Peel Rivet: The Comprehensive Guide to Peel Type Blind Rivets

Table of Contents

How to achieve reliable mechanical connections on soft or brittle materials? Traditional blind rivets often cause material tearing or pull-through when used on plastics, woods or composite boards, which affects the connection strength and appearance. The emergence of Peel Rivet (split blind rivet) is precisely to solve this problem.

Peel Rivet, also known as Peel Type Blind Rivet, will “bloom” into multiple supporting flaps at the tail end during installation, enabling it to form a larger contact area and uniform force distribution on soft substrates. This design not only prevents substrate deformation but also significantly enhances tensile retention strength and fatigue life. This blog will deeply analyze the structural principle, application fields, selection criteria and installation techniques of Peel Rivet, helping you choose the most suitable riveting solution for lightweight materials.

What Are Peel Rivet?

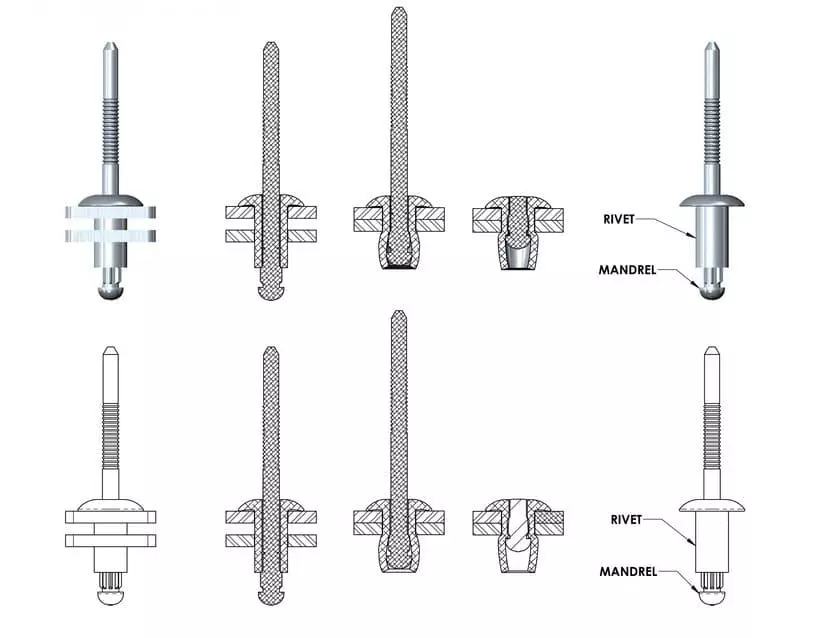

Peel Rivet (splitting blind rivet) is a mechanical fastener specifically designed for soft or brittle substrates. Its distinctive feature is that when the mandrel (core shaft) is pulled, the tail of the rivet will split along the preset groove direction and ‘bloom’ into a 3-4 leaf-veined structure. These leaf-like structures will unfold on the back of the material, forming a wide supporting surface, which effectively disperses the clamping force and prevents the substrate from being pulled through or undergoing local compression deformation.

From a structural perspective, the Peel Rivet is mainly composed of three parts: the head, the body, and the mandrel. The head is used to distribute surface pressure, the body provides the main connection strength, and the mandrel is responsible for guiding the splitting action during installation. Compared with traditional blind rivets, the Peel Rivet has more uniform force distribution and better adaptability, and is particularly suitable for non-metallic materials such as plastics, wood, and composite boards.

Its design and performance typically follow international standards such as ISO 15973, DIN 7337, and SAE J491, ensuring connection strength, molding consistency, and reliability. It is precisely this structural advantage that makes Peel Rivet one of the most stable solutions for assembly of soft materials.

How Does a Peel Rivet Work?

The core working principle of Peel Rivet lies in the “splitting expansion locking” mechanism. When the rivet is pulled by the installation tool, the mandrel (core shaft) generates axial tension inside the rivet body, causing the tail end to gradually split along the pre-fabricated groove. The tail metal then forms 3 to 4 leaf-like structures (Peel Legs), opening outward and covering the back of the material, thereby achieving “mechanical encapsulation locking”.

