Home » blind rivet supplier » hem firm rivet

Hemlock Rivets

Your single source for wholesale Hemlock rivets, offering factory-direct structural blind fastening.

Hemlock Rivets for Mechanical Locking Applications

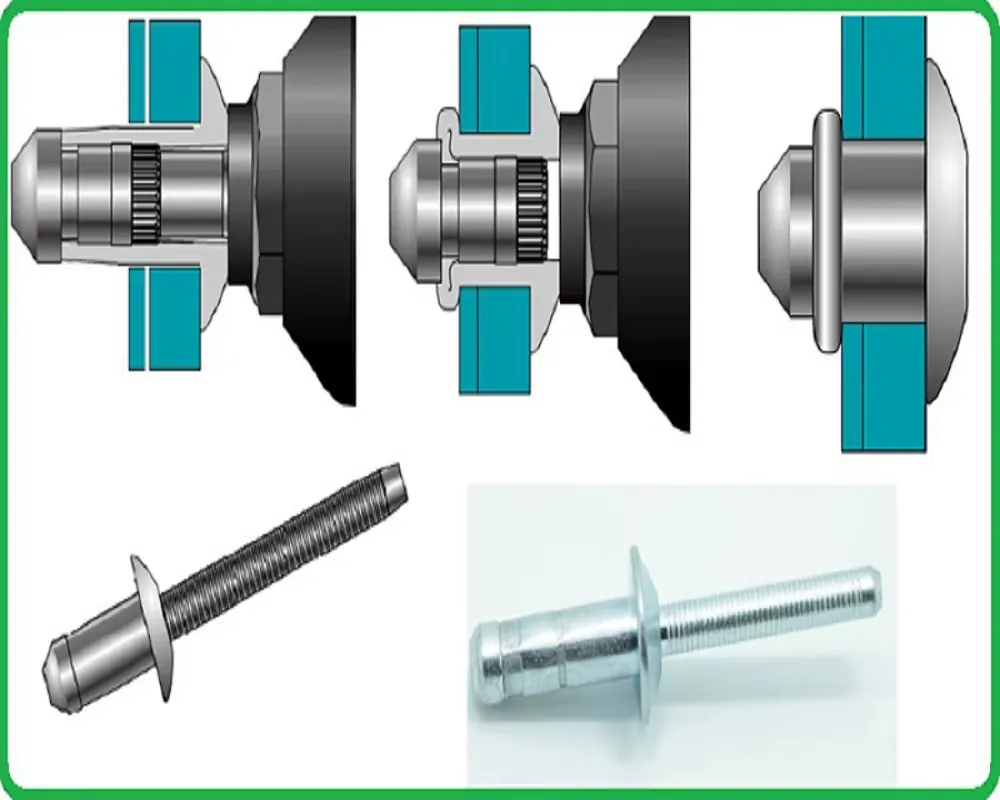

The Hemlock Rivet is a structural blind rivet designed to achieve high-strength, vibration-resistant permanent connections in applications where installation is only possible from one side. Unlike conventional blind rivets that rely on core pin fracture, the Hemlock Rivet mechanically locks the core pin within the rivet body after installation, creating a stable, non-retractable locking state.

Mechanical Locking Mechanism Explained

The core principle of the Hemlock Rivet lies in mechanical locking, rather than relying on friction retention after the mandrel breaks. During installation, the mandrel is drawn into the locking groove within the rivet body and is permanently secured within it by the deformed locking structure.

This locking occurs within a pre-engineered structural zone inside the rivet body, not through indirect constraints created by the tail’s forming process. This design ensures that after the mandrel breaks, it will not spring back or loosen due to vibration, impact, or load cycling, fundamentally eliminating the risk of mandrel loss common in standard blind rivets.

