Rivet Corrosion: Causes, Prevention, and Engineering Solutions

Table of Contents

As a crucial connecting component, rivets play a vital role in maintaining the overall strength and stability of the structure. However, rivet corrosion (rivet rusting) is often a neglected yet highly destructive hazard. When rivets undergo corrosion in conditions such as moisture, salt fog, chemical media, or electrochemical action, it will lead to a decrease in the strength of the connection point, imbalance in the stress distribution of the structure, and even cause the overall structure to fail. For users, this means a higher likelihood of serious safety accidents.

This article will start from the corrosion mechanism, combined with actual cases, to comprehensively analyze the detection methods, protection plans and solution paths for stud corrosion. It will help you build a complete chain of anti-corrosion system from material selection, surface treatment to regular inspections. This will ensure the long-term reliability and safety of the structure.

Mechanical Analysis of Rivet Corrosion

1. Electrochemical Corrosion

When the rivets and the materials being connected are made of different metals (such as aluminum plates and stainless steel rivets) and are in an environment containing electrolytes (rainwater, seawater, industrial moisture), a galvanic cell reaction occurs, and the metal with a lower potential is corroded first.

This phenomenon is particularly common in ships, aircraft, and coastal buildings.

2. Gaps Corrosion

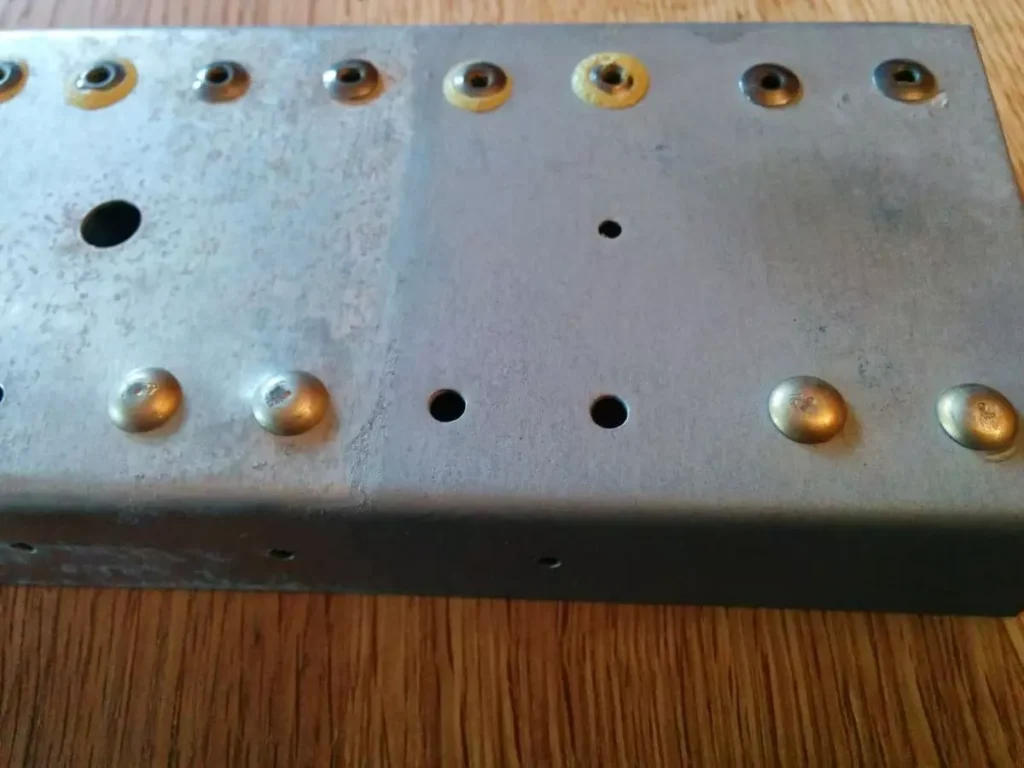

There are often small gaps between the head of the rivet and the sheet metal, or around the installation holes. These gaps are prone to trapping moisture, salts and contaminants, resulting in local oxygen deficiency and thus creating a highly corrosive environment. Gaps corrosion not only progresses rapidly but is also difficult to be detected by the naked eye. It often leads to severe metal thinning and even structural loosening by the time it is detected.