This structure offers significant advantages in soft materials. The wide supporting surface provided by the leaflets can effectively distribute stress, preventing the material from being pulled through or local collapse. Even on uneven surfaces, Peel Rivet can ensure a tight fit through adaptive deformation.

Why Choose a Peel Blind Rivet?

The greatest advantage of Peel Rivet lies in its ability to achieve a secure connection without damaging the material. Unlike traditional rivets, Peel Rivet uses a “flap expansion” structure to create a uniform supporting surface at the tail end on the back of the material, significantly enhancing the connection stability.

Pull-Through Resistant:

When the “leaf-like” parts at the tail end are unfolded, they form a ring-shaped/multi-lobed supporting surface, converting the axial tensile force into compressive stress over a larger area and internal friction. On the low-strength back surfaces such as plastics, woods, and honeycomb panels, there will no longer be point load impacts, significantly reducing pull-through and edge peeling. For very thin or foam core panels, when combined with large flange caps or back gaskets, the anti-pull-through margin is even higher.

Even Load Distribution:

The leaf-shaped geometry provides multiple points of contact. Compared to the “local bulge” of standard rivets, Peel Rivet has a larger contact radius and a smoother stress gradient. The stress concentration coefficient at the joint is reduced, making it more tolerant of repeated loads and vibrations, and lowering the risk of early crack initiation. Plastic shells/decorative parts, thin aluminum panels, 3D-shaped parts, achieving both excellent appearance and longevity.

Suitable for soft and brittle substrates:

It can be safely applied to PVC, ABS, PC, FRP, thin wood boards, veneer composites, honeycomb sandwich, etc. The leaf flaps have a small-angle self-adjustment at the end of the molding process, which can fit slightly non-planar surfaces or coating surfaces, and does not require high alignment accuracy.

Blind Side Installation:

Single-sided assembly (Blind Side) is suitable for shell bodies, closed cavities, and positions that are difficult to access on the backside. It has lower requirements for the coaxiality of the hole positions and the back support; it is friendly to the assembly cycle and reduces the complexity of the tooling. It is compatible with pneumatic/electric riveting guns and torque/行程 monitoring systems, facilitating batch consistency control.

Cost-Effective Solution:

No need for threads, welding or adhesives. The installation efficiency is high and it is suitable for batch assembly production lines.

Applications of Peel Rivets

The design of Peel Rivet is aimed at providing a safer and more efficient fastening solution for soft, brittle, and lightweight structures. Its unique “petal unfolding” tail structure enables a stable connection without damaging the substrate. Here are the five most typical application scenarios:

① Wood and Furniture Assembly

Peel Rivet performs exceptionally well in wooden structures. The tail flaps can distribute pressure along the fiber direction, effectively preventing the wood grain from cracking.

- Advantages: No need for threaded insertion; unaffected by wood density.

- Typical Applications: Furniture frames, wooden trim pieces, display stands.

② Plastics & Composites

On materials such as plastic, FRP and PVC, traditional rivets or threaded connections are prone to thermal deformation or loosening. The multi-ribbed supporting structure of Peel Rivet can disperse the clamping force and prevent local indentation.

- Advantage: No welding or heating required, and it does not alter the material properties.

- Typical Applications: Plastic covers, composite plates, and instrument panel fixation.

- Rivmate Recommendation: For plastics with a thickness less than 3mm, it is recommended to use aluminum or copper Peel Rivets to avoid stress concentration.

③ Automotive Interiors & Electronics

Peel Rivet is commonly used in the automotive and electronics industries for the assembly of lightweight non-structural components. Its small deformation force and stable locking characteristics make it highly suitable for thin plates or easily deformed parts.

- Advantage: Can be installed on one side without damaging the decorative surface.

- Typical Applications: Dashboard, audio frame, plastic bracket, electronic housing.

- Industry Standards: Meets the strength and fatigue requirements for thin-walled fasteners as stipulated by ISO 14589.

