Table of Contents

In today’s era of pursuing lightweight, aluminum is being used more and more. Therefore spr technology is also becoming more and more popular. So do you know how to choose self piercing rivets for aluminum?

By reading this blog, you will learn about the conditions of use, application scenarios, and benefits of self piercing rivets for alulminum.

Table of Contents

Self Piercing Rivets - Basic Overview

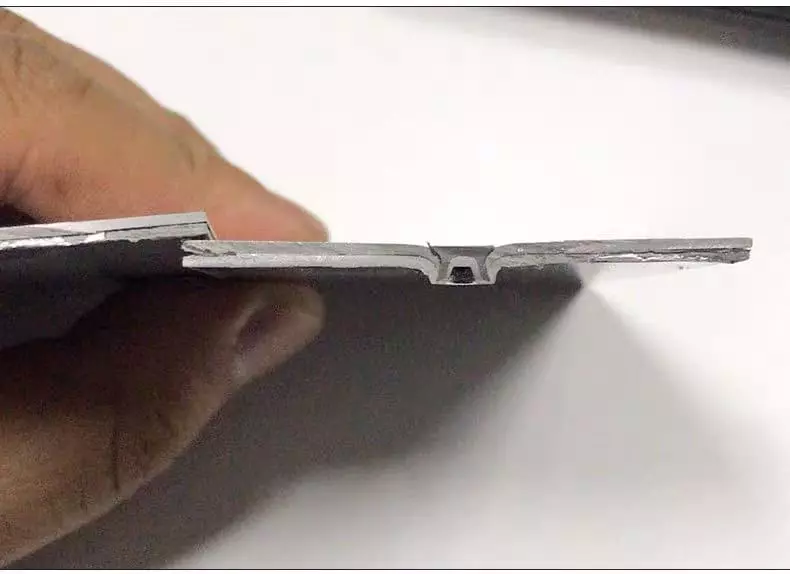

Self Piercing Rivets (SPR) is a riveting technique that eliminates the need for pre-cut holes. In recent years, the SPR process has been replacing traditional welding.The principle of SPR is to pressurize two layers of riveted material to form a rigid joint with high strength and low distortion.

How do Self Piercing Rivets Work with Aluminium?

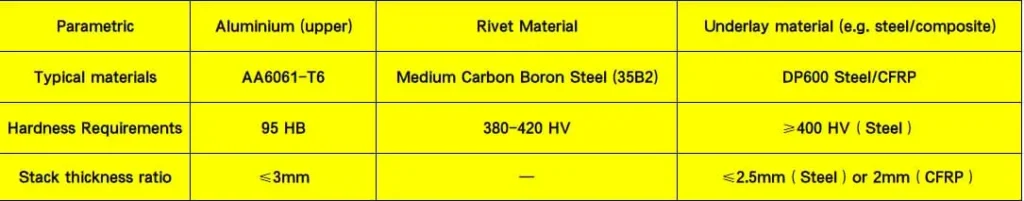

There are many classifications of aluminium alloys, I will use the AA5xxx series (e.g. AA5754), AA6xxx series (e.g. AA6061-T6) as examples.Self piercing rivets need to meet the following conditions if they are to perform well on these types of aluminium:

- Hardness range: 60-100 HB (matching the recrystallisation softening temperature of aluminium).

- Tensile strength: ≥ 240 MPa (to ensure sufficient ductility during cold deformation).

Of course, due to the nature of the aluminium material, spr rivets need to be pre-treated. The following are the corresponding requirements:

- Surface de-oxidised (e.g. chemically cleaned or mechanically polished, Sa value ≥ 2.5).

- Thickness of anodised layer ≤ 10μm (to avoid passivation film obstructing plastic flow).

Matching of the rivet material to the material to be joined

Do You Have Any Questions?

Let Us Solve Your Problem

Why Use Self Piercing Rivets on Aluminum?

The advantages of Self-Pierce Riveting (SPR) for aluminium can be summarised in the following five core technical values.

I. Circumvention of aluminium thermal connection defects (core advantage)

SPR is a total cold forming process. The installation of SPR requires no heat and generates no heat, which effectively circumvents the following problems arising from aluminium welding.

- Thermal cracking: Conventional melt welding (e.g. MIG) is prone to cracking of the weld due to the high coefficient of thermal expansion of aluminium (24 x 10-⁶/°C) (as shown in the figure below);

- Heat-affected zone weakening: avoiding the recrystallisation softening that occurs in aluminium sheet above 300°C (30% drop in HAZ hardness of 6061-T6 base material).

Tesla ditches laser welding for SPR+ gluing in Model S aluminium battery packs. As a result its shear strength is boosted to 12kN.

Ⅱ. Perfect adaptation of heterogeneous material connection

No heat is generated due to the installation process of spr. It is therefore ideally suited for joining dissimilar materials. For example, the efficient connection of aluminium-steel and aluminium-composite materials.

