Table of Contents

When describing the rivets you need to the rivet manufacturer, you need to provide the rivet diameter and rivet length. So do you know how to determine rivet diameter? Through this article, you will understand all this and know exactly how to choose the most suitable rivet diameter for your business.

Table of Contents

What is the Rivet Diameter?

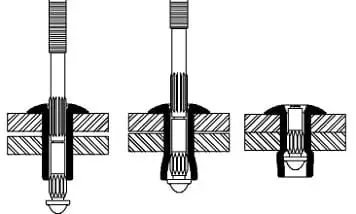

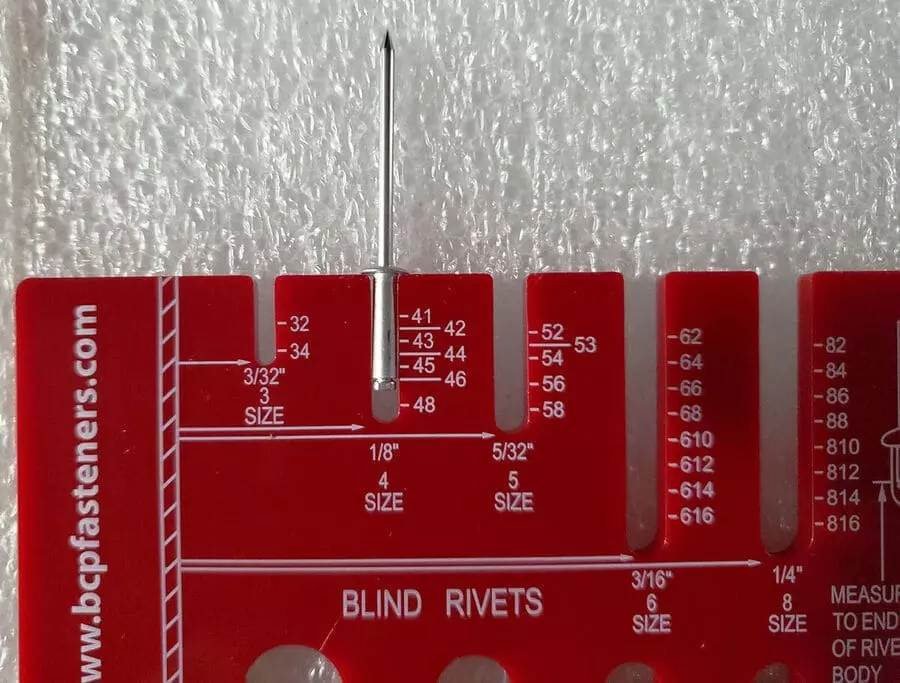

Rivet Diameter is the external diameter of a rivet, usually the diameter of the largest circular portion of the head (or body) of the rivet. This size is one of the most critical parameters when selecting a rivet, as it directly determines whether or not the rivet will fit correctly and hold the material effectively.

Rivet size is usually described as a combination of rivet diameter and rivet length. Common sizes for rivet diameters typically range from 1.6mm (1/16“) to 6.4mm (1/4”).

Importance of Rivet Diameter

Rivet diameter has a direct impact on the effectiveness of the riveting process, the strength of the connection and the reliability of the product. Choosing the right rivet diameter is critical to ensuring the quality and performance of the connection.

1. Ensuring the Strength of the Connection

Rivet diameter is closely related to the strength of the connection. Larger diameter rivets provide greater expansion force and stronger holding power and are suitable for use in connections with thicker or more heavily loaded materials. Rivet diameters that are too small may result in a connection that is not strong enough to withstand the expected working loads, thus compromising the safety and long-term performance of the connection.

- Large Diameter Rivets: For applications that are thicker or need to withstand greater forces (e.g. heavy machinery, automotive, marine structures).

- Small diameter rivets: for thin plates or lighter loads (e.g., appliances, electronic equipment).

2. Ensure that the Rivet Matches the Hole Diameter

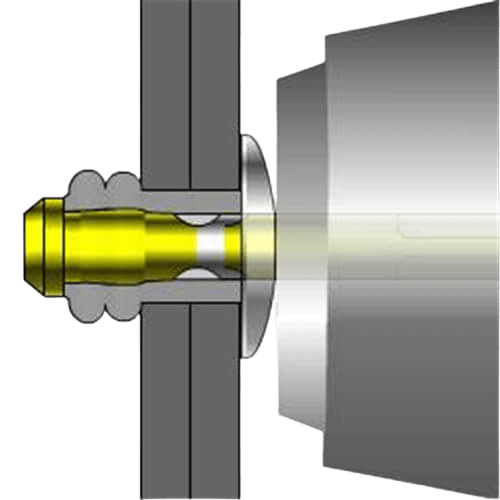

The diameter of the rivet must match the diameter of the riveted hole. A rivet that is too large will cause the hole to deform or split, and a rivet that is too small will not provide sufficient holding power. Therefore, the correct diameter ensures that the rivet will fully expand and hold the material securely after installation.

In general, the diameter of the rivet should be slightly larger than the hole diameter to ensure that the rivet can expand effectively and generate sufficient tension during installation.

3. Impact on Installation Process and Cost

Rivet diameter affects the ease and cost of installation. Larger rivet diameters require larger riveting equipment and stronger tools, as well as increased material costs. Smaller rivet diameters are easier and less costly to install. Choosing the right diameter can help reduce production costs and improve efficiency while ensuring a strong joint.

