Table of Contents

Monel Rivets are an expensive type of rivet. It can be used in extremely harsh environments. Do you know the exact scenarios in which it is used? Let’s learn more about “What are Monel Rivets used for“.

Table of Contents

Why Use Monel Rivets?

Monel is a very expensive metal material. Despite this, monel rivets are very popular in harsh environments. The main reason for this is that the material of monel rivets has excellent properties, especially in corrosive environments and high strength requirements. Below are the key benefits of Monel Rivets.

1. Excellent Corrosion Resistance

The corrosion resistance of Monel material is very strong. Therefore Monel rivets are often used in marine and chemical environments.

- Marine environments: Monel rivets have excellent salt water corrosion resistance properties, making them particularly suitable for use in marine, marine, desalination equipment and other scenarios.

- Chemical resistance: monel rivets are resistant to corrosion by acids, alkalis, chlorides and other chemicals such as sulfuric acid, hydrochloric acid and hydrofluoric acid (HF).

2. High Strength and Fatigue Resistance

Monel rivets continue to perform well under dynamic loading conditions. It is therefore widely recognized.

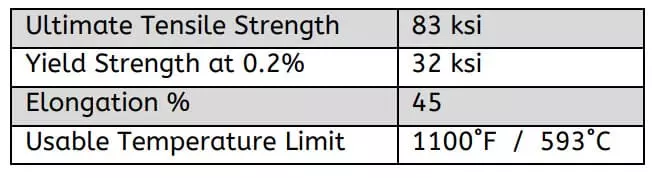

- Tensile strength: Monel 400 has a tensile strength of up to 83 ksi (approx. 572 MPa). This makes monel rivets suitable for high stress and dynamic loading environments.

- Fatigue resistance: monel rivets continue to perform well in high vibration and shock environments, such as aerospace and heavy industrial equipment.

3. High and Low Temperature Resistance

Monel Rivets retain their mechanical properties even at extreme temperatures, from cryogenic to 1000°F/537°C. If your projects are in hot and cold environments, such as aero-engines and deep-sea equipment, then monel rivets are an excellent choice.

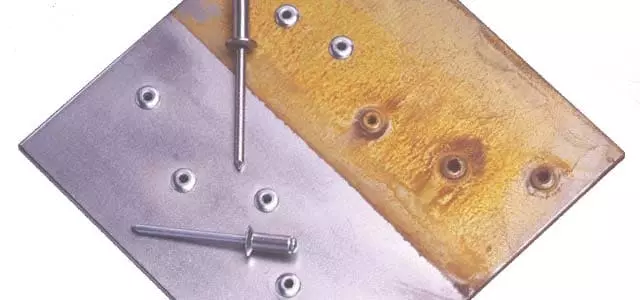

4. Excellent Galvanic Resistance

In practice, rivets are usually used to join thin sheets of many different materials. This can lead to a problem – galvanic corrosion. Monel is so resistant to galvanic corrosion that galvanic coupling is very difficult. Therefore, monel rivets are the ideal multi-metal combination fastener for multi-metal connections.

5. Long-term Durability

Monel rivets have a very long service life. Monel rivets remain stable even in harsh environments. This significantly reduces replacement and maintenance costs. This is exciting news for your project.

What Are Monel Rivets Used for?

Monel material has excellent corrosion resistance and high strength properties, so monel rivets are widely used in environmentally demanding scenarios. Below are the main applications for monel rivets.

Maritime Industry

Monel materials are extremely resistant to corrosion in salt spray and seawater environments. They are also less susceptible to galvanic corrosion in multi-metal connections. The following are common applications of monel rivets in the marine industry:

- Fastening of hull, deck and compartment connections.

- Fastening of metal components on offshore drilling rigs.

- Assembly of structural components in desalination equipment.

Chemical Industry

Even in strong acid and alkali media, monel rivets still have excellent corrosion resistance. It maintains long-term stability in corrosive chemical environments.Common applications of monel rivets in the chemical industry are as follows:

- Connecting reactors, tanks and pipes in chemical plants.

