What Size Drill Bit for 1/8 Rivet

Table of Contents

What size drill bit is for 1/8 rivet? We will combine American and metric standards to provide authoritative drill bit recommendations, reasonable tolerance ranges, and hole diameter adjustment suggestions for different materials. This will help beginners and professional assembly engineers avoid riveting defects caused by improper selection.

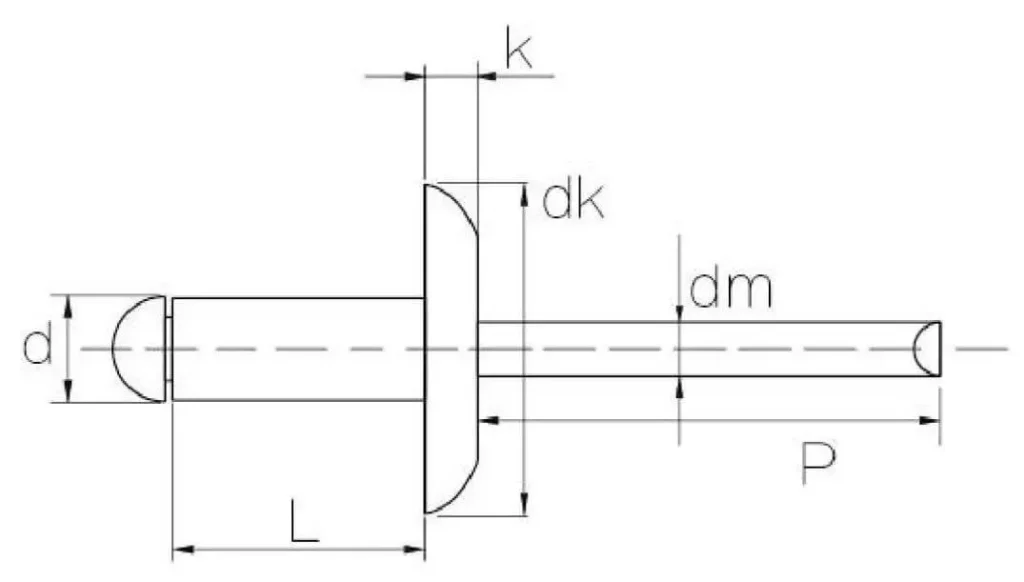

What is the specification of a 1/8 rivet?

“1/8 rivet” refers to a shank diameter of 1/8 inch (approximately 3.175 mm). This size is one of the most common standard sizes in industrial and DIY applications. This specification is suitable for various types of blind rivets and solid rivets, and is widely used in sheet metal assembly, plastic connections, electronic enclosures, and lightweight structural components.

Common materials for 1/8-inch rivets include aluminum, stainless steel, carbon steel, and copper. Different materials have distinct characteristics in terms of strength, expansion properties, and corrosion resistance, necessitating minor adjustments to the installation holes. For example, stainless steel rivets, due to their high hardness, typically require a slightly larger hole diameter to reduce assembly resistance and prevent breakage. Accurately identifying the rivet specification is the first step in ensuring proper hole diameter matching and reliable connections.

What Size Drill Bit for 1/8 Rivet

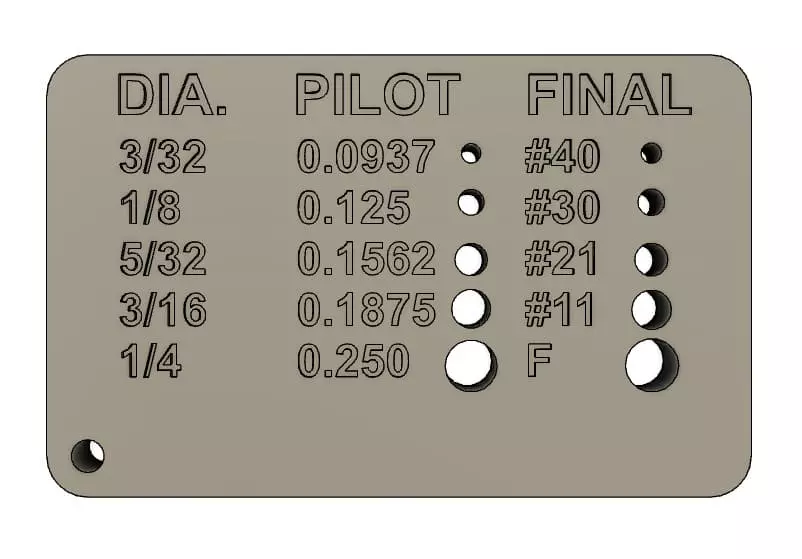

In riveting processes, to ensure that the rivet can be inserted smoothly and achieve sufficient expansion clamping effect, the hole diameter should be slightly larger than the rivet shank diameter. Taking a 1/8-inch (0.125“) rivet as an example, the most suitable drill hole size should be approximately 0.003” to 0.005″ larger than the shank diameter. This size avoids the issues of being too tight, which can cause insertion difficulties, while also preventing the hole from being too large, which can lead to loosening and seal failure.

