Riveting vs Welding: How to Choose the Right Connection?

Table of Contents

Among the common metal joining methods, riveting and welding are the two most fundamental and frequently compared processes. Which one is better? Riveting vs welding – which should be used in practical projects? This blog will based on engineering practice, provide a comprehensive analysis of the differences between Riveting and Welding and help you make the most appropriate technical choice in different applications.

Riveting is a method of achieving permanent connection through mechanical deformation. When the rivets are installed, they expand to create a clamping force, thereby securely fixing two or more pieces of materials together. Its key features include:

- Thermal-free process: No heating or melting of materials is required.

- Single-side installation (Blind Installation): Suitable for enclosed spaces or structures where the backside cannot be accessed.

- Stable force application: The expanded head of the rivet bears the main shear force.

- Applicable to thin plates, composite materials, and soft materials.

Riveting connections are particularly suitable for sheet metal assembly, roofing systems, transportation equipment and vibration conditions.

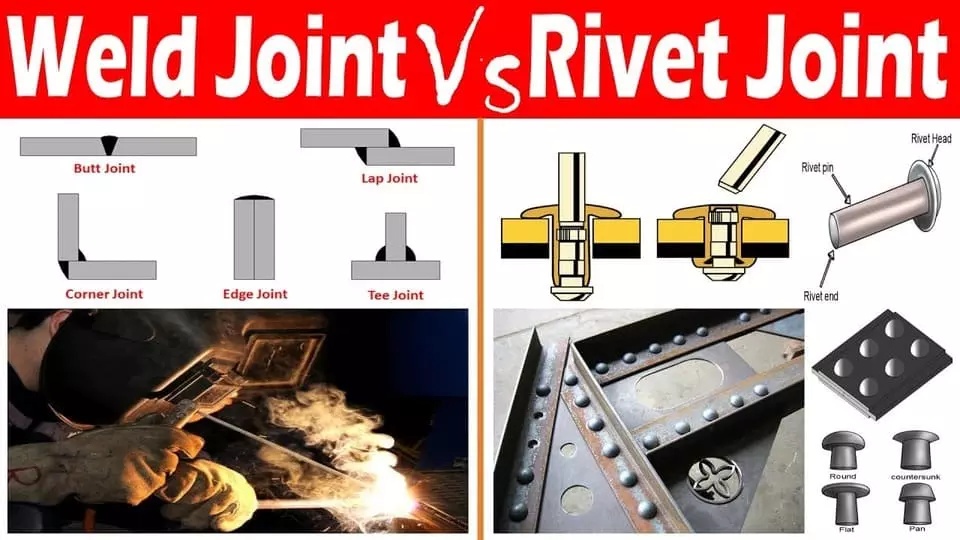

Types of Riveting Joints

The riveted joints have different designs. They are often selected as the appropriate design based on the assembly of the riveted joint, design considerations, and conditions of use. We can make a simple categorization. According to the number of rows and arrangement of rivets can be divided into the following two types.

- Lap Joint

- Butt Joint

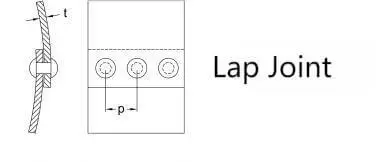

1.Lap Joint

Lap joints are two overlapping materials joined together by rivets. This type of riveted joint is usually used when there is a need to overlap one material on top of another. An example would be the joining of sheet metal. The diagram on the right shows how Lap Joint, a type of riveted joint, is represented.

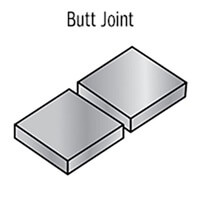

2.Butt Joint

Butt Joints are often required to join three pieces of material. This type of riveted joint joins the ends of two materials together and then uses rivets to secure them.Butt Joints are often used in structural applications where a flush and strong joint is required. The diagram to the left clearly illustrates the connection characteristics of the Butt Joint.

What is Welding?

