Table of Contents

Wood is a special material. It is a soft material and its surface tears easily.ButBut as long asBut by choosingBut by choosingBut by choosing the rightBut as long as you choose the right popBut by choosing the rightBut by choosing the right blind But this can be avoided by choosing the right blend rivets for wood. In this comprehensive guide, we will take you through all the key aspects of choosing blind rivets for wood. From understanding the basics and choosing the right wood rivets to achieving the perfect come-set, we cover it all. By the end, you’ll be well versed in blind rivets for wood and understand why Rivmate is the preferred choice of professionals worldwide.

Table of Contents

Learn About Blind Rivets and Their Application on Wood

Blind rivets utilize their precision and efficiency to achieve consistent installations with specialized blind rivet guns. This advanced technology offers numerous advantages over traditional joining techniques. Making it the first choice for joining thin timber panels. Blind rivets are able to complete the entire installation process from a limited space.

What Are Blind Rivets?

You can see blind rivets in many industrial areas. For example, in automobile manufacturing, body panels are connected, fenders are fixed and vin plate rivet, and in building construction, metal plates, plastic plates and other materials are connected. Of course, the industrial choice to use blind rivets is not without reason. Blind rivets offer advantages that other fasteners do not.

- Single-sided operation

- Suitable for mass production and installation

- Suitable for a wide range of materials

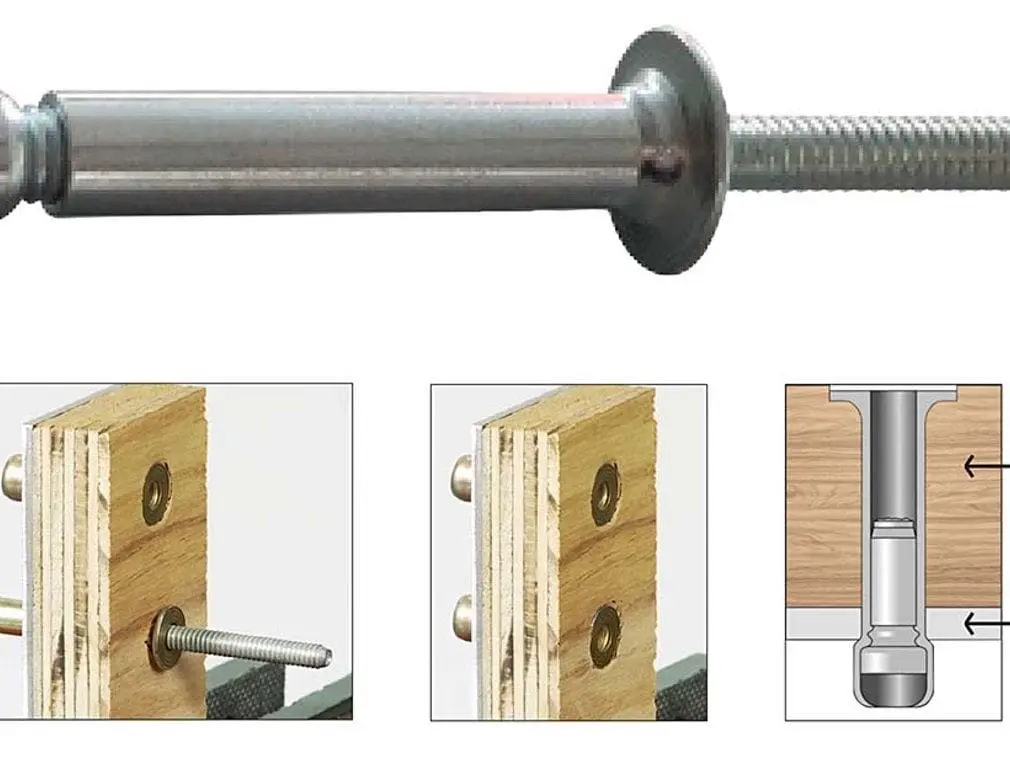

- Under dynamic loads

A blind rivet consists of two parts: the rivet body and the rivet mandrel, which are produced separately and then assembled. Blind rivets are ideal for securing two or more materials together.

Why Using Blind Rivets for Wood?

Let’s explore the reasons and applications why using blind rivets for wood.

- One-sided operation: In timber constructions, the space in which you can operate is generally too small to reach the back side. Blind Rivets offer an excellent solution to this problem. Blind Rivets provide an excellent solution to this problem, as they do not need to be operated from both sides in order to make a solid connection.

- Stable fastening force: Blind Rivets hold the timber in place by means of expansion. And the strength of the connection is so reliable that it will not loosen due to the softness of the wood.

- Connecting dissimilar materials: In practice, it is often necessary to fasten metal parts to timber in applications (e.g. construction, furniture making or window and door frames). Many fasteners do not allow the entire installation to be done in one go. Blind rivets are ideally suited for joining dissimilar materials, ensuring a strong connection between dissimilar materials.

- Prevents wood splitting: Blind Rivets provide fastening by expanding and locking, rather than relying on rotation to access the material as screws do. This expansion fixing reduces the risk of wood cracking.

Types of Blind Rivets for Wood

There are many types of blind rivets for wood. Each rivet type has its own advantages for different product applications.

