Hucklok Rivets - Huck Lok Rivet

Rivamte Fastener - Top Rivets Maker in China

Home » blind rivet supplier » Hucklok Rivets for Sale

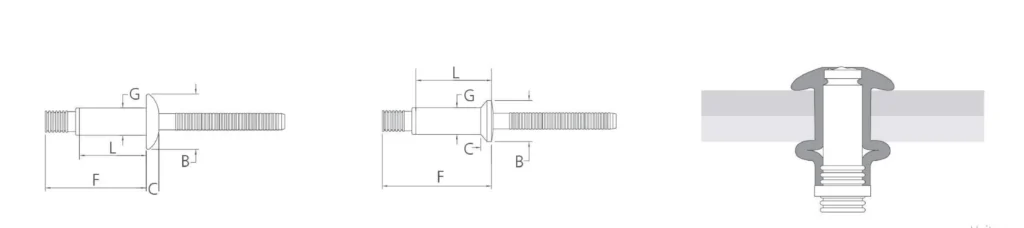

Hucklok Rivet (Double-locking System)

Mandrel

Surface

Certificate of quality

Carbon Steel/Carbon Steel

Green trivalent eletroplating blue white zinc

ISO certificate, IATF certificate

The more you buy. The lower the price!

Return Policy:

Whenever you purchase Hucklok Rivet from Rivmate. products have quality problems within two years, Rivmate promises a full refund!

| Code | Grip Range | |

| Min | Max | |

| SNLK-R6-5 | 1.60 | 7.90 |

| Dome Head | ||

| SNLK-R6-7 | 4.75 | 11.10 |

| SNLK-R8-6 | 2.50 | 9.50 |

| SNLK-R8-7 | 4.75 | 11.10 |

| SNLK-R8-10 | 9.50 | 15.90 |

| SNLK-R8-12 | 12.70 | 19.10 |

| SNLK-R8-14 | 15.90 | 22.20 |

| Truss Head | ||

| SSNLKTF-R8-6 | 2.50 | 9.50 |

| SSNLKTF-R8-7 | 4.75 | 11.10 |

| SSNLKTF-R8-10 | 9.50 | 15.90 |

| SSNLKTF-R8-12 | 12.70 | 19.10 |

| SSNLKTF-R8-14 | 15.90 | 22.20 |

| CSK Head | ||

| SSHBUC-R8-M4 | 3.80 | 5.80 |

| SSHBUC-R8-M5 | 4.80 | 6.80 |

| SSHBUC-R8-M6 | 5.80 | 7.80 |

| SSHBUC-R8-M7 | 6.80 | 8.80 |

| SSHBUC-R8-M9 | 8.80 | 10.80 |

| SSHBUC-R8-M10 | 9.80 | 11.80 |

| SSHBUC-R8-M13 | 12.80 | 14.80 |

| SSHBUC-R10-5 | 6.40 | 8.90 |

| SSHBUC-R10-6 | 7.60 | 10.20 |

| SSHBUC-R10-7 | 8.90 | 11.40 |

| SSHBUC-R10-8 | 10.20 | 12.70 |

| SSHBUC-R10-9 | 11.40 | 14.00 |

| SSHBUC-R10-10 | 12.70 | 15.20 |

| SSHBUC-R10-11 | 14.00 | 16.50 |

| SSHBUC-R10-12 | 15.20 | 17.80 |

| SSHBUC-R10-13 | 16.50 | 19.10 |

What Are Hucklok Blind Rivets?

Hucklok Blind Rivets are a type of high-strength structural blind rivet primarily used in industrial applications demanding high joint strength, vibration resistance, and long-term reliability. Their core feature lies in their mechanical locking mechanism. After installation, the mandrel is permanently locked within the rivet body rather than simply breaking off like conventional pop rivets, significantly enhancing overall joint performance.

In practical applications, Hucklok Blind Rivets represent a classic example of structural-grade fasteners. They are commonly employed in steel structures, commercial vehicles, rail transportation, construction machinery, and energy equipment. Their single-side installation capability offers distinct advantages in structures where access from the reverse side is impossible. Additionally, they can replace certain high-strength bolts or locking rivet solutions, balancing installation efficiency with structural performance.

Advantages of Hucklok Blind Rivets

Hucklok Blind Rivets are renowned for their structural-grade performance, making them ideal for high-strength, high-reliability joining applications. Below are their core advantages.

High Structural Strength

Hucklok Blind Rivets utilize a mechanical locking mechanism, permanently locking the mandrel within the rivet body after installation. Compared to standard blind rivets, their shear and tensile strength typically increases by 30%–60%, approaching the level of structural fasteners.

Excellent Vibration Resistance

Without relying on friction or torque for locking, Hucklok Blind Rivets resist loosening under vibration and cyclic loading, making them ideal for dynamic applications like vehicles and construction machinery.

100% Mandrel Retention

The mandrel remains fully retained within the rivet body, eliminating safety hazards from mandrel detachment while enhancing overall joint rigidity and long-term stability.

Single-Side Installation Capability

Hucklok Blind Rivets offer single-side installation advantages, enabling high-strength connections in structures with inaccessible backsides. This significantly enhances construction and assembly flexibility.

Consistent Clamp Force

The installation process is controlled by specialized tools, ensuring stable and consistent clamping force independent of manual experience. This helps reduce quality fluctuations in mass production.

Reduced Maintenance Cost

The stable mechanical locking structure minimizes the risk of loosening and rework, contributing to lower maintenance and operational costs over the entire lifecycle.

Wide Industrial Acceptance

Hucklok Blind Rivets have been extensively adopted in steel structures, commercial vehicles, rail transportation, and energy equipment sectors. Their performance and reliability have been validated through long-term engineering practice.