Welding is a connection method that uses high temperature to cause local melting of metal materials and their fusion into a single entity. After welding, the connected area becomes an integral part of the base material. Its core characteristics include:

- The melting of metals forms metallurgical bonding, resulting in a continuous structure and high strength.

- It requires bilateral or complete contact with the space, and is usually not feasible to operate in a closed cavity.

- High material requirements: The metal must have good weldability.

- The heat affected zone (HAZ) may alter the material properties, and strict process control is necessary.

Welding is widely used in heavy machinery, steel structures, pipeline systems and vehicle manufacturing.

Types of Welding Joints

Butt Joint: A butt joint is formed when the ends of two workpieces are aligned in the same plane and welded together along the seam. This is one of the most common types of joints in welding.

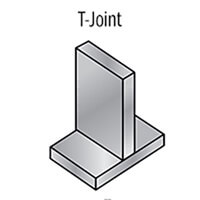

T-Joint: A T-joint is formed when one workpiece is placed perpendicularly to the other, creating a T-shape. Welding is done along the intersection of the two pieces. T-joints are commonly used for connecting two materials at a right angle.

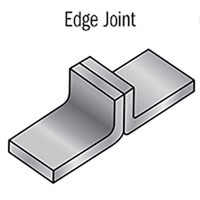

Edge Joint: An edge joint is formed when the edges of two workpieces are placed in contact with each other and welded along the edge. This joint is often used for joining plates or panels.

4. Corner Joint: Corner joints are formed when two workpieces meet at a corner, and welding is done along the corner. This type of joint is commonly used in box-like structures or frames.

5. Lap Joint: In a lap joint, one workpiece overlaps the other, and welding is done along the overlapping region. Lap joints are often used for joining sheet metal or thin materials.

Riveting vs. Welding: A Side-by-Side Comparison

Riveting vs welding, Which method is truly more reliable in terms of structural performance? To facilitate understanding, this section analyzes six key dimensions from an engineering perspective: strength, vibration performance, heat influence, corrosion, fatigue life, and structural deformation.

Riveting vs. Welding: Performance Comparison Table

| Performance Aspect | Riveting | Welding |

|---|---|---|

| Shear Strength | ★★★★☆ (Excellent for sheet-to-sheet lap joints) | ★★★★★ (Metallurgical fusion provides maximum strength) |

| Tensile Strength | ★★★☆☆ | ★★★★★ |

| Vibration Resistance | ★★★★★ (Joint does not loosen over time) | ★★★☆☆ (Welds may develop fatigue cracks) |

| Heat-Affected Zone (HAZ) Risk | None | Present — metal softening, annealing, hardness reduction |

| Corrosion Resistance | ★★★★☆ (Protected by plating or coating) | ★★☆☆☆ (Weld seams prone to pitting and corrosion) |

| Fatigue Life | ★★★★★ (Stress distributed across multiple joints) | ★★★☆☆ (Stress concentration at weld toes) |

| Distortion of Panels | No thermal distortion | High heat causes warping and distortion |

| Weight Impact | Lightweight, minimal added material | Additional weld material increases overall weight |

1. Shear & Tensile Strength

The welding strength is high, capable of approaching or reaching the level of the base material, making it highly suitable for load-bearing structures. The shear strength of riveting is even better, especially suitable for interlayer connections between plates. Rivmate structural rivets (such as Monobolt) can achieve 80–90% of the weld strength.

Applicable logic: Thick plates → Welding; Thin plates → Riveting.

2. Vibration Resistance Performance

The riveted connection performs more stably under vibration conditions. The expansion body continuously provides clamping force, preventing loosening. Welding may result in weld seam fatigue cracks under continuous vibration, requiring reinforcement ribs or subsequent maintenance.

For example: Internal testing by Rivmate showed that after 500,000 vibration cycles, there were no cracks in the riveted samples; while the weld samples showed minor cracks.

3. Risk of Heat Affected Zone (HAZ)

Welding generates high temperatures, which alters the crystal structure of the metal and makes certain areas more brittle.