④ Appliance & Equipment Enclosures

Peel Rivet is widely used in the combined structures of sheet metal and plastic. Its anti-loosening property and attractive appearance make it the preferred choice for products such as electrical enclosures, air conditioners, and washing machines.

- Advantages: No need for threading, no welding, reducing manufacturing steps.

- Typical applications: Motor bodies, panel supports, electronic control modules.

⑤ DIY & On-Site Repair

The Peel Rivet has a simple structure and requires minimal installation tools. It is particularly suitable for quick repairs and modifications in non-industrial environments.

- Advantage: Manual riveting gun can be used, no power supply required.

- Typical applications: Plastic shell repair, wooden box reinforcement, rapid equipment assembly.

Choosing the Right Material for Peel Rivets

When working with different substrates and environments, choosing the right material for Peel Rivets is of utmost importance. The material not only affects the connection strength, but also directly determines the corrosion resistance, conductivity and long-term stability. Here are Rivmate’s professional recommendations for various Peel Rivet materials:

a. Aluminum Alloy

Features: Lightweight, excellent corrosion resistance, and no electrochemical reaction with soft materials such as plastics and wood.

Analysis of Advantages:

- Suitable for light loads and flexible structures, avoiding material damage caused by hardness differences.

- The aluminum alloy has excellent ductility, enabling a more uniform formation of the tail “blade” shape.

Recommended Applications: Plastic casings, wooden frames, appliance assembly, lightweight equipment casings.

b. Steel (Zinc-Plated)

Features: High strength, high cost-effectiveness, capable of withstanding large clamping force.

Analysis of Advantages:

- The galvanized layer prevents oxidation and is suitable for short-term outdoor or industrial use.

- The tail is “split” for stability and can be used for connecting composite boards to thin steel parts.

Recommended Applications: Sheet metal assembly, mechanical supports, composite panel structures.

c. Stainless Steel (304 / 316)

Features: Corrosion-resistant, resistant to salt fog, with high fatigue resistance, suitable for high humidity or extreme environments.

Analysis of Advantages:

- Maintain stable performance in marine, outdoor and rail transit environments.

- Have good compatibility with non-metallic materials such as FRP, PVC and carbon fiber.

Recommended Applications: Outdoor equipment, interior of rail vehicles, ship structures, electrical cabinet assembly.

d. Copper / Brass

Features: Excellent conductivity and decorative properties, along with good ductility.

Analysis of Advantages:

- It is not only suitable for electrical connections, but is also commonly used in appearance components and instrument structures.

- During riveting, it expands evenly and is unlikely to damage the delicate surfaces.

Recommended Applications: Electrical grounding, electronic enclosures, decorative panels, control modules.

How to Install a Peel Rivet?

When using Peel Rivet (split blind rivet), the accuracy of installation directly determines the quality and durability of the final connection. Since soft materials (such as plastic, wood, and composite panels) are extremely sensitive to stress distribution, during the operation, the tensioning force and expansion angle should be carefully controlled.

Step 1: Drilling the Hole

Recommended aperture size: Larger than the diameter of the rivet body by 0.1–0.2 mm to ensure that the tail can expand freely.

Key Points for Drilling:

- Keep the drilling in a vertical direction to avoid skewing or burrs on the hole walls.

- It is recommended to use a low-speed drill bit on wood or plastic to prevent melting or cracking.

Step 2: Insert the Rivet

Insert the Peel Rivet into the pre-drilled hole, ensuring that the flange part (Flange) is fully in contact with the surface. If the substrate is soft (such as PVC or foam board), you can add a large flange washer on the surface to enhance the supporting surface. Check if the rivet is inserted vertically to avoid eccentricity that causes uneven leaf flap expansion.

Step 3: Rivet Setting Process

Start the riveting gun and pull the mandrel. When the pulling force reaches the designed value, the tail of the rivet begins to “split” into a petal-like shape and unfolds.

Key Control Points:

- Use the low-speed constant force control mode (this function is available in the Rivmate SmartGrip series) to prevent excessive expansion of the tail.

- For plastic or wood materials, avoid high-speed impact riveting.

- After the riveting is completed, the core shaft should automatically break and lock in the designed position.

