Advantages and Disadvantages of Pop Rivets

Table of Contents

When it comes to sheetrock connections, there are many options. One of the most popular is the blind rivet. blind rivets have many advantages over other types of connecting fasteners. Let’s take a look at the advantages and disadvantages of pop rivets.

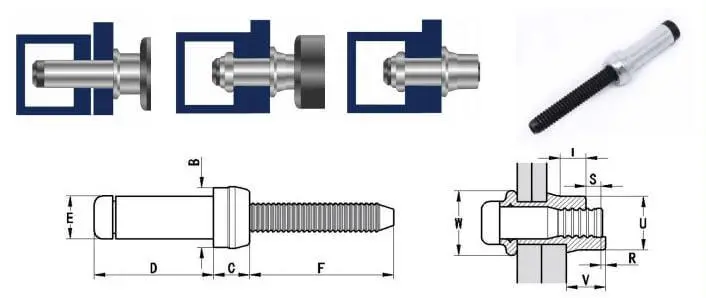

To evaluate the advantages and disadvantages of Pop Rivet, one must first understand its structure and working mechanism. The primary reason why Pop Rivet is widely used in the sheet metal industry is its one-sided installation, mechanical locking, and stable structure working principle.

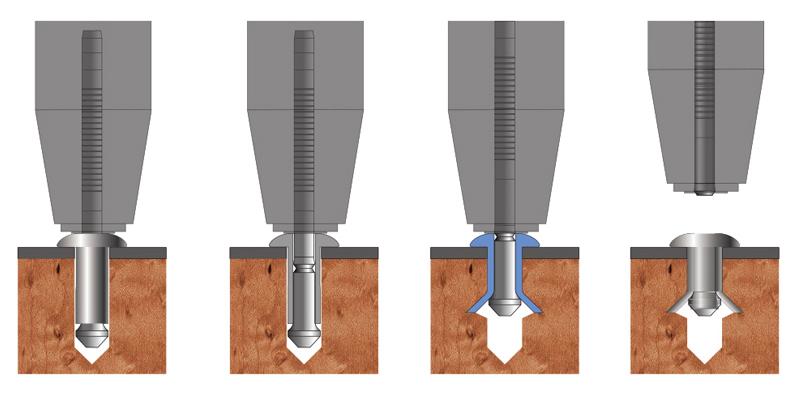

a. Mandrel Pull → Expansion & Clamping

During installation, the riveting gun will pull the core shaft. The special chamfer on the core shaft will force the tail end of the rivet head to expand outward. After expansion, a “back lock point” is formed, tightly clamping two or more layers of sheet materials together. This deformation is permanent and will not return to its original state due to vibration.

b. Mandrel Breaks at a Set Point

When the expansion force reaches the designed value, the mandrel will break at the “breakage groove” position. The broken mandrel usually remains partially or completely inside the cap body. This ensures that the clamping force meets the standard and also guarantees the assembly reliability.

c. Blind Installation

Pop Rivet does not require contact with the back side of the workpiece. The installation tool can complete the riveting simply by operating on the front side. This makes it particularly suitable for:

- Closed structure

- Pipe material

- Cabinet or chassis

- Assembly scenario where it is impossible to access the back side

This is the core advantage of Pop Rivet, which enables it to be widely used in sheet metal manufacturing and field construction.

d. Permanent Fastening

Due to the irreversible nature of the expansion structure, the rivets become permanent connections. To remove them, drilling is usually required. This is both an advantage and a disadvantage:

- Advantage: Does not loosen

- Disadvantage: Cannot be reused

This “non-detachable” feature is an engineering factor that we must take into account when evaluating the suitability of Pop Rivet.

Advantages of Pop Rivets

The advantages are obvious – cheap, fast and easy to install。

1. Single-Side Installation

The foremost advantage of Pop Rivets is their blind installation capability, requiring operation from a single side of the workpiece. No access to the reverse side is needed, nor are threaded structures or backing plates required. They are suitable for enclosures, metal-enclosed spaces, tubing, and applications with restricted installation access. This simplifies the installation process, reduces cycle times, and lowers labour costs.

2. Fast and Efficient Assembly

The assembly speed of pop rivets is typically 2–4 times faster than that of screws. A single operation with a rivet gun completes the locking, forming, and breaking off of the rivet core, ensuring high operational consistency. In mass production, assembly efficiency is significantly enhanced, reducing manual labour time. This is also why blind rivets are extensively adopted in the home appliance industry.

