Table of Contents

Blind Rivet Sizes are something that must be considered before purchasing a Blind Rivet. So what are the parts of blind rivet sizes? How do I confirm the size of these parts? And how to measure blind rivets? Through this article, you will understand all of this!

Table of Contents

Why is Blind Rivet Sizes Important?

You need to have a deep understanding of the dimensions of the blind rivets before proceeding with a project. So why is it so important to have a deep understanding of the blind rivet sizes? To put in the first step of starting a project. There are several main reasons:

- Correctly sized rivets provide enough tightening force to ensure that the connected parts are held together securely. Under-sizing may result in insufficient tightening force and a loose connection; over-sizing may result in difficult installation or material damage.

- The right rivet size and hole match can simplify the installation process, reduce installation time and increase productivity.

- Correctly sized rivets are more reliable after installation, reducing the need for rework and maintenance due to connection failure.

- In critical structural components, selecting the correct size rivets prevents structural failure and ensures overall structural safety, especially in applications subjected to high loads or critical locations.

- matching the rivet diameter to the hole diameter ensures that the rivet expands and deforms correctly in the hole, providing a strong mechanical fixing. If the hole diameter does not match the rivet diameter, the reliability and strength of the connection will be compromised.

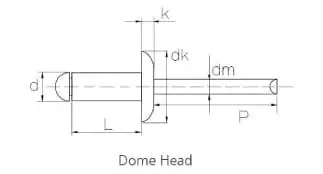

The diameter of a blind rivet is the outside diameter of the rivet stem, which is an important dimension in determining the size of the hole between the rivet and the material being joined. Selecting the proper rivet diameter is critical to ensuring the strength and stability of the connection.

The diagram above illustrates the structure of a blind rivet. The letter “d” represents the diameter of the rivet.

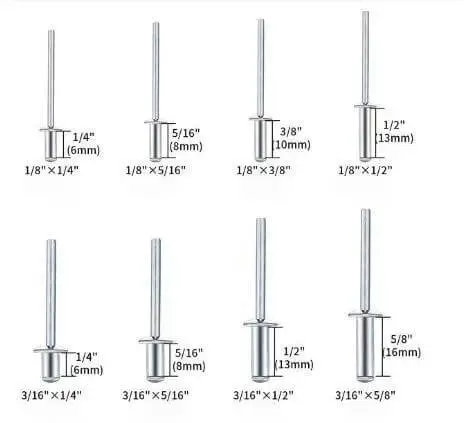

The diameter of a blind rivet is usually expressed in metric (millimeters, mm) or imperial (inches, inch). The following are common specifications:

| Rievt Diameter | |

| Metric | Inch |

| 2.4mm | 3/32″ |

| 3.2mm | 1/8″ |

| 4.0mm | 5/32“ |

| 4.8mm | 3/16” |

| 5.0mm | 6/31″ |

| 6.0mm | 15/64″ |

| 6.4mm | 1/4″ |

Selecting the proper Blind Rivet diameter is an important step in ensuring a strong and secure connection. Considering factors such as material thickness, hole size, load requirements and material properties can help you determine the most appropriate rivet diameter specification. In practice, following these principles will not only help to achieve a reliable connection, but also avoid installation and use problems associated with poor selection.

How to Choose The Right Rivet Diameter?

When you have this problem, the first thing you need to consider is the load requirements that the connection needs to withstand. Larger diameters provide higher pullout and shear forces.

Of course, if you have holes already drilled in the top of your product, you’ll want to choose a rivet diameter that matches the hole diameter. This will allow the rivet to be inserted and deformed smoothly.

