Wholesael Interlock Rivets from China Manufacturer

Interlock Rivets are high-strength structural blind rivets specifically engineered to withstand shear loads, vibration, and prolonged use. Their core advantage lies in the permanent locking of the mandrel within the rivet body through a mechanical interlocking mechanism after installation. This eliminates reliance on friction for joint retention, making them ideal for load-bearing applications demanding high structural stability.

Whether it’s different head designs (such as dome head or large flange) or diverse material combinations (aluminum, steel, stainless steel), Rivmate delivers consistently high-quality interlock blind rivets to meet varying load requirements, environmental conditions, and project standards.

Types of Interlock Rivets

At Rivmate, you can buy all kinds of interlock structural rivets. there is a wide range of materials and head styles to choose from.

Carbon Steel Interlock Blind Rivets

Stainless Steel Interlock Blind Rivets

Aluminum Interlock Blind Rivets

Dome Head Interlock Structural Rivets

100° Csk Head Interlock Structural Rivets

Wholesale Interlock Blind Rivets from Manufacturer In China

Not every rivet manufacturer possesses the capability to produce Interlock Blind Rivets (structural mechanical locking blind rivets). Compared to standard blind rivets, Interlock Rivets impose stricter requirements on locking mechanism precision, mandrel-to-rivet body fit, tolerance control, and heat treatment/material consistency. Any inadequacy in these processes directly compromises locking reliability and structural performance. Therefore, selecting an Interlock Rivet manufacturer with proven expertise and systematic capabilities is paramount.

Rivmate stands as one of China’s leading manufacturers of structural rivets, boasting over 20 years of rivet production and application expertise. Serving global markets for decades, our products are extensively utilized in automotive, industrial equipment, furniture, and other load-bearing structural applications. We possess deep insights into rivet failure modes under diverse operating conditions and the selection criteria for optimal rivet types.

Regarding quality and systems, Rivmate’s engineering and manufacturing processes are certified under multiple international standards including IATF 16949, ISO 9001, and CE. This ensures compliance with stringent requirements for structural fasteners throughout the entire process—from raw material procurement and process control to finished product inspection.

Choosing Rivmate means selecting not just a rivet supplier, but a manufacturing partner who truly understands structural connection risks and engineering demands.

Advantages of Interlock Rivets

- Structural Break Stem Rivet.

- The stem is mechanically locked into the valve body.

- Blind hole, single side mounting capability.

- High shear strength and tensile strength.

- Excellent hole filling by radially expanding body.

- Multiple mounting tools available.

- Compensates for irregular, oversized, slotted or unaligned holes.

- Can stop sheet movement in non-standard holes.

- Closes gaps with high capacity.

Interlock Rivets Sizes and Materials

We can provide all the common interlock blind rivets sizes on the market.

- 4.8mm (3/16″)

- 6.4mm(1/4″)

- 9.8mm/10mm (3/8″)

Available materials include:

- Aluminum

- Carbon Steel

- Stainless Steel

Applications of Interlock Rivets

There are many products that use interlock blind rivets. Here are a few common applications.

- Automotive Manufacturing – Tesla Chassis

- Truck Assembly

- Furniture Installation

- Large appliance enclosure assembly

- Building Component Connections

- Transformer shell assembly

- Cabinets and enclosures

- Heating and ventilation equipment

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

What is an Interlock Rivet?

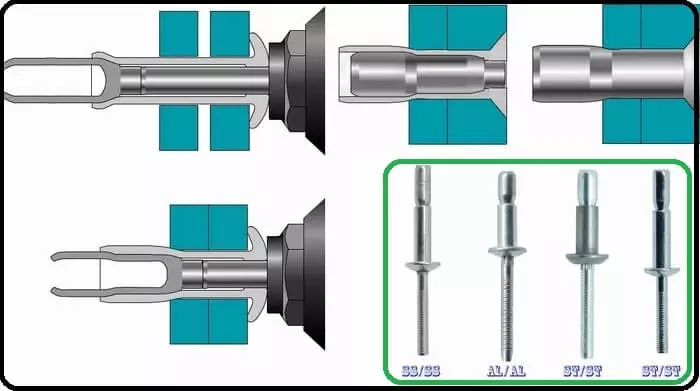

Interlock Rivet is a type of structural blind rivet whose core feature is that, after installation, the mandrel is permanently locked within the rivet body through a mechanical interlocking structure, rather than relying solely on fracture or frictional retention.

