Table of Contents

Steel can be joined in a variety of ways, and riveting steel is one of the most efficient ways of joining. So how to riveting steel? This guide will give you a detailed overview of all aspects of riveting steel. Find out how to riveting steel now!

Table of Contents

What is Riveting Steel?

Riveting Steel refers to the joining or fixing of Steel using the Riveting technique. Riveting is a process of firmly joining two or more pieces of steel together through the mechanical deformation of the rivet, and is a common method of mechanical joining, especially suitable for thin plates, frames, pipes and other scenarios.

Simple and flexible compared to welding and bolting, Riveting Steel is an efficient and reliable method of joining steel and is particularly suited to thin steel plates, closed structures and scenarios where one-sided operation is required.

Why Use Blind Rivets to Riveting Steel?

Steel is the most used type of metal material in practical applications. So how to go about fixing steel materials or steel products has become a matter of concern. Blind Rivets provide a solution for steel that is superior in terms of efficiency, strength and practicality. Below are the main reasons and advantages of using blind rivets for steel project joining:

1. High Strength Connections

Blind rivets can provide fastened connections from low to high strength. Whereas steel is often used in products or applications that require high strength, steel blind rivets can provide high tensile and shear strength through rivet tail deformation.

Special structural rivets such as monobolt rivets can further enhance the strength of the connection and are ideal for heavy steel structures.

2.Avoiding Thermal Effects

Conventional welded connections can result in localized heat affected zone (HAZ) distortion or loss of strength of the steel, which is completely avoided with blind rivets.

Blind rivets use mechanical deformation to complete the connection and do not generate high temperatures during installation. In applications where material properties are required to be maintained, such as high tensile steel or thin steel plates, blind rivets are a safer choice.

3. Suitable for Dynamic Loads and Vibration Environments

One great feature of the blind rivet is that it has a tough joint that absorbs some of the vibration and shock.

In high vibration applications such as machinery and vehicles, blind rivets are more resistant to breakaway than bolts. And monobolt rivets and interlock rivets ensure that the joint remains stable under dynamic loads.

4. Provision of Special Functions

There are many types of blind rivets that can provide special features for steel projects. For example, sealed rivets are used to provide a sealed connection to steel to prevent liquid or gas leakage. Use heat resistant rivets to join steel that requires heat resistance, such as boiler casings or high temperature equipment.

What Rivets to Use on Steel?

Steel material is basically less likely to react chemically with other metal materials, so basically all common metal blind rivets can come riveting steel.

We can choose the best blind rivet for your steel project based on your project needs.

- High strength, common connection: use steel blind rivets. it can provide high connection strength and good compatibility with steel for most industrial and construction applications.

- Light duty connections or thin steel plates: use aluminium mandrel steel body blind rivets. it provides a good lightweight design and puts less pressure on thin steel plates to avoid deformation of the material.

- High vibration environments or high load requirements: use monobolt rivets. structural rivets provide maximum strength and excellent relaxation properties, making them ideal for high intensity and dynamic load environments.

- Sealing requirements: use watertight blind rivets. Waterproof rivets can provide waterproof and dustproof effect, suitable for pipe connection or outdoor assembly.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How to Riveting Steel?

Installing a blind rivet on steel is no different than installing a regular blind rivet. Both use a riveting tool to complete the rivet installation process.

The important thing to note is that you need to make sure that the holes are accurate and in place when you do this. This will ensure the stability of riveting steel.