The Technical Parameters of Hem-Firm Blind Rivets

| L(+1/-0) | Grip Range | Rivet Size(d) | Hole Dia | Tensile ref. | Shear ref. | Breaking Load(Max) | Retention load(Min) |

| 9.0 | 1.5-3.5 | 4.8 | 4.9-5.1 | 4400N | 6000N | 9000N | 1000N |

| 11.5 | 3.5-6.0 | 7500N | |||||

| 14.0 | 6.0-8.5 | 7800N | |||||

| 16.5 | 8.5-11.0 | ||||||

| 19.0 | 11.0-13.5 | ||||||

| 9.0 | 1.5-3..5 | 6.4 | 6.6-6.8 | 7920N | 7700N | 15000N | 1800N |

| 10.5 | 2.0-4.5 | 9450N | |||||

| 12.5 | 3.5-6.5 | 10800N | |||||

| 14.5 | 5.5-8.5 | ||||||

| 16.5 | 7.5-10.5 | 12500N | |||||

| 18.5 | 9.5-12.5 | ||||||

| 20.5 | 11.0-14.0 | ||||||

| 22.5 | 13.0-16.0 | ||||||

| 24.5 | 14.5-18.0 | ||||||

| 26.5 | 16.5-20.0 | ||||||

| 28.5 | 18.5-22.0 | ||||||

| 30.5 | 20.5-24.0 | ||||||

| 32.5 | 22.5-26.0 | ||||||

| 13.5 | 4.0-7.0 | 7.8 | 8.1-8.3 | 11500N | 15500N | 23000N | 2500N |

| 16.5 | 7.0-10.0 | 18000N | |||||

| 19.5 | 10.0-13.0 | ||||||

| 22.5 | 13.0-16.0 | ||||||

| 16.5 | 4.0-7.0 | 9.8 | 10.0-14.0 | 12740N | 21500N | 33000N | 3000N |

| 19.5 | 7.0-10.0 | ||||||

| 22.5 | 10.0-13.0 | ||||||

| 25.5 | 13.0-16.0 | ||||||

| 28.5 | 16.0-19.0 | ||||||

| 31.5 | 19.0-22.0 |

WHY USE IT

Hemlock Rivets Product Features & Advantages

Mechanical Locking Design

The mandrel is permanently secured within the rivet body via an internal mechanical locking mechanism, eliminating the risk of loosening under vibration or cyclic loading.

High Shear and Tensile Strength

The mandrel contributes to load-bearing capacity, providing the riveted joint with superior shear and tensile strength. This makes it suitable for medium-to-high load structural connections.

Superior Vibration Resistance

Mechanical locking relies on no friction retention, maintaining stable connections under prolonged vibration or impact conditions.

Consistent Long-Term Performance

The locking mechanism does not degrade over time, ensuring consistent connection performance throughout the entire service life.

Blind-Side Structural Fastening

Enables structural-grade connections in single-side installation scenarios, meeting assembly requirements for enclosed structures or inaccessible backsides.

Reduced Failure and Maintenance Risk

Effectively minimizes common failure modes such as core pin loss and connection loosening, reducing rework and long-term maintenance costs.

Structural Performance

Structural Performance Data

I. Tensile Strength

Hemlock Rivets demonstrate exceptional tensile load capacity in common specifications. For instance, certain models with a 1/4″ (≈ 6.4 mm) diameter exhibit typical tensile strengths reaching approximately 2090 lbs (about 9300 N), ensuring more stable connections under axial tensile forces.

In engineering practice, this level of tensile strength far exceeds that of most standard blind rivets, which rely solely on tail-end deformation friction to maintain the connection.

II. Shear Strength

Hemlock Rivets also demonstrate exceptional shear load capacity. Using the aforementioned 1/4″ diameter as an example, their shear strength reaches approximately 3820 lbs (≈ 17 000 N). This metric indicates superior resistance to shear failure under lateral loads.

This strength stems from its internal locking mechanism and larger blind-side bearing surface, which distribute shear loads more evenly and reinforce the joint.

