What are Pop Rivets?

Table of Contents

Pop rivet is now another generic term for a blind rivet. But actually pop rivet is a brand of blind rivets, it’s just that users often refer to blind rivets as pop rivets.

The history of pop rivet dates back to the early 20th century.

Riveting as a method of operation has been around for a long time. Early riveting techniques generally involved the use of a heavy object (such as a hammer) to strike the end of a rivet, causing the rivet to expand to form a joint. This method of operation is more time-consuming and the operator’s strength, and also requires specialized training to be able to complete the riveting connection well.

Invention of the pop rivet

With the development of the times, people have higher requirements for the quality of products. Pop Rivet is used especially in industries such as automotive manufacturing, aerospace, construction and home improvement.

But it also creates problems. The rivets were too difficult to install and no longer fit the times. So in 1916. Inventor Carl Cherry invented and patented the pop rivet.He designed a blind rivet that could be installed quickly with only manual operation. This invention greatly improved the speed of rivet installation and ease of use.

Current status of pop rivets and technological improvements

Nowadays, pop rivet has become a common connection solution. It is a quick solution for connecting different materials and is suitable for a variety of different application scenarios.

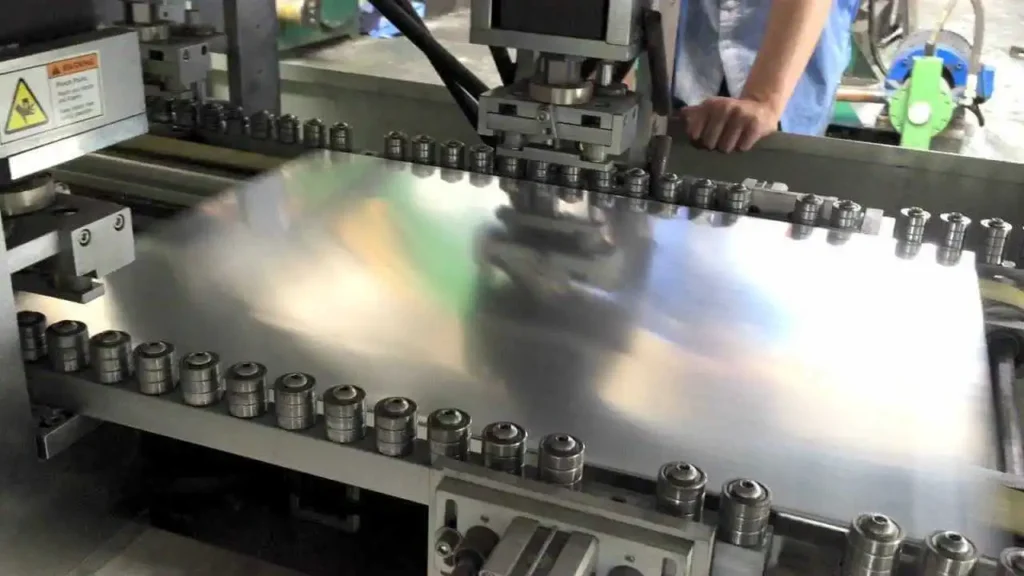

The technology of pop rivet has been improved and innovated over the course of the pop rivet’s use. In industrial production, automated riveting equipment has become the main mode of operation for large-scale pop rivet installation.

In modern manufacturing, pop rivet is widely used. They are often used to connect automobile body parts, aircraft shell connections, metal structures, pipes, furniture and electronic equipment.

The great thing about Pop rivet is that it is quick and easy to install and provides a very reliable connection. Therefore, in many industries, when it comes to solving the problem of connecting materials, the first choice is the pop rivet!

