Wholesale Aluminum Blind Rivets from Factory

Purchasing high-quality Aluminum Blind Rivets directly from a professional blind rivet supplier offers multiple tangible benefits for your business, particularly for long-term projects and bulk procurement needs.

- More Competitive Pricing: Factory-direct sourcing eliminates intermediaries, significantly reducing per-unit costs.

- Greater Customization Options: Tailor specifications, head types, and packaging to application requirements for precise project alignment.

- Support for Large-Volume Orders: Stable production capacity accommodates sustained or one-time bulk procurement.

- Comprehensive After-Sales Support: Quality traceability and direct issue resolution minimize procurement risks.

- Long-Term Partnership Potential: Consistent supply and technical assistance foster sustainable collaborative relationships.

For enterprises prioritizing cost control, supply stability, and engineering support, sourcing aluminum pop rivets directly from the source supplier represents a more efficient and reliable choice.

Types of Aluminum Blind Rivets

Based on varying structural designs and application requirements, the market offers multiple types of aluminum pop rivets to meet diverse demands for strength, appearance, and material combinations. By appropriately selecting the rivet type, diameter, and clamping range, a suitable aluminum pop rivet solution can be found for nearly all light-duty to medium-duty applications.

Aluminum Open Type Blind Rivets

Aluminum Sealed Type Blind Rivets

Aluminum Multi-grip Blind Rivets

All Aluminum Tri Fold Rivets

Aluminum Bulb Tite Rivet

Aluminum Interlock Rivet

Aluminum Monobolt Rivet

Aluminum Hemlok Rivet

Aluminum Grooved Type Blind Rivet

Aluminum Q-Lock Blind Rivet

Aluminum Speed Rivet(BRV Series)

Aluminum Speed Rivet(CBT Series)

Rivmate – The Top Aluminum Blind Rivets Manufacturer in China

Purchase Aluminum Blind Rivets that meet your project specifications directly from a professional Pop Rivet manufacturer. This approach significantly streamlines the procurement process while reducing selection and delivery risks. You can clearly communicate your application requirements, ensuring the products you receive perfectly match your project specifications in terms of dimensions, performance, and assembly results.

We offer a one-stop procurement service, handling everything from rivet selection and specification confirmation to bulk supply and technical support within a single supply chain. This model effectively reduces communication overhead, shortens lead times, and eliminates uncertainties associated with coordinating multiple suppliers.

Through centralized procurement and expert support, you’ll save substantial time and overall costs. If you’re seeking a reliable, convenient, and long-term solution for aluminum blind rivets, contact us today to begin efficient procurement.

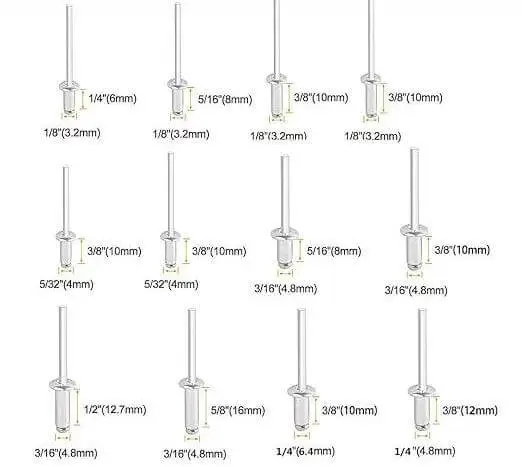

Aluminum Blind Rivets Sizes

Rivmate can provide you with all sizes of rivets on the market. Whether it’s a universal standard or a US standard aluminum rivet.

- 3/32″(2.4mm)

- 7/61″(3.0mm)

- 1/8″(3.2mm)

- 5/32″(4.0mm)

- 3/16″(4.8mm)

- 6/31″(5.0mm)

- 15/64″(6.0mm)

- 1/4″(6.4mm)

Material Combinations for Aluminum Blind Rivets

Aluminum / Carbon Steel

This is one of the most common combinations. The aluminum body offers lightweight properties and excellent corrosion resistance, while the carbon steel mandrel provides sufficient tensile strength to ensure stable back forming. Suitable for light to medium-duty applications, it strikes a good balance between cost and performance.

