Table of Contents

Why pop rivet mandrel not breaking? There are many reasons that can cause this problem and we need to troubleshoot it step by step. Usually it is because of using low quality pop rivets, mismatch of pop rivets and tools and wrong use of tools.

By reading this blog, you will learn about the common causes of “pop rivet mandrel not breaking” and the solutions.

Table of Contents

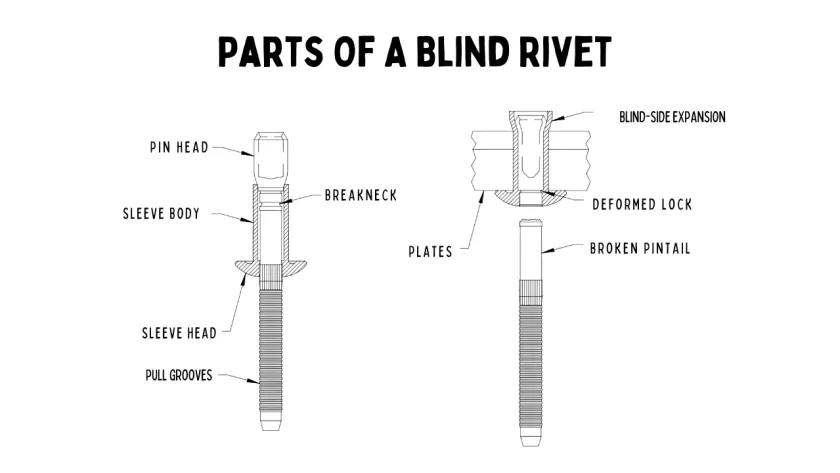

What is Pop Rivet Mandrel not Breaking?

The pop rivet mandrel not breaking is a phenomenon in which the core of the nail is not pulled off normally during installation. If this occurs it may result in rivet failure or insufficient joint strength.

Blind Rivet mandrel unbroken problem in the use of the more common riveting faults, the frequency of its occurrence is closely related to the operating specifications, the state of the tool and rivet selection. The following are possible causes of this problem:

- Insufficient rivet gun power or air pressure

- Rivet gun claws worn or improperly adjusted

- Rivet length and riveting thickness mismatch

- Nail core quality problems

6 Common Causes of Pop Rivets Mandrel not Breaking

There are many reasons why pop rivets mandrel not breaking. Next I will list the 6 most common reasons. This will solve most of your problems.

1. Excessive core tension

Nail core tension designed to exceed the tolerance limit of the rivet material may result in the rivet mandrel being pulled out as a whole rather than breaking normally. This is usually associated with improper rivet manufacturing processes or material selection, such as substandard heat treatment or excessive core strength.

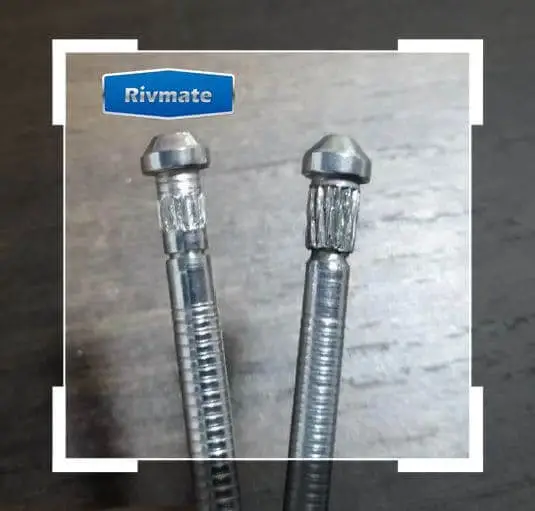

2. Nail core cap diameter is small

Rivet head with too small a diameter can result in insufficient friction with the inner hole of the rivet body to create effective resistance during the riveting process, so that the nail core is completely pulled out. In this case, the core cap is unable to create sufficient expansion pressure inside the rivet body.

3. Rivet body material is too soft

If the rivet body material is not hard enough (e.g., over annealed or not properly heat treated), the rivet body will not effectively clamp the core under force, resulting in core slippage. A soft rivet body may also cause problems such as loosening or cracking after riveting.