3. Low Cost

The Pop Rivet features a simple construction comprising only a cap body and a mandrel. The cold heading process is highly automated with excellent material utilisation, resulting in exceptionally low production costs. Aluminium Pop Rivets are particularly economical yet still meet most thin-sheet joining requirements. This makes the Pop Rivet one of the most cost-effective metal joining solutions available.

4. Lightweight

Materials such as aluminium, aluminium-steel composites, and galvanised steel confer significant weight advantages upon Pop Rivets. Compared to screws, Pop Rivets feature no threads and require no washers, resulting in a simpler construction. Their application in automotive, electrical, and aerospace components for light loads contributes to overall weight reduction.

5. Consistent Performance

The deformation process of Pop Rivet is determined by the core shaft surface, so the expansion amount is very stable. The Rivmate test shows:

- Standard aluminum rivets’ tensile strength: 300–400 N

- Steel rivets’ tensile strength: 500–900 N (depending on size)

- Discrepancy in shear strength is less than ±8%

This consistency makes Pop Rivet highly suitable for automation and mass production.

6. Works on Thin Sheet Metal

Thin plates cannot provide threaded engagement, and screws are prone to slipping or loosening. The Pop Rivet, however, relies entirely on mechanical expansion for locking, without using threads.

Therefore:

- 0.3 – 1.0 mm thick plates can also be securely connected.

- The thinner the plate, the more pronounced the advantage.

This makes blind rivets the preferred fastening method in the sheet metal industry.

Disadvantages of Pop Rivets

1. Not Removable

Pop Rivet is a permanent connection method. Once the riveting is formed, it cannot be reused like screws. If you want to remove it, you can only drill out the rivet, which will damage the hole diameter and increase the maintenance cost. Therefore, it is not suitable for structures that require regular maintenance or disassembly.

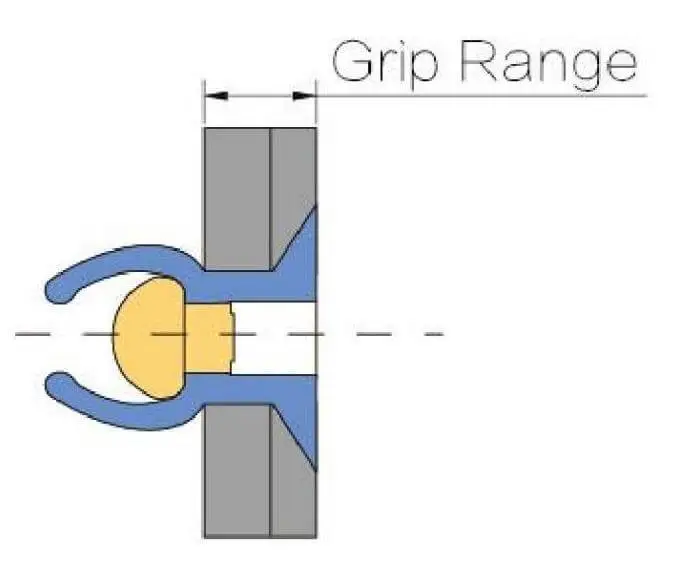

2. Limited by Grip Range

The grip range of Pop Rivet is fixed and limited. If the thickness of the plate exceeds the range, the rivet cannot expand properly; if the plate thickness is too thin, it cannot generate sufficient clamping force. This requires engineers to strictly select the correct size based on the plate thickness when making the design.