Large Flange Pop Rivets

Wood is known to be a soft material and the use of conventional blind rivets may fracture the wood. So in order to better distribute the pressure, large flange pop rivets provide a larger head contact area, which can avoid localized indentation or damage to the wood.

Grooved pop rivets are specially designed blind rivets. It has a grooved or fluted surface and is specialized for fastening soft materials. So grooved pop rivets are perfect for joining wood.

Grooved pop rivets have a series of longitudinal grooves on the body of the rivet that increase the friction and bite of the rivet in soft materials. Grooved pop rivets are not suitable for joining in hard materials.

Colored Pop Rivets

Wood is often used to make furniture, and the color of the furniture will change depending on the style of the décor. Colored rivets can change depending on the color of the furniture wood. Colored rivets provide both fastening power and a decorative effect.

In situations where an aesthetic effect is desired, such as wood furniture or display racks, colored rivets can be coordinated with the wood color to provide a neat appearance.

Tri fold rivets have a rivet body that splits into three flaps when installed, creating a type of trefoil structure. This design allows tri fold rivets to provide a stronger and more distributed hold on wood.

The tri-lobe structure of tri fold rivets effectively distributes stresses and causes less damage to fragile or softer materials. This design prevents deformation, cracking or damage to the wood compared to traditional rivets.

Peel type blind rivets expand and burst open at the end of the rivet to form a petal shape after installation is complete. This joint design provides a large contact area for the material being joined, reducing the potential for wood damage.

However, peel rivets do not have a very strong connection and are suitable for light duty applications.

There are several factors to consider when choosing blind rivets for wood. These factors include the application and thickness of the wood being joined, the strength required, and the total budget for the project. For thicker wood materials, large flange blind rivets are required, while colored blind rivets are preferred if there is a need for decoration.

The total budget of the project is also crucial when choosing wood blind rivets. This will help determine the best type of pop rivets to use for joining the wood.

Achieve Optimal Installation Results

Correct Installation Procedure

In order to obtain high quality riveting results when riveting WOOD, it is important to follow the correct installation procedure. Here are some tips to achieve good riveting results:

- Choose the right type of rivets: Different rivets have different riveting effects. Wood is suitable for rivets such as Large Flange Rivets and Multi-Grip Rivets.

- Drill preparation: The hole diameter must match the rivet diameter. A hole that is too large or too small will prevent the rivet from being properly effective. Also make sure the hole is free of wood chips or debris.

- Use the right tool: Make sure the tool matches the rivet.

Avoid Common Mistakes

While striving for the correct type of rivet, it is important to be aware of some common mistakes. These mistakes may affect the results of blind rivets for wood. Here are some pitfalls to avoid:

- Ignoring riveting order: If the wood is large or multiple rivets are used, incorrect riveting order may result in localized stress concentrations leading to distortion or cracking of the material. It is recommended that rivets be installed sequentially in diagonal order.

- Neglecting proper clamping force: The length of the rivet should be 1.5 to 2 times the thickness of the material to ensure that the tail of the rivet grips the material firmly when it expands.

- Neglecting protection: When wood is exposed to moisture or other corrosive environments, it is recommended to use Sealed Rivets or apply an anti-corrosive coating to the rivets to prevent moisture from entering the wood.

Why Choose Rivmate Rivet for Wood Connections?

In short, Rivmate rivet is an expert in the field of riveting. With an in-depth knowledge of blind rivets and their application on thin sheet materials, they offer a wide range of blind rivets to meet different needs.

Excellent Rivet Quality

Rivmate rivets are known for their outstanding quality. When choosing a pop rivet manufacturer, you need to choose a real rivet factory. Our rivet factories can provide PPAP documentation for whatever your project application is.Rivmate rivet is fully compliant with huck, avdel highest standards.

Multiple Options for Different Needs

Rivmate rivet offers a variety of options for different applications. We offer a wide range of blind rivets with different strengths, special properties and different materials, allowing customers to choose the perfect rivet for their specific needs.

Rivmate has blind rivets for joining a wide range of sheet metal materials and thicknesses, allowing it to play an important role in a variety of applications. Whether it’s a light-duty application or a heavy-duty piece of equipment, the Rivmate rivet offers a customizable solution.

So, what are you waiting for? Utilize Rivmate rivet’s professional just and high quality blind rivets to enhance your project benefits. Get samples now!

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Frequently Asked Questions

Can Blind Rivets Only Connect Wood?

Of course not, one of the features of a blind rivet is that it can join many different materials. The same Blind Rivet can be used to join metal, wood, plastic and more!

Are Blind Rivets Cost-effective Compared to Other Fasteners?

Compared to bolts and screws, blind rivets are highly cost-effective due to consistent installation quality, no wasted material and quick installation. If you want to learn about rivet vs bolt or rivet vs screw, read on.

How Consistent is the Installation Quality of Blind Rivets?

The tool used to install the blind rivets is a pneumatic rivet gun. The operator can adjust the length of the drawn core rivet by adjusting the stroke of the pneumatic rivet gun. Therefore, the installation quality of the blind rivets is very consistent.

Conclusion

By now, you should have a good understanding of wood blind rivets, from the basics to the types of blind rivets you can use and best practices. What did you find most interesting about the process? If you’re ready to complete your wood project with a Rivmate rivet, contact one of our experts for personalized help.