Home » Rivmate-Pneumatic Tool for blind rivet and nut » Pneumatic Rivnut Tool Buy

A912 Pneumatic Rivnut Tool

Specifications

| Pull Force | >19.1KN |

| Stroke | 7mm |

| Standard Pressure | 0.55MPa |

| Used/Air Pressure | 0.5-0.7MPa |

| Air Consumption | 4.6 litres |

| Motor Speed | 2000RPM |

| Vibration | 2.5m/s² |

| Noise Level | <75dB(A) |

| Weight | 2.2Kg |

| (L*H*W)/Size | 280×250×115mm |

| Rivet Nut Material | All Material |

| Rivet Nut Specifications | M3-M12(1/8" - 1/2") |

Details of High Quality Pneumatic Rivet Nut Tool

Rivet Nut Gun Heads

Rivet Nut Gun Heads manufactured from high-strength hardened steel with heat-treated critical load-bearing areas, these heads offer excellent wear resistance and dimensional stability, making them suitable for long-term, high-frequency use. Their well-designed structure maintains assembly precision while minimizing wear-induced impacts on riveting quality.

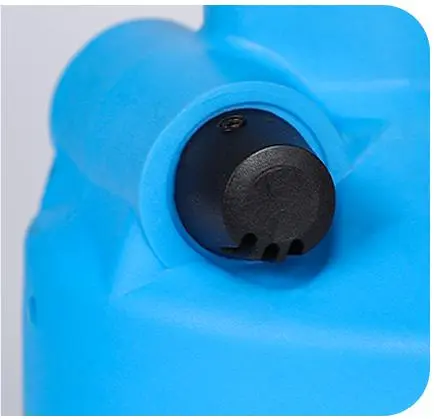

Air Vent

Air Vent Features an optimized vent hole structure design that ensures smooth airflow while effectively reducing noise caused by airflow impact. Integrated internal sound-absorbing components minimize high-frequency air noise, enabling quieter and more stable operation. This design enhances the operating environment and reduces prolonged noise exposure for operators.

Universal Air Connector

Universal Air Connector Features a standard 1/4-inch inlet compatible with most industrial pneumatic systems, enabling easy connection without additional adapters. The connector supports 360° rotation for flexible directional adjustment based on operating posture. This design effectively prevents hose entanglement or pulling, reducing wear and leakage risks caused by hose stress.

Travel Regulator

Travel Regulator can be precisely adjusted by loosening the adjustment plug and rotating the rear cover, offering simple and intuitive operation. After adjustment, the locating pin can be reset to ensure stable and reliable parameter settings. This design facilitates quick adjustments for different riveting specifications, enhancing installation consistency and preventing over-tightening or under-tightening issues.

Non-slip Rubber Mat

Non-slip Rubber Mat constructed from high-friction rubber material, this mat effectively prevents tools from sliding on workbenches or floors, ensuring secure placement. The rubber surface provides excellent cushioning to reduce vibration and impact. This design helps avoid scratches on tool surfaces or accidental drops, protecting valuable equipment while enhancing overall workplace safety and user experience.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

What Is a Pneumatic Rivnut Tool?

The Pneumatic Rivnut Tool is a professional installation tool powered by compressed air, designed to rapidly and reliably install Rivet Nuts into thin plates or hollow structures. Its operating principle involves applying constant tensile force through a pneumatic system, causing plastic deformation of the rivet nut on the back side of the substrate to form a secure internal threaded connection. The entire process offers high controllability and excellent repeatability, making it suitable for industrial-grade applications.

Compared to manual rivnut tools, the pneumatic rivnut tool requires minimal manual force, significantly reducing operator fatigue and boosting installation efficiency. Compared to electric rivnut tools, its pneumatic design offers simpler construction and more stable output, making it particularly suitable for continuous operation and high-frequency assembly scenarios. Under equivalent conditions, pneumatic riveting yields a lower scrap rate.

Pneumatic rivnut tools are commonly used in batch assembly, production line operations, and industrial manufacturing, such as automotive manufacturing, sheet metal fabrication, electrical cabinet assembly, and industrial equipment assembly.

How Does a Pneumatic Rivnut Tool Work?

The operation of the pneumatic rivnut tool relies on a stable pneumatic drive system. Upon connecting to compressed air, the tool generates axial tensile force through its cylinder, enabling the rivet nut to complete the riveting forming and retraction within a short timeframe. The entire process is: compressed air drive → screw pulls rivet nut → backside expansion locking → automatic retraction, ensuring smooth and efficient operation.

Travel control is critical for ensuring installation quality. The travel regulator enables precise setting of the riveting stroke according to different Rivet Nut specifications. Maintaining stable tensile force output helps prevent over-tensioning or insufficient tension issues, thereby enhancing assembly consistency.

Key Features & Advantages of Pneumatic Rivnut Tool

High Installation Efficiency

Pneumatic drive enables rapid riveting and automatic retraction, significantly reducing single-cycle installation time. Ideal for production lines and continuous batch operations.

Stable Pull Force Output

Consistent pull force delivered by the pneumatic system eliminates installation variations caused by manual fluctuations, effectively reducing rivet nut deformation defects and rework rates.

Adjustable Stroke Control

Stroke length precisely adjusts for different Rivet Nut specifications, ensuring consistent riveting formation across multiple sizes and materials.

Ergonomic Tool Design

Ergonomic tool structure minimizes operator effort, significantly reducing fatigue during extended use.

