How Does a Self Piercing Rivet Work?

Table of Contents

In modern manufacturing, lightweighting and the application of multiple materials have become mainstream trends. The extensive use of aluminum, galvanized steel, and composite materials has posed challenges to traditional welding and riveting methods. These methods often fail to balance strength, efficiency, and consistency in appearance. At this point, the industry began to focus on a more advanced solution – Self-Piercing Riveting (SPR). Many engineers and manufacturers would ask: “How does a self piercing rivet work?” How does it achieve high-strength connections without the need for pre-drilling and welding?

This blog will provide an in-depth analysis of the working principle and application value of SPR from a professional perspective. We will gradually break down its core process flow and compare it with traditional riveting and welding to reveal the advantages of SPR in terms of efficiency, material compatibility and consistency.

Self-Piercing Rivets (SPR) are an advanced type of mechanical fastener. Their most distinctive feature is that they do not require pre-drilling. Under high pressure, the rivet can directly pierce through the upper layer of material and expand in the lower layer, thus forming a secure mechanical lock. The entire process is completed in one step, without the need for additional heat sources or pre-treatment.

Structurally speaking, self-piercing rivets are typically composed of three key parts:

- Head: Provides the insertion force and bearing surface to ensure a smooth appearance after connection.

- Shank: Achieves the penetration function and bears the main mechanical strength.

- Partially Hollow Tail: Expands during the forming process to create a mechanical lock, ensuring a reliable bond between different materials.

This structural design enables SPR to simultaneously possess the mechanical reliability of riveting and the high efficiency of automated production. Therefore, it has become a widely adopted high-performance fastening solution in the automotive manufacturing, aerospace, and home appliance industries.

How Does a Self-Piercing Rivet Work?

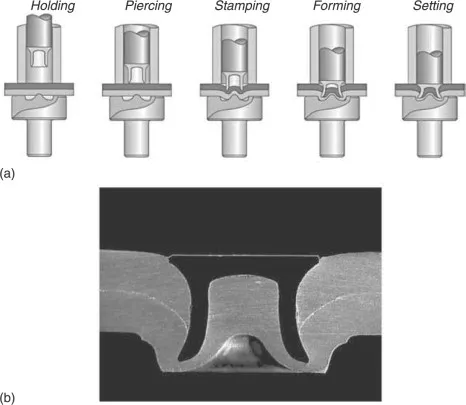

The working process of a Self-Piercing Rivet (SPR) can be divided into four key steps, each of which ensures the reliability and efficiency of the connection:

Positioning

Before starting the riveting process, the rivets are placed on the surface of the materials to be joined. The equipment is usually a hydraulic or servo-driven riveting machine, which can precisely control the position and pressure. The positioning step is crucial because any deviation could cause the rivets to be skewed or poorly locked. On automated production lines, robotic arms can ensure repeatability accuracy, with common errors being less than ±0.1 mm.

Piercing Upper Layer

As the pressure increases, the head of the rivet penetrates the upper layer material. The key to this step lies in controlling the penetration depth. The SPR only penetrates the upper layer and does not completely pierce through the lower layer. This not only avoids hole leakage but also protects the integrity of the lower layer material.

Unlike traditional rivets, the tip of the SPR is specially designed (usually conical or semi-hollow), enabling plastic deformation without removing any material. This means no chip residue, which is more environmentally friendly.

Expansion in Lower Layer

When the tail end of the rivet enters the lower layer material, the shape of the lower mold (anvil) forces it to undergo radial expansion. The tail end expands and embeds into the lower layer material, forming a structure similar to a “hook”. This process ensures a tight fit between different materials, even for combinations such as aluminum + steel or galvanized steel + composite materials, maintaining high strength and stability.

The experiment has proved that the expansion process of SPR can form a “circular stress zone”, significantly enhancing the tensile and shear strengths.

Mechanical Interlock

Ultimately, the tail end of the rivet is completely locked to the underlying material, forming a permanent mechanical bond. Unlike welding, this locking process has no heat affected zone (HAZ) and does not cause changes in the metal structure or damage to the coating. Unlike traditional riveting, it also does not require double-sided operation or additional fasteners.

