Table of Contents

Avex rivet is a structured blind rivet from AVDEL. It is very similar to the multi grip blind rivets, just with a different name. This blog describes everything about the avex rivet. Including types, applications, benefits and how to choose.

Table of Contents

What is an Avex Rivet?

Avex Rivet is a high performance Multi-Grip blind rivet. The best feature of this type of rivet is that it can be designed to rivet materials of varying thicknesses, providing reliable fastening performance and a convenient installation experience.

Avex rivets are break bar rivets with a retaining bar. It has very good hole filling properties and a large blind side load area, making avex rivets ideal for thin sheet materials. In addition to open type blind rivets, avex rivets (multi grip blind rivets) are the most used rivets on the market today.

Avex rivets are a very cost effective alternative to open type blind rivets. The same size avex rivets can be riveted to a variety of different metal thicknesses, an advantage that can reduce the pressure on your inventory.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Types of Avex Rivets

To meet the needs of different applications, avex rivets’ rivet bodies and rivet mandrels are available in different metal material combinations. The following are common types of combinations:

- Carbon Steel Mandrel / Aluminum Body

- 304 Stainless Steel Mandrel / Aluminum Body

- Carbon Steel Mandrel / Carbon Steel Body

- 304 Series Stainless Steel Mandrel / 304 Series Stainless Steel Body

How do Avex Rivets Work?

Like other blind rivets, avex rivets form a tight connection by the expansion and deformation of the rivet body. Once you have done all the pre-riveting preparation, the riveting process is as simple as mounting the avex rivets on the workpiece and pressing the tool button.

Below are the basic installation steps for avex rivets.

1. Preparation Stage

The installation of Avex rivets requires pre-drilling of holes, which is the basis of all riveting operations.

- Drilling: Drill holes of suitable diameter in the material to be joined.

The hole diameter is slightly larger than the rivet diameter (e.g. a 4.8mm diameter rivet requires a 5.0mm hole). - Rivet Selection: Select an Avex rivet that is suitable for the range of material thicknesses.

For example, one Avex rivet may cover a total material thickness of 2.0mm-6.0mm.

2. Inserting the Rivet

Insert the rivet body of the Avex rivet into the pre-drilled hole, making sure that the head of the rivet (usually rounded, large brimmed, or countersunk) fits snugly against the surface of the workpiece.

3. Installation Tool Preparation

The installation of blind rivets usually requires the use of a rivet gun (manual, electric or pneumatic rivet tool).

For riveting of rivets, the operator needs to use the rivet gun to clamp the rivet mandrel. The pulling jaws of the rivet gun grasp the end of the mandrel, ready to apply tension.

4. Pulling Mandrel

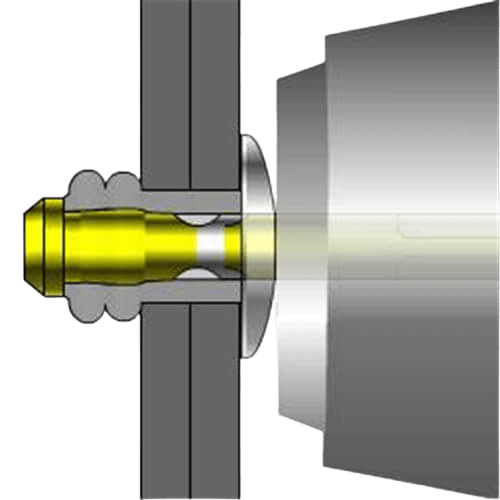

The rivet body undergoes a series of changes when pressure is applied to the rivet. The following is the process of change.

- Pulling effect: The rivet gun applies upward pulling force by pulling the mandrel, so that the tail of the rivet begins to expand and deform.

- Rivet body deformation: The tail of the rivet body is pushed outward by the head of the mandrel to form a wide riveting surface.

- Multi-Grip Function: The deformation of the rivet body tail is designed to accommodate materials of varying thicknesses, ensuring that gaps between materials are completely filled.

5. Mandrel Breakage

When the tensile force on the mandrel reaches a set value (usually determined by the design of the mandrel’s break point), the mandrel breaks at a predetermined location, creating a flush riveted joint.

The riveted joint is completed:

- The end of the rivet body firmly clamps the connecting material, providing a secure hold.

- The residual portion of the mandrel does not affect the function of the rivet and the break point is smooth and aesthetically pleasing.

5 Advantages of Avex Rivets(Multi Grip Blind Rivets)

Here are some of the most important benefits of avex rivets.

1. Reduce Rivet Inventory

Because one model of avex rivets can accommodate multiple thicknesses of material, users can reduce the cost of inventory management.

The multi-grip range of Avex rivets is a very popular feature among users.

2. Portable Installation

Avex rivets is quick and easy to install. The entire installation process can be done quickly using just a regular get the job done rivet gun. This is perfect for high volume production.

3. Economical and Practical

Avex rivets effectively reduce the need for multiple rivet models for a single application scenario with their multi-grip design.

4. Superior Clamping Force

Avex rivets create a wide deformation of the rivet tail after riveting, a structure that provides reliable clamping force and vibration resistance.

5. High Vibration Resistance

As a result of avex rivets the rivet body tail extension is strong and less likely to come loose due to vibration.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Applications of Avex Rivets

There are still more scenarios where Avex rivets can be used. Below I have listed common applications for multi grip blind rivets.

- Aerospace: Fixing of lightweight panels for aircraft interiors. Assembly of aluminum frames, cockpit interior brackets. Installation of antennas, navigation equipment or lightweight additional components.