Aluminum / Aluminum

A fully aluminum construction, offering the lightest weight and superior corrosion resistance. Suitable for scenarios where strength requirements are low but rust resistance and weight are critical, such as thin sheet metal, decorative components, and general consumer products.

Aluminum / Stainless Steel (Aluminum Rivet Body / Stainless Steel Mandrel)

Retains the lightweight advantage of the aluminum rivet body while the stainless steel mandrel provides higher riveting strength and superior corrosion resistance.

Aluminum / Steel (Aluminum Rivet Body / Steel Mandrel)

Similar to carbon steel mandrels but offers varying strength levels based on specific steel grades. Ideal for assemblies requiring higher forming force or more stable backing structures.

Types of Aluminum Blind Rivets Head

Rivmate offers common aluminum blind rivet head styles available on the market to accommodate diverse assembly requirements and aesthetic specifications. Selecting the appropriate head style achieves a balance between joint strength, material protection, and visual appearance.

- Dome Head: Highly versatile with stable installation, suitable for most standard assembly and structural joining applications.

- Countersunk Head: Flush with the surface after installation, ideal for projects requiring flatness and visual consistency.

- Large Flange Head: Provides a larger load-bearing surface, effectively protecting thin sheets or soft materials, suitable for brittle or low-strength substrates.

If your project has special or non-standard requirements for rivet head types, please send us your specific needs. Rivmate supports customized solutions to help you obtain aluminum blind rivets that better match your actual working conditions.

Surface Treatment of Aluminum Blind Rivets

Aluminum Blind Rivets can be enhanced through various surface treatment processes to improve corrosion resistance, aesthetic quality, and suitability for specific application environments. Different treatments vary in protective efficacy and application focus.

- Anodizing: Forms a dense oxide layer on aluminum surfaces, significantly improving corrosion resistance while enabling diverse color effects. Ideal for applications demanding both aesthetics and durability.

- Electroplating: Enhances surface protection through metallic coatings while improving appearance. Commonly used in environments requiring additional safeguards.

- Chemical Conversion Coating / Chromate Conversion: Provides fundamental corrosion protection and improves paint adhesion, widely used in industrial assembly.

- Coating: Enhances environmental resistance through spraying or film application, meeting color or functional requirements.

- Polishing: Improves surface finish and visual appeal, suitable for decorative or appearance-critical applications.

- Sandblasting / Bead Blasting: Creates a uniform matte surface, enhances coating adhesion, and improves appearance consistency.

- Cleaning and Passivation: Removes surface contaminants, forms a protective film, and enhances basic corrosion resistance, suitable for general-purpose applications.

What Are Aluminum Blind Rivets Used for?

Aluminum Blind Rivets for Boats

Ships use stainless steel blind rivets and aluminum blind rivets because they are always in a marine environment. Aluminum blind rivets are often used to secure aluminum decks and bulkheads in the construction of small yachts and boats. It ensures a durable structure and does not add weight to the boat.