The hole diameter of a blind rivet is the diameter of the hole that needs to be drilled in the material being joined when the rivet is installed. This hole diameter must be slightly larger than the diameter of the rivet itself in order for the rivet to be inserted smoothly and secured properly. Below are some common blind rivet sizes and their corresponding recommended hole diameters:

| Rivet Diameter(mm/inch) | Hole Diameter(mm/inch) |

| 2.4 mm | 2.5 – 2.7 mm |

| 3.2 mm | 3.3 – 3.5 mm |

| 4.0 mm | 4.1 – 4.3 mm |

| 4.8 mm | 4.9 – 5.1 mm |

| 5.0 mm | 5.1 – 5.3 mm |

| 6.0 m | 6.1 – 6.4 mm |

| 6.4 mm | 6.5 – 6.8 mm |

| 3/32″ (0.0938 inch) | 0.098 – 0.102 inch |

| 1/8″ (0.1250 inch) | 0.129 – 0.133 inch |

| 5/32″ (0.1563 inch) | 0.161 – 0.165 inch |

| 3/16″ (0.1875 inch) | 0.192 – 0.196 inch |

| 1/4″ (0.2500 inch) | 0.255 – 0.261 inch |

Why is it Important to Match the Rivet Diameter to the Hole Diameter?

Matching rivet diameter to hole diameter is critical to the quality of the riveted joint, affecting the stability, strength and durability of the connection. Both too large and too small hole diameters can have an impact.

Hole Diameter > Rivet Diameter

- Rivets do not properly deform and expand to fill the entire hole

- The force area of the rivet is reduced and the shear strength decreases

- Loose connections may allow moisture and gas to enter the gap between the rivet and the hole wall, resulting in seal failure.

- Because the hole is too large, the rivet moves through the hole and can generate unwanted noise, especially in noise-sensitive applications such as mechanical equipment or automotive interiors.

Hole Diameter < Rivet Diameter

- Difficult to insert rivets

- If the rivet is difficult to insert fully into the hole, the expanding portion of the rivet may not be able to expand and deform sufficiently in the hole, resulting in a failure to form a strong fixing.

- When working with brittle materials (e.g., certain plastics, fiberglass), forcing a rivet into a hole that is too small may cause the material to break or crack.

Drill of Blind Rivets

Drilling holes with a drill is the first step in the procedure for installing blind rivets. The size of the drill bit is usually the same as the diameter of the hole. So the degree of match between the drill bit and the rivet diameter can be referred to the degree of match between the rivet diameter and the hole diameter.

Rivet Body Length

The blind rivet Body Length is the total length of the rivet before installation, excluding the head and core section. This length is an important parameter in selecting the right rivet, as it must be long enough to pass through all the layers of material to be joined, while still forming a reliable fixing on the backside of the material.

The body length of the rivet must be long enough to ensure that it will pass through the material to be joined and leave enough to deform and fix. A short body length may result in the rivet not being able to fully penetrate the material to form a reliable connection. The body length of the rivet shall be at least equal to or slightly greater than the cumulative thickness of all layers to be joined.

Assuming that the total thickness of the material to be joined is 5 mm, the body length of the rivet selected should be at least 5 mm to ensure that the rivet can fully penetrate the material and create sufficient holding force on the backside. Typically, a suitable rivet body length may be slightly longer than the total thickness to ensure that there is sufficient room for deformation.

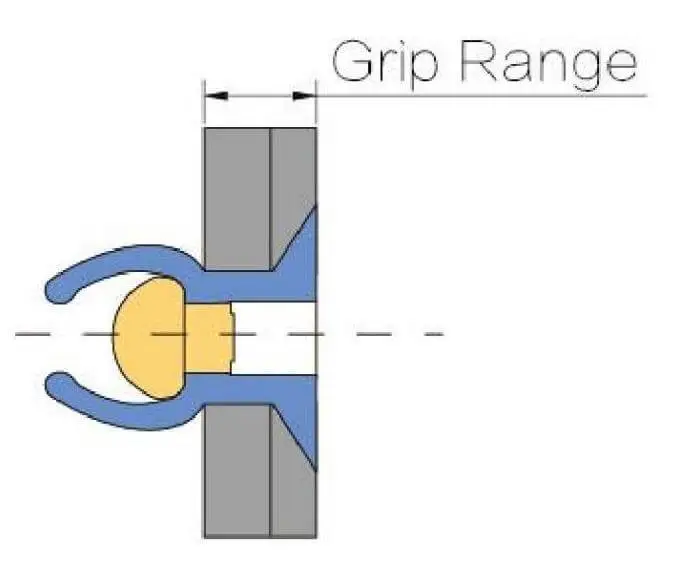

Grip Range

The riveting range of a blind rivet, often referred to as the Rivet Grip Range, is the range of thicknesses over which the rivet can effectively grip and hold material. This parameter determines the thickness of the material that the rivet can securely hold during installation and is a key indicator of the type of rivet that is appropriate for the application.