Easy Maintenance Structure

Key components feature modular design, allowing individual replacement of wear parts. This minimizes downtime and reduces long-term maintenance costs.

Industrial-Grade Reliability

Suitable for high-frequency use environments, it delivers stable long-term operation, meeting industrial assembly demands for consistency and reliability.

How to Use Pneumatic Rivet nut Gun for Riveting?

Step Decomposition

Stroke Adjustment Instructions for Pneumatic Rivnut Tool

Basic Adjustment Method

Gently pull forward and press the tool while rotating the rear cover to adjust the stroke. Turning clockwise shortens the stroke, while turning counterclockwise increases it. Adjust according to actual riveting requirements. Stroke length directly affects the deformation of the rivet nut. After adjustment, secure the stroke with the positioning lock to ensure parameter stability.

A912 Pneumatic Rivet Nut Gun Adjustment Steps

For first-time use, test-install one rivet nut. After installation, inspect whether the rivet nut is securely clamped to the steel plate.

If insufficient clamping is observed, incrementally increase the stroke by small increments only. Repeat test riveting several times until the rivet nut securely grips the plate, then proceed to normal operation.

Usage Precautions

Avoid excessive single-step stroke adjustments. Gradual fine-tuning is recommended to prevent over-stretching risks.

If counterclockwise adjustment exceeds approximately 5 turns, excessive stroke may cause the screw rod to stop rotating or result in air leakage. Simply rotate the rear cover clockwise to appropriately shorten the stroke and restore normal operation.

Operational Recommendations

Proper stroke configuration enhances riveting consistency, reduces rivet nut damage and rework rates, and is a critical step in ensuring stable operation of the Pneumatic Rivnut Tool.

How to Maintain the Pneumatic Rivet Nut Gun Tool?

Daily Lubrication Maintenance

Proper lubrication is essential for the normal operation of pneumatic rivet nut guns. Before use, the operator should apply several drops of pneumatic-specific lubricating oil to the air inlet. Then, idle the tool several times to ensure the lubricant thoroughly penetrates the internal moving parts, thereby maintaining stable power output.

Preventing Moisture and Corrosion

Compressed air typically contains moisture, which can form condensation inside the tool during prolonged use. This moisture readily causes rust or corrosion on internal components, compromising tool performance. Regular lubrication creates a protective film on metal surfaces, significantly reducing corrosion risks.

Key to Extended Service Life

Without proper lubrication and basic maintenance, the Pneumatic Rivnut Tool will wear significantly faster, drastically shortening its lifespan. Adhering to simple daily upkeep not only ensures consistent riveting quality but also reduces failure rates and maintenance costs.

Maintenance Recommendations

Incorporating lubrication as a routine step before each work session is essential for ensuring the long-term stable and efficient operation of the pneumatic rivnut gun.

Can I use a regular rivet gun to rivet nuts?

No. Standard pop rivet guns cannot be used to install rivet nuts.

Standard rivet guns operate by breaking the mandrel to secure pop rivets. They lack the structural design and stroke control necessary to compress and form rivet nuts. Therefore, standard rivet guns cannot install rivet nuts or create reliable connections.

Rivet nuts must be installed using specialized tools. The Rivet Nut Tool is designed to apply axial tension, causing controlled deformation of the rivet nut on the back side of the substrate to form a stable internal threaded connection. This process has precise requirements for tension force, stroke, and concentricity, which only specialized tools can meet.

Pneumatic rivet nut guns deliver consistent tension and adjustable stroke, accommodating various rivet nut sizes and types. They not only ensure installation quality but also enhance efficiency while minimizing rivet nut damage and rework risks. To guarantee proper installation and connection strength, always select the appropriate Rivet Nut Tool instead of substituting with a standard rivet gun.

Can I install rivnut without tools?

Installing Rivnut blind rivet nuts without specialized tools is not recommended.

Manual or “tool-free” installation methods are cumbersome to operate, making it difficult to control tension and the forming process, and virtually impossible to guarantee installation quality. Rivnut installation requires controlled compressive deformation on the back side of the base material, a process demanding high precision in axial tension and stroke accuracy.

Specialized Rivnut tools are specifically designed to overcome these installation challenges. They ensure the Rivnut is compressed correctly, forming a stable and reliable internal threaded connection while preventing over-tightening or insufficient deformation.

Forcing installation without proper tools often leads to nut rotation, loosening, or even damage to the base material. Using specialized tools significantly enhances connection strength and consistency while reducing rework and material scrap risks. To guarantee strength, stability, and assembly quality, always use a professional Rivet Nut Tool when installing Rivet Nuts—never attempt tool-free installation methods.

What is the purpose of a pneumatic rivet nut gun?

Pneumatic rivet nut guns are designed to install rivets and nuts efficiently and consistently.Safe and fast installation of rivets and nuts is achieved by compressed air.Pneumatic rivet guns have many advantages over manual installation tools:

- Fast and efficient:The most important feature of the pneumatic rivet nut gun is that it can quickly complete the installation of a large number of rivet nuts. Enhance the efficiency of riveting and reduce the cost of labor.

- Enhanced motivation:Pneumatic rivet nut tools can provide a high level of pressure. This allows the rivet nut to be firmly attached to the workpiece.

- Suitable for a wide range of sizes:Pneumatic rivet nut guns have many interchangeable heads. Capable of riveting different sizes and types of rivet nuts. This versatility allows the Air Rivet Nut Gun to handle a variety of different applications and fastener sizes.

Related Products

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com