Riveting is a cold processing method with no heat-affected zone and does not change the properties of the base material.

For high-strength steel (HSS) or aluminum alloys, the issue of heat-affected zone (HAZ) during welding is particularly prominent.

4. Corrosion Resistance

Riveted connections can be uniformly electroplated or anodized before installation, ensuring stable corrosion resistance. However, due to the exposure of metals and high-temperature oxidation, spot corrosion and stress corrosion cracking are more likely to occur in welds. If used in outdoor or humid areas, the long-term corrosion resistance of riveted connections is superior.

5. Fatigue Life

- The riveted connection has many connection points and can disperse stress well, showing excellent performance in long-term fatigue.

- The welding is a continuous weld seam, with stress concentration. Fatigue cracks often start from the weld toe.

Engineering cases have confirmed that in the aerospace industry, riveting is widely used because its fatigue life is more controllable and stable compared to welding.

6. Distortion & Weight

Welding at high temperatures can cause thermal deformation, especially in thin plate structures. This effect is particularly pronounced. Riveting, on the other hand, has no heat impact and the plates are less likely to warp or sag. The riveted connection points are lightweight and offer more advantages in scenarios such as aircraft bodies.

Riveting vs Welding: How to Choose for Different Applications

In actual engineering scenarios, there is no single answer to the question “Which is better, riveting or welding?” Various factors such as the materials, loads, vibration levels, and appearance requirements in different conditions will all influence the final choice.

Application-Based Selection Guide: Riveting vs Welding

| Application Scenario | Recommended Method | Reason |

|---|---|---|

| Thin Sheet Structures (0.3–2 mm) | Riveting | Welding concentrates heat and can cause burn-through or visible distortion; riveting keeps the sheet surface flat and stable. |

| High-Vibration Structures (Machinery, Vehicles) | Riveting (Structural Blind Rivet) | Weld seams may develop fatigue cracks under continuous vibration; structural rivets maintain long-term stability through mechanical locking. |

| Heavy-Load Steel Structures (Beams, Frames, Supports) | Welding | High load-bearing structures require welding to provide integrated strength and satisfy high shear and tensile demands. |

| Composite + Metal Hybrid Structures | Riveting | Composite materials cannot be welded; riveting is the only practical method for cross-material joining. |

| High-Appearance Requirements (No Thermal Deformation, e.g., Decorative Panels) | Riveting | No heat-affected zone, avoiding warping, dents, burn marks, or welding blemishes. |

- The material is thin and prone to deformation

- High vibration and high fatigue conditions

- Requires precise appearance and is sensitive to heat

- Involves composite materials, plastics or multi-layer structures

- Requires on-site rapid installation and no need for welding equipment

- The project aims for lightweighting

The characteristics of riveting are cold connection, stability and strong vibration resistance, making it suitable for sheet metal, household appliances, vehicle body panels, aerospace and outdoor equipment.

When to Use Welding

- The structure needs to withstand heavy loads.

- The material is thick (more than 3 mm).

- An integrated whole structure is required.

- High sealing requirements (for pipelines, pressure vessels).

- There is a mature welding process and sufficient operation space.

Welding is suitable for scenarios with high load-bearing requirements such as heavy machinery, steel structures, vehicle chassis, and pressure pipelines.

Is Welding Cheaper than Riveting?

In practice, welding is more costly than riveting.

- Welding usually requires specialized equipment such as welding machines, power sources, welding guns and protective gear. The economic investment in welding equipment may be higher compared to that required for riveting.

- Consumables such as welding rods, wires, shielding gases and fluxes are usually used in the welding process. These consumables may increase the total cost of welding.

- The operation of welding requires skilled welders who must be properly trained and certified. This is especially true for complex or large projects. Welding may also require additional time and effort for setup, positioning, and post-weld processing (such as grinding and finishing). So the labor cost of welding is also high.