How to Install Hucklok Blind Rivets?

Hucklok Blind Rivets are structural blind rivets featuring a standardized, highly controllable installation process. Proper installation is critical to ensuring their high strength and long-term reliability.

1. Prepare the Hole and Materials

Before installation, drill holes according to the diameter requirements of the Hucklok Blind Rivet. Hole dimensions must meet recommended tolerances. An oversized hole reduces locking effectiveness; an undersized hole impedes rivet insertion. The materials being joined should be properly aligned, free of foreign objects.

2. Insert the Hucklok Blind Rivet

Insert the Hucklok Blind Rivet into the hole from the accessible side until the rivet head is flush with the workpiece surface. No back-side operation is required at this stage, highlighting its typical single-side installation advantage.

3. Use the Dedicated Installation Tool

Hucklok Blind Rivets must be installed using the dedicated installation tool. The tool applies axial tension to the mandrel while supporting the rivet head, ensuring the rivet body expands correctly and locks on the back side.

4. Mandrel Locking and Clamp Formation

As tension increases, the rivet body undergoes controlled deformation on the backside, forming a stable bearing surface. Simultaneously, the mandrel is mechanically locked within the rivet body rather than simply breaking off. This process creates a stable and consistent clamping force, a core advantage of Hucklok.

5. Mandrel Break and Installation Completion

When tension reaches the design value, the mandrel breaks at its predetermined fracture point. The broken mandrel head remains retained within the rivet, completing the installation. The entire process is tool-controlled, minimizing human error.

6. Visual Inspection and Quality Check

After installation, quality can be confirmed through visual inspection. Key points include: whether the rivet head is flush, whether the backside is fully expanded, and whether the mandrel is completely retained. Typically, no complex testing is required to determine if the connection is acceptable.

Applications of Hucklok Blind Rivets

Commercial Vehicles and Trucks

Hucklok Blind Rivets are widely used for structural connections in commercial vehicles and trucks. They withstand long-term vibration and dynamic loads. Suitable for chassis, side panels, and load-bearing areas.

Steel Structures and Infrastructure

In steel structures and infrastructure projects, Hucklok Blind Rivets deliver strength comparable to structural fasteners. Their single-side installation capability enhances construction efficiency and safety.

Rail Transit Systems

Rail transit equipment demands exceptional connection stability. Hucklok Blind Rivets offer excellent fatigue resistance, making them suitable for vehicle structures and auxiliary component connections.

Construction and Heavy Equipment

In construction machinery and heavy equipment, Hucklok Blind Rivets maintain stable clamping force under harsh conditions, reducing loosening and maintenance frequency.

Energy and Industrial Equipment

Suitable for structural connections in energy equipment and industrial installations. Their mechanical locking mechanism meets long-term operational and high-reliability requirements.

Can Hucklok blind rives be used in harsh environments?

Yes. Hucklok Blind Rivets are exceptionally well-suited for demanding operating conditions.

Their structural design, material selection, and installation method are all optimized for high loads, intense vibration, and complex environments.

First, regarding structural reliability, Hucklok Blind Rivets employ a mechanical locking design. The mandrel remains 100% retained within the rivet body after installation. This structure delivers stable clamping force and resists loosening under prolonged vibration and cyclic loading. Compared to standard pop rivets, they offer significantly higher connection reliability in heavy-duty and dynamic applications.

Second, Hucklok Blind Rivets excel in vibration resistance and fatigue performance. Since the connection relies neither on torque nor friction, its clamping force is structurally locked. This ensures long-term stable connections in continuously vibrating environments like vehicles, construction machinery, and rail transit.

Regarding corrosion resistance, Hucklok Blind Rivets can be customized through material selection and surface treatments. For instance, using stainless steel or high-corrosion-resistant alloys, combined with zinc plating or other anti-corrosion coatings, meets requirements for outdoor, humid, or industrial corrosive environments. With appropriate material selection, their durability typically surpasses that of standard carbon steel fasteners.

Buy Hucklok Blind Rivets from Blind Rivet Manufacturer

Hucklok blind rivets are usually used in load-bearing areas, hence its high price.

If you want to buy high quality hucklok blind rivets directly from a blind rivet manufacturer, please contact us!

FAQs – Hucklok Rivets

Q1. What Are Hucklok Rivets Used For?

Hucklok Rivets are primarily used for structural connections requiring high strength, vibration resistance, and long-term reliability. Common applications include steel structures, commercial vehicles, construction machinery, and rail transportation.

Q2. How Do Hucklok Rivets Differ from Standard Blind Rivets?

Hucklok Rivets feature a mechanical locking mechanism where the mandrel is fully locked within the rivet body after installation. Compared to standard blind rivets, they typically offer higher shear and tensile strength and exhibit greater stability in vibrating environments.

Q3. Do Hucklok Rivets Require Special Installation Tools?

Yes. Hucklok Rivets necessitate specialized installation tools to complete the mandrel stretching and locking process. Dedicated tools ensure consistent clamping force and minimize installation errors.

Q4. Are Hucklok Rivets Suitable for Harsh Environments?

Yes. By selecting appropriate materials and surface treatments, Hucklok Rivets can be used in demanding conditions such as high humidity, severe vibration, and outdoor applications while maintaining long-term stable connections.

Q5. Can Hucklok Rivets Replace Bolts or Welding?

In many single-access structural connections, Hucklok Rivets can partially replace bolts or welding solutions. They offer significant advantages in installation efficiency, consistency, and maintenance costs. However, suitability for replacement must be evaluated based on specific application conditions.

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com