SPR joint has excellent fatigue performance and can remain stable even in environments with vibration and impact. For instance, in the automotive body-in-white (BIW), the fatigue life of the SPR connection is typically 1.5 to 2 times that of spot welding.

The entire process requires no drilling, no heat source, and no additional fasteners. Compared to traditional methods, the SPR connection is more efficient and stable, and is particularly suitable for mixed assembly of aluminum, steel, and composite materials.

In modern manufacturing, self-piercing riveting (Self-Piercing Riveting, SPR) has gradually become the mainstream alternative to traditional welding and riveting due to its unique process. Its advantages mainly lie in the following aspects:

a. No need for pre-drilling

SPR can be directly connected onto the material. This eliminates the need for drilling, which not only enhances production efficiency but also reduces tool wear and maintenance costs.

b. Suitable for different materials

It can efficiently connect combinations such as aluminum + steel, galvanized steel + composite materials. In these scenarios, welding often poses technical difficulties, but SPR can maintain high strength and stability.

c. No Heat Affected Zone (HAZ)

SPR belongs to cold processing and does not cause any changes in the material’s structure, nor does it damage the coating. Compared to welding, it can better maintain the original strength and corrosion resistance of the material.

d. Automated-friendly

The SPR process is easy to integrate with robotic production lines. The single-point connection time is usually around 1 second, which is suitable for large-scale automated production, such as the manufacturing of automotive body panels.

e. High connection consistency

The process has a high degree of standardization, relying on equipment rather than human accuracy. Compared to traditional riveting, SPR significantly reduces human errors and ensures the consistency of connections in mass production.

SPR has been widely applied in industries such as automobiles, aviation and home appliances. It not only optimizes production efficiency, but also provides a reliable connection solution for lightweighting and multi-material design.

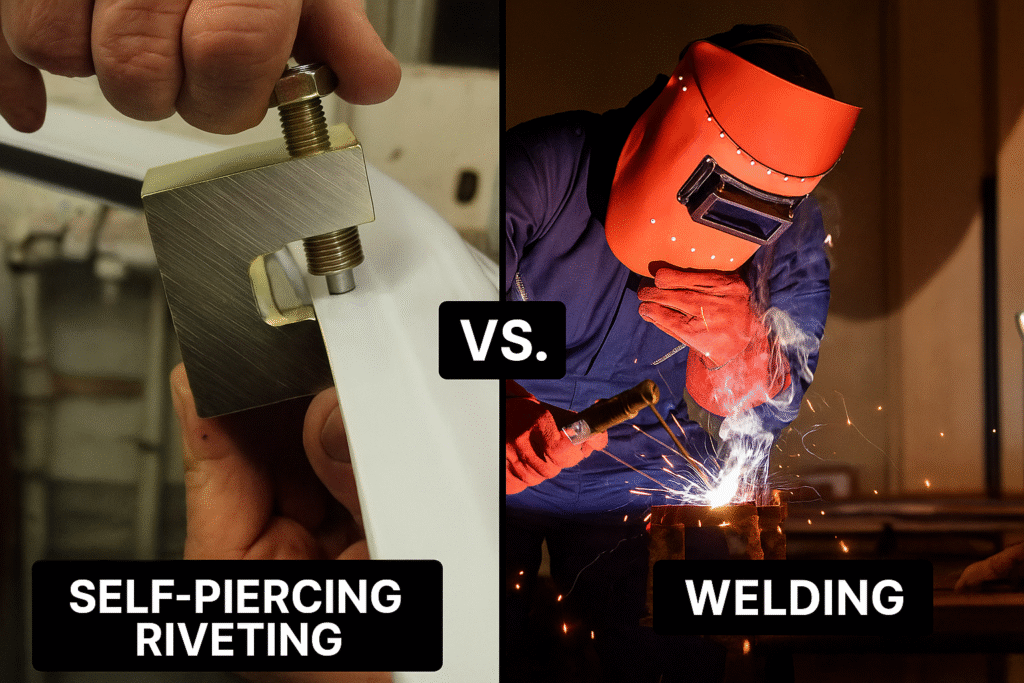

SPR vs Other Joining Methods

In the manufacturing industry, common connection methods include traditional riveting, welding and bolt connections. Compared with these processes, self-piercing riveting (SPR) demonstrates unique advantages, while also having its limitations.