Hemlock Rivets vs Standard Blind Rivets

Hemlock Rivets vs Standard Blind Rivets: Structural Strength

| Comparison Item | Hemlock Rivets (Structural Locking) | Standard Blind Rivets |

|---|---|---|

| Locking Method | Internal mechanical lock with mandrel permanently retained in the rivet body | Relies on blind-side deformation and frictional holding |

| Vibration Resistance | High; mechanical locking prevents mandrel loosening | Low; mandrel may loosen or be lost under vibration |

| Long-Term Stability | High; mechanical lock does not degrade over time | Moderate; friction-based retention degrades over time |

| Failure Risk | Low; reliable under vibration and cyclic loading | High; prone to failure under vibration and load variation |

The core advantage of Hemlock Rivets stems from their internal mechanical locking mechanism, rather than the tail friction or strain retention relied upon by conventional blind rivets.

This locking method enables Hemlock Rivets to maintain secure fastening without core-shank loosening or joint failure under high shear, heavy loads, and vibrational environments. Standard blind rivets, whose locking relies on tail friction, are more prone to failure, loosening, or performance degradation under vibration or load cycling.

Therefore, when a connection point requires structural strength, long-term stability, and vibration resistance, Hemlock Rivets offer a more reliable choice than conventional blind rivets.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

Hemlock RIVETS INSTALLATION

Installation Guidelines of Hemlock Structural Blind Rivets

Special Tools Required

Hemlock Rivets can be installed using standard pneumatic or electric rivet guns without requiring specialized locking tools. The key factor is the rivet gun’s consistent pull force output, not the tool model itself.

Installation Consistency Requirements

To ensure proper formation of the mechanical locking structure, maintain perpendicular alignment between the rivet gun and the workpiece during installation. In batch assembly, consistent pulling force directly impacts locking quality and forms the foundation for long-term reliability.

APPLICATIONS

Typical Applications of Hemlock Rivets

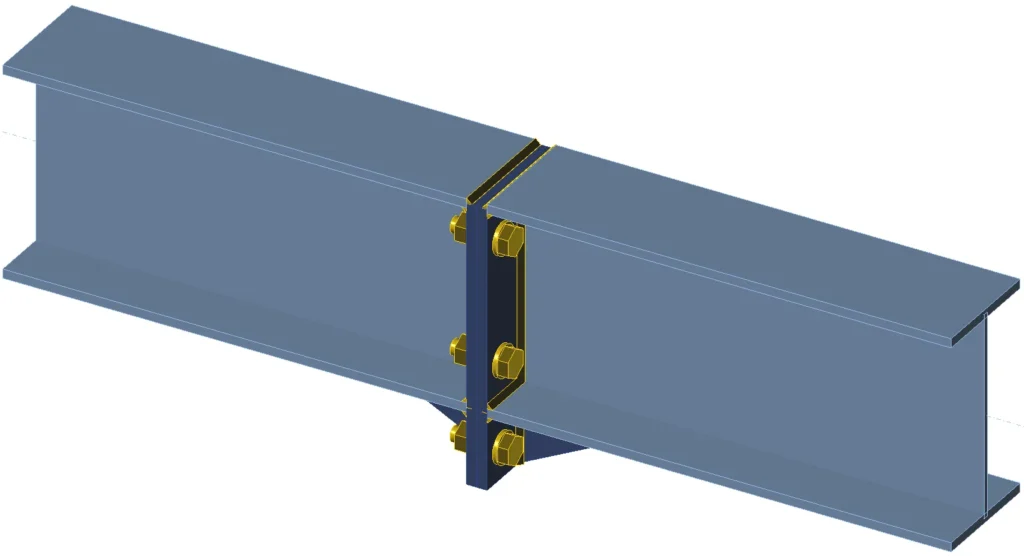

Vibration-Resistant Assembly

Suitable for connection points subjected to prolonged vibration or impact loads, effectively preventing core rod loosening and connection failure.