If you want to know more about rivet sizes and how to measure them, you can refer to my article “how to measure blind rivet“.

The following is a table comparing the recommended standards:

| Rivet Size (inches) | Recommended Drill Bit # | Hole Diameter (in) | Metric Equivalent (mm) | Fit Type |

|---|---|---|---|---|

| 1/8″ (0.125″) | #30 | 0.1285″ | 3.26 mm | Standard Fit (Typical) |

| 3.3 mm | 0.1299″ | 3.30 mm | Metric Alternative | |

| #29 | 0.1360″ | 3.45 mm | Loose Fit (Special Use) |

Recommendation:

- The #30 drill bit is the recommended industrial standard size. This size drill bit provides a stable and reliable mechanical fit for 1/8 rivets and is a common choice in North American and aerospace manufacturing.

- If using a metric tool system, a 3.3 mm drill bit can be used. The error is within the allowable range and is suitable for general assembly scenarios.

- If the structure is made of soft materials (such as plastic or thin aluminum) or requires manual installation, a slightly larger hole diameter facilitates insertion. A #29 drill bit or 3.4–3.5 mm drill bit can be used, but be mindful of the risk of reduced clamping force.

Processing Precautions:

- Drill bit wear can cause fluctuations in hole diameter, so drill bits should be replaced or calibrated regularly.

- Off-center drilling or burrs will directly affect the center positioning and expansion quality of the rivets.

- It is recommended to use a limit drill sleeve or positioning guide hole fixture to improve drilling consistency.

- When riveting multiple layers of material, it is recommended to pre-drill or expand the holes layer by layer to avoid misalignment between layers.

Different 1/8 Rivet Types Require Different Hole Sizes

Although “1/8-inch rivets” are uniformly designated as 0.125 inches (3.175 mm) in nominal size, there are significant differences between rivets made of different materials in terms of forming behavior, hardness, thermal expansion characteristics, and installation resistance. Therefore, during the hole design stage, the hole diameter must be adjusted appropriately according to the rivet material.

- Features: Lightweight, good ductility, sufficient expansion, high tolerance for hole diameter.

- Recommended hole diameter: A standard #30 drill bit (0.1285″) or 3.3 mm drill bit is sufficient.

- Additional information: Suitable for most sheet metal connections. For manual installation or soft substrates, the hole diameter can be slightly widened to 3.4 mm to reduce insertion force.

- Features: High hardness, high strength, strong expansion resistance, and more sensitive to hole diameter size.

- Hole Size Recommendations: We recommend using a #29 drill bit (0.1360″) or a 3.4–3.5 mm drill bit to ensure smooth insertion and full expansion.

- Risk Control: A hole size that is too small can cause excessive load on the rivet gun, leading to the rivet not being securely fastened or the core not being cleanly severed.

- Features: High strength but slightly brittle, suitable for structural load-bearing connections. Requires slightly higher drilling accuracy.

- Recommended hole diameter: A #30 drill bit can be used, but the hole walls must be clean and free of burrs. If necessary, use a 3.35–3.4 mm drill bit to improve insertion force stability.

- Additional notes: Forced expansion may damage the base material. It is recommended to test before mass application.

- Features: Soft, fully expandable and deformable, suitable for decorative parts, leather, and woodworking structures.

- Recommended hole diameter: A standard #30 drill bit is sufficient. If used on soft substrates, the hole diameter can be appropriately widened to 3.4 mm to prevent skewing.

- Risk control: Avoid excessive hole diameter, which may cause loose clamping or skewed installation.

Common Errors and Remedial Recommendations

Even if the correct rivet and drill bit models are selected, operational errors, equipment deviations, or misjudgments during the construction process can still cause connection defects, which in turn affect the overall strength, sealing, and service life of the structure. The following are common types of drilling and installation errors and their corresponding remedial measures.

Error 1: Using a 1/8“ drill bit to directly drill a 1/8” rivet hole

- Issue: A 1/8″ drill bit is equivalent to the diameter of the rivet shaft, resulting in an overly tight fit, making insertion difficult, and potentially causing material damage or rivet failure.

- Remedy: Use a #30 drill bit (0.1285“) or 3.3 mm drill bit instead to ensure a 0.003–0.005” installation clearance. If the hole has already been drilled incorrectly, consider using a slight taper to enlarge the hole and correct the diameter.

Error 2: Off-center or skewed drilling

- Issue: Rivets cannot expand vertically after installation, resulting in insufficient clamping on one side, which may cause loosening or tearing.