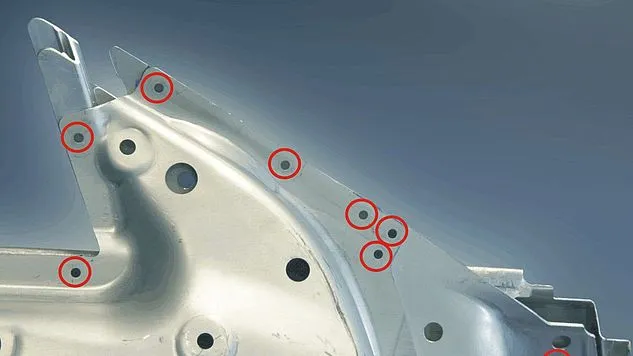

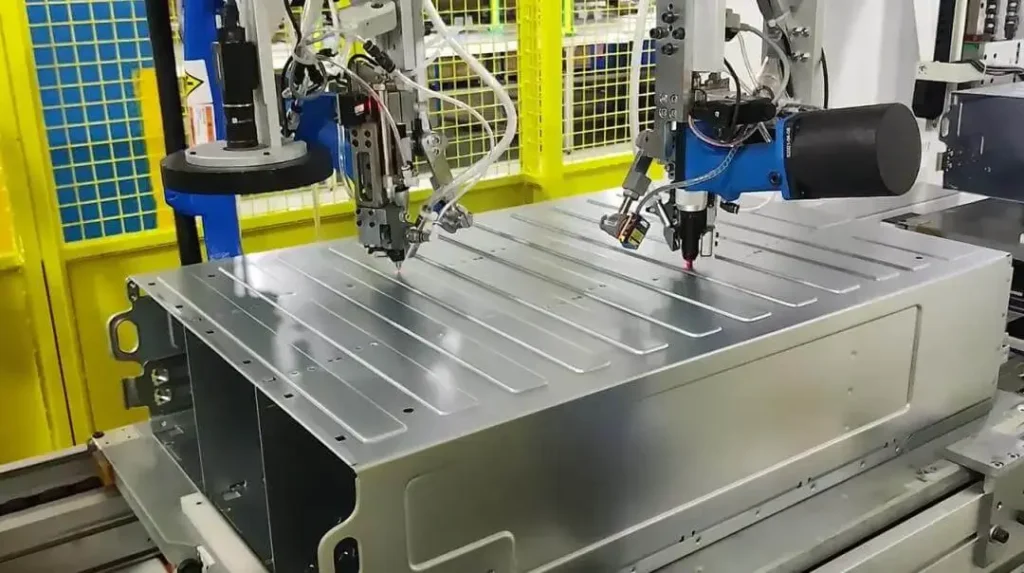

Aluminum Blind Rivets for Car

Aluminum blind rivets are importantly very light. This is perfectly in line with the lightweight requirements in automobile manufacturing. So aluminum pop rivets are used a lot in automobiles. Aluminum pop rivets are often used to secure aluminum body panels to support brackets, including automotive body panels, doors, dashboards and interior components.

Aluminum Blind Rivets for Constructions

In the field of building construction, blind rivets are often used to join curtain walls, window frames, roofing materials and external decorative panels.

Aluminum pop rivets are widely used to secure aluminum panels to metal frames during curtain wall installations in high-rise buildings. It provides an attractive appearance and good weather resistance.

Aluminum Blind Rivets for Furniture Manufacturing

Aluminum pop rivets are often used for metal framed furniture, outdoor furniture fixing and assembly.

In the production of aluminum garden furniture, aluminum pop rivets are often used to fix metal frames for seats and tables. Aluminum pop rivets ensure that the furniture is both durable and very lightweight.

Aluminum Blind Rivets for Home Appliance Manufacturing

Some household appliances come into contact with water on a regular basis, so they are susceptible to corrosion. Therefore these household appliances will choose to use aluminum pop rivets to hold the components in place.

For example, metal brackets for washing machines, refrigerators and air conditioners use aluminum pop rivets to ensure structural stability. This effectively prevents rust and corrosion.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

What Are the Tensile Strength and Shear Strengths of Aluminum Blind Rivets?

The tensile and shear strengths affecting aluminum pop rivets depend on the size of the rivet. Below are typical tensile and shear strength ranges for some common sizes of aluminum pop rivets:

| Rivet Diameter | Tensile Strength | Shear Strength |

| 3/32″ (2.4mm) | 200-250 N (45-56 lbf) | 150-200 N (34-45 lbf) |

| 1/8″ (3.2mm) | 400-500 N (90-112 lbf) | 300-400 N (68-90 lbf) |

| 5/32″ (4.0mm) | 600-700 N (135-157 lbf) | 500-600 N (112-135 lbf) |

| 3/16″ (4.8mm) | 1000-1200 N (225-270 lbf) | 800-1000 N (180-225 lbf) |

| 1/4″ (6.4mm) | 1500-1700 N (337-382 lbf) | 1200-1500 N (270-337 lbf) |

In general, the tensile and shear strengths of aluminum blind rivets are suitable for medium strength applications and are not suitable for structural connections with extremely high strength requirements. If specific tensile and shear strength data is required, you can contact our engineers!

Can Aluminum Blind Rivets Withstand High Temperatures?

Aluminum pop rivets have very limited performance in high temperature environments. Aluminum materials lose some of their strength at high temperatures, resulting in a reduction in their load-bearing capacity.

Aluminum pop rivets are suitable for use in environments with temperatures ranging from -50 degrees Celsius to 120 degrees Celsius. Within this range, aluminum pop rivets maintain their mechanical properties and stability.

When the temperature exceeds 150 degrees Celsius, the strength of aluminum begins to decrease significantly. When temperatures exceed 200 degrees Celsius, the strength of aluminum pop rivets decreases significantly, which can affect the reliability of the connection.

