Table of Contents

Rivet diameter is an important component for blind rivet sizes. So do you know HOW to determine rivet length? With this article, you will learn in detail how to choose the most suitable rivet length for your project.

Table of Contents

What is Rivet Length?

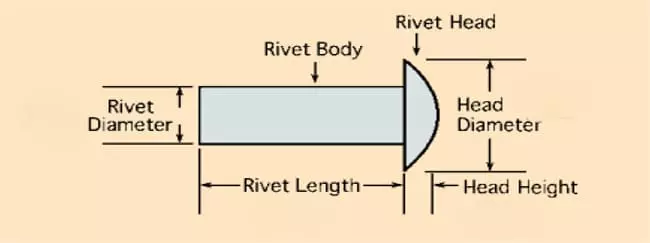

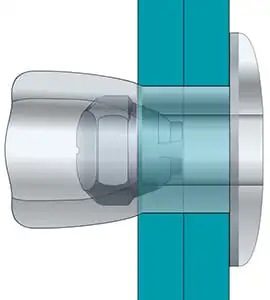

Blind rivet length refers to the total length of the rivet from the head to the bottom of the rivet (as shown below). For Blind Rivets, this length is a very important parameter that directly affects the installation, grip range and strength of the final connection.

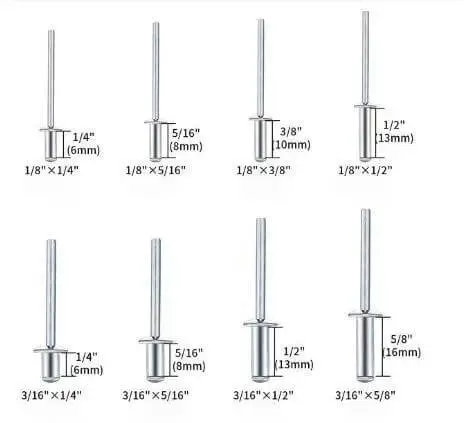

Rivet length standard sizes usually range from 3mm to over 30mm. Depending on the actual application, the common lengths are 4mm, 6mm, 8mm, 10mm, 12mm and so on.

In some specialized industries, customized rivet lengths may be required to meet specific structural or design requirements.

Importance of Right Rivet Length

Using the correct rivet length is critical to the quality, stability and ultimate performance of the riveted joint. Rivet length determines how well the rivet will fit in the material and directly affects the robustness and safety of the connection. Below is a summary of the importance and implications of the proper selection and use of rivet length:

1. Ensuring Secure Riveted Joints

Adequate material grip: The rivet length must exceed the total thickness of the material to be riveted to ensure that the rivet can completely penetrate the material and grip it securely. If the rivet length is insufficient, a complete connection may not be formed, resulting in loosening or even failure.

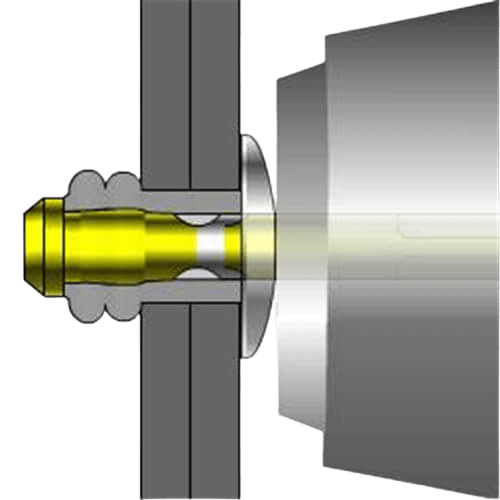

Rivets work by deforming the head and tail of the rivet to hold the material in place. The rivet tail therefore creates a tail expansion on the backside of the material during installation. The correct length rivet ensures that the tail expands sufficiently to provide a solid locking force.

2. Avoid Material Damage

If the rivet is too long, the expanding tail may put too much pressure on the material. This can cause deformation or tearing of softer or thinner materials (e.g. plastics, aluminum).

If the rivet length is too short it can result in the head of the rivet exerting uneven pressure on the surface of the material during installation. This is likely to damage the surface coating or cause cracks in the material.

3. Ensure the Strength of the Connection

Insufficient rivet length may result in the rivet’s tensile force not being sufficiently applied to the material. This can therefore reduce tensile and shear Strength, ultimately affecting the overall strength of the connection.

Of course, the correct length of rivet can provide sufficient grip to make the connection more stable. Even in high vibration environments (e.g. automotive, aerospace), rivets of the correct length can still be very stable.

4. Improve Installation Efficiency

Rivets that are not the proper length may make the actual installation process difficult. For example, rivets that are too short may not clamp properly, and rivets that are too long may get stuck in the riveting tool or require additional adjustments.

Correct rivet length can prevent rework or repeat installations.

5. Reducing Safety Risks

Incorrect rivet length may result in a riveted connection that is not strong enough. In critical applications (e.g. construction, aerospace), this can lead to serious safety hazards.

The correct rivet length ensures a strong connection and prevents the material from loosening or falling off due to vibration or stress after prolonged use.

| Issue | Consequences |

| Rivet length too short | – Rivet cannot fully penetrate the material |

| – Incomplete tail expansion | |

| – Insufficient fastening strength, prone to loosening or falling off | |

| Rivet length too long | – Excessive tail expansion may damage the material |

| – Affects installation efficiency, may not properly secure | |

| Using incompatible tools with rivet length | – Tools cannot grip or pull the rivet properly |

| – Increases installation time, leads to rework or tool damage |

Do You Have Any Questions?