- Remedy: Use a pilot hole fixture or drilling stop device. For off-center holes, replace with structural pop rivets or double-claw closed-type compensation structures.

Error 3: Failure to remove burrs or oxide layers after drilling

- Issue: Residual burrs can obstruct rivet expansion, leading to uneven clamping force or stress concentration, which may result in fatigue cracking over time.

- Remedial recommendation: After drilling, use deburring tools or pneumatic brushes to clean the hole walls, and perform corrosion-resistant pretreatment (e.g., zinc-chromium coating, rust-preventive agent cleaning, etc.).

Error 4: Excessively large hole diameter causes rivets to shake or fail to clamp properly

- Issue: Loose fit prevents rivets from expanding properly or applying clamping force, resulting in “play” or structural loosening at the connection point.

- Remedial recommendation: If the tolerance deviation does not exceed 0.1 mm, use an oversized rivet (e.g., 5/32″ specification as an alternative) or install a sealing washer to assist with clamping. For severe deviations, it is recommended to drill and re-drill.

Error 5: Improper alignment or uneven force during installation

- Problem: Core displacement, incomplete expansion, or asymmetrical tail end formation can easily create potential sources of fatigue cracks.

- Remedial recommendation: Use automatic riveting tools or set force limiters to avoid over-tightening or uneven tightening. It is recommended to rivet in stages along the diagonal in multi-point riveting structures to improve uniformity.

Preparation:

Prepare the required tools and materials in advance, including 1/8 rivets, drilling tools of the corresponding size and rivet installation tools.

Drill Hole Preparation:

Using an appropriately sized drill bit, drill a hole in the material to be joined. The diameter of the drill hole should match the diameter of the body of the 1/8 rivet to ensure that the rivet can be inserted smoothly.

Inserting the rivet:

Insert the body of the 1/8 rivet into the drilled hole, making sure that the head of the rivet is on the side of the material to be joined. Make sure the rivet is fully inserted into the drilled hole.

Installation Pressure:

Apply appropriate installation pressure using a rivet gun or similar tool. Ensure that the pressure applied is sufficient to fully extend the tail (cored portion) of the rivet and clamp the joining material securely.

Inspecting the Connection:

After installation, check the quality and strength of the connection. Ensure that the rivets are firmly seated in the joining material and that there is no visible looseness or deformation in the joint.

Precautions for Installing 1/8 Rivets

- The diameter of the drilled hole should match the diameter of the body of the 1/8 rivet to ensure proper insertion and joint strength.

- During installation, ensure that sufficient installation pressure is applied to the rivet, but avoid over-application of force resulting in material damage.

- Select the appropriate rivet head shape for the specific application to provide the desired appearance and connection strength.

- After checking the connection, ensure that the connection is strong and reliable with no visible looseness or deformation.

FAQs

Q1: Can I use a 1/8“ drill bit to drill holes for installing 1/8” rivets?

A: We do not recommend doing so. Since the 1/8“ drill bit (0.125”) has the same diameter as the rivet shaft, it will result in an overly tight fit, making insertion difficult and potentially preventing proper expansion clamping. We recommend using a #30 drill bit (0.1285″) or a 3.3 mm drill bit to ensure sufficient installation clearance.

Q2: Can a 3.2 mm drill bit be used instead of a 3.3 mm drill bit?

A: Avoid doing so if possible. The 3.2 mm hole diameter is only 0.025 mm larger than the rivet shaft diameter, which can easily cause interference fit, especially posing a significant risk for high-hardness materials such as stainless steel rivets. It is recommended to use standard 3.3 mm or 3.4 mm drill bits to ensure smooth assembly.

Q3: Can the rivet still be used if the hole diameter is too large?

A: If the deviation is minor (no more than 0.2 mm), consider using an oversize rivet or adding a washer to increase the clamping force. If the hole is too large and clamping fails, it is recommended to seal the hole, re-drill it, and use a larger rivet (such as 5/32″).

Q4: Is deburring necessary after drilling?

A: Yes. Residual burrs not only affect the expansion quality of rivets, but can also become stress concentration points, inducing cracks or premature structural fatigue failure. Be sure to use a deburring tool or special tool to clean the hole edges, which is especially important in multi-layer connection structures.

Buying 1/8 Rivet? Rivmate can Help you !

Are you struggling with the consistent quality but high price of 1/8 rivet? Are you looking for a 1/8 rivet with the right price and stable quality? It’s time to connect with a reliable 1/8 rivet supplier! Whether you are buying regular rivets or custom rivets, you can achieve your success with Rivmate!

The safety of a project is dependent on the composition of each component, and a good rivet can provide security and stability to the connection of components. Make sure every connection is secure!

Visit Rivmate Rivet to learn more about purchasing our 1/8 rivets and Contact Us Today!

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met