- Automotive industry: attachment of thin sheet metal parts such as doors, fenders, roof frames. Fixing of interior panels, carpet brackets and sound insulation materials. Component mounting of battery box or electric control equipment for electric vehicles.

- Construction and building decoration: fixing of curtain walls, metal window and door frames. Connection of aluminum alloy panels, plastic panels and composite materials. Installation of interior decorative parts, partition wall panels.

- Electronic equipment and household appliances: fixing of electronic equipment housings, such as laptop computers, server chassis. Assembly of internal frames and external panels of household appliances, such as washing machines, refrigerators and microwave ovens.

- Rail transportation: assembly of interior panels and seat supports for trains. Connection of window frames and metal structures. Fixing of air-conditioning system and lighting equipment.

- Marine & Offshore Engineering: Installation of additional parts for aluminum hulls, such as brackets, railings and guards. Assembly of lightweight partitions in ship’s cabin. Fastening of electrical equipment on board.

- Industrial equipment: fastening of light mechanical equipment housings and frames. Installation of industrial pipe supports, duct connections and equipment guards. Modular component assembly on automated production lines.

- Furniture manufacturing: assembly of aluminum or steel furniture frames. Fixing of thin metal or plastic panels in office furniture (e.g. filing cabinets, desks and chairs). Connection of decorative strips or lightweight accessories in decorative furniture.

- Electrical and energy industry: fixing of solar photovoltaic mounts. Wind turbine internal bracket and housing connection. Installation of cable bridges or equipment housings.

Tips for Choosing the Right Avex Rivets

The trick to choosing the right avex rivets is that you need to be very knowledgeable about your business needs. You need multi grip blind rivets that can fully meet the needs of your application.

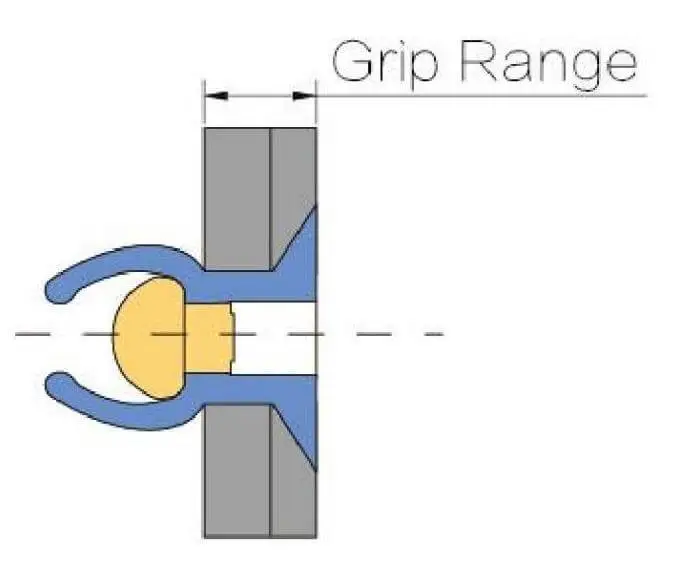

Determine the Range of Material Thicknesses

Before choosing avex rivets, business owners need to account for the total thickness range of the joining material, including the stacked thickness of all layers.

- Avex Rivets are multi-grip rivets where a single model can accommodate multiple thickness ranges. Simply select the rivet size that covers that thickness range.

Example:For a total thickness of 3mm-5mm, select Avex Rivets labeled for 2mm-6mm.

Note: Avoid rivets with a grip range much greater than the actual thickness to ensure clamping force and deflection.

Selecting the Right Head Type

- Dome Head: This is the generic type that applies to the vast majority of connection scenarios. This provides a moderate contact area and good clamping force.

- Large Flange Head: Suitable for thin plates, soft or brittle materials (e.g. plastics, composites). The cap rim distributes the pressure and prevents the material from being damaged.

- Countersunk Head: For applications where a flat surface or hidden rivet head is required. Examples include decorative structures or aerodynamically demanding scenarios.

Selecting the Right Diameter Specification

Select the rivet diameter according to the hole diameter and load requirements of the connected material.

- Hole Diameter Requirement: The rivet diameter should match the hole diameter, usually the hole diameter is 0.1-0.2mm larger than the rivet diameter.

- Load Requirements: The larger the diameter, the greater the clamping force and shear resistance provided by the rivet.

Example:

- For lightweight components (e.g., electronic equipment panels), use 3.2mm or 4.0mm rivets.

- For components that carry higher loads, such as automotive frames, use 4.8mm or larger diameter rivets.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Frequently Asked Questions

1. Avex Rivets Size

Size: 3.2mm (1/8“), 4.0mm (5/32”), 4.8mm (3/16“), 6.4mm (1/4”).

2. What are Common Problems with Avex Rivets?

- Insufficient clamping force: The rivet may have been selected with too much or too little grip range.

- Installation Failure: Mismatched hole diameters, rivets that are too long or insufficient tool tension.

- Corrosion problems: Rivet material is not compatible with the parent material.

3.Does Avex Rivets Require Follow-up Maintenance?

Usually not required.Avex Rivets are permanent fasteners and require no additional maintenance after installation. However, in extreme environments, they may be periodically checked for corrosion.

Utilizing Rivmate Rivets to Enhance Your Business

Rivmate is a high quality blind rivet manufacturer and supplier. we have over 20 years of experience in the global rivet market. Our superior quality structural rivets and avex rivets are trusted by our customers.

We offer free sample support as a way to help you maximize your business potential.

Enhance your business with Rivmate. Contact us today!