Step 4: Backside Inspection

Turn the rivet over and observe the back side. Ensure that the leaf flaps are fully extended and evenly symmetrical. Check for the following issues:

- The leaf blade fails to fully unfold → Insufficient pulling force;

- Cracks appear in the material → Insufficient hole diameter or excessive riveting.

In normal condition, it should be in a “petal-like” shape with all four petals fully extended and tightly adhered without any gaps. If a higher level of protection is required, an anti-corrosion gasket or sealing gasket can be added to the back.

Step 5: Quality Verification

Perform a visual inspection + manual tensile test to ensure the connection is secure. For critical assembly parts (such as car interiors and appliance shells), a Rivmate Pull-Test Gauge can be used for spot testing of pull-off strength. Recommended reference standards:

- ISO 14589 (Mechanical Properties of Blind Rivets)

- ASTM F1470 (Test Methods for Riveting)

FAQ

Q1: What is a Peel Rivet used for?

The Peel Rivet is mainly used for the fixation of soft or brittle materials, such as plastics, wood, composite panels, FRP, PVC, etc. Its tail “opens up” during the riveting process to form a multi-lobed structure, which can disperse the force on the back of the material and prevent tearing. Typical Applications: Household appliance assembly, automotive interiors, electronic device casings, wooden structural components.

Q2: Can Peel Rivets be used in plastic or wood?

Yes, and it is one of the most recommended riveting methods. The structure of Peel Rivet is specifically designed for soft substrates and does not require pre-drilled threads or heating treatment. It can form a “fan-shaped” locking structure on the back, significantly reducing the risk of plastic cracking or wood splitting.

Rivmate Suggestion: For low-density materials (such as foam boards or soft plastics), it is recommended to use large flange washers in combination to further distribute the clamping force.

Although Peel Rivet is a lightweight structural fastener, its actual performance in soft materials is very stable. It enhances the tensile retention force through “multiple support”, and compared to ordinary blind rivets, it improves the connection stability by approximately 40% – 60%. For non-structural connections (such as interior components and lightweight enclosures), its strength is fully sufficient.

Q4: What’s the difference between Peel Rivet and Standard Blind Rivet?

| Comparison Item | Peel Rivet | Standard Blind Rivet |

|---|---|---|

| Tail Formation | Splits into 3–4 petals during setting | Forms a single expansion zone during setting |

| Load Distribution | Evenly distributed, prevents pull-through | Concentrated stress, may damage soft materials |

| Suitable Materials | Plastic, wood, composite panels | Thin metal sheets |

| Installation Result | Smooth surface with full backside support | Concentrated clamping force, visible backside bulge |

In short, the Peel Rivet is a blind rivet variant optimised for soft materials, offering significantly superior safety and crack resistance compared to standard types.

Q5: Do I need washers when using Peel Rivets?

In most cases, no additional washers are required as the “flowering structure” of the Peel Rivet already provides sufficient force distribution. However, in the following situations, it is recommended to add a backing washer on the back side:

- The substrate thickness is less than 2 mm;

- The material is very soft (such as foam board, EVA, soft plastic);

- It needs to bear a long-term load or prevent the wear of the hole opening.

Choose Rivmate Peel Rivet Systems

Peel Rivet is a professional fastening solution specifically designed for soft and brittle materials. It achieves efficient locking through the “petal-shaped” expansion structure at the tail end without damaging the material.

Whether it is plastic, wood or composite board structure, Peel Rivet can achieve a perfect balance between lightweighting and structural safety. Compared with traditional rivets or screws, it performs better in terms of tensile separation resistance, crack resistance, and assembly consistency.

Rivmate offers a more stable and efficient fastening experience for the manufacturing and assembly industries through its meticulously designed Peel Rivet System, combined with intelligent riveting tools. By choosing the right materials and models, you can significantly enhance assembly quality and product lifespan.

Contact us immediately to explore the complete range of solutions for Peel Rivets for plastics, wood and composite materials. Make every connection feature lightweight strength, flexible support and verifiable engineering reliability.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met