Home » 未分类

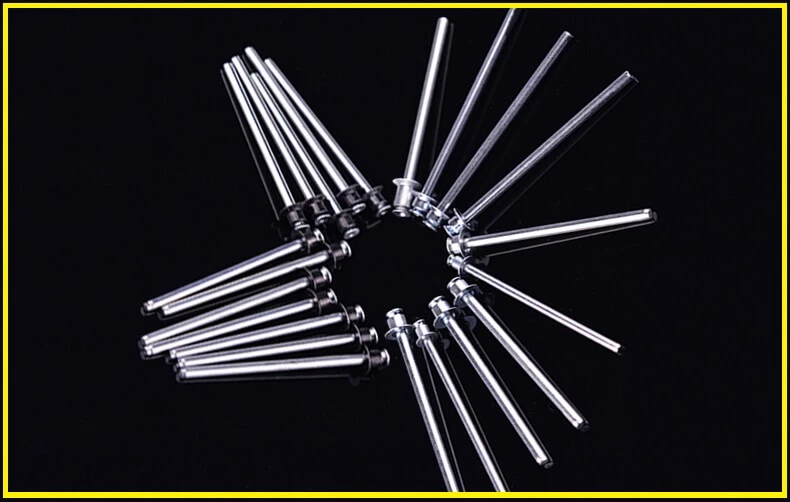

Double Countersunk Head Pull Through Rivets

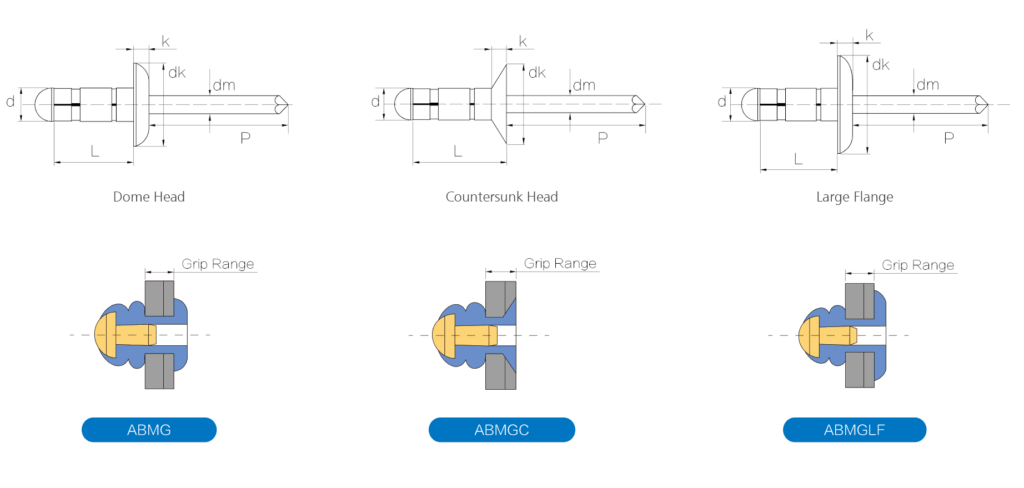