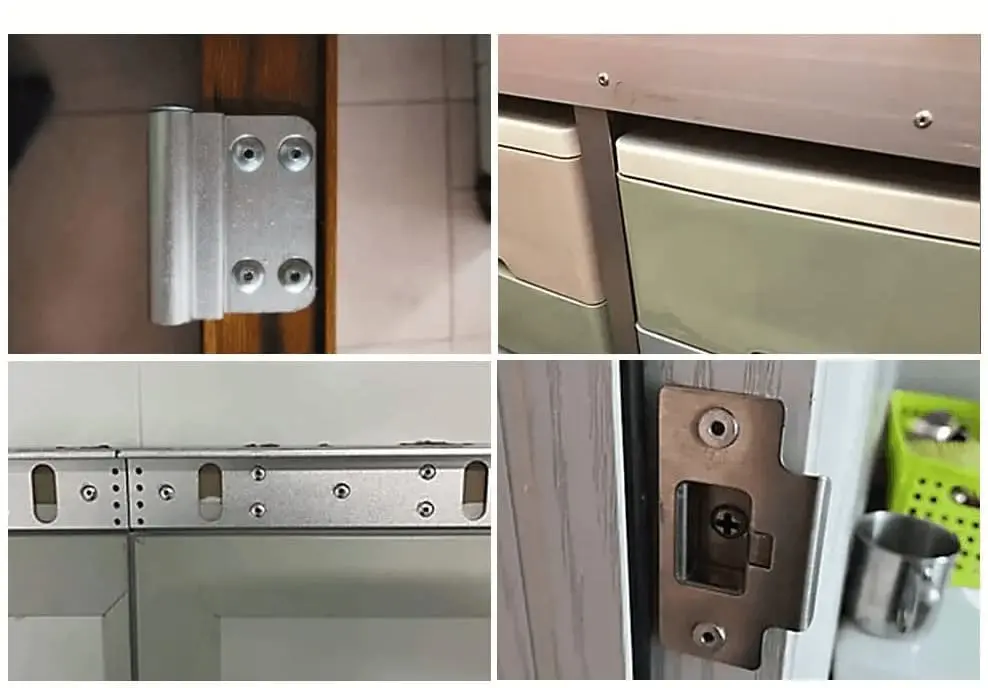

Structural Sheet Metal Joining

Used for sheet metal structures with specific shear and tensile strength requirements, ensuring long-term structural stability.

Vehicle and Engineering Equipment Frames

Suitable for frame and support structure connections in commercial vehicles, construction machinery, and other applications where regular maintenance is impractical.

Safety-Critical Joints

Applied to critical junctions where failure could pose safety risks, reducing the probability of connection loosening.

Single-Access Load-Bearing Structures

Provides reliable solutions for scenarios requiring structural integrity despite installation access from only one side.

Frequently Cycled Load Connections

Suitable for areas subjected to repeated loading or fatigue conditions, maintaining connection performance without degradation over time.

Frequently Asked Questions About Hemlock Rivets

1) What is a Hemlock Rivet used for?

Hemlock Rivets are a type of structural blind rivet used for connections where installation is only possible from one side but structural strength is still required. Typical scenarios include: fastening components subjected to shear loads, vibration, or load cycling where loosening is not permitted. Compared to standard blind rivets, they are better suited for “load-bearing assemblies” rather than decorative or light-load connections. When selecting, prioritize confirming: whether the connection is a structural node, if long-term vibration exists, and if back-side access is impossible.

2) How does a Hemlock Rivet differ from a standard blind rivet?

The core difference lies in the locking mechanism. Hemlock Rivets permanently secure the mandrel within the rivet body via an internal mechanical locking structure, eliminating reliance on friction for retention after locking; Standard blind rivets primarily rely on blind-side forming and clamping friction to maintain the connection. The engineering implications are clear: under vibration and load cycling, mechanically locked connections offer superior long-term stability, while friction-based connections are more prone to performance degradation. If your failure risk stems from vibration-induced loosening or mandrel loss, prioritize Hemlock.

3) Are Hemlock Rivets suitable for vibration-prone applications?

Yes. Hemlock is specifically engineered to maintain locking integrity under vibration and shock conditions, minimizing core pin dislodgement and joint loosening. The key lies not in “vibration resistance” but in its locking mechanism, which eliminates reliance on installation-moment friction conditions. For assemblies where vibration is unavoidable—such as in vehicles, equipment frames, or long-term operational mechanisms—Hemlock offers superior reliability. Ensure controlled hole diameter and installation perpendicularity during use; otherwise, even the best locking mechanism may fail to lock fully due to installation deviations.