Riveting range refers to the total material thickness that can be reliably clamped by a blind rivet, including the cumulative thickness of all materials clamped. It is usually expressed as a range, e.g. 1.6 – 3.2 mm, indicating that the rivet is suitable for material combinations with thicknesses between 1.6 mm and 3.2 mm.

Correct selection of the riveting range is important.

- Ensuring Reliable Connections: Selecting the correct rivet range ensures that the rivet creates the proper deformation zone on the backside of the material, providing a reliable mechanical fixing. A rivet with too little or too much reach may result in an unstable connection or failure to install correctly.

- Accommodate varying material thicknesses: In practical applications, material thicknesses may vary due to manufacturing tolerances, coatings or other factors. Choosing the right rivet range can effectively address these variations and ensure a strong and stable connection.

Examples of common riveting ranges:

- 1.6 – 3.2 mm: For materials with a total thickness between 1.6 mm and 3.2 mm.

- 3.2 – 4.8 mm: for materials with a total thickness between 3.2 mm and 4.8 mm.

- 4.8 – 6.4 mm: for materials with a total thickness between 4.8 mm and 6.4 mm.

Head Diameter and Width

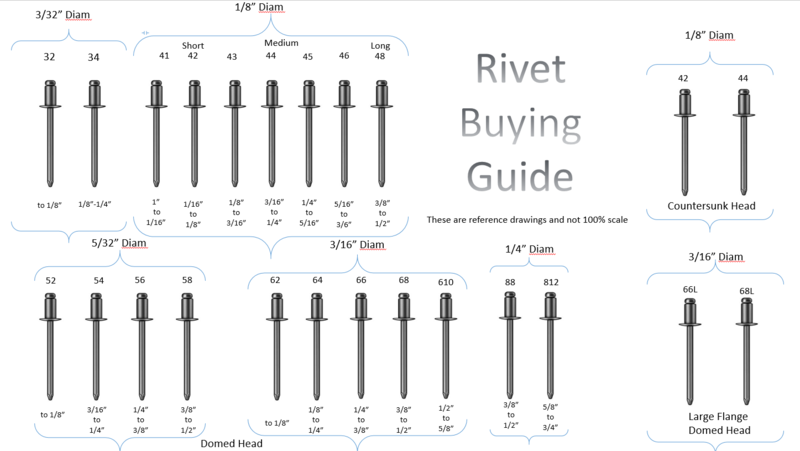

Before we go into detail about the diameter and thickness of rivet head types, we need to know that there are several head types of rivets. The main head types of rivets are categorized as follows:

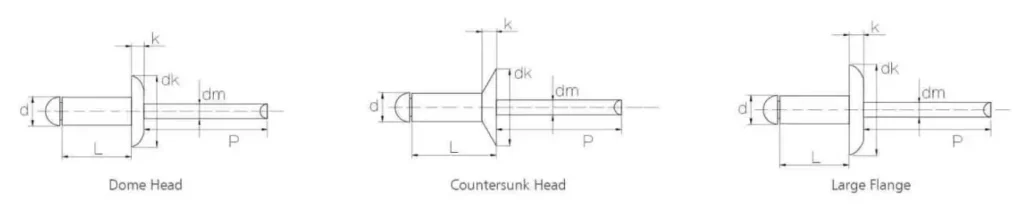

The “dk” and “k” in the chart above represent the head diameter and head thickness of the blind rivet, respectively.

dk – head diameter

k – head thickness

Dome Head

The Dome Head Blind Rivet is one of the most common head types with a semi-circular head. This design provides good tensile and shear strength.

Head Diameter: typically 1.5 to 2 times the rivet diameter. For example, a 3.2 mm diameter rivet will typically have a head diameter between 6 mm and 6.4 mm.

Head Height: The height of a round head is generally relatively small, providing a moderate level of head projection.