- Equipment handling strong acids (e.g. hydrochloric acid, hydrofluoric acid) and alkaline environments.

Aerospace

The monel material retains its strength in environments up to 537°C. The monel rivets are very stable in environments with high vibration and dynamic loads. And monel rivets are very stable in environments with high vibration and dynamic loads.

- Fixed components of fuel tanks and engines.

- Structural connections in high vibration areas on the exterior of the aircraft.

Automobiles and Railroads

From the above, we can know that monel rivets have strong corrosion resistance and high temperature resistance. Therefore automobiles also use monel rivets frequently.

- Exhaust systems for high performance vehicles.

- Railroad car shells exposed to salt spray.

Do You Have Any Questions?

Let Us Solve Your Problem

Tips of Monel Rivets in Aluminum

When using Monel Rivets in aluminum, there are three issues to be aware of:

- Electrochemical corrosion

- Pressure control during riveting

- Effects of vibration environments

So how do you ensure that Monel Rivets will maintain a reliable connection and long-term durability on aluminum?

1. Prevention of Galvanic Corrosion

Contact between Monel and aluminum in a humid or salt water environment may result in galvanic corrosion of the aluminum due to the large difference in electrochemical potential between the two metals.

So how to solve it?

- Use an insulating gasket or a corrosion-resistant coating (e.g., painted or anodized aluminum surface) between the Monel Rivet and the aluminum material.

- Seal the joint with a corrosion-resistant sealant to prevent humid air or salt from coming into contact with the metal surface.

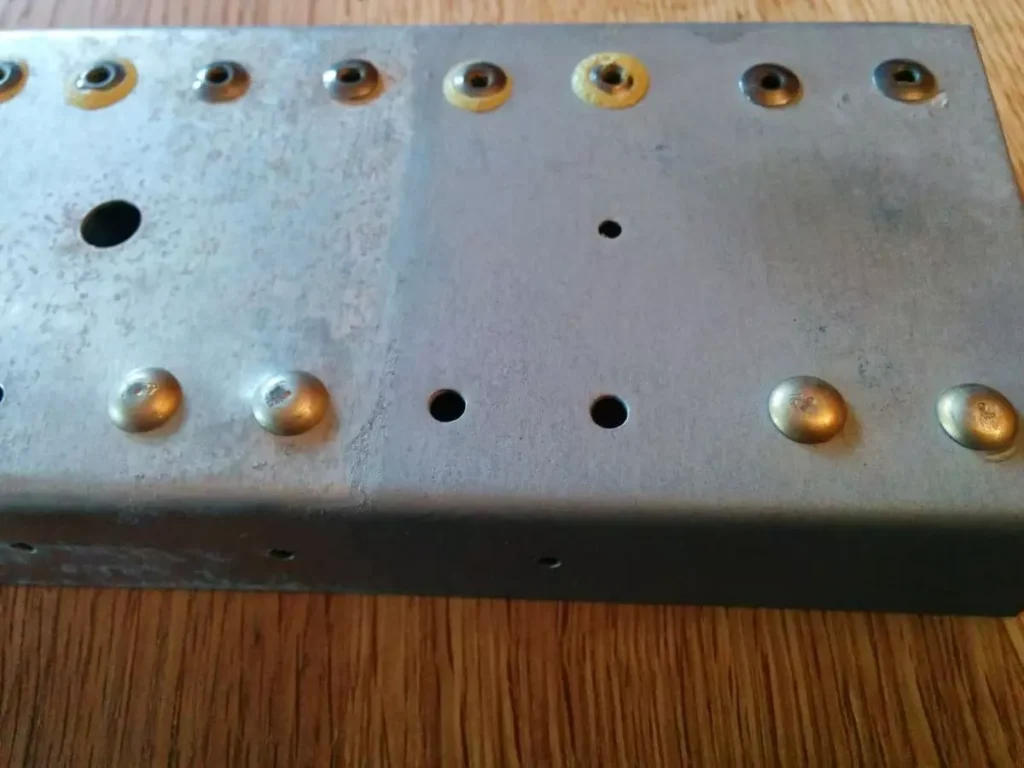

2. Mounting Pressure During Riveting

Monel Rivets are harder than aluminum materials and may cause excessive squeezing pressure on the aluminum during riveting, resulting in deformation or cracking of the aluminum material.