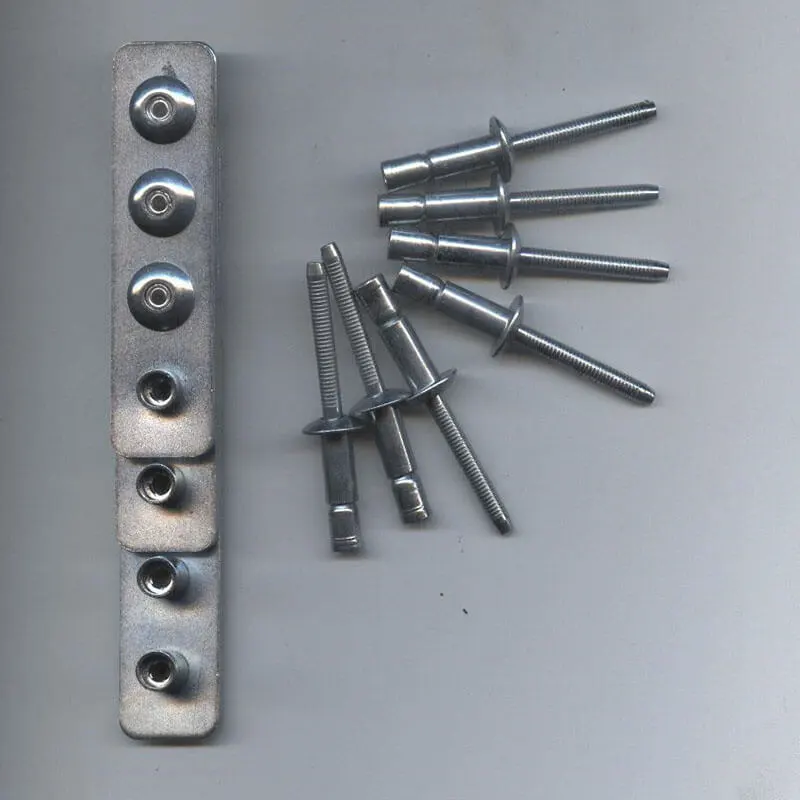

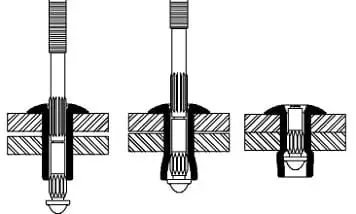

The process of forming a tight connection with a blind rivet is divided into four parts: use rivet gun > deformation of the rivet tail > mandrel breakage > removal of the broken core.

What is the Difference Between Welded and Riveted Steel?

| Comparison Item | Welding | Riveting |

| Connection Method | Fuses steel surfaces together through high heat, creating a permanent joint. | Joins materials mechanically by deforming the rivet to secure them. |

| Material Impact | High heat may alter the steel’s microstructure, reducing material performance. | No alteration to material properties; retains the steel’s original performance. |

| Strength | Provides high overall strength, suitable for high tensile and shear loads. | Strength depends on the number and distribution of rivets; suitable for medium-strength needs. |

| Vibration Resistance | High structural integrity but may crack under vibrations or dynamic loads. | Rivet joints offer flexibility, making them better for high-vibration environments with anti-loosening measures. |

| Skill Requirement | High skill level needed; requires trained welders for quality work. | Easy to operate; low skill level, suitable for mass production. |

| Time & Efficiency | Slower process, especially for precision welding. | Fast installation, high efficiency, ideal for large-scale production. |

| Thermal Impact | High heat can cause deformation, hardness reduction, or Heat-Affected Zone (HAZ) issues. | Cold process, no heat effect, suitable for thin steel and special alloys. |

| Thin Steel Suitability | Prone to burn-through or deformation, requiring precise temperature control. | Excellent for thin steel; large-flange rivets prevent pull-through. |

| Equipment Cost | High cost for welding machines, gas supply, and long-term maintenance. | Simple, low-cost equipment, suitable for budget-conscious projects. |

| Labor Cost | High due to the need for skilled welders. | Low labor cost; easy to train operators. |

| Material Cost | Welding materials (filler rods, gas) are relatively expensive. | Rivets are inexpensive, especially when purchased in bulk. |

| Environmental Suitability | Requires controlled conditions (dry, wind-free environment) to ensure quality. | Suitable for various environments, including wet or harsh conditions. |

Summary of recommendations

- Choose Welding Steel: Suitable for connections with high strength and high sealing requirements. Examples include pressure vessels, bridges or large steel structures. Welding provides greater integrity, but is more costly and requires more skill in handling.

- Choose Riveting Steel: Suitable for thin steel plates, closed structures or scenarios where disassembly and lightweighting are required. Examples include steel frames, equipment housings or vehicle assemblies. Riveting is simple, efficient and suitable for mass production and on-site construction.

FAQs about Riveting Steel

Can I Use Aluminum Rivets on Steel?

It is certainly possible to use aluminum rivets on steel structures, but the following conditions need to be met:

- The joint is not subjected to high or dynamic loads.

- It is in a dry or low corrosive environment.

- Effective corrosion protection measures are taken (e.g. insulating gaskets or coatings).

If the application scenario requires high strength and corrosion resistance, steel rivets, stainless steel rivets or aluminum shell steel core rivets are recommended as alternatives.

How do I check for quality after Riveting steel?

- The head of the rivet should be tightly attached to the surface of the steel without obvious gaps.

- The tail of the rivet shall be uniformly deformed and close to the steel to ensure that there is no looseness.

Custom Blind Rivets for Your Steel Project

Are you looking for reliable riveting fasteners for your steel projects? Riveting steel sheet, blind rivets are excellent choices. Whether you are looking for standard blind rivets or high strength structural rivets, Rivmate has you covered.