Large Flange Head

Large Flange Head Blind Rivets have a larger head diameter than standard round heads and are often used to increase the contact area and thus spread the pressure. This design is particularly suited to softer materials such as plastics or thin sheet metal.

Head Diameter: Typically 2 to 3 times the diameter of the rivet. For example, a 3.2 mm diameter rivet may have a head diameter between 8 mm and 9.6 mm.

Head Height: The height of a large flange head is generally similar to that of a round head, but its larger head diameter provides a larger support surface.

Countersunk Head

Countersunk head blind rivets have a head designed to be fully embedded in the joining material, with the head being flush with the surface of the material. This design is used where a smooth appearance is desired or to avoid interference from a protruding head.

Head Diameter: Countersunk heads are typically slightly larger than the rivet diameter, depending on the rivet standard. For example, a 3.2 mm diameter rivet will typically have a head diameter between 6.5 mm and 7 mm.

Head Width: The angle of the countersunk head is typically 90 or 120 degrees, depending on the design requirements. The embedment depth and width of the head needs to take into account the thickness of the material being joined.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Blind rivet size comparison table

| Rivet Diameter | Grip Range | Recommended Hole Size | Drill Bit # |

|---|---|---|---|

| 1/8″ (3.2 mm) | 0.063″ – 0.125″ (1.6–3.2 mm) | 0.1285″ (3.26 mm) | #30 |

| 5/32″ (4.0 mm) | 0.125″ – 0.250″ (3.2–6.4 mm) | 0.1360″ (3.45 mm) | #29 |

| 3/16″ (4.8 mm) | 0.188″ – 0.375″ (4.8–9.5 mm) | 0.1920″ (4.88 mm) | #11 |

| 1/4″ (6.4 mm) | 0.250″ – 0.500″ (6.4–12.7 mm) | 0.2570″ (6.53 mm) | F drill |

A proper understanding of the dimensional relationships and standard classifications of blind rivets is the foundation for achieving high-strength, high-consistency connection quality.

Professional advice:

- When selecting a blind rivet, the clamping range should be the primary reference criterion, rather than the total length. The total length may be misleading under different head types.

- For environments with vibration or high fatigue, prioritize blind rivets with larger shank diameters and structural designs, and ensure hole diameter fitting accuracy.

- It is recommended to reserve a ±0.1 mm holding margin in engineering design to account for sheet metal tolerances and installation process variations.

Although blind rivets have a simple structure, their size selection involves multiple factors. When choosing the right blind rivet sizes, it is necessary to comprehensively evaluate factors such as sheet thickness, connection strength requirements, installation process, and hole diameter accuracy.

Step 1: Determine the total thickness of the sheet metal → Match the appropriate rivet grip range

The grip range of a blind rivet refers to the total thickness range of sheet metal that can be reliably clamped after riveting. This is the most critical parameter in selecting the size of a blind rivet.

Example: If the total sheet thickness is 3.0 mm, it is recommended to select specifications with a grip range of 2.5–4.0 mm or 2.0–4.5 mm to ensure adequate clamping and reasonable installation clearance.

- If the grip is too small, it may result in the rivet core not fully expanding, leading to insufficient clamping force.

- If the grip is too large, the expansion may be insufficient, causing the rivet core to slip out or the connection to be loose.

✅ It is recommended to prioritize determining the grip range rather than the total length.

Step 2: Confirm material type and connection strength requirements

Different material combinations have different requirements for rivet size and expansion structure:

- Lightweight structures (such as aluminum + plastic): Choose softer aluminum rivets and control the shaft diameter to prevent material bulging and cracking;

- Steel + steel structures: Use steel or stainless steel rivets with a shaft diameter of at least 4.0 mm to ensure shear strength;

- High-strength/high-vibration areas: Prioritize structural rivets and increase the diameter to prevent loosening or fatigue cracks.

Step 3: Select the appropriate shank diameter and head style.

The larger the shank diameter, the greater the load-bearing capacity. Common sizes include:

- 1/8″ (3.2 mm): Light-duty structures, recommended for single-layer aluminum plates, electronic enclosures, etc.;

- 5/32″ (4.0 mm): Medium-load connections;

- 3/16″ (4.8 mm) and above: Heavy-duty structures or multi-layer plate riveting.