Why are Aircraft Riveted and not Welded?

a. Aerospace-grade aluminum alloys are not suitable for welding

The fuselage of the aircraft extensively uses 2xxx and 7xxx series aluminum alloys. These materials have high strength but poor weldability. Welding will disrupt the original aging hardening mechanism, causing a significant decrease in the strength of the material in the heat affected zone (HAZ). Coarse grain formation, unstable hardness and the appearance of microcracks will reduce the overall reliability of the fuselage. Moreover, these aluminum alloys are prone to develop stress corrosion cracks after welding, which is particularly dangerous in the high-cycle pressure environment of aviation. Therefore, from the perspective of material nature, welding cannot meet the requirements for the long-term stability of the aviation structure.

b. The aircraft structure has extremely high requirements for fatigue life

Each takeoff and landing of an aircraft involves repeated changes in cabin pressure, which is a typical high-cycle fatigue condition. The weld seam is a location where stress concentration occurs, and cracks are prone to start expanding from the weld toe. In aviation applications, this poses extremely high risks. In contrast, riveting is a multi-point connection, with the load shared by tens of thousands of rivets. Stress can be dispersed, making fatigue cracks less likely to form and preventing rapid expansion within the structure. This is precisely the reason why the aviation industry still chooses riveting to this day.

c. Assembly can prevent thermal deformation and keep the skin flat

The fuselage skin of an aircraft is extremely thin, typically only 1–2 mm thick. The high temperature generated by welding can cause local contraction or expansion of the sheet, resulting in warping, dents, or misalignment. These geometric deformations not only affect the appearance but also damage the accuracy of the fuselage shape, thereby impacting aerodynamic performance and fuel efficiency. Riveting is a cold processing method that does not generate heat and does not damage the shape of the thin sheet, making it more suitable for installing large-area skins.

d. Assembly makes maintenance and replacement easier

Aviation structures need to be in service for a long time, and regular maintenance is inevitable. Once cracks appear in the welds, repair is difficult and must be done by using high-standard techniques and re-welding, which is costly and time-consuming. Riveting, on the other hand, has excellent maintainability. Damaged or loose rivets can be quickly drilled out and replaced without affecting the surrounding structure. For fuselage structures that require maintenance cycles of several decades, riveting has significant advantages in terms of maintenance efficiency and cost control.

e. Assembly can provide higher redundancy

Aircraft fuselage may use between 100,000 and 1,000,000 rivets. This multi-point fixation method inherently has redundancy advantages. If a rivet fails due to fatigue or corrosion, the overall structure can still maintain strength and stability. Welding is a continuous structure. Once a crack occurs at a certain point, the crack is likely to spread along the weld seam, leading to local or even overall failure. Redundancy is one of the most important principles in aviation safety design, and riveting naturally possesses this characteristic.

f. The assembly process is more controllable and the quality is more consistent

The welding quality is highly dependent on the skills of the operators, environmental conditions, and the precision of the welding equipment. Even with mature processes, welding is still difficult to maintain absolute consistency in large-scale production. Riveting has higher repeatability, easier parameter control, and a more standardized assembly process, making it suitable for the strict quality system requirements of the aerospace industry. Automated riveting equipment can also further ensure consistency and reduce human errors.

Get the Right Joining Solution for Your Project

In the comparison between riveting and welding, there is no absolute “best process”; only the one that best suits your structural requirements.

- If the structure is in a high-vibration, corrosive environment or has strict requirements for appearance and flatness, riveting is always more reliable.

- When a project needs to bear extremely high loads or involves thick steel plates, welding remains the most stable method.

- In scenarios involving composite materials, multi-layer structures, or those that cannot withstand heat effects, riveting is the only feasible option.

As a manufacturer specializing in fastening and assembly technologies, Rivmate can offer a complete range of riveting solutions, including blind rivets, structural rivets, riv nuts, and specialized installation tools. We can also provide professional engineering evaluations based on your materials, loads, and application requirements.

If you are evaluating the connection method of the project or need samples of the Rivmate fasteners for adaptation, please feel free to contact our engineering team directly:

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met