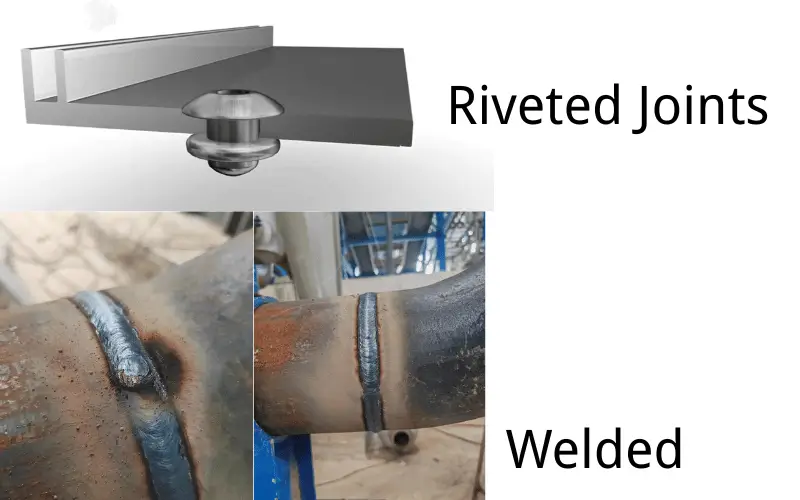

3. Not Ideal for High-Structural Loads

Although Pop Rivet performs well in thin plates, it is not the primary fastening method for handling heavy loads. In structures with high shear, high tensile strength, or those with extremely high safety requirements (such as large-scale steel structures), bolts, welding, or structural rivets are more reliable. Pop Rivet is suitable as a connection solution for lightweight structures, rather than for primary load-bearing connections.

4. Mandrel Retention Issues

In standard open-type rivets, the core shaft remains after fracture, but it does not completely lock. Under long-term vibration conditions, the core shaft may slightly loosen and produce noise. Structural rivets mechanically lock the core, but ordinary rivets do not have this capability. This can occasionally become a noise source in household appliances and mechanical equipment.

5. Requires Precise Hole Size

The rivets require matching hole sizes to ensure the expansion effect.

The hole is too large → This will lead to loosening and a decrease in shear resistance.

The hole is too small → It is difficult to insert or install the rivet, or it may deform.

This means that the processing accuracy must be controllable; otherwise, the reliability of the connection will be compromised.

6. Appearance Less Premium

The head of the Pop Rivet will be exposed on the material surface, which is a visible fixation method. For scenarios that require a completely smooth appearance (such as high-end shells and decorative panels), welding, countersunk screws, or concealed fasteners might be more suitable. Therefore, the Pop Rivet may not be the best choice in appearance-sensitive situations.

Pop Rivets vs Other Fasteners

| Comparison Aspect | Pop Rivet (Blind Rivet) | Screw | Welding | Structural Rivet (Monobolt / Structural Blind Rivet) |

|---|---|---|---|---|

| Installation Method | Installed from one side; ideal for blind or closed structures | Requires access to both sides or at least the threaded side | Requires welding space, equipment, and skilled labor | Installed from one side but requires a high-strength riveting tool |

| Removability | ❌ Not removable; must be drilled out | ✅ Fully removable and reusable | ❌ Permanent connection; must be cut or ground off | ❌ Not removable |

| Suitable Material Thickness | Thin sheet metal, 0.3–3.0 mm | Medium to thick materials; requires enough thickness for threading | Any thickness depending on welding process | Thin sheet metal + structural joints, 0.8–6 mm |

| Tensile / Shear Strength | Medium; sufficient for most sheet-metal assemblies | Medium–High depending on grade and diameter | Very high; suitable for primary structural connections | High–Very High; can replace bolts or welds in many structural applications |

| Appearance | Visible head; industrial look | Visible head; countersunk options available | Can be ground smooth for seamless appearance | Larger head; used mainly for structural joints |

| Cost | Low; ideal for high-volume production | Medium; varies by screw grade and coating | High due to labor, equipment, and inspection | Higher unit cost, but replaces welding or bolting in structural use |

| Typical Applications | Sheet metal parts, appliances, enclosures, roofing | Furniture, equipment installation, serviceable components | Steel structures, pressure vessels, heavy-duty frameworks | Vehicle frames, construction machinery, rail equipment |

When Should You Use Pop Rivets?

Pop Rivets are particularly suitable for situations involving thin plates, single-sided operation, cost sensitivity, and the need for stable clamping force. The following environments are typically the best choice for using Pop Rivets:

- Sheet metal assembly

The thin sheet cannot provide sufficient thread depth, while the Pop Rivet can be stably formed in plates ranging from 0.3 to 3.0 mm. - HVAC enclosures

The outer shell structure is mostly made of thin-walled metal and needs to be assembled quickly. Riveting can ensure that it does not loosen or leak water. - Metal roofing

The closed-type or ring-fitted Pop Rivet has excellent waterproofing properties and is suitable for long-term outdoor exposure. - Appliances

Lightweight, thin plate, high aesthetic requirements; screws are prone to slipping, while rivets provide a more stable assembly. - Automotive interior

It is mostly composed of thin plates and plastic, and is not suitable for welding or threading. The Pop Rivet is low in cost and reliable in terms of shock resistance. - Electrical boxes

It requires quick installation and excellent anti-loosening performance. Pop Rivet can maintain structural integrity. - Thin aluminum structures

Aluminum is soft, and screws tend to slip off easily. However, riveting in soft materials can provide a more stable clamping force.

