Table of Contents

Nowadays, pop rivets are being used more and more widely. So do you know when were pop rivets invented and who invented the pop rivets? Through this blog, you will learn the history of pop rivets. Including the promotion process, the order of invention and the importance of pop rivets.

Table of Contents

History of Pop Rivets - When were Pop Rivets Invented ?

To meet the needs of different industries and applications, Pop Rivets (Blind Rivets) have gone through many innovations and evolutions since their invention. Below is a timeline of the invention of the different types of Pop Rivets, as well as the purpose and background of their respective inventions.

To solve the riveting problem in the aerospace industry. The Pop Rivet Company invented pop rivets around the 1930’s. Conventional rivets require access on both sides of the riveted surface and cannot be operated on one side. The Pop Rivet, however, allows for one-sided riveting, solving the problem of not being able to access the other side in aircraft construction and other similar applications.

Pop rivets were originally used in the aerospace industry, particularly in aircraft construction. After World War II, Pop Rivet quickly found its way into the automotive manufacturing and construction industries.

Aluminum Pop Rivets - Invented 1940s

With the growing need for lightweighting in the aviation industry, aluminum pop rivets were invented in the 1940s.

Aluminum Pop Rivets were invented to meet the demand for lighter weight. Aluminum rivets are lighter than steel rivets for the aerospace and automotive industries. And the corrosion resistance and good formability of aluminum alloys also make them ideal.

Aluminum pop rivets were first used in aircraft housings and automotive manufacturing. Today, aluminum pop rivets are used in a wide range of applications requiring low weight and high strength components.

Because of the many advantages of pop rivets, it is increasingly used in a wide range of applications. Thus in response to the need for high strength and corrosion resistance, stainless steel Pop Rivets were developed in the 1950s.

Stainless steel pop rivets are so resistant to corrosion that they are often used in high temperature or humid environments. Examples include the construction, marine, chemical and petroleum industries.

Copper Pop Rivets - Invented 1960s

To solve the problem of electrical conductivity and corrosion resistance, copper pop rivets appeared in the 1960s. The electrical conductivity of copper makes it an important application in the electronics industry and electrical equipment. For example, electrical equipment and electronics shell connection.

As sealing technology evolved, waterproof Pop Rivets were invented. This type of rivet creates a seal during the riveting process, preventing water, air and other liquids from penetrating. It is usually equipped with special rubber gaskets or seals.

In applications where high water resistance and corrosion resistance is required. For example, in construction, water treatment equipment and marine environments, you will often see waterproof rivets.

Structural Rivets - Invented 1980s - 1990s

As technology evolved, structural rivets that could withstand greater pressure and strength were invented. There are many types of structural rivets, but they all have one thing in common – extremely high tensile and shear strength. As a result, structural rivets are widely used in heavy equipment, industrial machinery and riveting in high stress environments.

Why are Pop Rivets so important?