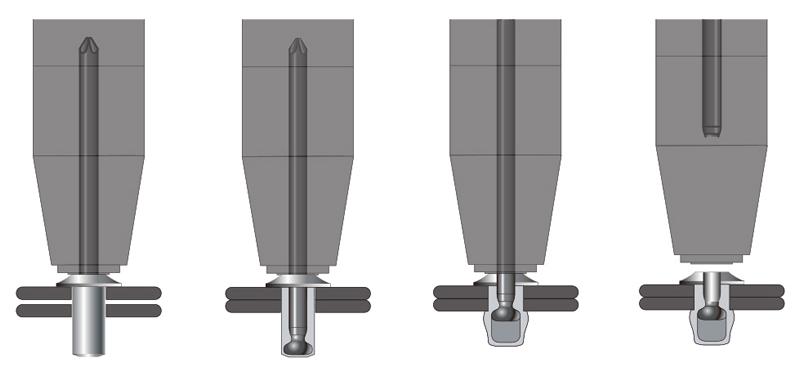

The installation process of Pop Rivet is based on mechanical stretching and plastic deformation. The core principle is as follows:

- Drilling

Drill holes on the two materials to be connected that match the diameter of the rivets. The aperture should be approximately 0.1–0.2 mm larger than the diameter of the rivet body to ensure smooth insertion and to guarantee the locking accuracy. - Inserting the Rivet

Insert the rivet body into the hole, ensuring that the cap part closely adheres to the material surface. At this point, the mandrel still passes through the rivet body. - Pulling the Mandrel

Use the rivet gun to pull the head of the core shaft. When the mandrel is pulled, it will cause the tail of the rivet body to undergo plastic expansion, forming a “bulb-shaped lock head” on the back of the material. This process firmly held the two pieces of material together. - Mandrel Break-Off

When the pulling force reaches the set value, the core shaft breaks at the designed fracture groove, and the remaining part stays inside the rivet. At this point, Pop Rivet has been successfully installed, forming a stable and highly shear-resistant permanent connection point.

Key Benefits of Using Pop Rivets

Compared to threaded connections or welding, the structural advantages of Pop Rivets are not only reflected in the ease of installation, but also in their overall reliability and economy. The following is an analysis of the core structural advantages of Pop Rivets.

①. One-Side Installation

The main feature of Pop Rivet is that it can be installed in structures that can only be accessed on one side. This “blind access” characteristic makes it highly suitable for use in sealed structures, inside pipes, interior panels of vehicles, and other working conditions where it cannot be operated from the back. The installation tool is simple and the fixation can be completed with just one pull.

②. Fast Assembly Process

Compared with bolts or welding, the installation of Pop Rivets is faster and does not require high temperatures or thread processing. Just drill a hole, insert the rivet and pull out the core shaft. The entire process is usually completed within 3–5 seconds. On mass production lines, using pneumatic or electric riveting guns can further enhance efficiency and achieve standardized assembly.

③. Lightweight Strength

Pop Rivet is mostly made of aluminum, galvanized steel or stainless steel, balancing strength and weight. Particularly, the aluminum rivets have a density only one-third that of steel, allowing for significant weight reduction without compromising structural stability. This is especially crucial in scenarios with lightweight requirements such as in automobiles, aviation, and rail transportation.

④. Excellent vibration resistance performance

After installation, the Pop Rivet forms a tight mechanical locking structure, effectively preventing loosening. Compared with traditional threaded connections, it performs better in high-frequency vibration environments and does not fail due to small displacements. Therefore, it is widely used in parts with frequent vibrations such as vehicle body structures, mechanical frames, and equipment shells.

⑤. Maintenance-Free Design

Once installed, Pop Rivet does not require any further tightening or lubrication. It is a truly “permanent connection component”.

In long-term operating environments (such as in household appliances, equipment casings or building facades), Pop Rivet can maintain a stable clamping force and does not require additional maintenance costs.

⑥. Corrosion and Sealing Options

For outdoor or humid environments, you can choose closed-end rivets or stainless steel materials to achieve waterproof, anti-corrosion and dust-proof effects. This structure is particularly practical in scenarios such as aluminum ships, air conditioning shells, and building facades.