- The melting point of aluminium (660°C) is much lower than that of steel (1500°C). SPR avoids brittle Fe-Al intermetallic compounds by mechanical interlocking instead of metallurgical bonding.

- SPR connections of aluminium sheets to carbon fibre reinforced polymers (CFRP) can be up to three times stronger than bonding.

III. Optimisation of surface anti-corrosion properties

Anodic oxide retention of >97% for materials using SPR.

The commonly used anodic oxide film on aluminium (10-25 μm thick) is only slightly abraded (damage area <1 mm²) in SPR cold joints. The electromagnetic forces and high temperatures of resistance welding completely destroy the oxide layer, resulting in a 5-fold faster corrosion rate (salt spray test data comparison: SPR 500 hours without red rust vs. spot welding 100 hours of rusting).

The Audi A8 D5 all-aluminium bodywork with SPR has a 10-year anti-corrosion warranty with no need to return the coating for repair.

IV. Engineering benefits of combining light weight and high strength

1. Weight reduction of 60% compared to conventional bolts

- Rivet lightweight design: SPR rivets for aluminium are made of high-strength boron steel (density 7.8g/cm³) instead of stainless steel (8.0g/cm³), with a single point weight of only 1.2-2.0g;

- No additional fasteners required: significant weight reduction benefits compared to bolt + nut combinations (≈5-8g per set).

The Ford F-150 aluminium body uses SPR to reduce the overall vehicle weight by 317kg (with riveting contributing around 18kg).

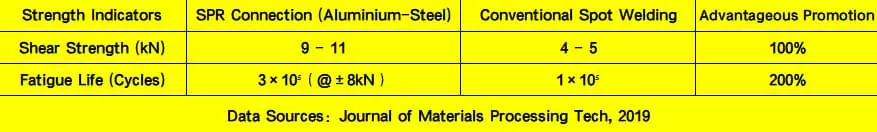

2. Static and dynamic strength advantages

V. Environmental protection and automated production fit

1. zero pollution emission

- No welding fumes: spot welding of aluminium produces Al₂O₃ particles (PM2.5 emission rate >50mg/m³), SPR completely avoids dust pollution and meets ISO 14001 environmental standards.

- Energy saving and carbon reduction: the energy consumption of SPR at a single point is only 0.05kWh, which is 66% more energy efficient than resistance welding (0.15kWh) (annual CO₂ emission reduction of Volvo’s SPR line is ≈ 320 tonnes).

2. Fully automated production line integration capabilities

BMW Leipzig plant i3 production line deployed ABB robot + SPR workstation, riveting yield > 99.8%.

Do You Have Any Questions?

Let Us Solve Your Problem

Application for Self Piercing Rivets on Aluminium

Self-Piercing Riveting (SPR) has become the technology of choice for aluminium in demanding scenarios in a variety of industries due to its cold joining characteristics of no pre-drilling and no heat input.

Automotive manufacturing (more than 60 per cent of core areas)

1. Steel-aluminium hybrid body structure

Application: roof longitudinal beam, door impact beam, front longitudinal beam.

Process value:

- Lightweight: 40% weight reduction by replacing steel parts with aluminium.

- Strength compatibility: aluminium alloy connected to high strength steel (e.g. 22MnB5) with shear strength of 9-11kN, 80% higher than spot welding.

Typical case:

- Jaguar XJ all-aluminium body: 3,200 SPR rivet points achieve torsional stiffness of 19,000 Nm/°. A 30% improvement over the previous generation’s steel and aluminium structure.

- Azera ET7: SPR connects high-pressure cast aluminium shock absorber towers to steel plates, optimising the crash-absorbing structure and reducing peak side-impact acceleration by 15%.

2. Battery pack housing and chassis

- Aluminium shell connection: SPR solves the mechanical synergy between aluminium alloy and structural adhesive, shell sealing surface deformation <0.1mm, better than welding.

- Case: BYD blade battery pack shell (AA6061) adopts

SPR + pop rivet composite process, helium leakage rate as low as 0.02cc/hr (industry average 0.1cc/hr); - Standardised process: SPR fixed module bracket in Ningde Times CELL TO PACK programme, with single point fatigue life exceeding 1×10⁶ times (load 2kN sine wave).

2. Aerospace (high value-added scenarios)

1. Fuselage skin-to-skeleton connection

- Plate combination: AA2024-T3 aluminium skin (1.2mm) + titanium alloy frame (Ti-6Al-4V).

- Rivet Selection: Customised titanium SPR rivets (TC4 material, with molybdenum disulphide coating to reduce friction by 20%).

- Performance index: shear strength ≥12kN, passed -50°C to +150°C thermal cycle test (Airbus A350 standard).

