Table of Contents

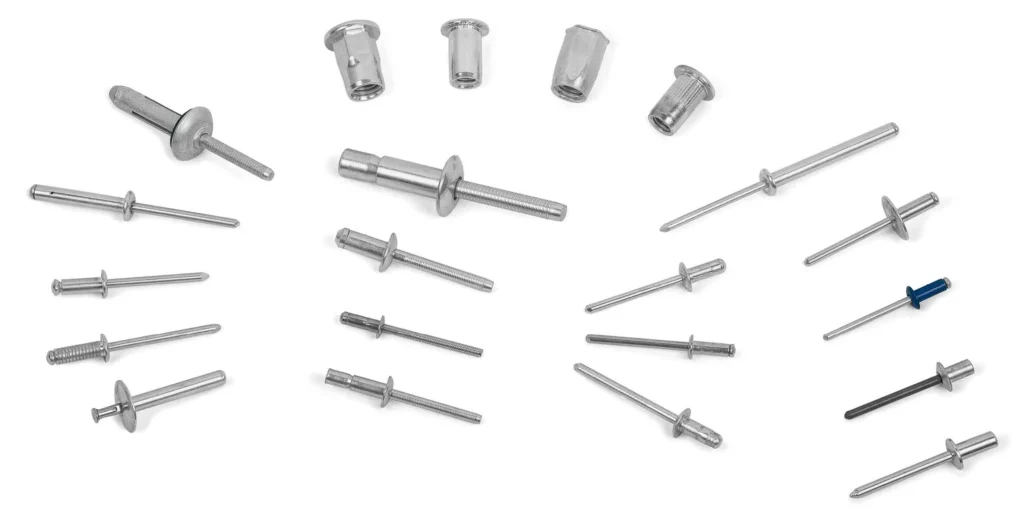

There are many types of pop rivets for metal. But choosing the most suitable one is difficult. This blog will introduce you to 5 types of pop rivets for metal, their uses, how to choose and the pros and cons of pop rivets for metal.

Table of Contents

POP rivets are fasteners that allow material connections to be made by unilateral operation. It consists of two parts: a hollow rivet body (cap) and a mandrel (spigot). During installation, the mandrel is broken by tension applied by a tool (e.g. rivet gun) and the rivet tail expands to form a permanent fixing.

Difference between pop rivets and other rivets types

| Comparison Criteria | POP Rivets (Blind Rivets) | Solid Rivets | Structural Rivets |

| Installation | Single-side access; tool pulls and snaps mandrel to form a head | Requires two-side access; hammering or pressing required | Requires specialized equipment (e.g., hydraulic tools) |

| Structure | Hollow body with a breakable mandrel | Solid material deformed on both ends | High-strength solid design for heavy loads |

| Applications | Lightweight assemblies (electronics, furniture) | Heavy machinery, bridges | Aerospace, construction (critical joints) |

| Reversibility | Permanent; removal requires destruction | Permanent; removal via drilling/cutting | Permanent; requires specialized removal |

| Cost & Efficiency | Low cost, fast installation | Higher labor cost, slower process | High equipment cost but superior strength |

5 Types of Pop Rivets for Metal and Their Uses

There are many types of rivets applied to metal materials. Next I will list 5 common types of pop rivets for metal and their uses.

open end pop rivets are suitable for general metal connections. It consists of a rivet body and a rivet mandrel, which are installed with a mandrel break to form the fastening.

- It is widely used for quick connection of metal plates and thin-walled tubes. Such as air conditioning systems, electrical cabinet assembly.

- Suitable for scenarios that require one-sided operation. For example, riveting of vehicle interiors or mechanical equipment housings.

Closed end pop rivets are mainly used on metal connections where there is a need to prevent the leakage of liquids or gases. closed end blind rivets have a rivet body head that is completely closed to form a watertight sealing structure. Common applications are as follows:

- Ships, outdoor equipment and other metal connections that require waterproofing, such as ship riveting, outdoor electrical box sealing.

- Connections of waterproof parts of the body in automobile manufacturing (e.g. doors, hoods).

Large flange head pop rivets have very large flange diameters to provide wider contact surfaces and load dispersion. Common applications on metallic materials are listed below:

- Connection of thin plates to thick metals (e.g. railroad car bodies and chassis).

- Metal structures in high vibration environments (e.g. aircraft interiors, industrial machinery) to prevent loosening.

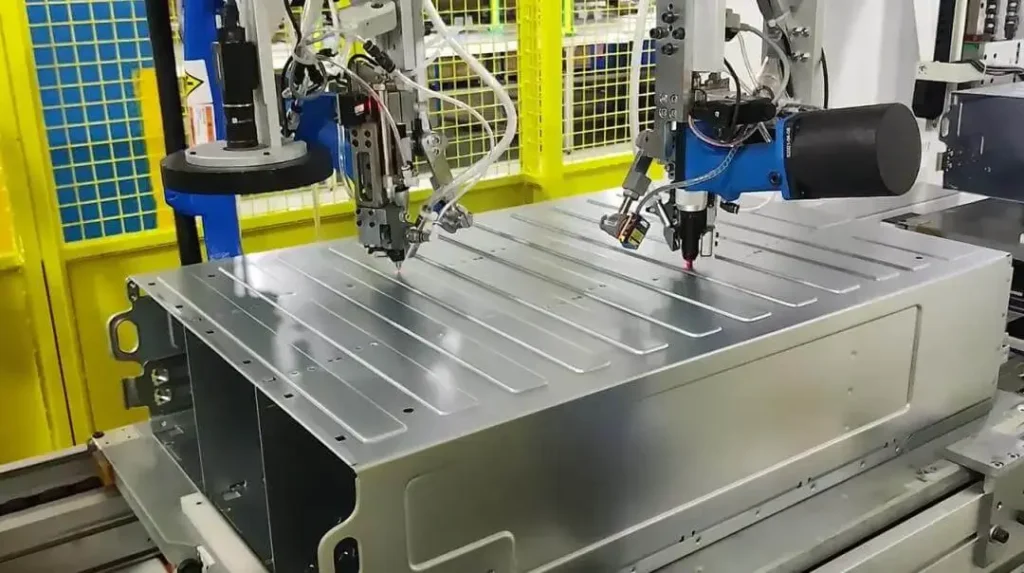

Multi grip pop rivets are high strength blind rivets that can be adapted to metal materials with varying thicknesses. Its most important feature is that a single size rivet can cover a wide range of sheet thickness combinations, which can effectively reduce inventory specifications. multi grip pop rivets are typically used in the following industries:

- New Energy Vehicle Battery Tray: using aluminum Multi Grip Rivets to achieve a balance of lightweight and high strength.

- Logistics storage racks: Replace bolts with high shear rivets to avoid the risk of loosening.

- Outdoor equipment cabinets: Stainless steel with a closed design to withstand humid environments.

Structural pop rivets are used primarily on metal structures that require high strength connections. Structural rivets use interference technology, the mandrel breaks to form a large nail tail to spread the load, so it has high shear and tensile strength. structural pop rivets are generally load-bearing structures.

- High-strength connections in automobile manufacturing (e.g. body to chassis, battery pack fixing).

- Thick and thin plate connections in rail transportation and building steel structures (e.g. bridges, electrical cabinets).

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose Pop Rivets for Metal?

For the best riveting effect, you need to choose the most suitable pop rivets for your metal project.

Depending on the type of metal material

- Ordinary carbon steel / low alloy steel: recommended aluminum rivets or steel rivets. If you need lightweight and no high strength requirements, aluminum rivets (such as 5052/5056 aluminum alloy) can meet the needs; if you need high shear strength, prefer steel rivets (such as carbon steel or stainless steel). It should be noted that steel rivets need to be galvanized or coated to prevent corrosion.

- Stainless steel: Stainless steel rivets (e.g. 304/316) are recommended. Stainless steel and carbon steel contact prone to galvanic corrosion, need to avoid mixing materials. If you have to mix the materials, you can use rivets with insulating sleeve or add sealant to isolate.

- Aluminum alloy: recommended aluminum or aluminum-plated rivets. Aluminum alloy rivets (such as 5056) lightweight and corrosion-resistant, suitable for non-load-bearing structure; if you need more strength, you can choose titanium alloy rivets.

- Copper/Titanium Alloys: Titanium or nickel-based alloy rivets are recommended. Copper alloys need to be matched with rivets of the same material to prevent corrosion; titanium alloy rivets are high-temperature resistant and strong, suitable for aerospace applications.

Depending on metal thickness

- Thin plate (<4mm): the applicable rivet diameter of 3-4mm, length 6-12mm. need to choose short shank rivets to avoid excessive deformation, give priority to the use of open end type rivets.

- Medium-thick plate (4-20mm): the applicable rivet diameter of 4-6mm, length 12-25mm. multi grip pop rivets or structural rivets are recommended to enhance the clamping force; if the material hardness is high (such as high carbon steel), it is necessary to match with high tensile strength rivets (such as steel).

- Extra-thick plate (>20mm): suitable for rivet diameter 6-8mm, length 25-50mm. need to use high-strength structural rivets (such as steel or titanium alloy), and with pneumatic riveting tools to ensure penetration.

Depending on application environment

- Humid/corrosive environment: choose stainless steel, galvanized steel or aluminum-magnesium alloy rivets, avoid ordinary carbon steel. (Plating requirements: hot-dip galvanized layer ≥ 318g/m² or use PVDF coated color steel matching rivets.)

- High-temperature environment: heat-resistant alloy rivets (such as nickel-based alloy) can withstand high temperatures of more than 800 ℃; ordinary steel rivets applicable temperature ≤ 300 ℃.

- Vibration/fatigue environment: Priority is given to closed end or internal locking rivets to reduce the risk of loosening; structural rivets (e.g., Monobolt) can enhance the anti-fatigue performance.

Do You Have Any Questions?

Let Us Solve Your Problem

Pros and Cons of Pop Rivets for Metal

Pros

The core advantages of pop rivets for metal are as follows:

- Single-side mounting capability

- Suitable for complex spaces

- High installation efficiency

- No heating or welding machine required

- Adaptation to diverse material combinations

- No risk of thermal damage

- Shallow hole requirements

Cons

- Lower strength than traditional rivets and welds

- Irreversible connections

- Material and environmental compatibility limitations

- Insufficient surface flatness

- Multi-layer thickness adaptation challenges

Frequently Asked Questions about Pop Rivets for Metal

How Thick of metal can you rivet?

Ordinary POP rivets are suitable for ≤10mm metal; multi-clamp and structural rivets can be extended to 25~30mm. when the total thickness of the plate>15mm, preferred to choose “High-Strength” or “Structural” rivets with high power tools. When the total thickness of the sheet is >15mm, the rivets labeled with “High-Strength” or “Structural” are preferred, together with high-power tools.

what are the strongest rivets for metal?

If you are looking for maximum strength, prefer structural rivets or hemlok rivets with high carbon steel/stainless steel. Meanwhile, it is necessary to pay attention to the matching of tools and installation specifications to ensure the riveting effect.

Custom Pop Rivets for Metal with Rivmate

Are you looking for a reliable pop rivets manufacturer for your METAL project? Don’t worry, Rivmate will provide you with pop rivets that are of high quality and fully meet your requirements.

Get pop rivets for testing immediately.

Get Rivets Quote

Buy Open Type Blind Rivets

Buy Structural Blind Rivets