4. Excessive lubrication of the rivet bore surface

Excessive lubrication of the rivet bore can significantly reduce the frictional resistance between the core and the rivet body, making it easier for the core to be pulled out as a whole. This can be caused by excessive lubrication during the manufacturing process or improper surface preparation.

5. Underpowered or improperly adjusted rivet guns

Insufficient power to the rivet gun (e.g., low air pressure or loss of hydraulic fluid) may result in an incomplete riveting stroke, preventing sufficient tension from being applied to break the nail core at the intended location. In addition, a worn rivet gun jaw or failure to adjust to the same plane may cause a shearing effect on the nail core instead of normal tensile breakage.

6. Rivet and workpiece thickness mismatch

If the rivet length is too long and the riveted workpiece is thin, the distance between the core break and the core head exceeds the actual riveted thickness, which may result in the core slipping off directly without being pulled off.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Troubleshoot “Pop Rivet Mandrel not Breaking”?

In addition to encountering the cause of the problem, we need to engage in problem solving. By following these steps you can easily solve pop rivets mandrel not breadking problem.

Step 1: Check and clean rivet gun jaws (Jaws)

There are many reasons why pop rivets mandrel not breaking, first check the rivet gun jaws.

- Worn or damaged gripping jaws that prevent firm gripping of the mandrel.

- Metal shavings or dirt inside the jaws, affecting gripping ability.

- Loose or damaged jaw springs, resulting in insufficient clamping force.

The following steps can be followed to check for problems with the clamping jaws.

- Disassemble the jaw assembly and inspect for visible wear or cracks.

- Clean the clamping jaws using compressed air or a brush to remove metal shavings and dust.

- Apply an appropriate amount of lubricant to maintain the flexibility of the clamping jaws.

- If the jaws are badly worn, replace them with new jaws to ensure a secure grip on the mandrel.

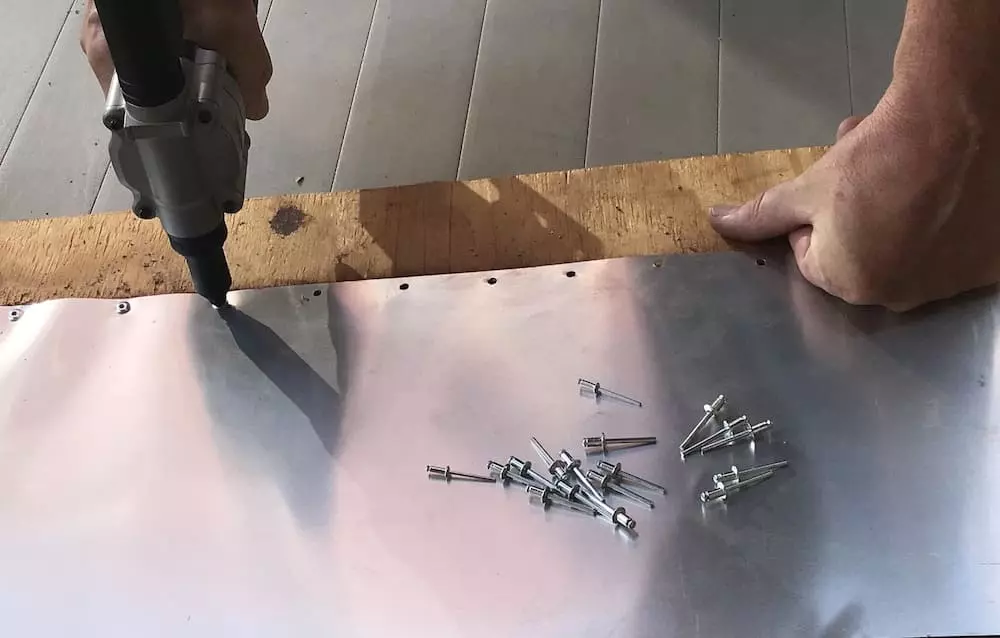

Step 2: Ensure that the rivet specification matches the workpiece

In addition to a faulty rivet gun jaw, there may be a mismatch in rivet size.

