Table of Contents

Hot riveting is a riveting technique used in heavy duty applications. This technique requires a high level of equipment and operator training, and hot riveting provides a very high level of strength. So what is hot riveting?

Table of Contents

What is Hot Riveting?

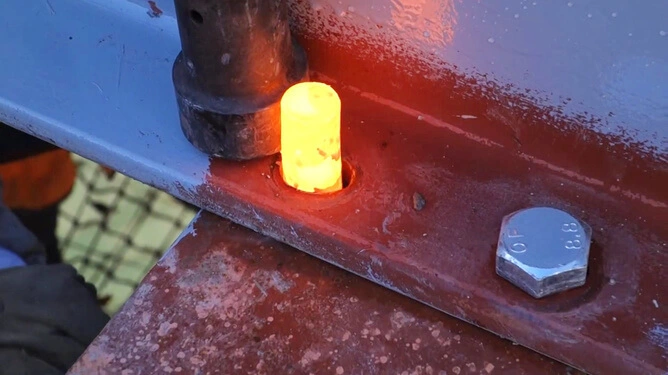

There are two methods of connecting rivets, one is cold riveting and the other is hot riveting. both of these riveting techniques permanently hold materials together. Hot riveting is done by heating the rivets to a certain temperature and then riveting them together, utilizing the expansion of the heated rivets and the contraction of the cooled rivets to achieve a tight connection. Hot riveting is a technique generally used for structural joints where high strength and durability are required.

Hot riveting techniques are often found on heavy duty applications. However, it has obvious drawbacks, as it requires a high level of equipment and operators to install it. Therefore, with the development of modern technology, hot riveting is slowly diminishing, but it is still irreplaceable in certain specific areas.

What are the Advantages of Hot Riveting?

Hot riveting is a technique that has been around for a long time. There is a reason why it has never been completely replaced, Hot riveting has many advantages, especially in structures that require high strength, durability and stability. The following are the main advantages of hot riveting.

1. High Strength Connections

Hot riveting is done by heating the rivet and then forming it, the rivet shrinks during the cooling process, a process that creates a strong tightening force. The cooled rivet will press the connecting material tightly together, making the riveted joint very strong and able to withstand large tensile and shear forces.

2. Permanent Connection

It is well known that rivets are permanent connections. Hot riveting is certainly no exception. That’s why rivets are better suited for applications in structures that require a long-term, stable connection. During the process of hot riveting, the rivets cool down to form a fastening point that is so strong that no subsequent maintenance or adjustment is usually required.

3. High Durability

Hot riveted joints exhibit excellent durability over long periods of time and are able to maintain structural integrity in harsh environments. It has good fatigue and vibration resistance, making it suitable for use in bridges, ships and other engineered structures that are exposed for long periods of time.

4. Suitable for Thick and Heavy and Large Size Structure

Hot riveting is ideally suited for joining thick materials. Between thicker steel plates and metal components, hot riveting provides a strong hold and is suitable for large structures such as bridges, railroad cars, ship hulls, and more.

5. No Welding Contamination

In contrast to welding, hot riveting does not produce weld spatter or slag, making it more suitable for use in structures with high surface finish requirements. In addition, hot riveting eliminates the need to consider porosity or cracking that can occur during the welding process.

Disadvantages of Hot Riveting

Hot riveting, despite its many advantages, has some disadvantages.

1. Time-consuming Process

The process of hot riveting involves heating the rivets, riveting them manually and cooling them, which makes the whole process relatively slow. Compared to modern welding and bolting, hot riveting takes longer and is less efficient, especially in mass production or installation.

2. High Labor Intensity

Riveting requires a high level of skill and physical strength on the part of the worker. The rivets need to be heated to a high temperature, then riveted and cooled quickly, and workers need to have skillful operating skills. Long-term operation of hot riveting tools is a high-intensity physical labor for workers, especially in high temperature and harsh construction environment.

3. Difficult to Adapt to Modern Complex Structures

Modern architectural and mechanical structures are becoming increasingly complex, with many components designed to be delicate and difficult to reach, making the application of the hot riveting process in these areas relatively difficult. In some complex structures, rivets may not be easily inserted or riveted, which limits the scope of application of hot riveting.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Applications of Hot Riveting

Although hot riveting is now used in fewer scenarios, but there are still many scenarios where hot riveting still has irreplaceable advantages.

- Bridge construction: Hot riveting used to be the main connection method for steel bridge construction, widely used to connect large members such as steel girders and plates. Some famous early steel bridges, such as the Forth Bridge in England, were built using hot riveting. Many modern bridges still maintain some of the applications of hot riveting.

- Shipbuilding: in the early 20th century in the manufacture of large steel ships, hot riveting is widely used in the fixing of the hull steel plate, such as the construction of the Titanic used a large number of hot riveting.

- Railroad vehicles: in the steam locomotive and freight carriages in the early manufacturing process, the carriage side panels, chassis and frame part of the hot riveting technology.

- Aircraft manufacturing: hot riveting is used to connect the aluminum or steel parts of the aircraft, many military aircraft fuselage and wing construction are using hot riveting. Most of the connections between the fuselage skeleton and the external skin use hot riveting.

- Heavy machinery: hot riveting is commonly used in the assembly of heavy machinery and equipment, especially those subject to greater vibration and shock of the mechanical parts. Hot riveting in mining machinery, excavators, cranes and other large-scale equipment is widely used.

- Military products: In the manufacture of some military equipment, hot riveting is still used in armored vehicles, military machinery and other high-stress and high-demand structure due to its durability and shock resistance. For example, some key structures of military equipment such as tanks and armored vehicles will use hot riveting technology.

What is the Difference Between Hot and Cold Riveting?

| Attribute | Hot riveting | Cold riveting |

| Rivet treatment | Rivet is heated, expands, and contracts upon cooling for a tighter connection | Rivet is deformed mechanically at room temperature to secure the connection |

| Process complexity | Requires heating equipment, more complex and time-consuming | Simple process, faster operation |

| Connection strength | High strength, suitable for heavy materials and high-load structures | Lower strength, suitable for thin materials and light-load structures |

| Suitable materials | Thick steel plates, heavy metal structures | Thin metal sheets, plastics, lightweight materials |

| Vibration resistance | Excellent vibration and shock resistance, ideal for environments with prolonged vibration or dynamic loads | Good vibration resistance but less suitable for high-vibration environments compared to hot riveting |

| Applications | Bridges, ships, railway vehicles, heavy machinery | Household appliances, lightweight equipment, precision industries |

- Hot riveting is suitable for thick and heavy materials and large size rivets, which require high strength and long-lasting stable connection, commonly used in bridges, ships and other large structures, although the process is complicated but the connection strength is high.

- Cold riveting, on the other hand, is suitable for thin materials and lightweight structures, easy and fast to operate, suitable for daily industrial and lightweight manufacturing, such as home appliances, electronic products.

If you want to know more, please read this article “Difference Betwenn Hot Riveting and Cold Riveting”. You can learn more.

Conclusion

Cold riveting and cold riveting are both rivet solutions. there is a lot of difference between their application scenarios. Although many applications of hot riveting have been replaced by cold riveting. But still can not ignore its importance.

Customize riveting solutions for your project. Contact our engineers today!