Applications and Types of Pop Rivets

The pop rivet is one of the most commonly used rivets. Whether it’s steel, plastic, aluminium, carbon and stainless steel or other materials of different strengths and thicknesses, you can find different types of pop rivet for your project at Rivmate.You can choose from different types of nail cores, nail heads and nail bodies.

This is the most basic and common type of Pop Rivet. The tail end of the mandrel breaks after installation, leaving a part inside the rivet body. The tail end of the rivet body forms a flange, completing the clamping function.

- Low cost, suitable for mass production.

- Quick installation, can be completed on one side.

- Lightweight structure, compatible with various materials (aluminum, steel, stainless steel).

It is applied to the exteriors of household appliances, the splicing of metal plates, sheet metal assembly, and general industrial structures. For standard metal connections with non-sealing requirements, the open type is the most economical and efficient solution.

The tail end is completely sealed, and after the core shaft breaks, it remains inside the housing. This forms a sealed cavity structure to prevent the penetration of liquids or gases.

- It has waterproof, dustproof and anti-corrosion functions.

- It can prevent electrolytic corrosion from occurring.

- After riveting, the surface is smooth and the sealing performance is excellent.

It is applied in shipbuilding, car exteriors, air conditioning units, aluminum doors and windows, and outdoor equipment. The closed-type rivets passed the ASTM B117 salt spray test for 1000 hours, and the retention rate of sealing performance exceeded 95%.

During the installation process, the tail end of the rivet body will split longitudinally into four parts, resembling petals. Each part spreads outward and closely adheres to the surface of the material, forming a flexible clamping force.

- Distribute stress to prevent brittle materials from cracking.

- It is particularly suitable for non-metallic substrates such as wood, plastic, and composite materials.

- After riveting, the structure is stable and not prone to detachment.

It is applied to wooden furniture, plastic shells, composite board assembly, and light industrial products. In non-metallic connections, split-type rivets are safer than traditional metal rivets as they do not cause material cracking due to local stress concentration.

It has a special rivet body structure that can adapt to various thickness combinations. One model can cover multiple traditional rivet specifications.

- Reduce inventory and simplify selection.

- Enhance assembly flexibility and tolerate hole diameter errors.

- The locking core shaft is firmly fixed after riveting and is not prone to loosening.

It is applied in automotive assembly lines, equipment maintenance sites, and the assembly of steel plates and plastic components. The use of multiple clamping rivets can reduce the number of inventory models by approximately 35%, significantly lowering storage costs.

Choosing The Right Type Of Pop Rivet

a. Based on Material Compatibility

The material of the rivets should match that of the connected components to prevent galvanic corrosion.

| Rivet Material | Recommended Base Material | Key Characteristics |

|---|---|---|

| Aluminum | Aluminum sheets, plastics, thin steel plates | Lightweight, corrosion-resistant, cost-effective |

| Stainless Steel | Stainless steel, steel plates | High strength, excellent corrosion resistance |

| Steel | Carbon steel structures, mechanical components | Strong shear resistance, suitable for heavy-duty joints |

| Copper / Brass | Electrical components, decorative parts | Good conductivity, strong anti-rust performance |

b. Based on Grip Range

Grip Range determines whether the rivet can fully secure the two layers of material. A rivet that is too short will result in insufficient clamping, while a rivet that is too long may deform or become loose.

The selected Grip Range should be slightly larger than the total thickness of the connected material (TMT), and a safety margin of approximately 1–1.5mm should be left. When the clamping range is well-matched, the structural strength is typically enhanced by 15%–20%.

c. Based on Environmental Conditions

- Indoor dry environment: Use open type blind rivets. Low cost, quick installation, suitable for appliance shells and sheet metal assembly.

- Wet or outdoor environment: Choose closed type blind rivets. Sealed tail, waterproof and dustproof, strong corrosion resistance, suitable for ships or building curtain walls.

- High vibration conditions: Recommend structural rivets. Core shaft locking design, anti-loosening, high shear strength, suitable for vehicles and heavy machinery.