Head style selection depends on load requirements and aesthetic needs:

- Dome Head: General-purpose, suitable for most applications;

- Countersunk: Suitable for applications requiring a flat surface, such as door panels or panels;

- Large Flange: Used for soft materials or structures requiring an expanded clamping area, such as plastic or composite panels.

Step 4: Beware of selection pitfalls: Never judge rivet specifications based on “total length”

Many users only refer to the “total length” of rivets when selecting them, while ignoring the most critical “grip range.” This is a common pitfall that leads to riveting failure.

- Rivets with the same total length may be suitable for completely different grip ranges due to differences in head shape and shaft diameter.

- The correct approach is: first confirm the structural thickness → match the appropriate grip range → then select the shaft diameter and head shape based on material and process requirements.

Key factors affecting the selection of blind rivet size

When selecting blind rivet sizes, considering only the thickness of the sheet material is insufficient. The following factors have a decisive influence on selection:

- Sheet material type and thickness tolerance: Soft materials (such as plastic or aluminum) require larger rivet head surfaces and clamping allowances. Structures with significant thickness deviations should prioritize rivet specifications with a wide clamping range (Grip).

- Load type and strength requirements: If the connection point must withstand high shear or tensile loads, it is recommended to use rivets with larger shank diameters or structural designs, and to match them with appropriate hole diameters and installation forces.

- Installation process constraints: Factors such as whether manual assembly or automated equipment is used, and whether there are single-sided accessibility restrictions, will all influence the appropriate configuration of size and head type.

- Hole spacing, edge distance, and space constraints: In compact structural areas, consider whether the head type (e.g., countersunk or small cap) interferes with adjacent components, and assess the impact of hole diameter and edge distance on strength.

- Rivet material and thermal expansion differences: In structures subject to temperature changes, avoid stress concentration caused by inconsistent material expansion.

Common selection recommendations for different structural applications

| Application Scenario | Recommended Rivet Diameter | Recommended Grip Range | Suggested Head Style | Rivet Material |

|---|---|---|---|---|

| Sheet Metal Assembly | 1/8″ (3.2 mm) | 1.5–3.5 mm | Dome Head | Aluminum |

| Plastic Components | 1/8″ or 5/32″ (3.2–4.0 mm) | 2.0–4.5 mm | Large Flange | Aluminum or Copper |

| Stainless Steel Panels | 3/16″ (4.8 mm) | 3.0–6.5 mm | Dome or Countersunk | Stainless Steel |

| Waterproof/Sealed Enclosure | 1/8″ or 5/32″ | 1.5–4.0 mm | Dome + EPDM Sealing Washer | Sealed or Closed-End Type |

| Industrial Machine Frames | 3/16″ or 1/4″ | 4.5–9.5 mm | Dome or Structural Head | Steel or Stainless Steel |

| Automotive Trim/Interior | 1/8″ | 2.0–4.0 mm | Countersunk or Dome Head | Aluminum + Steel Mandrel |

| Electronic Housings | 3.2 mm | 1.5–3.0 mm | Dome Head | Aluminum |

This table can be used as a quick reference for initial selection decisions. However, the final decision should be based on structural drawings, mechanical requirements, and the rivet manufacturer’s technical data sheet (TDS) to ensure that the rivets meet the actual application requirements.

Conclusion

By reading the above information, I’m sure you’ve gained a deep understanding of Blind Rivet Sizes. The dimensions of Blind Rivet include rivet diameter, rivet length, riveting range, hole diameter, rivet head type diameter and thickness.

With the above dimensional information, you will have a figurative impression of the Blind Rivet. We believe that this information can be a great help before you formally place an order.

Order Blind Rivets from Rivmate

Rivmate is a top manufacturer of Blind Rivets in China. We can offer you full size blind rivets, including 2.4mm(3/32″),3.2mm(1/8″),4.0mm(5/32″),4.8mm(3/16″),5.0mm(6/31″),6.0mm(15/64″),6.4mm(1/4″).

Of course, if your project has special requirements for the Blind Rivet Sizes. We also provide customized service, please understand to contact our engineers.