2. Aviation interiors and cargo hold structures

The Boeing 787 cabin magnesium-aluminium alloy frame (AZ31B) is connected to the CFRP floor by SPR, which has helped the aircraft to achieve a weight reduction of 45g at a single point, and a weight reduction of 220kg for the whole aircraft.

3. Rail transport (large-size lightweight structures)

1. High-speed railway/subway car body

Self piercing rivets technology plays a significant role in aluminium profile body splicing. Aluminium profile car body usually adopts AA7xxx series aluminium alloy profiles (e.g. AA7005) lap splicing, SPR allows 0.5-1.0mm assembly tolerance, which improves the efficiency of riveting by 50% compared with traditional riveting.

For example, the roof of the European Talgo 250 train is SPR glued rivet composite process, with a fatigue life of 1×10⁷ times (standard EN 12663).

2. Lightweight containers and frames

When riveting aluminium-magnesium alloy cargo containers, SPR connects AA5083 base plate and Mg-Al-Zn frame, and the bending load resistance can reach 90kN/m (15% higher than MIG welding). And no welding deformation, container assembly flatness error <1mm/10m, reduce operational wind resistance by 3%.

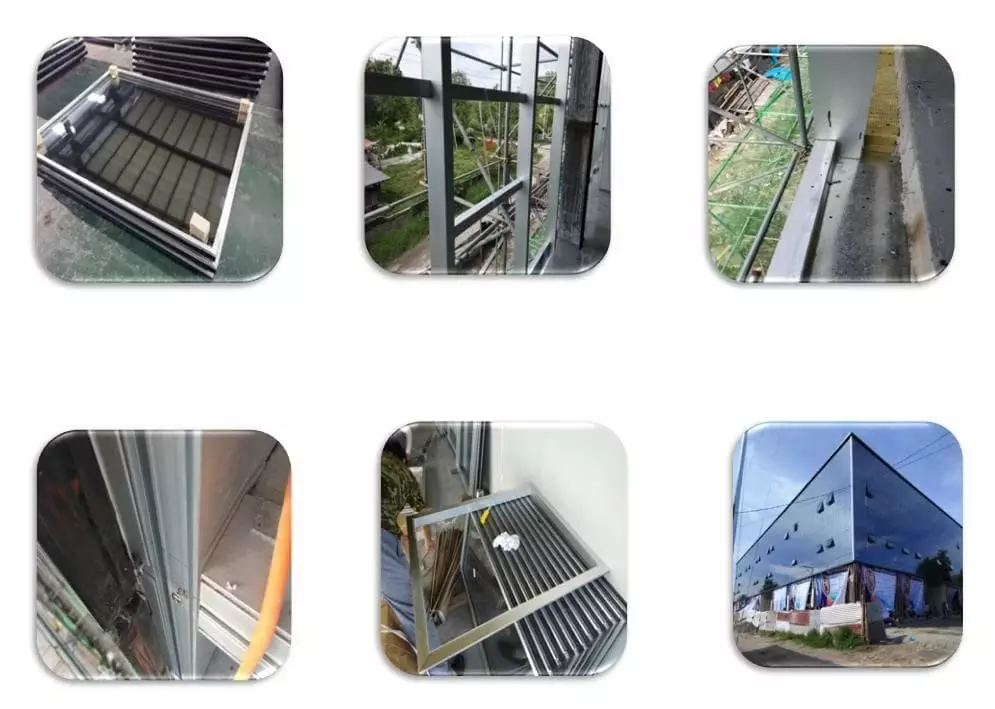

4. Buildings and infrastructure (predominantly non-load-bearing structures)

There are many scenarios where SPR technology is used in construction. But it is generally concentrated on non-load bearing structures.

- Curtain wall and decorative panel fixing: aluminium composite panel (ACP) installation. SPR replaced chemical anchor bolts in the aluminium curtain wall system of Shanghai Center Building, and the installation efficiency was increased by 40%.

- Aluminium roof and catwalk connection: shaped aluminium profile splicing. 5 series aluminium alloy (e.g. AA5052) roof panels are sealed and connected by SPR to achieve zero water leakage.

5. Consumer electronics (emerging areas of penetration)

With the advantages of SPR riveting technology highlights, SPR application industry is more and more. For example, SPR can now connect the AA6063 frame of Huawei’s Matebook X Pro with the stainless steel middle plate, and the precision of a single point can reach ±0.05mm. Apple’s MacBook aluminium hinge also uses SPR technology, and the life span of opening and closing is increased from 30,000 times to 100,000 times.

Custom Self Piercing Rivets Solutions for Your Aluminum Project

By reading this guide, I am sure you are clear about how to choose self piercing rivets for aluminum.If you are looking for a reliable self piercing rivets manufacturer for your aluminum project, Rivmate is an excellent choice for you.

Get samples for testing today.