4. Adapt to Different Application Scenarios

Different application scenarios require different rivet diameters. For example, in the aerospace industry, due to the extremely high requirements on the strength and durability of the connection, it is often necessary to choose a larger rivet diameter. In some light industries, such as home appliances and electronic products, small diameter rivets may be more common.

5. Prevent Deformation of Material

A rivet diameter that is too large will cause excessive stress on the material around the hole, which may cause distortion or rupture. Selecting the proper rivet diameter prevents excessive stress on the material and maintains the structural integrity of the material.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Determine Rivet Diameter?

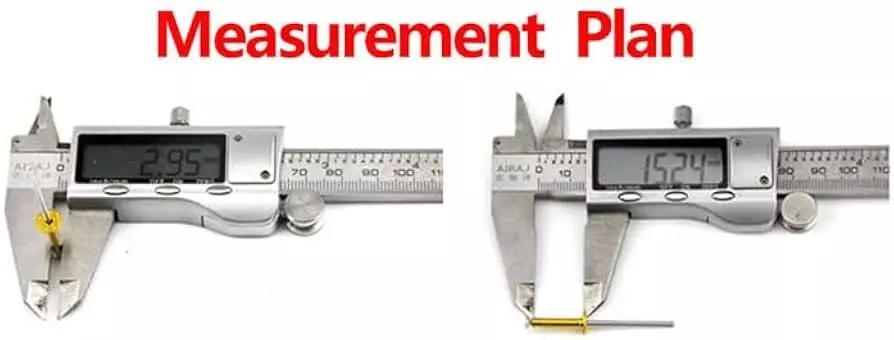

Rivet diameter is the outside diameter of the head of the rivet (or the diameter of the shank portion of the nail), and it is often one of the most critical dimensions when selecting and using rivets. Measuring rivet diameter needs to be precise to ensure that the rivet will fit correctly and meet the requirements of the connection. Here are the steps to measure rivet diameter:

Tools Required

- Calipers (OD calipers): used to accurately measure the diameter of rivets.

- Steel Tape Measure (Auxiliary): For measuring large size rivets, especially longer rivets.

Steps of Determine Rivet Diameter

1. Cleaning Rivets

Before measuring, make sure the rivet surface is clean and free of any dirt or rust. Dirt may affect the accuracy of the measurement.

2. Measurement of Rivet Head Diameter

- Clamp the head of the rivet (i.e., the expanded portion of the rivet) using the outer measuring end of the caliper.

- Make sure the caliper is perpendicular to the rivet and accurately measure the maximum outside diameter of the head.

- Record the value displayed by the caliper, which is the diameter of the rivet head.

3. Repeated Measurement

To ensure accuracy, it is best to measure the rivet diameter several times from different angles and record the measurements. If possible, take at least two or three measurements and average them to minimize errors.

4. Record the Diameter Value

Record accurate values of rivet diameter, usually in millimeters (mm). Ensure that the appropriate system of units (e.g. imperial or metric) is used for the measurement to avoid unit confusion.

How to Choose the Right Rivet Diameter for Your Project?

The proper rivet diameter is an important factor in ensuring a strong, stable and reliable riveted joint. Depending on the needs of the project, the type of material, and the requirements of the riveting application, the correct selection of rivet diameter can avoid many potential joining problems. Here are a few important factors to consider when selecting the right rivet diameter for your project:

1. Consideration of the Thickness and Strength of the Material to be Connected

The diameter of the rivet needs to match the thickness of the material being joined. A rivet diameter that is too small will not provide adequate clamping force, while a diameter that is too large may result in damage to the hole or uneven pressure distribution. Typically, the rivet diameter should be proportional to the thickness of the material.

- Thin materials (e.g. sheet metal, aluminum): For smaller thicknesses (e.g. 1mm-3mm), a smaller diameter rivet (e.g. 2mm or 3mm) is usually selected.

- Thick materials: For thicker materials (e.g., 6mm or more), larger rivet diameters (e.g., 4mm-6mm) may be required to ensure adequate tensile strength and sealing performance.

2. Rivet Diameter Selection Based on Load Carrying Capacity

It is well known that the larger the diameter of the rivet, the greater its load-bearing capacity usually is. Therefore, when selecting rivets, take into account the load-bearing requirements of the riveted joints and choose the appropriate rivet diameter to ensure the strength of the connection.

- If the connection point is required to carry a large mechanical load or tensile force, a larger diameter rivet (e.g., 6mm or larger) may be selected.

- For less loaded joints, smaller diameter rivets (e.g., 2mm or 3mm) can be selected.

3. Consider the Hole Size of the Rivet

The diameter of the rivet needs to match the hole diameter. If the hole diameter is too large or too small, it will not ensure a tight riveted joint. Normally, the rivet diameter should be slightly larger than the hole diameter (usually a difference of 0.1mm-0.2mm) to ensure that the head of the rivet can fully contact and wrap around the edge of the hole.

Standard fit: For example, with a 3mm diameter rivet, a hole diameter of 3.1mm to 3.2mm should normally be selected.

Do You Have Any Questions?

Let Us Solve Your Problem

Custom Rivet Diameter for Your Project

If you use an incorrect rivet diameter for your project, the odds are that your project is going to have problems. That is why it is very important to choose the right rivet diameter. I think through this article, you should have been very clear about how to determine rivet diameter.

If your project has special requirements for rivet diameter, please contact us for customization. Get rivet samples now.