- Wrong choice of rivet diameter or length, resulting in the core bar not being able to generate sufficient shear force to fracture.

- Rivet material is too hard or too soft, affecting the fracture behavior of the core bar.

The inspection steps are as follows:

- Check that the diameter and length of the rivets meet the requirements of the workpiece thickness.

- Select the type of rivet that is suitable for the rivet gun (e.g. stainless steel rivets require greater tension).

- Avoid using low quality or inferior rivets and make sure they meet industry standards.

Step 3: Maintaining the internal components of the rivet gun

Rivet size is fine, jaws are fine. Then there may be a failure in the internal components of the rivet gun.

- Carbon buildup or sticking of the piston or cylinder that prevents the rivet gun from producing sufficient pulling force.

- Deteriorated or damaged internal seals (O-Ring) affecting the power output of the pneumatic rivet gun.

- Leaks or insufficient pressure in the hydraulic system (for hydraulic rivet guns)

In order to solve this problem, the following elements need to be done when using it:

- Periodically disassemble the rivet gun and clean the internal parts to prevent carbon buildup or clogging by foreign objects.

- Check whether the sealing ring (O-Ring) is aging or deformed, and replace with new parts if necessary.

- Check the pneumatic system or hydraulic system for air or oil leaks to ensure adequate working pressure.

Step 4: Adjusting the Rivet Gun Tension Setting

If the rivets are OK, then it is likely that the rivet gun tension is set incorrectly.

- Tension set too low, resulting in the mandrel not being pulled off sufficiently.

- Insufficient rivet pulling stroke to generate sufficient shear force.

To adjust the rivet gun proceed as follows:

- Adjust the air pressure of the pneumatic rivet gun (typically 90-120 PSI) to ensure adequate tension is provided.

- If using an electric or hydraulic rivet gun, adjust the tension output parameters to suit the rivet material and specifications.

- Test different rivet gun settings to find the proper tension setting.

Step 5: Ensure proper riveting operation

It could also be an operational problem.

- The rivet gun is not vertically aligned with the rivet, resulting in uneven distribution of tension and failure of the mandrel to break properly.

- Failure to hold the rivet gun tightly against the surface of the workpiece, resulting in incomplete deformation of the rivet.

- Releasing the trigger too soon, resulting in the mandrel not being fully sheared.

Solution:

- Ensure that the rivet gun is vertically aligned with the surface of the workpiece to avoid skewed pull rivets.

- Hold the muzzle of the rivet gun firmly against the surface of the workpiece to ensure that the head of the rivet is fully deformed.

- Press and hold the trigger until you hear a “pop” sound, and then release it after confirming that the mandrel is completely broken.

Step 6: Changing Rivet Gun or Rivet Type

Possible causes:

- Mismatch between the rivet gun and the rivet, e.g. using a lightweight rivet gun to install high strength rivets.

- Mandrel material is too stiff and requires a tool with greater tension to break.

Solution:

- Check that the pulling power capacity of the rivet gun is suitable for the current rivet type.

- If the rivet material is hard (e.g. stainless steel), consider using a higher power rivet gun.

- Use brand name quality, reliable rivets to ensure that the mandrel design meets standard breaking forces.

How to Prevent Pop Rivet Mandrel Not Breaking?

So how should you avoid pop rivet mandrel not breaking this problem in advance? You need to take some measures in advance. For example:

- Regularly train operators to ensure that they have the correct riveting techniques and tool usage.

- Establish and follow a maintenance program for the rivet gun and regularly inspect and service the equipment.

- Select high quality rivets and rivet guns to ensure the reliability of tools and consumables.

Do You Have Any Questions?

Let Us Solve Your Problem

Custom High Quality Pop Rivets for Your Business

Want to avoid problems using out rivets? Want to provide your customers with high quality pop rivets? Then you need to find a reliable rivet manufacturer, Rivmate is a leading global rivet manufacturer that has supplied a large number of high quality rivets to the world’s leading rivet brands.

If you want to buy high quality rivets or perfect riveting solutions, please contact our engineers!

Get Rivets Quote

You may also find these topics interesting

Buy Open Type Blind Rivets

Buy Structural Blind Rivets