Head Type

- Double Countersunk Head

Material

- Carbon Steel

Surface

- Zinc Plated

Custom Pull Rivets for your Project

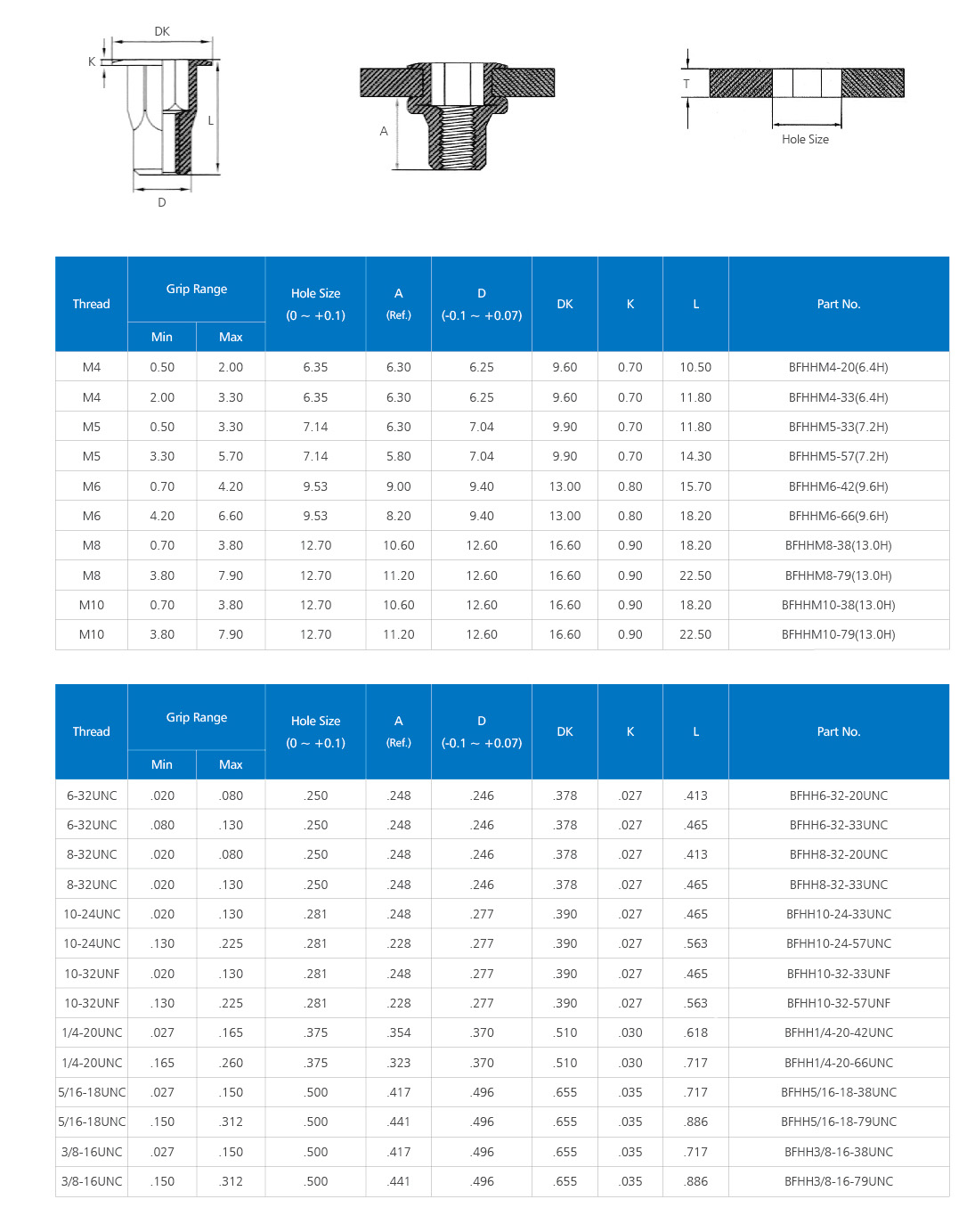

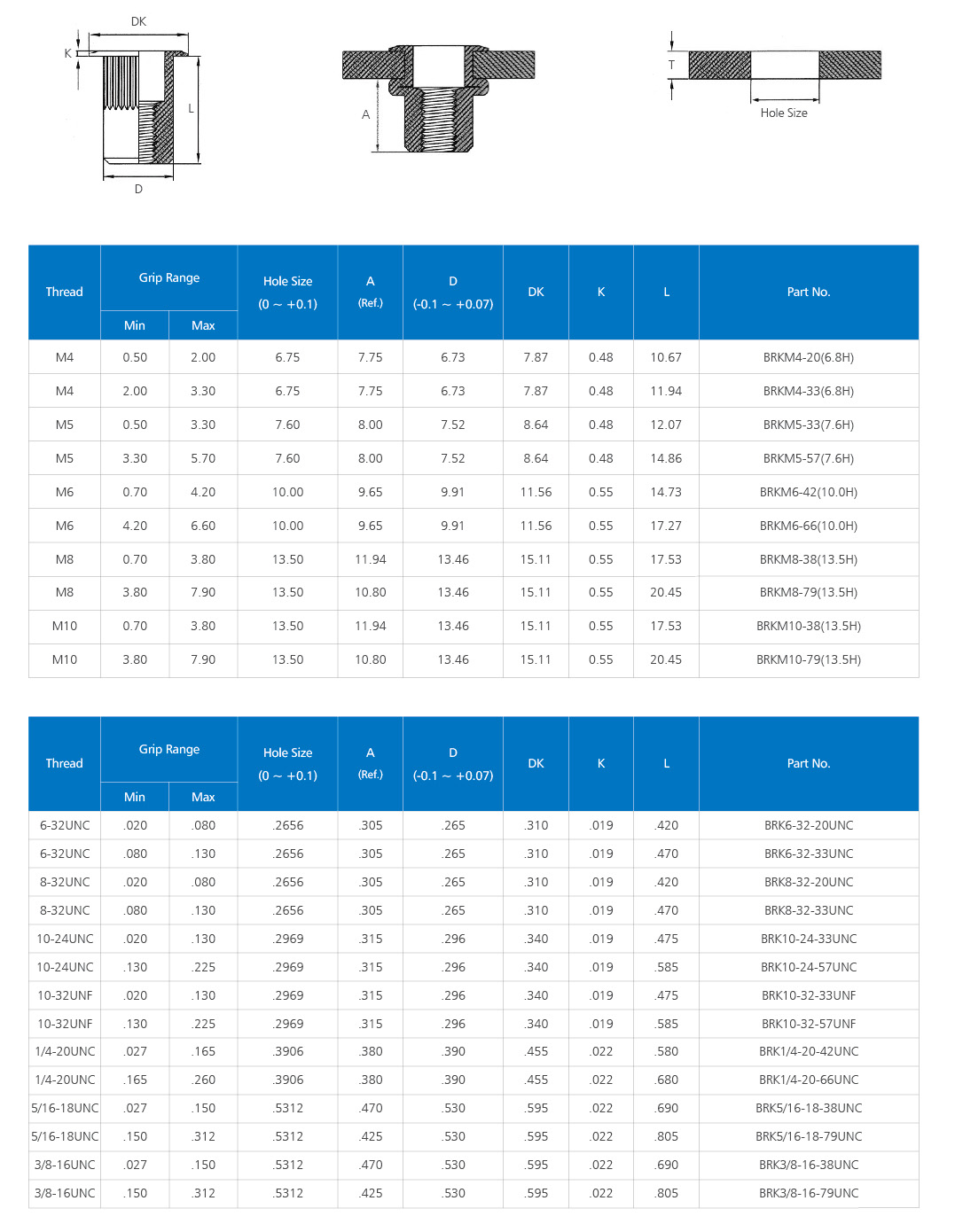