① Conventional Riveting

Traditional riveting requires pre-drilling, which involves multiple steps and has low efficiency. SPR, on the other hand, can be directly pressed into the material, eliminating the drilling process and shortening the production time.

② Welding

Welding relies on heat sources, which can easily cause material deformation, residual welding slag and heat-affected zones. SPR does not require heat energy, avoiding these problems. At the same time, it is more environmentally friendly and has lower energy consumption.

③ Bolting

The bolts are detachable and suitable for scenarios requiring maintenance. However, in comparison, the SPR connection is lighter and faster, and is particularly suitable for large-scale, one-time, permanent assembly.

Table: Joining Methods Comparison

| Comparison Dimension | Self-Piercing Riveting (SPR) | Conventional Riveting | Welding | Bolting |

|---|---|---|---|---|

| Installation Speed | Fast (≈1 second per point, suitable for automation) | Slow, requires pre-drilling | Medium, requires welding preparation | Slow, requires tightening |

| Applicable Materials | Dissimilar materials (aluminum + steel, steel + composites) | Mainly similar metals | Mainly similar metals, limited with dissimilar materials | Broad, suitable for almost all materials |

| Appearance Quality | Flat, neat, no spatter | Visible holes, average appearance | Likely spatter and discoloration, requires post-processing | Bolts exposed, affects appearance |

| Joint Strength | High strength, excellent fatigue resistance | Moderate, depends on operator skill | High, but prone to cracking under fatigue | High, and detachable |

| Environmental Impact | No heat, low energy consumption, eco-friendly | Produces chips (drilling waste), moderate eco-friendliness | High energy consumption, sparks and fumes | Moderate, requires additional fastener production |

Applications of Self-Piercing Rivets

With the continuous pursuit of lightweighting, multi-materiality and high efficiency in the manufacturing industry, self-piercing riveting (Self-Piercing Riveting, SPR) has been widely applied in various industries. Its technological advantages not only address the shortcomings of traditional welding and riveting, but also drive the development of new-generation structural designs.

- Automotive Industry

SPR is widely used in aluminum alloy vehicle bodies and lightweight frame structures. For instance, Tesla and Jaguar Land Rover extensively employ SPR in vehicle body manufacturing, using it for the connection of different materials such as aluminum and steel. This process not only ensures structural strength but also reduces the damage to the coating caused by welding, thereby extending the lifespan of the entire vehicle.

- Aerospace

SPR can achieve reliable connections between aluminum alloys and composite materials. Compared to welding, it avoids the heat affected zone (HAZ) and can better maintain the material properties and fatigue life. Therefore, SPR is often used in aircraft skins, hatches, and composite structural components. - Architecture and Household Appliances (Construction & Appliances)

In scenarios such as building curtain walls and metal roofs, SPR can quickly connect coated steel plates and maintain the integrity of the anti-corrosion layer. In the manufacturing of household appliances (such as refrigerators and washing machines), SPR is widely used in the assembly of thin-walled metal parts, not only providing a beautiful appearance but also enhancing production efficiency.

Limitations of SPR

Although Self-Piercing Riveting (SPR) has significant advantages in terms of efficiency, compatibility with different materials, and integration of automation, it is not the best choice in all application scenarios. Understanding its limitations can help manufacturing enterprises make more rational decisions in their process planning.