During installation, the mandrel is drawn into the rivet body’s interlock zone, forming a distinct mechanical lock through metal deformation. This locking mechanism ensures the mandrel remains irreversibly secured and cannot loosen after breaking, significantly enhancing long-term stability in connections subjected to vibration, impact, and cyclic loading.

Compared to standard blind rivets, Interlock Rivets deliver superior joint strength and reliability. Engineering data indicates that, at equivalent diameters, Interlock Rivets typically exhibit shear and tensile properties one grade higher than non-locking blind rivets, while effectively preventing the common failure mode of mandrel loss.

Riveting Tools for Installing Interlock Structural Blind Rivets

Interlock Blind Rivets are high-strength structural blind rivets. Their installation process requires a high and stable tensile force to ensure the mandrel achieves mechanical interlocking and fractures correctly. Insufficient tensile force prevents the locking mechanism from fully forming, directly compromising joint strength and reliability.

In engineering practice, pneumatic rivet guns are essential for installing Interlock structural rivets. Compared to manual or lightweight tools, pneumatic tools deliver consistent, controllable tensile force output, ensuring each rivet achieves the designed locked state.

The Rivmate C Series pneumatic rivet gun is specifically engineered for structural blind rivets. Its tension rating range covers all Interlock Rivet installation requirements, making it ideal for mass production and structural component assembly. Its stable tension output helps minimize common installation issues such as incomplete locking and abnormal shank breakage.

Interlock Rivets vs Monobolt Rivets

1) Commonality

Both are used for single-side accessible connections requiring structural strength, typically aiming to enhance shear/tensile load capacity, vibration resistance, and long-term stability. They fall under the category of “structural blind rivets.”

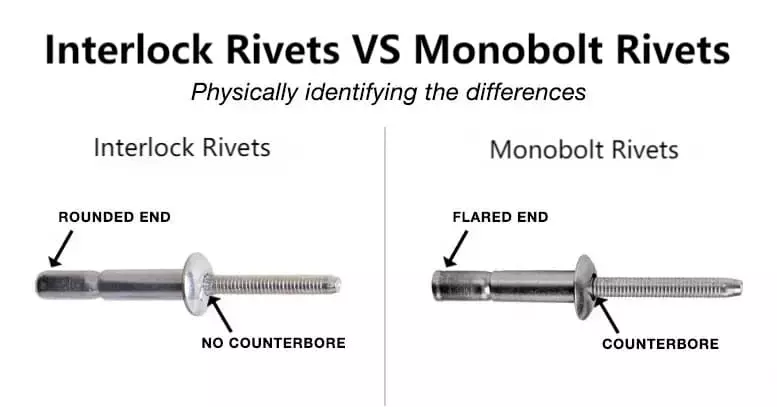

2) Appearance Differences

- Monobolt: Head typically features a flared profile with distinct counterbore (countersink/step recess) between the flange and shank. This design aligns with specific nose tip protrusions for positioning.

- Interlock: Features a rounded/domed head profile, typically lacking the counterbore structure found on Monobolt for nose tip alignment (details vary by manufacturer, but the presence/absence of counterbore for nose tip alignment is the key distinguishing feature).

3) Internal Structural Differences

Monobolt (locked breakstem + hole fill): Emphasizes locked breakstem and positive hole fill capability; installation typically requires a specific nose tip to ensure proper core locking within the drive body.

Interlock (interlocking / S-lock family): Core principle involves mechanical interlocking between the nail body’s internal structure and the core stem’s grooves/locking zones after stem fracture. Its locking logic differs from Monobolt’s structural details.

Conclusion: Both achieve “core pin locking within the body,” but their locking structure zones and tool dependency points differ, impacting field installation consistency and failure modes.