3. Pitting Corrosion and Intergranular Corrosion

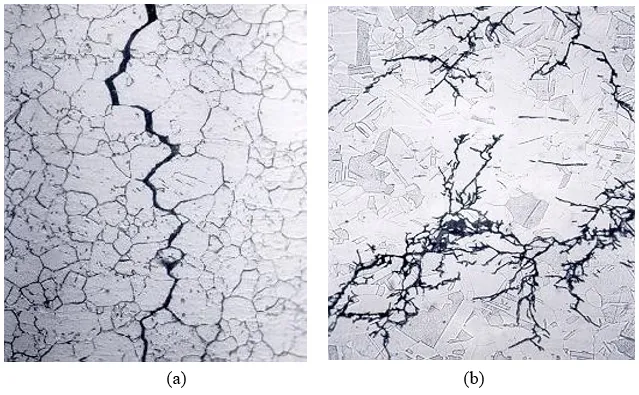

In an environment with a high concentration of chloride ions (Cl⁻), points of corrosion may occur on the surfaces of aluminum alloys and some stainless steel rivets, forming needle-like or crater-like corrosion pits. For stainless steel materials with a higher carbon content, improper heat treatment may also lead to intergranular corrosion, causing the material to crack along the grain boundaries and significantly reducing the fatigue life.

When rivets are subjected to constant or alternating loads for a long time and are in corrosive media, stress corrosion cracking will occur. SCC damage is delayed and may suddenly fracture after many years of service. In the aerospace industry, SCC is one of the important hazards causing the failure of the connection of aircraft fuselage skins.

High-risk application scenarios and corrosion manifestations

Bolts have the advantages of high strength and good fatigue resistance in metal structure connections. However, in certain environments, the risk of corrosion significantly increases. According to the “China Corrosion Situation Survey Report”, global economic losses caused by metal corrosion account for 3% to 4% of GDP, and marine, aerospace and outdoor engineering are the areas with the most concentrated corrosion.

Marine and Coastal Engineering

The application scenarios include ship hulls, dock structures, offshore wind turbine towers, etc. These environments are constantly exposed to high salt spray, high humidity and temperature fluctuations. Chloride ions can penetrate the paint film or protective layer, causing pitting corrosion and crevice corrosion.

- Typical manifestation: Red-brown rust appears at the head of the rivet or at the joint, with local metal powdering. In severe cases, the rivet may become loose or even cause structural failure.

- Data reference: The salt spray corrosion test (ASTM B117) indicates that on the surface of ordinary carbon steel rivets, obvious rust can be observed after 48 hours in a 5% NaCl solution.

Aviation and Transportation

In applications such as aircraft fuselage skins, train car bodies, and truck cargo compartments, rivets are often exposed to complex environments including periodic wet heat, de-icing fluids, and fuel vapors.

- Typical manifestations: The coating around the rivets bubbles or peels off, the surface of the aluminum rivets is powdery (white corrosion products), and stress corrosion cracking (SCC) occurs at the structural bonding interface.

- Risk description: Corrosion of aviation rivets not only affects the appearance, but also accelerates crack propagation under fatigue loads, shortening the maintenance cycle.

Outdoor Building Structures

Commonly found in curtain wall connectors, advertising board frameworks, metal roofs, etc., which are exposed to rain, acid rain and ultraviolet rays for a long time.

- Typical manifestation: The rivets in the affected area show circular rusting due to rainwater erosion. Under acid rain conditions, the coating of the surface layer fails rapidly, causing the exposed metal to flake off and corrode.