- Initial equipment cost is relatively high

SPR requires a dedicated press-bending machine, usually with hydraulic or servo drive systems. Compared to traditional riveting or welding equipment, the initial investment is higher. For small and medium-sized manufacturers, they must consider the payback period of the investment. - Not applicable to extremely thick or extremely hard materials

The penetration and expansion capabilities of SPR rivets are limited. For materials with excessive thickness or hardness, a reliable locking structure may not be achievable. In such cases, welding or bolt connections might be more appropriate. - Belongs to a permanent connection

Once the SPR is formed, it is difficult to disassemble without damaging the material. Therefore, it is not suitable for applications that require frequent assembly, maintenance or component replacement. For example, in electrical equipment or mechanical systems with high maintenance requirements, threaded fasteners remain a more reasonable choice.

Rivmate Expertise & Solutions

As a professional supplier of fastening technology, Rivmate offers manufacturing enterprises a comprehensive range of self-tapping riveting (SPR) products and services. Its advantages are not only reflected in the performance of the rivets themselves, but also in the systematic ability to adapt the process and provide technical support.

Product Features of Rivmate SPR

- Multiple material options available: Offer aluminum, stainless steel, and steel rivets to meet various material combinations and strength requirements.

- Comprehensive Grip Range compatibility solution: Cover a wide range of thicknesses from thin sheets to multi-layer structures, ensuring flexibility in assembly.

- Compliant with international standards: All products meet the ISO 14589 / DIN 7337 standards, ensuring consistency and compatibility with global supply chains.

Services provided by Rivmate

- Process Evaluation and Selection Guidance: Based on material properties and structural requirements, recommend the most optimal rivet solution for customers.

- Compatibility Support for Automated Production Lines: Ensure that SPR rivets can be seamlessly integrated with existing press riveting equipment and robotic production systems, reducing additional investment.

- Customized Solutions: For special application scenarios, provide non-standard rivet design, small-batch prototyping and verification, enhancing the flexibility of customer R&D and production.

With the combination of standardized products + specialized services, Rivmate is not only a supplier of rivets, but also an important partner for enterprises to optimize assembly processes and enhance production efficiency.

FAQ

Q1: Can SPR replace welding?

It is possible in many scenarios. Especially in combinations of aluminum + steel, galvanized steel + composite materials, the reliability and consistency of SPR are often superior to welding. However, in thick plate steel structures or scenarios requiring extremely high load-bearing capacity, welding still has advantages. Therefore, SPR and welding are usually in a complementary relationship, rather than being completely substitutable.

Q2: Is SPR stronger than traditional rivets?

The strength performance varies depending on the application. SPR outperforms traditional riveting in terms of fatigue resistance, consistency, and automation efficiency, and does not rely on human accuracy. However, in some low-load and low-cost applications, traditional rivets are still sufficient. Therefore, SPR is more suitable for high-end manufacturing and mass production.

Q3: Is SPR suitable for the connection of aluminum and steel?

It is highly suitable. SPR is specifically designed for intermetallic material bonding, and can maintain high strength and durability in the aluminum + steel combination. Compared to welding, SPR does not damage the coating and does not create a heat affected zone (HAZ), thus better preserving the corrosion resistance.

Q4: Does Rivmate provide the SPR selection table and installation guide?

Yes. Rivmate offers standardized SPR selection tables, covering materials, Grip Range and application scenarios. It also provides installation guidelines and process consultation, helping customers achieve equipment compatibility and process optimization. For special requirements, Rivmate can also provide customized solutions.

Get Your SPR Solution with Rivmate Today

Self-Piercing Riveting (SPR) has emerged as the preferred method for lightweighting and connecting dissimilar materials due to its advantages of being efficient, environmentally friendly, and reliable. It not only enhances production efficiency but also reduces energy consumption and subsequent processing costs. The application scope of SPR is expanding in industries such as automotive, aerospace, home appliances, and construction.

If you are looking for a better connection solution, Rivmate can offer you professional SPR selection tables, installation guidelines, and process evaluation support. Whether it’s standardized products or customized solutions, Rivmate can help your production achieve a more rapid, stronger, and greener upgrade.

📩 Contact Rivmate immediately to obtain exclusive SPR selection and process consultation services.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met