Why are these scenarios suitable for Pop Rivets?

Because these industries generally possess several common characteristics:

- The material is thin and not suitable for tapping;

- The back side cannot be in contact and can only be installed on one side;

- High efficiency and mass production are required;

- Long-term stability of the connection is necessary without loosening;

- Cost-sensitive, not suitable for using welding or bolt structures.

When Should You Not Use Pop Rivets?

Although Pop Rivets perform exceptionally well in thin plates, single-side installation, and mass production, they are not universal solutions. In the following scenarios, Pop Rivets are not the optimal choice and may even lead to structural failure.

- High-load structures are not suitable for using Pop Rivets.

When the structure needs to withstand continuous tension, shear force or structural loads (such as steel beam connections, load-bearing supports), the strength of standard Pop Rivets is insufficient. In such cases, solid rivets, structural blind rivets or bolt welding solutions should be used. - Products that require disassembly for maintenance are not suitable for using Pop Rivets.

Pop Rivets are for permanent connection. Any subsequent repairs will require the removal of the rivets, which may damage the base material. If the structure needs frequent disassembly and assembly, screws, Rivet Nuts or bolts should be chosen. - It is not recommended to use the decorative surface with extremely strict requirements for appearance.

The surface of the rivet will leave a head, which is less smooth compared to welded or concealed fasteners, and may affect the decorative quality. - The thick plate structure is not suitable for using Pop Rivets.

The Grip Range of Pop Rivets is limited and is usually only applicable to materials ranging from 0.3 to 6 mm. For thick steel plates or multi-layered laminated plates, the clamping force and expansion capacity are insufficient. - Mechanical structures that are subjected to impact loads or strong vibrations are not applicable.

In situations involving large machinery, engineering equipment, and heavy power systems, there are instantaneous high impact loads. Ordinary Pop Rivets will experience fatigue, looseness, and even fracture. Therefore, high-strength bolts or structural-type rivets should be used.

FAQ:Advantages and Disadvantages of Pop Rivets

Q1. What are the advantages of pop rivets?

Pop rivets offer key advantages including single-side installation, rapid assembly, low cost, suitability for thin sheets, excellent vibration resistance, and the option for waterproof structural designs.

Q2. What are the disadvantages of pop rivets?

They are non-removable, have strict requirements for hole diameters, and are unsuitable for high-load structures. Some models may exhibit residual mandrel loosening, and their appearance is not as smooth as welded joints.

Extremely reliable for joining thin sheet metal, with shear strength reaching 200–500 lbf. However, for heavy-duty structures, structural rivets or bolts should be used instead.

Standard open-ended rivets are not waterproof; closed-end, sealed rivets, and rivets with EPDM gaskets can achieve near 100% waterproofing.

Q5. Do pop rivets loosen over time?

Within the correct aperture and clamping range, Pop Rivets will not loosen spontaneously. However, if the aperture is too large or the material is fatigued, the structure may exhibit micro-movement.

Get Your Pop Rivet Selection & Samples from Rivmate

Choosing the right Pop Rivets is not complicated, but it must be based on the thickness of the plate, the material, the load and the environmental requirements. To help your project get off the ground quickly, Rivmate offers a complete and free technical support service.

We can offer you:

- Free Samples – Suitable for testing strength, assembly feel and compatibility

- Free Configuration Service – Provide board thickness, material, and load information, and we will offer professional recommendations within 4 hours

- Engineer’s Structural Matching Suggestions – Include hole diameter, tolerance, and clamping range calculations

- OEM Brand Packaging – Supports engineering projects and distribution business

- Long-Term Stable Supply – ISO factory, automated production, annual production capacity can support continuous purchasing

If you are looking for high-quality, cost-effective Pop Rivets that are suitable for thin plate structures, please feel free to contact the engineers at Rivmate. We will assist you in obtaining the best fastening solution at the lowest cost.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met