18% (Source: Paper for the 2023 Annual Conference of the Chinese Society of Automotive Engineering).

2. Reliable joining of heterogeneous materials

Self piercing rivets have a very high mechanical interlocking strength. For example, the shear strength of aluminum-steel joints from spr can reach 6-10 kN (compared to 2-4 kN for conventional bonding) (experimental data: MDPI Materials 2021).

In the Azera ET5 carbon fiber rear floor and aluminum frame, Azera Motors Manufacturing uses SPR+ structural adhesive, which improves torsional stiffness by 25% (Ref: Azera ET5 Technical White Paper).

3. Surface coating protection capability

Self piercing rivets damage the coating of galvanized steel sheets by only 2-3 mm² (whereas spot welding causes 15-20 mm² damage).

Beyond this, the corrosion protection value of SELF PIERCING RIVETS is very high. The Audi e-tron battery pack housing (made of aluminum) is an example of an SPR connection, and as a result it has an extended salt spray test life of 2,000 hours (compared to 1,200 hours for conventional welding solutions).

4. Environmental characteristics

According to the DTechEx Lightweighting Report, SPR consumes approximately 0.05kWh of energy for a single-point installation (resistance welding requires 0.15kWh), with a 66% reduction in carbon.

And SPR is fully compliant with the German Blue Angel environmental certification (RAL-UZ 205), which emits <5mg/m³ of VOCs (measured data from the plant).

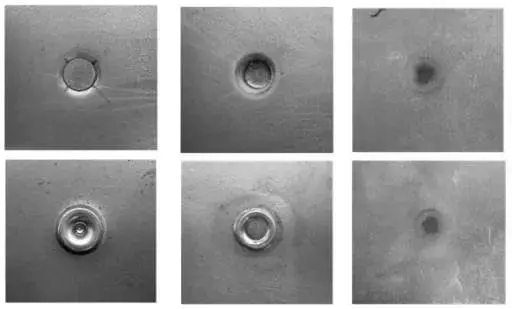

5. Online quality monitoring

With advances in science, some automotive manufacturers have been able to capture 10kHz stamping force profiles in real time with piezoelectric force sensors (accuracy ±1.5% FS). This technology can detect spr rivet breakage (>15% drop in peak force) or failure to penetrate (>10% increase in peak force) anomalies.

Disadvantages of Self Piercing Rivets

Of course, no technology is perfect. There are advantages and disadvantages.

1. High initial investment

The equipment costs for installing SPR Rivets are very high. A fully automated SPR workstation (with robot, mold bank) is about 800-1.2 million euros (source: Böllhoff quotation 2023), which is 3-4 times more than spot welding equipment (about 250,000 euros).

The introduction of 6 SPR machines at the Zhaoqing plant of China’s Xiaopeng Automobile 2022, with a total investment of more than 50 million yuan, will require a payback period of 4.2 years.

2. Stack thickness limitations

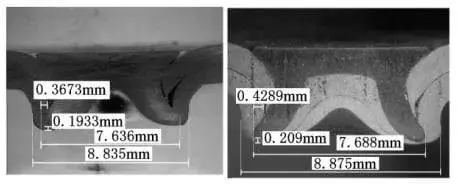

The use of Self piercing rivets has certain requirements on the thickness of the riveted joint. If the thickness of the stack is too thick, it may lead to riveting failure. Usually the total thickness of the aluminum-steel combination ≤ 6mm, of which the aluminum plate ≤ 3mm, steel plate ≤ 2.5mm (more than easy to lead to incomplete locking, see the figure of the failure of the sample).

A Korean Hyundai model had a 60% drop in fatigue life of the SPR joint due to an over-thickness (3.2mm) of the lower steel plate.

3. Harsh material hardness matching

When riveting with Self piercing rivets, a mismatch between the hardness of the upper and lower layers of material and the hardness of the spr can easily lead to rivet failure.

The hardness gradient rule is as follows:

Lower material hardness ≥ 1.2 x rivet hardness ≥ 1.5 x upper material hardness

Rivtec HB62 rivets (450HV hardness) are suitable for joining AA6061 aluminum alloy (95HB hardness) to DP600 steel (180HB hardness), but have less than 70% lock formation for AA7075 (150HB hardness).

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

The core value of SPR technology is applicable to lightweight, multi-material and high corrosion resistance requirements (e.g. new energy vehicles, aviation).

- Recommended scenarios: mixed-material car body, battery pack shell, aviation interior parts.

- Scenarios not applicable for the time being: large-thickness joints (>6mm), closed-cavity structures (e.g. C-pillar panels), and production lines with ultra-low cost requirements.

Why Buy SPR Rivets from Rivmate Rivet?

Self piercing rivets must always be purchased from a reliable manufacturer or supplier. Since spr rivets are used in so many scenarios in automobiles, the quality of self piercing rivets is a matter of safety of people’s lives and properties.Rivmate rivets is a quality supplier that offers a full range of spr rivets solutions.

Rivmate rivets offers high quality riveting solutions at a much cheaper price than its competitors. In addition, the company has over a decade of experience in providing high quality Self piercing rivets solutions.

Rivmate rivets is also the first rivet factory in China to fully produce self piercing rivets, providing customers with rivet quality that far exceeds international standards.

Ready to buy from Rivmate Rivets? Contact us today.