1. Wide Range of Application Scenarios

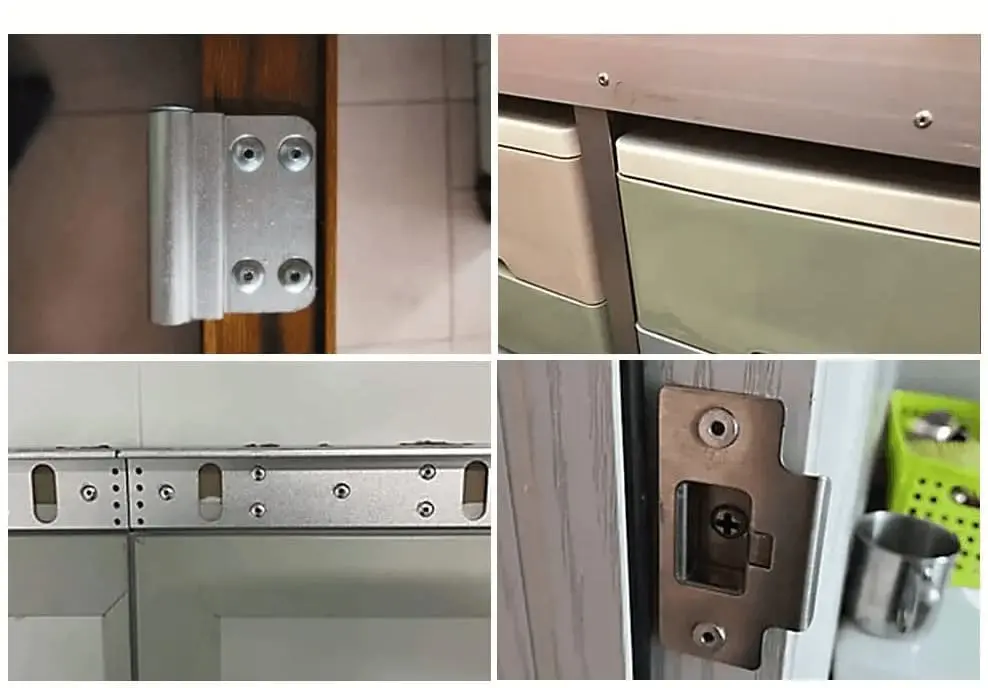

The application scenarios for Pop rivets are quite extensive. Basically any thin sheet connection can use pop rivets to improve installation efficiency.

- Aerospace: Pop Rivets were first used extensively in aircraft manufacturing because they allow fastening to be accomplished quickly in hard-to-reach areas such as fuselages and wing panels.

- Automotive industry: Used for body panels and interior part connections, providing a lightweight, high-strength solution.

- Construction and household appliances: Pop Rivets are used in scenarios such as façade fastening and equipment housing installation.

2. Convenience and Safety

- Pop Rivets are designed for ease of operation, reducing the skill level required of workers during installation and minimizing the possibility of installation errors.

- Its single-side mounting feature also increases safety in high-risk environments, such as working at heights.

3. Cost Effectiveness

Riveting offers significant economic savings compared to traditional joining methods. So how do pop rivets reduce overall project costs?

- The use of Pop Rivets reduces the complexity of production line equipment by eliminating the need to align and manipulate from both sides.

- The rivet cost is inexpensive. But provide extremely high reliability in complex scenarios, reducing maintenance costs over time

4. Durability and Versatility

Pop rivets provide a connection that is permanent. Therefore it provides excellent resistance to vibration. Even when used in dynamic loading scenarios, pop rivets will not easily loosen.

In addition to this, it is adapted to corrosive environments (e.g. salt spray, moisture) or high temperature application scenarios with a wide range of material compatibility (e.g. aluminum, stainless steel, copper, etc.).

Do You Have Any Questions?

Let Us Solve Your Problem

Who Invented the Pop Rivets?

Pop Rivets were invented in the 1930s by the George Tucker Eyelet Company (later Tucker Fasteners Ltd.). This company, based in Birmingham, England, originally developed the rivets to meet the aerospace industry’s need for single-sided riveting.

The Process of Popularizing Pop Rivets

Although pop rivets were invented in the 1930s. But its real popularity came after the second end of the Great War. Since then, the use of pop rivets has not only been limited to the aviation industry, but has gradually entered more industrial fields.

In the 1950s, the use of pop rivets in the automobile industry was widely popularized. Since then, instead of relying on welding or traditional rivets, pop rivets have been used to join many metal plates in the body structure, and the productivity of automobiles has been greatly improved since then.

The popularity of pop rivets also extends to the construction industry and the production of household appliances due to their high performance and ease of installation. Its simple and efficient installation and time-saving features have made it a standard part in modern manufacturing.

Do You Have Any Questions?

Let Us Solve Your Problem

Modern Applications of Pop Rivets

Today, Pop Rivets occupy an important position in many industries. Typical areas of application include:

- Aerospace: Pop Rivets are used in the assembly of airplanes and spacecraft, especially in the joining of housings and inner frames.

- Automotive: In modern automotive manufacturing, Pop Rivets are used to join body panels, interior trim, electronic equipment housings, etc.

- Construction: Pop Rivets are particularly useful in the connection of metal structures and prefabricated components.

- Electronics: Pop Rivets are used in the housings and interior components of many electronic devices.

- Home Appliances: Pop Rivets are also used in the metal housings and internal connections of some home appliances to increase manufacturing efficiency.

The Future of Pop Rivets

As material science and manufacturing technology continue to improve, the future of pop rivets remains full of endless possibilities. In the future, pop rivets may be used in more lightweight, environmentally friendly, and high-strength applications. At the same time, with the development of automation and robotics, pop rivets will be installed in a smarter and more efficient way.

Wholesale Pop Rivets from Rivmate

If you want to be in the process of finding high quality pop rivets for your project or business, please contact us.

You can get standard blind rivets, structural blind rivets and high strength rivets. And we offer you customized riveting services and customized packaging services.

Get a free sample of rivets for testing now.