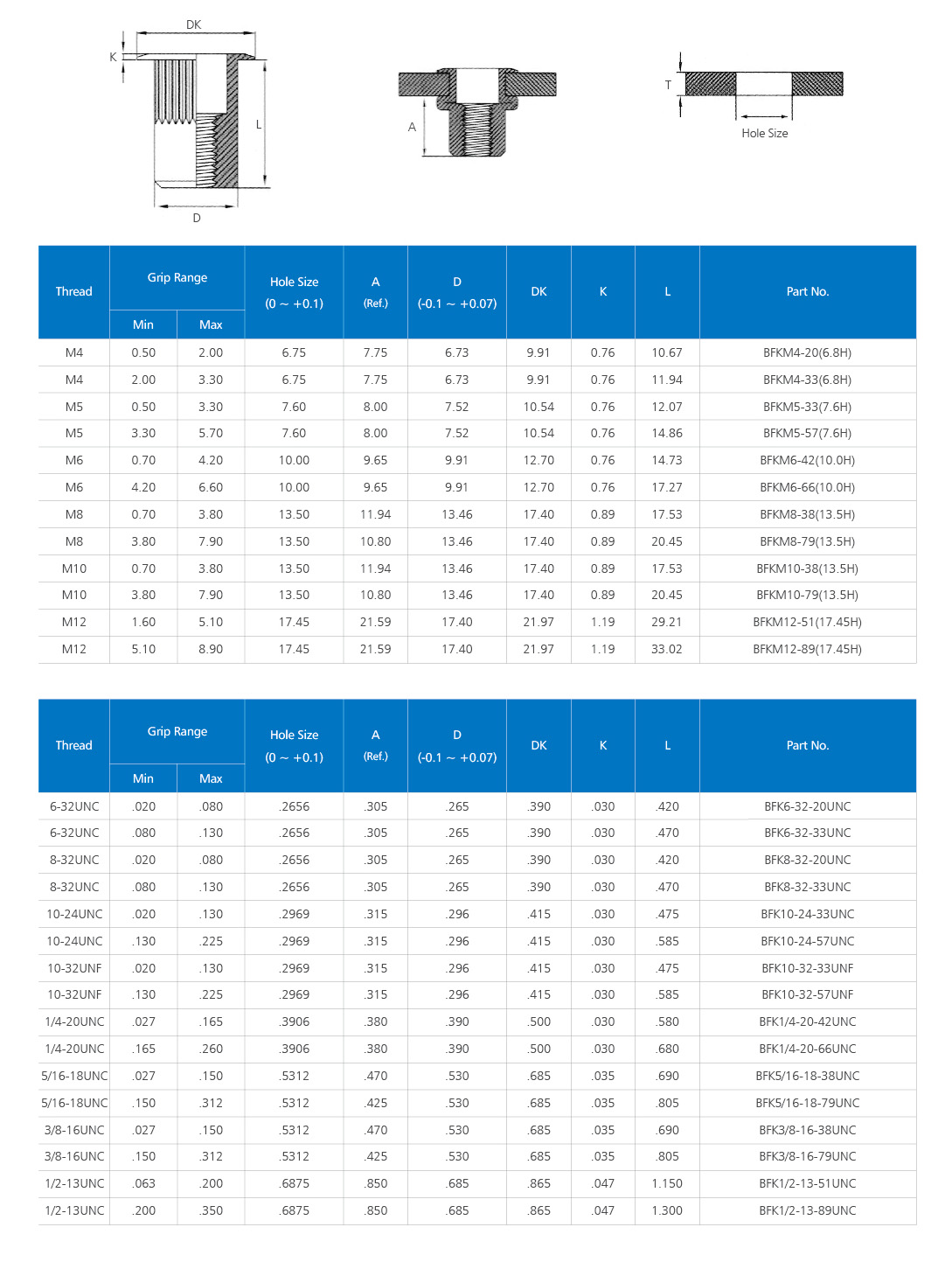

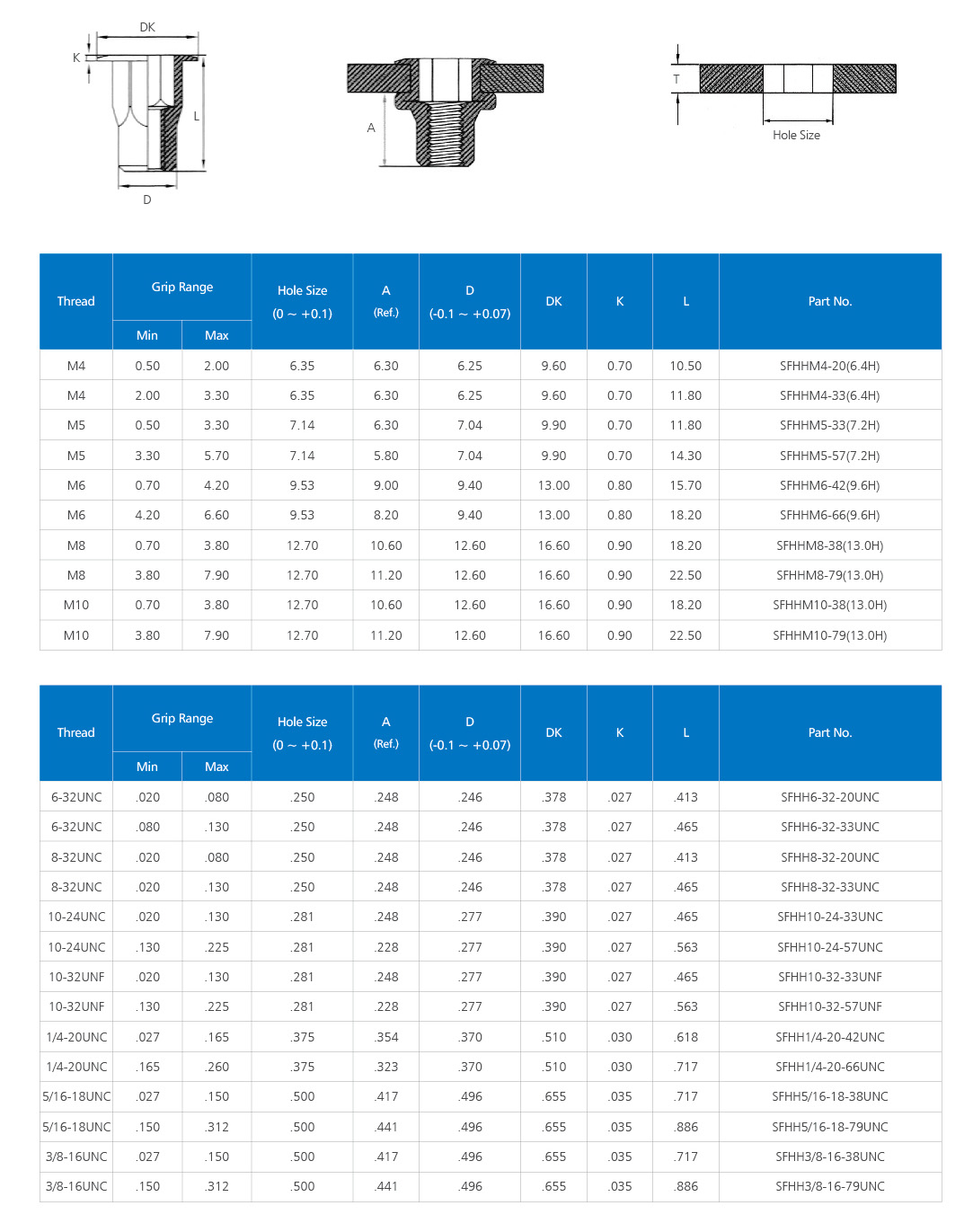

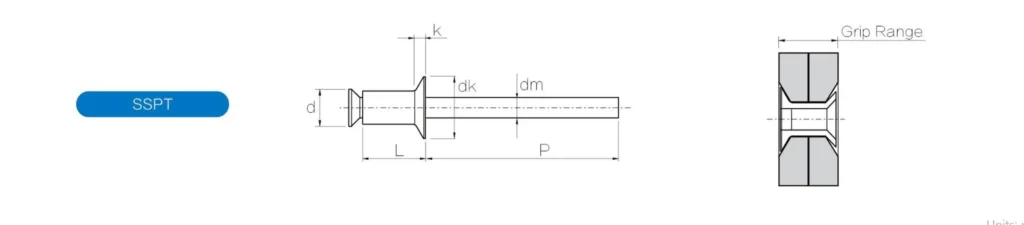

Technical Parameters of Pulled Rivets

| Diameter[d] | Size | Body Length [L] | Grip Range | Drill | dk | k | Tensile | Shear |