Solution:

- Ensure that the pre-drilled holes are accurate in size and match the diameter of the rivets to avoid excessive gaps or too tight a fit.

- Control the pressure of the installation tool and use riveting equipment suitable for Monel Rivets to avoid excessive compression.

3. Consider Vibration and Fatigue Stresses

Monel Rivets are often used in high-strength and high-vibration environments, but the aluminum material can be subject to fatigue that can lead to loose connections over time.

Solution:

- Use elastomeric sealants or vibration isolation washers at connection points to minimize the effects of vibration.

- Periodically check the tightness of the connection to prevent loosening.

Can Monel Rivets Resist that Level of Corrosion?

There are many types of acidic environments.

| Acid Type | Corrosion Resistance | Remarks |

| Hydrochloric Acid (HCl) | Excellent | Monel rivets resist hydrochloric acid well, especially at low to medium concentrations. High temperatures and concentrations may reduce effectiveness. |

| Hydrofluoric Acid (HF) | Outstanding | Exceptional resistance at all concentrations and temperatures, including boiling points, making Monel ideal for HF environments. |

| Sulfuric Acid (H2SO4) | Good (at lower concentrations) | Effective against medium concentrations of sulfuric acid but may corrode under high temperatures or concentrations. |

| Nitric Acid (HNO3) | Limited | Performs poorly in oxidative acids like nitric acid, especially at high concentrations and temperatures. |

| Acetic Acid (CH3COOH) | Excellent | Highly resistant, making it suitable for food processing and chemical industries. |

| Phosphoric Acid (H3PO4) | Good | Resists phosphoric acid well, especially at low to medium concentrations. |

| Formic Acid (HCOOH) | Excellent | Outstanding resistance across all concentrations and temperatures. |

| Chloride Solutions (e.g., Chlorine, Hypochlorous Acid) | Outstanding | Exceptional performance in chloride environments, ideal for marine and chemical applications. |

| Ammonia Solutions (NH3) | Outstanding | Highly resistant to alkaline ammonia solutions, used in chemical processing and cooling systems. |

Monel rivets excel in non-oxidizing acids (e.g., HCl, HF) and perform less effectively in oxidizing acids (e.g., HNO3).

Do You Have Any Questions?

Let Us Solve Your Problem

How Much do Monel Rivets Cost?

Within the Blind Rivet family, monel rivets are much more costly. Although the cost of rivets varies depending on a number of factors including size, gauge, quantity purchased, and market fluctuations. But the most significant cost affecting monel rivets is the fact that monel, the raw material, is so expensive. The price range of monel rivets is as follows:

- Unit price range: each rivet costs approximately ¥0.0731 to ¥19.01, depending on the size and specification of the rivet.

- Bulk Purchase: Bulk purchases usually enjoy more favorable prices. For example, blind Monel rivets from a blind rivet supplier are available for about ¥0.0728 to ¥0.3637, but require a minimum order of 50,000 pieces.

It should be noted that the price of Monel alloy is relatively high, the main reasons include:

- Material Cost: Monel alloys are composed primarily of nickel and copper, and contain small amounts of iron, manganese, carbon and silicon. The market price of these metals directly affects the cost of Monel rivets.

- Difficulty of machining: Monel alloys are subject to work-hardening during machining, requiring the use of lower feed rates and slower cutting speeds, which increases manufacturing costs.

Therefore, when selecting a Monel rivet, it is recommended to consider its excellent corrosion resistance and mechanical properties, as well as its relatively high cost, based on specific application requirements and budget.

Custom Monel Rivets Solutions for You

There are not many blind rivets manufacturers that can offer monel rivets with consistent performance. And Rivmate is one. If you need to buy a large quantity of high quality monel rivets for your project, you can contact us.

We provide free samples of monel rivets for your project. Get a quote now.