- Case data: In the acid rain simulation experiment with a pH of 4.0, the lifespan of the protective layer of galvanized steel rivets is approximately 40% shorter than that under neutral conditions.

Forms of Corrosion

- Rust Staining: Oxidation of iron-based alloys results in the formation of iron oxide, with colors ranging from orange-brown to dark brown.

- Chalking/Powdering: Loose white corrosion products form on the surface of aluminum alloys or galvanized layers.

- Exfoliation Corrosion: Layered corrosion causes sheet-like peeling of the metal, which is commonly observed in the aging process of aluminum alloy rivets in humid environments.

Comparison of Corrosion Resistance of Different Materials of Rivets

The corrosion resistance of rivets is not only determined by the material itself, but also depends on the usage environment, the risk of galvanic corrosion, and the protective treatment process. Inappropriate material selection can lead to accelerated local corrosion, especially in humid, salt spray or acid-base conditions.

Table: Corrosion Resistance Ratings of Common Rivet Materials

| Rivet Material | Corrosion Resistance (Grade 1–5, 5 = Highest) | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Aluminum Alloy (Series 2xxx, 5xxx, 6xxx) | 3–4 | Lightweight, oxidation resistant, easy to process | Susceptible to pitting and exfoliation corrosion | Aircraft skins, lightweight structures |

| Carbon Steel (Plain or Galvanized) | 2–3 | High strength, low cost | Rapid corrosion once coating is damaged | Building steel structures, vehicle assembly |

| Stainless Steel (304/316) | 4–5 | Excellent corrosion resistance, high strength | High cost, potential galvanic corrosion with aluminum | Marine facilities, chemical equipment |

| Copper and Copper Alloys | 3–4 | Good atmospheric and microbial corrosion resistance | Lower strength, prone to color darkening | Roofing decoration, weather-resistant structures |

| Monel Alloy (Monel 400, etc.) | 5 | Outstanding seawater, acid, and alkali resistance | Very high cost | Deep-sea marine engineering, military equipment |

Note: The corrosion resistance grade is determined based on comprehensive assessment of normal temperature, neutral salt spray test (ASTM B117), and long-term service experience. It is provided for reference only in engineering selection.

Table: Corrosion Matching Table (Bolt Material vs Plate Material)

When two different metals come into contact in a conductive medium (such as seawater or rainwater), galvanic corrosion occurs. The greater the potential difference, the higher the risk of corrosion. The following table classifies these risks into three levels based on electrochemical potential difference and actual service data.

| Rivet Material vs Sheet Material | Aluminum Sheet | Carbon Steel Sheet | Stainless Steel Sheet | Copper Sheet | Titanium Sheet |

|---|---|---|---|---|---|

| Aluminum Alloy Rivet | ✅ Safe | ⚠ Medium Risk | ❌ High Risk | ❌ High Risk | ✅ Safe |

| Carbon Steel Rivet | ⚠ Medium Risk | ✅ Safe | ⚠ Medium Risk | ❌ High Risk | ⚠ Medium Risk |

| Stainless Steel Rivet | ❌ High Risk | ⚠ Medium Risk | ✅ Safe | ⚠ Medium Risk | ✅ Safe |

| Copper Rivet | ❌ High Risk | ❌ High Risk | ⚠ Medium Risk | ✅ Safe | ❌ High Risk |

| Monel Alloy Rivet | ⚠ Medium Risk | ⚠ Medium Risk | ✅ Safe | ✅ Safe | ✅ Safe |

✅ Safe: Small potential difference, low risk of corrosion

⚠ Medium Risk: Requires measures such as isolation gaskets or protective coatings

❌ High Risk: Direct contact not recommended without isolation and protection

Rivmate's Recommended Material Selection Strategy

Based on years of experience in using rivets and experimental data, Rivmate recommends the following selection approach:

① Marine/Salt Spray Environment

- Preferred: 316 stainless steel rivets, Monel alloy rivets

- In case of necessity, apply fluorocarbon coating or epoxy isolation gaskets

- Avoid direct connection of aluminum and stainless steel

② Aerospace and Transportation

- Preferred: 5xxx corrosion-resistant aluminum rivets, 7075-T73 aluminum rivets (anodized)

- For high-stress areas, stainless steel can be selected and additional anti-corrosion isolation measures can be implemented

③ Outdoor Architecture and Curtain Walls

- Preferred: 304/316 stainless steel rivets

- If aluminum panels are used, apply sealing glue on the contact surfaces to prevent galvanic corrosion

④ Chemical and Acid/Alkali Environments

- Preferred: Monel alloy rivets or titanium rivets

- Conduct corrosion resistance level assessment based on the nature of the medium

Preventive Strategies for Rivet Corrosion

The corrosion of rivets not only affects the appearance of the structure, but also may lead to a decrease in connection strength, shortened fatigue life, and even failure. According to statistics from NACE (American Society of Corrosion Engineers), by selecting appropriate materials and implementing protective design, approximately 30% – 50% of the corrosion losses during service life can be reduced. Here are systematic suggestions for anti-corrosion strategies.

1. Material Selection and Matching

- Principle: Preferentially use homogeneous metals (such as aluminum plate + aluminum rivet, stainless steel plate + stainless steel rivet), and avoid combinations with strong potential differences (such as aluminum + stainless steel, carbon steel + copper).

- Engineering basis: The rate of galvanic corrosion is directly proportional to the potential difference between two metals. In a 3.5% NaCl environment, the corrosion rate of the aluminum + stainless steel combination can reach 5 to 10 times that of the aluminum + aluminum combination.

2. Surface Protection

- Process Selection:

- Aluminum alloy: Anodizing (AA, hard film anodizing), polyurethane/flexo-fiber coating.

- Carbon steel: Hot-dip galvanizing, electroplating nickel/zinc alloy layer.

- Stainless steel: Passivation treatment (ASTM A967), fluoropolymer coating.

- Data Support: Through ASTM B117 salt spray test, the corrosion resistance lifespan of hot-dip galvanized carbon steel rivets can be increased by 5 to 8 times.

3. Optimization of Structural Design

- Avoid water accumulation: In the design, ensure that there are drainage channels at the connection points of the rivets to prevent water accumulation.

- Reduce gaps: Ensure close fit to avoid water absorption due to capillary action.

- Optimize airflow and drainage: In aircraft or vehicle exteriors, adopt streamlined layout to reduce water droplet retention.

- Example: After changing the drainage design at the rivet connection points of a high-speed train to a sloping surface, the annual corrosion rate at the connection area decreased by 40%.

4. Sealing Measures

- Gasket: Use EPDM (ethylene propylene diene monomer) or fluorine rubber gaskets, which have excellent resistance to ultraviolet rays and salt fog.

- Sealant: Select neutral anti-corrosion sealing glue (such as silicone sealant, polyurethane glue) to seal around the rivet holes.

- Closed-end rivets: Effectively prevent water vapor from entering the hollow part, especially suitable for outdoor and marine environments.

5. Installation Process Control

- Anti-scratch: Construction tools should avoid direct contact with the coating surface. If necessary, add protective films.

- Diameter tolerance: Follow ISO 15977 or MIL-STD-403 standards to ensure a tight fit between the hole diameter and the rivet diameter, reducing crevice corrosion.

- Tension setting: Use the specified tension setting values for the riveting gun to avoid excessive deformation of the rivet or insufficient clamping.

Corrosion Detection and Maintenance Recommendations

Once the corrosion of rivets reaches the stage of structural failure, the repair cost will increase exponentially. According to the research of NACE (American Society of Corrosion Engineers), 80% of structural corrosion accidents could have been avoided through early detection. Therefore, establishing a scientific detection and maintenance system is the key to extending the service life of rivets and ensuring the safety of the structure.