|---|---|---|---|---|---|---|---|---|

| 2.4(3/32") | 2.4×2.1 | 1.9-2.3 | 1.3-1.8 | 2.5-2.6 | 3.8±0.2 | 0.7±0.1 | 500N | 600N |

| 2.4×2.4 | 2.2-2.6 | 1.6-2.0 | ||||||

| 2.4×2.8 | 2.6-3.0 | 2.0-2.5 | ||||||

| 2.4×3.3 | 2.1-3.5 | 2.5-3.0 | ||||||

| 2.4×3.8 | 3.6-4.0 | 3.0-3.5 | ||||||

| 2.4×4.3 | 4.1-4.5 | 3.5-4.0 | ||||||

| 2.4×4.8 | 4.6-5.0 | 4.0-4.5 | ||||||

| 2.4×5.3 | 5.1-5.5 | 4.5-5.0 | ||||||

| 2.4×5.8 | 5.6-6.0 | 5.0-5.5 | ||||||

| 2.4×6.3 | 6.1-6.5 | 5.5-6.0 | ||||||

| 3.0(7/61") | 3.0×2.3 | 2.0-2.6 | 1.5-2.0 | 3.1-3.2 | 4.9-5.4 | 0.7-0.98 | 700N | 800N |

| 3.0×2.8 | 2.5-3.1 | 2.0-2.5 | ||||||

| 3.0×3.3 | 3.0-3.6 | 2.5-3.0 | ||||||

| 3.0×3.8 | 3.5-4.1 | 3.0-3.5 | ||||||

| 3.0×4.3 | 4.0-4.6 | 3.5-4.0 | ||||||

| 3.0×4.8 | 4.5-5.1 | 4.0-4.5 | ||||||

| 3.0×5.3 | 5.0-5.6 | 4.5-5.0 | ||||||

| 3.0×5.8 | 5.5-6.1 | 5.0-5.5 | ||||||

| 3.0×6.3 | 6.0-6.6 | 5.5-6.0 | ||||||

| 3.2(1/8") | 3.2×2.1 | 1.8-2.4 | 1.3-1.8 | 3.3-3.4 | 4.9-5.4 | 0.7-0.95 | 800N | 900N |

| 3.2×2.4 | 2.1-2.7 | 1.6-2.0 | ||||||

| 3.2×2.8 | 2.5-3.1 | 2.0-2.5 | ||||||

| 3.2×3.3 | 3.0-3.6 | 2.5-3.0 | ||||||

| 3.2×3.8 | 3.5-4.1 | 3.0-3.5 | ||||||

| 3.2×4.3 | 4.0-4.6 | 3.5-4.0 | ||||||

| 3.2×4.8 | 4.5-5.1 | 4.0-4.5 | ||||||

| 3.2×5.3 | 5.0-5.6 | 4.5-5.0 | ||||||

| 3.2×5.8 | 5.5-6.1 | 5.0-5.5 | ||||||

| 3.2×6.3 | 6.0-6.6 | 5.5-6.0 |

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com

CONTACT PERSON SEARCH

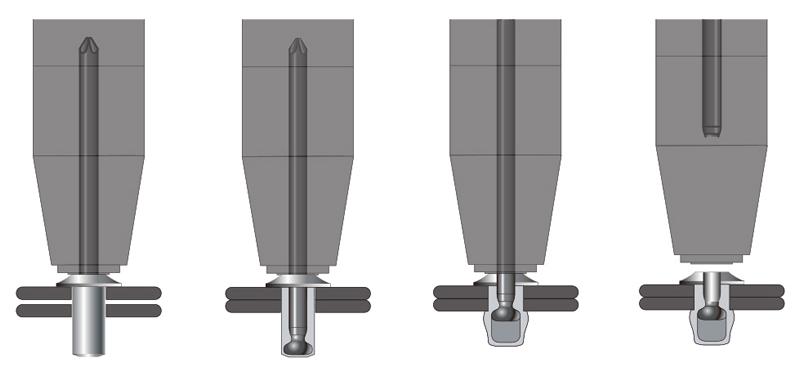

How to Install Pulled Rivets?

One of the best features of blind rivets is that they are quick and easy to install.

Installing pull rivets also requires no specialized skills.

Just need to prepare a professional riveting tool.

The riveting process can be completed with a simple operation.

Advantages of Rivmate Pull Rivets

- Double Countersunk Head Design

- Can be used for insertion on both sides of the workpiece

- Draw mandrel coreless nail head design

- No nail heads to fall off

- Flat surface on both sides of the workpiece after riveting is completed

- Good rust and corrosion resistance

- Not easily deformed, easy to use

Double Countersunk Head Pull Through Rivets are designed for products that require flatness on both sides after riveting. Therefore, the rivets have countersunk holes on both sides of the workpiece.

Double Countersunk Head Design

Ensure the integrity and smoothness of both sides of the workpiece after riveting.

Rivet Mandrel Design

Unique nailhead design. Ensure that the bottom of the rivet body riveted fully flanged, fully play a tightening effect.

Center hole Is Empty Design

No nail head falling off after riveting. Avoid bad cleanup when working in tight spaces

Frequently Asked Questions About Pull Rivets

What is the Production Lead Time and Availability of Pull Rivets?

The exact production cycle is less easy to determine. This needs to be based on the quantity and specifications of your order.

When you find us to give you our professional services, it will go through several stages:

- Confirm the order and determine the specification quantity.

- Processing production. After ten production processes to ensure the high quality of the product.

- Quality check and packaging. We have thirteen inspection processes to ensure that our products meet specifications and quality requirements.

- Delivery. Choose the delivery method according to your requirements and have the product delivered to you.

What are the standards and certifications for pull through rivets?

Rivmate is ITAF 16949:2016 fastener manufacturer in china.

And it is ISO certified.We have a professional technical team for quality testing. Make sure our products meet the requirements of the application.

How are pull rivets used in the automotive industry?

Pulled Rivets are widely used in the process of automobile manufacturing because of their light weight.

- Body assembly.Attaches to doors, engine hey, roof, etc.

- Interior assembly.Such as connecting parts such as seats, dashboards, center consoles, etc.

- Chassis and suspension.

- Engine and drivetrain.

- Shields and exterior parts.

Is technical and engineering support available?

We have a professional technical team to provide you with technical support. From order generation, we will provide one-on-one service to secure your order throughout the process.

We also offer customization of our products. We believe you can find all the products you need at Rivmate.

-1024x792.jpg)