- Multiple thickness combinations: Use multi-grip rivets. One rivet for multiple uses, adaptable, reduces inventory and selection complexity.

- Wood or plastic substrates: Select peel type rivets. Tail opens to distribute force, prevents material rupture, suitable for furniture or plastic component assembly.

The type of installation tools directly affects the construction efficiency and the consistency of locking.

- Manual Rivet Gun: Suitable for small-scale repairs and DIY projects.

- Pneumatic/Hydraulic Rivet Gun: Suitable for factory batch assembly.

- Cordless Rivet Tool: Combines flexibility and portability with high efficiency.

For frequent assembly or structural-type rivets, it is recommended to use Rivmate electric or hydraulic tools, which can ensure uniform tension and high consistency.

e. Based on Strength Requirements

When the project has specific requirements regarding the strength of connection, shear resistance or vibration stability, different types of Pop Rivets should be selected based on the structural load characteristics.

For assembly scenarios with moderate strength requirements, such as appliance housings, lightweight sheet metal parts, or non-load-bearing structures, it is recommended to use open type rivets. This type of rivet is easy to install and has a low cost, making it the most economical solution.

If the project involves medium to high-strength connections, the Multi-Grip Rivet can be chosen. This design can maintain a stable locking force in different thicknesses or material combinations, effectively preventing loosening or deformation. It is highly suitable for automotive components, equipment housings, and industrial assembly lines.

For high-load, highly-vibratory or critical structural parts, the structural rivets (Hemlock / Structural Rivet) should be given priority. These rivets feature a core shaft mechanical locking structure, offering high shear resistance, high tensile strength and anti-loosening performance. They can maintain stability over a long period in heavy-load or dynamic stress environments.

FAQs

A Pop rivet is a type of one-sided installation permanent fastener, suitable for use in structures where operation from the back is not possible. It is widely applied in fields such as automobile manufacturing, building curtain walls, electronic equipment, home appliance shells, and aviation maintenance. The core advantages of Pop rivets lie in their fast installation, stable connection, and low maintenance cost. Under the trend of lightweight and modular assembly, Pop rivets are gradually replacing traditional bolts and welding processes.

Q2. What materials are Pop Rivets made from?

Common materials for Pop rivets include:

- Aluminum : Lightweight, corrosion-resistant, suitable for aluminum plates or plastic parts;

- Stainless Steel: High strength, corrosion-resistant, suitable for outdoor or high-load environments;

- Steel : Strong shear resistance, commonly used for mechanical and structural connections;

- Copper / Brass: Good electrical conductivity, suitable for electrical assembly and decorative applications.

Standard open-type rivets do not have waterproof performance. If the project has requirements for waterproofing, dustproofing or anti-corrosion, Closed-End Blind Rivet should be selected. This type of rivet has a closed tail, which can prevent liquids and air from seeping in. It is very suitable for use in hot and humid environments such as ships, outdoor equipment, and solar brackets.

Q4. Are Pop Rivets strong enough for structural use?

Regular rivets are suitable for light to medium strength connections. If the project requires high shear or vibration resistance, structural rivets should be used. These rivets feature a core shaft mechanical locking design, which significantly enhances the tensile and shear strength, being 40%–60% stronger than standard blind rivets.

Build Smarter Connections with Rivmate Pop Rivets

Compared to traditional bolts or welding methods, Pop Rivet not only installs faster but also reduces production costs and maintenance risks. For high-demand application scenarios, Rivmate Closed-Type and Structural-Type Rivets Series can maintain safety and durability in extreme environments.

Choosing the appropriate type and material of rivets is crucial for ensuring the structural strength and lifespan. Rivmate boasts extensive industry experience and international standards certifications (ISO/ASTM), providing professional riveting solutions for users worldwide.

Contact our technicians immediately to obtain:

- Selection Guide for Bolts for Different Application Scenarios

- Data Sheet for High-Strength Structural Bolts and Closed-Type Series Products

- Recommendations for Matching Bolting Equipment and Technical Support

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met