What is the Corrosion Resistance of Aluminum Blind Rivets?

During use, a dense film of aluminum oxide forms on the surface of the aluminum. This allows aluminum pop rivets to exhibit good corrosion resistance. This aluminum oxide film is very resistant to water, air and oxygen.

Generally, the corrosion resistance of aluminum pop rivets performs well in freshwater environments. However, if exposed to the marine environment for a long period of time, pitting corrosion may occur.

Can Aluminum Blind Rivets Withstand Shock Loads?

Compared to stainless steel blind rivets and carbon steel blind rivets, aluminum blind rivets are less able to cope with impact loads. Aluminum’s flexibility and low density allow it to perform well at moderate strengths and dynamic loads, but the limitations of aluminum may become apparent when faced with higher impact loads.

Under high impact loads, aluminum pop rivets may deform, fatigue or even fracture. So in structural connections or heavy equipment, stainless steel blind rivets or carbon steel blind rivets are recommended. This ensures a reliable and durable connection.

Do Manufacturers of Aluminum Pop Rivets Offer Technical Support?

Sure. As a top pop rivet manufacturer, Rivmate will provide full technical support for customers. This includes customized rivet solutions, providing professional installation tools and installation guides. We will also provide perfect after-sales service if there is any problem with the product.

Can Aluminum Blind Rivets be Used with Other Metal Materials?

Blind Rivets can be riveted to many different materials. However, in some cases, it is important to be aware of the risk of galvanic corrosion of aluminum materials. In wet or corrosive environments, where aluminum is in contact with other metals, an electrochemical reaction may occur, resulting in accelerated corrosion of the aluminum material.

Common material pairings include the following:

- Aluminum & Stainless Steel

- Aluminum & Steel

- Aluminum & Copper

- Aluminum & Galvanized Steel

In humid environments, aluminum and stainless steel combinations, aluminum and steel combinations and aluminum and copper combinations are likely to corrode. That’s why gaskets or coatings are needed to solve this problem.

Can the Head of an Aluminum Pop Rivet Rust?

Aluminum pop rivets have very good corrosion resistance due to the presence of aluminum oxide.

Under normal use, the heads of aluminum pop rivets will not rust, but oxidation may occur. This is a natural protective phenomenon that enhances the corrosion resistance of the rivet. In most environments, aluminum rivets perform well and maintain their functionality and appearance over time. If the application is in a harsh corrosive environment, consider using aluminum rivets that have been anodized or other surface treatments.

If you want an in-depth look at do rivets rust, read this article now !

Are Aluminum Blind Rivets Suitable for High Conductivity Applications?

Aluminum has good electrical and thermal conductivity. Therefore, aluminum pop rivets are ideal for use in highly conductive applications.

The electrical conductivity of aluminum is about 60% of that of copper. For this reason, aluminum pop rivets are generally the first choice in lightweight designs.

Aluminum has a relatively high thermal conductivity of approximately 237 W/m-K. Therefore, aluminum pop rivets can be used in structures that require thermal management to help dissipate heat.

Are Aluminum Blind Rivets Environmentally Friendly?

Aluminum pop rivets are friendly to the environment. Aluminum pop rivets are the number one choice for projects where the environment is a concern. They offer the advantages of high recyclability, lower environmental impact of production, durability and lightweight design. Aluminum rivets are considered an environmentally friendly fastener in many applications as they help reduce resource consumption and waste generation during use.

What Are the Quality Certifications for Aluminum Pop Rivets?

Rivmate’s aluminum pop rivets follow ISO, DIN7337, IFI114, HUCK and Avdel standards. You can purchase high quality rivets that meet your project requirements.

Why Wholesale Aluminum Pop Rivets from Factory?

I’m sure you know many of the benefits of buying aluminum blind rivets directly from the factory. But usually the factories have a requirement of starting order quantity, which is usually 50000pcs to start ordering.

Here are the benefits of wholesale aluminum pop rivets from factory:

- Lower purchasing cost

- Stronger customized production capacity

- Strict product quality inspection

- Long-term and stable cooperation relationship

- Getting professional technical support and advice

If your project requires a large quantity of high quality blind rivets, then contact us! Get samples for testing now!

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!