Visual Inspection

Checkpoints:

- Color Changes: The iron-based rivets show orange-brown rust, the surface of the aluminum alloy becomes powdery and turns white, and the stainless steel becomes yellowish or develops brownish spots locally.

- Rust Spread: Check if the rust spreads along the joints and the arrangement direction of the rivets.

- Coating Bubbling or Peeling: This indicates the failure of the protective layer, which is prone to cause crevice corrosion.

Frequency Recommendation: In general environments, it is recommended to perform the operation once every 12 months. For marine or high-humidity environments, it is suggested to do so once every 6 months.

Non-destructive Testing

Ultrasonic Testing (UT): This method can be used to detect internal cracks or metal thinning at the junction of rivets and plates. It is suitable for thick plate structures and critical connection areas.

Eddy Current Testing (ET): Suitable for aluminum alloy and stainless steel rivets. It can detect early cracks and corrosion pits beneath the surface.

Magnetic Particle Testing (MT): Suitable for ferromagnetic rivets, it is convenient for detecting surface and near-surface defects.

Engineering Data: According to the aviation industry standard (SAE AIR4843), it is recommended that critical load-bearing rivets undergo a magnetic particle inspection every 1,000 flight hours to ensure that fatigue and corrosion cracks are not overlooked.

Evaluation of Corrosion Rate and Replacement Cycle

Rate Calculation: The commonly used unit is mm/year (mm/y), which can be obtained through the weight loss method (weight difference method) or electrochemical testing (LPR linear polarization method).

Change Strategy:

When the corrosion rate is ≥ 0.1 mm/year, it is recommended to replace it in advance.

For high-risk scenarios (offshore wind power, chemical pipe racks), a preventive replacement cycle of 3 to 5 years can be set.

Case Reference: A coastal dock shortened the inspection cycle of stainless steel rivets from 12 months to 6 months, resulting in a 42% reduction in corrosion failure rate.

Rivmate Inspection and Maintenance Service

Rivmate offers a complete cycle maintenance solution for rivet connections:

Portable eddy current detector: Capable of conducting on-site rapid detection of concealed corrosion defects within a depth range of 5 to 10 mm.

Corrosion Rate Sensor: Monitors the environmental corrosion rate at critical locations in real time.

Maintenance Training: Offer training courses on visual inspection, non-destructive testing and anti-corrosion maintenance for the engineering team.

Data Management Platform: Records the service status of rivets, generates replacement and protection recommendations, and supports the ISO 55000 asset management standard.

Conclusion

Rivet Corrosion is not only a common problem in structural maintenance, but also a key factor related to safety, lifespan and the total life cycle cost. According to the NACE International Corrosion Cost Study, the economic losses caused by corrosion globally account for 3% – 4% of the GDP. Among them, more than one-third are related to metal connection components. For this crucial connection component, establishing a systematic prevention, detection, repair and replacement strategy can effectively extend the service life, reduce maintenance costs, and enhance the structural reliability.

Choose Rivmate for Rivets You Can Trust

Rivmate is a professional supplier of bolting solutions. We possess comprehensive resources and technical capabilities in areas such as bolt material selection, anti-corrosion design, inspection tools, and maintenance training.

- Material and Design Support: Offers a wide range of corrosion-resistant rivets including aluminum alloy, stainless steel, and Monel alloy, along with guidance for electrochemical corrosion matching.

- Testing and Maintenance Tools: From portable eddy current detectors to corrosion rate sensors, helps customers achieve precise diagnosis and predictive maintenance.

- Industry Application Cases: Serves multiple industries such as ports and docks, aviation manufacturing, rail transportation, and offshore wind power, and has accumulated rich practical experience and reliable data.

The process of engineering material selection – structural design – surface protection – regular inspection – timely repair runs throughout the entire lifecycle management of rivets. Rivmate can help customers significantly reduce the risk of corrosion and ensure that the structure remains stable and operational for a long time in harsh environments.

Choose Rivetfix now to make your connection stronger and more durable!

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met