Let Us Solve Your Problem

What is the Rule for Rivet Length?

There are a set of rules and standards for the design of rivet lengths. These rules are designed to ensure that the rivet installation process is smooth, the connection is strong and meets the requirements of the application.

The following are the main rules for rivet length design:

a. Rivet length formula

The total length of the rivet shall consist of the following two parts:

- The total thickness of the material being riveted (Material Stack Thickness).

- The length of the rivet to form a tail swell (Bulb) on the backside of the material.

Common calculation formulas:

L=T+1.5D

- L: Total rivet length (Rivet Length).

- T: Total thickness of the connected material (Material Thickness).

- D: Rivet Diameter.

This formula ensures that the rivet length is sufficient to cover the Material Thickness and that there is enough for tail expansion.

b. Practical Case Studies

| Application Scenario | Material Thickness Range | Rivet Diameter | Recommended Rivet Length (L) | Tail Expansion Length |

| Automotive Thin Plate Join | 3 mm | 4.0 mm | 3+1.5×4=9mm3 + 1.5 \times 4 = 9 mm3+1.5×4=9mm | 6 mm |

| Multi-layer Composite Join | 10 mm | 6.4 mm | 10+1.5×6.4=19.6mm10 + 1.5 \times 6.4 = 19.6 mm10+1.5×6.4=19.6mm | 9.6 mm |

| Plastic and Metal Combo Join | 5 mm | 3.2 mm | 5+2×3.2=11.4mm5 + 2 \times 3.2 = 11.4 mm5+2×3.2=11.4mm | 6.4 mm |

c. Summary Rules for Designing Rivet Lengths

- Accurately measure the total material thickness: ensure that the rivet length is sufficient to cover the material thickness.

- Determine the tail expansion in proportion to the diameter: Typically, the tail expansion length is 1.5-2 times the rivet diameter.

- Consider the application environment: For high vibration and high load environments, the rivet length should be increased to increase the safety factor.

- Check tool compatibility: Make sure the rivet length matches the riveting tool to avoid problems during installation.

How to Determine Rivet Length?

Measuring the length of a rivet is a critical step in determining whether a rivet is suitable for a particular application. The length of the rivet has a direct impact on its ability to engage the connecting component and accommodate different thicknesses of material. The correct length ensures that the rivet will effectively secure the component while avoiding the problems associated with too long or too short rivets.

Steps for Determining Rivet Length

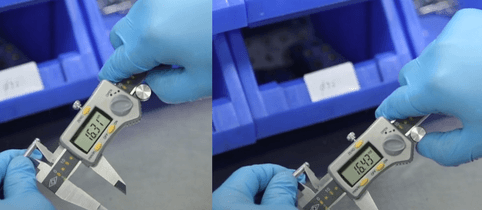

- Choose the right tool: Use calipers (vernier or digital) to accurately measure the length of the rivet. To ensure measurement accuracy, calipers should ideally provide millimeter-level readings.

- Measure the total length (L) of the rivet: Measure from the head of the rivet (usually round or flat) to the tail (the last part of the rivet), excluding the riveted portion of the stem.

Do You Have Any Questions?

Let Us Solve Your Problem

How Do You Choose the Rivet Length?

1. Determination of the Total Thickness of the Material

The length of the rivet must be sufficient to penetrate all the layers of material to be joined. Therefore the first step is to measure the total thickness of the material (including the superimposed thickness of all layers).

T=T1+T2+T3+…+Tn

- T:Total thickness

- T1,T2,T3…T_1, T_2, T_3…T1,T2,T3…:Thickness of each layer of material

Example:

If the thickness of two layers of sheet metal is 3mm and 2mm respectively, the total thickness is 5mm.

2. Consideration of Tail Expansion (Bulb Expansion)

The length of the rivet, in addition to being required to penetrate the material, must allow a margin for the formation of a tail swell. The length of this section is usually 1.5 to 2 times the diameter (D) of the rivet.

L=T+1.5D

- L: Total rivet length

- T: Total material thickness

- D: Rivet diameter

If a stronger hold is required, the length of the tail expansion can be increased to 2D.

3. Check the Rivet's Grip Range (Grip Range)

Grip range is an important parameter of a rivet, which indicates the range of material thicknesses that the rivet can hold. Make sure that the grip range of the selected rivet includes the total thickness of the material.

For example:

If the total material thickness is 6mm, select a rivet with a grip range of 4-8mm.

4. Consideration of Material Properties

- Soft materials (e.g. plastic, aluminum): the tail expansion can be slightly longer to ensure a firm grip on the material.

- Hard materials (e.g. steel, titanium alloys): the length of the expanding tail is usually designed to be 1.5D to avoid material damage caused by excessive pressure.

- Multi-layer materials: Special attention needs to be paid to rivet length if multiple layers of material are being joined. Ensure that it can penetrate all layers and create sufficient expansion behind the outermost material.

5. Avoid too Long or too Short

- Rivets that are too short: the tail does not form a sufficiently expanded portion and the connection is not strong enough, which may result in loosening or slipping.

- Overly long rivets: The expansion portion is too large and may cause damage to the material or interfere with other components in tight spaces.

Custom Rivet Length for Your Project

Are you looking for a specific rivet length for your project? Are you not sure HOW to determine rivet length? By reading this article, I think you have a clear idea of how to measure rivet length.

If you have a specific rivet length requirement for your project or business, please contact us!