4) Tooling and Installation Requirements

- Monobolt: Commonly requires a specific nose tip for proper locking; failure to use the correct tip may result in insufficient locking or abnormal shaft breakage. This is one of the most overlooked risk points in its application.

- Interlock: Also a high-strength structural blind rivet, typically requiring higher and more stable tensile force output; Within structural body/repair systems, structural blind rivet tool tension thresholds can reach 14,000 N (3,000 lbf) (as per specific repair specifications), making “structural rivets = high-tension tools” a mandatory requirement.

5) How to Select

- Prioritize Monobolt: When you emphasize hole filling, gap resistance, and low tolerance for loosening, and can ensure use of matched nozzles/fixtures.

- Prioritize Interlock: When your goal is structural-grade strength + mechanical interlocking core-shaft retention, and you prefer a product system structurally independent of Monobolt’s counterbore/nozzle compatibility features.

- Regardless of choice: Never use tools with low tensile strength or unstable output. Structural blind rivet performance hinges primarily on achieving the required locking force and using correct tooling.

6) Typical Applications

Both are common in manufacturing scenarios requiring structural connections: load cycling, vibration, single-side access, and assemblies needing long-term stability. Structural repair specifications mandating tool tension for structural rivets further validate their strength grade applications.

Frequently Asked Questions About Interlock Rivets

1) What are Interlock Rivets used for?

Interlock Rivets are high-strength structural blind rivets used in scenarios where installation is only possible from one side, yet the joint must withstand shear loads, vibration, or cyclic loading. They are commonly employed in automotive structural components, equipment frames, load-bearing furniture connections, and industrial sheet metal assemblies. Unlike standard blind rivets, Interlock Rivets are applied when the joint is considered a structural node rather than merely a fastening point.

2) How do Interlock Rivets differ from standard blind rivets?

The core difference lies in the locking mechanism of the mandrel. Interlock Rivets secure the mandrel within the rivet body through an internal mechanical interlocking structure, preventing mandrel retraction once locked. Standard blind rivets primarily rely on tail forming and frictional retention. The engineering implication is that Interlock Rivets offer significantly higher locking reliability and long-term stability under vibration or sustained loading.

3) Are Interlock Rivets suitable for vibration and load-cycling applications?

Yes. One design objective of Interlock Rivets is to prevent mandrel loosening during vibration and load cycling. The mechanical interlocking structure eliminates reliance on friction conditions, making them more reliable in vehicles, machinery, and continuously operating systems. However, this requires sufficient installation pull-through force and controlled hole diameter and installation angle.

4) Do Interlock Rivets require special installation tools?

Interlock Rivets do not require dedicated locking tools, but must be installed using pneumatic or electric rivet guns with sufficient tension output. As structural rivets, their installation tension requirements significantly exceed those of standard blind rivets. Insufficient tool tension may prevent complete interlocking, compromising structural strength and locking reliability.

5) Can Interlock Rivets replace Monobolt or other structural rivets?

Interlock Rivets can serve as equivalent replacements for certain Monobolt or other structural blind rivets when matching diameter, material, performance specifications, and installation conditions. However, substitution should not be based solely on appearance or nomenclature. Confirmation must be achieved through tensile/shear performance testing, locking consistency verification, and installation validation—particularly for project-specific or safety-critical applications.

6) What factors are critical when selecting Interlock Rivets?

Key selection criteria include:

Load type and rating (shear, tensile, vibration)

Panel thickness range (avoid prolonged use at grip limits)

Hole tolerance and wall quality (affects interlock formation)

Installation tool tension and stability

Operating environment (corrosive or outdoor conditions)

Neglecting any factor risks achieving “successful installation but structurally unreliable” outcomes.

Buy High Quality Interlock Blind Rivets for You

Interlock structural rivets are very similar to monobolt rivets. However, their locking mechanisms are different. interlock blind rivets are internally locked, whereas monobolt rivets have an observable locking mechanism.

If you would like to purchase a large quantity of high quality Interlock blind rivets and monobolt rivets for your project, please contact us!

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!