4) Do Hemlock Rivets require special installation tools?

Typically, no “special locking tools” are required, but a pneumatic/electric rivet gun with sufficient and stable tension output must be used. Structural blind rivets demand high tension; insufficient tension can result in incomplete locking formation, abnormal shank breakage, or inadequate clamping. In actual projects, tool selection should be based on the “minimum installation tension requirement for that rivet specification,” not just diameter. For mass assembly, pneumatic or electric tools with more stable tensile output are recommended to reduce quality variation.

5) Can Hemlock Rivets replace Huck or Avdel structural rivets?

They can serve as equivalent replacement candidates, but verification must be conducted under identical conditions: same specification, material combination, performance metrics, and installation requirements. Structural rivet replacements should not be based solely on appearance or name. Align the following: tensile/shear strength range, locking mechanism, applicable plate thickness, hole diameter requirements, and consistency between shank breakage and locking. For project-based clients, conduct installation verification and sampling with sample parts before bulk adoption to avoid long-term risks from locking mechanism differences.

6) What factors are critical when selecting Hemlock Rivets?

Five selection criteria are essential, with none being dispensable:

Load Type (shear/tension/vibration/impact) — determines structural rivet necessity;

Panel Thickness Range (min/max) — avoids prolonged operation near limits;

Hole diameter and wall quality (tolerance, roundness, burrs) — oversized holes or irregular walls weaken locking and clamping;

Installation tool capability (pull force output and stability) — Ensures the locking mechanism fully engages;

Environmental conditions (corrosion/outdoor use) — Determines material selection and long-term reliability.

Selecting based solely on diameter often leads to the hidden risk of “fitting but unreliable” solutions.

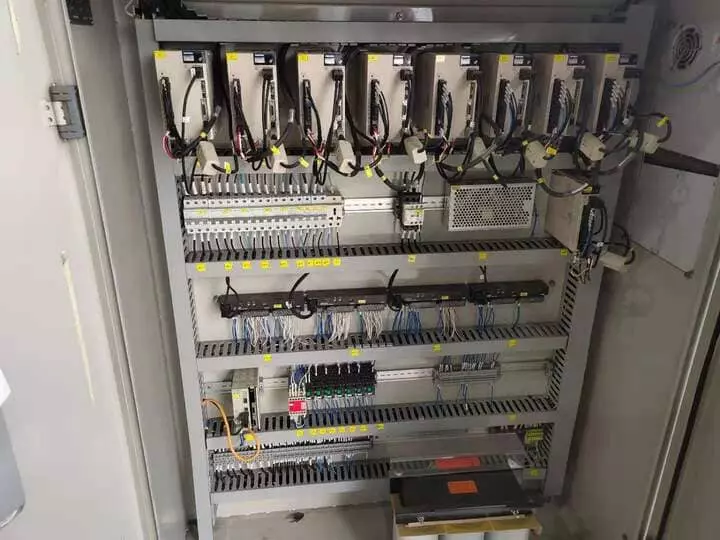

10 Autonomous Key Processes Ensure Fasteners' Quality

- Raw Material Inspection

- Cold Forming

- Thread Rolling

- Head Treatment

- Assembly

- Laser Selecting

- Warehouse of Semi-finished products

- Packaging

- Warehouse of finished Products

- Logistics

The key process of fastener manufacturing are made independently and intelligently, and each fastenerion process is closely monitored and managed to ensure the quality of each fastener.

13 Full Fastener testing and design verification equipment

- Spectrometer

- Image Mapping

- Surface Profiler

- Thickness measuring meter,Concentricity tester

- Measuring Prohector

- Computer Tensile & Shearing Set

- Vickers Hardness Tester

- Metallurgical Microscope

- Film Thickness Teaster

- Salt Spray Test Box

- Torsque Testing Machine

- Riveting Test

- Ejector Machine

From raw materials to finished fasteners, from design to manufacturing have reliable testing equipment and complete verification process, our laboratory has been approved by Volkswagen,Tesla, SAIC GAC,BAIC etc.